Broadband adjustable light and thin structure type ceramic-based wave-absorbing material and cross-scale design and preparation method thereof

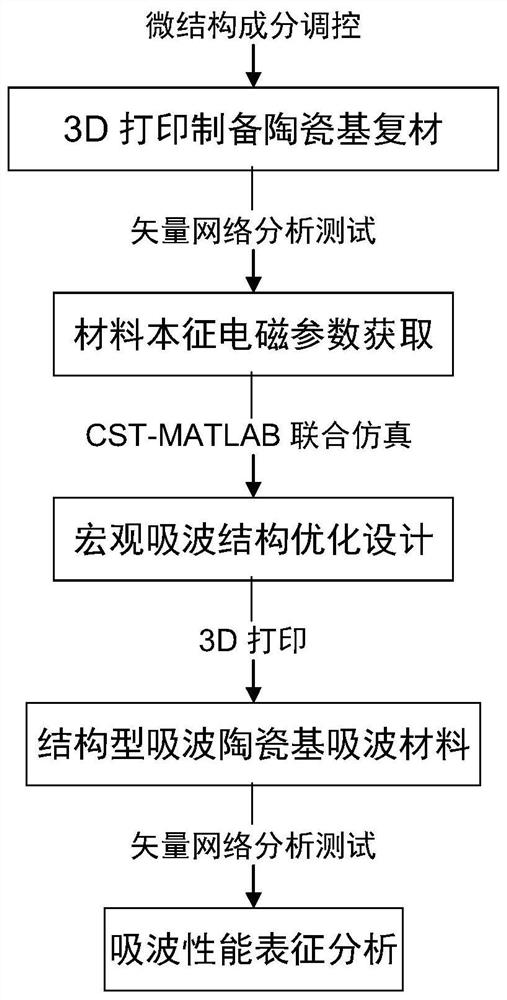

A wave absorbing material and ceramic-based technology, applied in the field of wave absorbing materials, can solve the problems of limited improvement of material wave absorbing performance, poor electromagnetic designability, poor mechanical properties, etc., and achieve the effect of electromagnetic designability of flexible materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Use Al 2 O 3 Photo curing ceramic slurry passes the single layer flat structure Al via the Form 2SLA photocurable 3D printer 2 O 3 Ceramic embryo, placed in the tube furnace in the air atmosphere of 5 ° C / min to 1500 ° C, after holding up for 6 hours, then cooled with the furnace to obtain a decentralized Al 2 O 3 ceramics.

[0046] (2) Using the CVI process in Al 2 O 3 SiC whiskers on the substrate (SiC w ), The growth temperature is 1000 ° C, the growth time is 150 hours, resulting in a flat plate structure Al 2 O 3 / SIC w Composite.

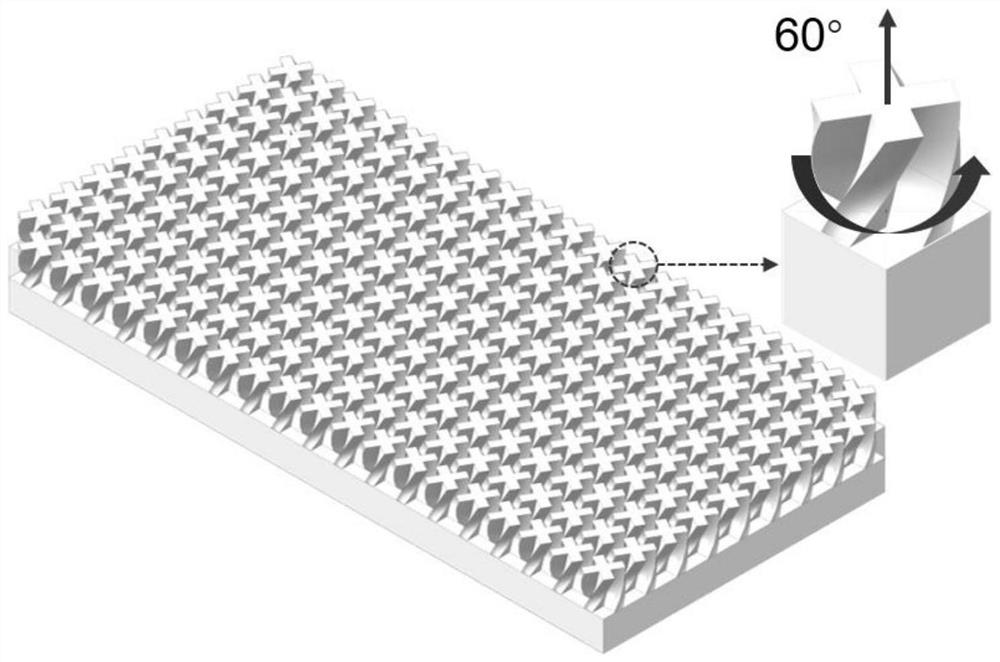

[0047] (3) Will the prepared Al 2 O 3 / SIC w The composite is cut and polished into an annular size of 3.01 mm, outer diameter of 7mm, thickness 3 mm. Using the vector network analysis tester to test the electromagnetic parameters of the radar full-band material, the parameter is substituted into the CST electromagnetic simulation software while using MATLAB pair Taxi-flat double-layer composite structure parameterization modeling, ...

Embodiment 2

[0055] Preparation of 90 ° Trummer - Flat-plate composite structural Al in accordance with an example 2 O 3 / SIC w Ceramic base absorbing material verifies its microwave absorption performance.

[0056] by Figure 4 It can be seen, 90 ° cross twisted - flat-plate composite structural Al 2 O 3 / SIC w Ceramic base absorbing material Get RL at 10.9 GHz min = -47.4dB, the corresponding material thickness was 3.45 mm; the maximum EAB was 4.0 GHz, the corresponding thickness was 3.60 mm.

[0057] In summary, 90 ° cross twisted - flat-plate composite structural Al 2 O 3 / SIC w Ceramic base absorbing material relative to 60 ° torsion angle, its RL min And the corresponding frequency, the maximum EAB has changed significantly, indicating that the change of the ceramic base reciprocity can be achieved by the cross twisting angle change, indicating the cross twisted - flat-plate composite structural Al1 2 O 3 / SIC w The ceramic base absorbing material is a wide frequency adjustable thin s...

Embodiment 3

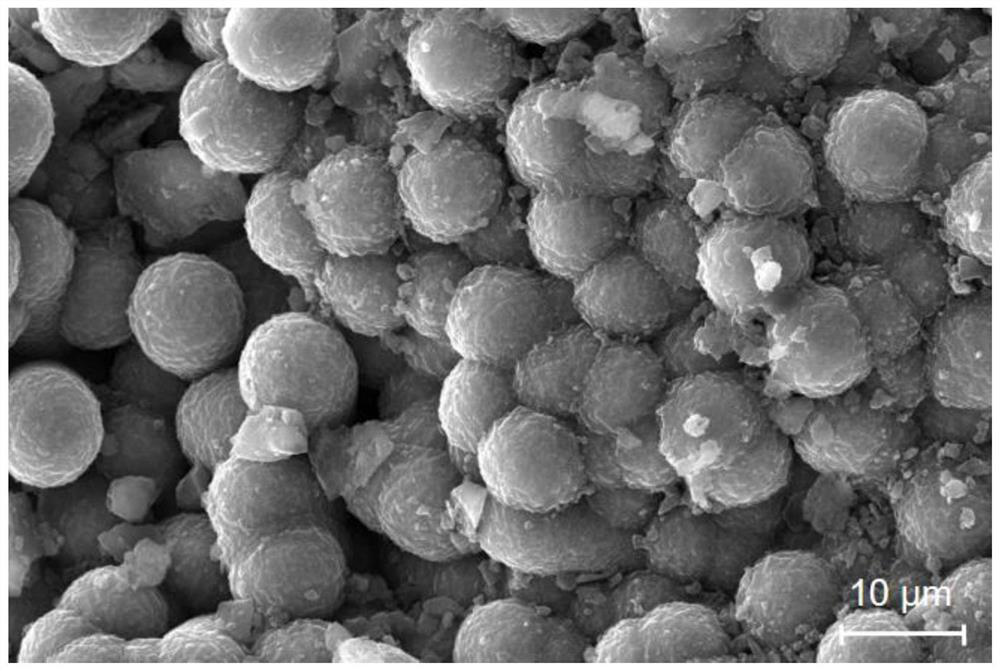

[0059] (1) Mix 15 wt% carbon nanotube (CNT) into a photocurable molded SiO 2 In the ceramic slurry, the magnetic stirrer is used for mechanical stirring for 5 hours, then ultrasonic emulsified dispersing machine is used to perform ultrasonic dispersion for 1 hour, thereby preparing a CNT dispersion uniform optical curing SiO. 2 / CNT ceramic slurry.

[0060] (2) Using Long Ceraform 100DLP Photocoction 3D Printed Panel Structure SIO 2 / CNT composite ceramic embryo. Thereafter, in the tubular furnace, in the nitrogen atmosphere, the temperature of the temperature of 5 ° C / min is 1000 ° C, and after 3 hours, the furnace is cooled to obtain a decentralized SiO. 2 / CNT composite.

[0061] (3) The SIO prepared 2 / CNT composites are cut and polished into an annular size of 3.01 mm, outer diameter of 7mm, and thickness 3 mm, and use the vector network analysis tester to obtain 2 to 18 GHz eccenter electromagnetic parameters, and substitute the parameter into the CST electromagnetic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Minimum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com