Absorbing paper and its preparation method and application

A wave-absorbing agent and wave-absorbing material technology, which is applied in the field of papermaking, can solve problems such as unfavorable impedance matching characteristics, absorber peeling, difficult gradient control of electromagnetic parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

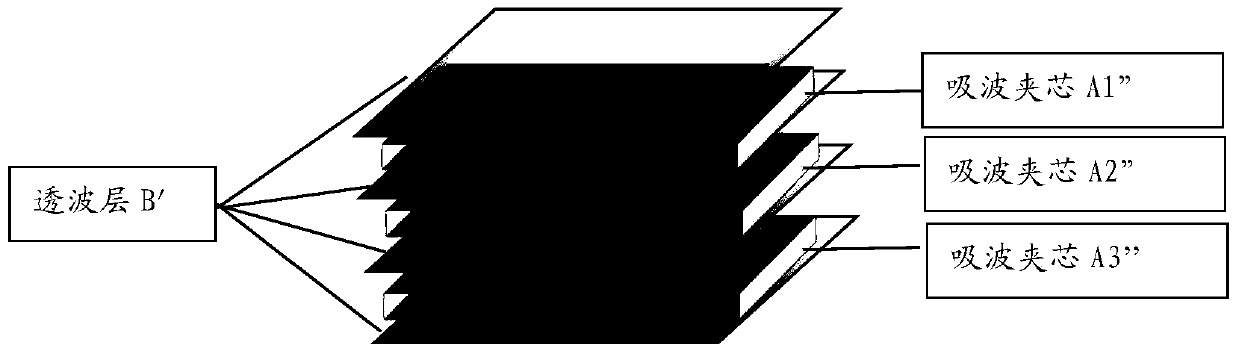

[0074] Mix 5wt% of carbon fiber and 95wt% of para-aramid fibrillated pulp to prepare slurry A1, mix 10wt% of carbon fiber and 90wt% of para-aramid fibrillated pulp to prepare slurry A2, and mix 15wt% of carbon fiber Mixed with para-aramid fiber fibrillated pulp 85wt% to prepare slurry A3, and slurry A1, A2, A3 were respectively formed by filtration to obtain wave-absorbing paper A1', A2', A3'. The fibrous wave-absorbing agent is carbon fiber (domestic), with a diameter of 10 μm and a length of 8 mm, and the wave-transmitting fiber is para-aramid fibrillated pulp.

[0075] like figure 1 In the preparation process shown, the above-mentioned carbon fiber is dispersed in water with a disintegrator, and the above-mentioned para-aramid fibrillated pulp is dispersed in water with a pulper to obtain two uniformly dispersed suspensions, and then the two suspensions are The liquid was mixed and stirred evenly to obtain a slurry with a concentration of 0.03%. Slurries A1, A2, and A3 we...

Embodiment 2

[0083] Mix 40wt% of silicon carbide fiber and 60wt% of para-aramid precipitated pulp to prepare slurry A1, mix 50wt% of silicon carbide fiber and 50wt% of para-aramid precipitated pulp to prepare slurry A2, and carbonize 60wt% of silicon fiber and 40wt% of para-aramid precipitated pulp were mixed to prepare slurry A3, and slurry A1, A2, and A3 were respectively formed by filtration to prepare wave-absorbing papers A1', A2', and A3'. The fiber absorbing agent is silicon carbide fiber (domestic), with a diameter of 12 μm and a length of 6 mm, and the wave-transmitting fiber is para-aramid precipitated pulp.

[0084] like figure 1 In the preparation process shown, the above-mentioned silicon carbide fiber is dispersed in water with a disintegrator, and the above-mentioned para-aramid precipitated pulp is dispersed in water with a pulper to obtain two uniformly dispersed suspensions, and then the two The suspensions were mixed and stirred evenly to obtain a slurry with a concentr...

Embodiment 3

[0087] Mix polycrystalline iron fiber 35wt%, carbon black 5wt% and PBO fibrillated pulp 60wt% to prepare slurry A1, polycrystalline iron fiber 37.5, carbon black 6wt%wt% and PBO fibrillated pulp 56.5wt % mixed to obtain slurry A2, 40wt% of polycrystalline iron fiber, 7wt% of carbon black and 53wt% of PBO fibrillated pulp were mixed to obtain slurry A3, and slurry A1, A2, and A3 were respectively filtered and formed to obtain Absorbing paper A1', A2', A3'. The fibrous wave-absorbing agent is polycrystalline iron fiber with a diameter of 5 μm and a length of 1 mm. The granular wave-absorbing agent is carbon black with a particle size of 5-10 μm. The wave-transmitting fiber is PBO fibrillated pulp.

[0088] like figure 1 In the preparation process shown, the above-mentioned polycrystalline iron fiber and carbon black are dispersed in water with a disintegrator, and the above-mentioned PBO fibrillation pulp is dispersed in water with a pulper to obtain three uniformly dispersed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com