Constant temperature adjusting method for air conditioning type constant temperature hydraulic oil tank

A technology of hydraulic oil tank and constant temperature adjustment, which is applied in the direction of oil supply tank device, fluid pressure actuating device, fixed tubular conduit assembly, etc. The effect of large market and promotion potential, high heat exchange efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

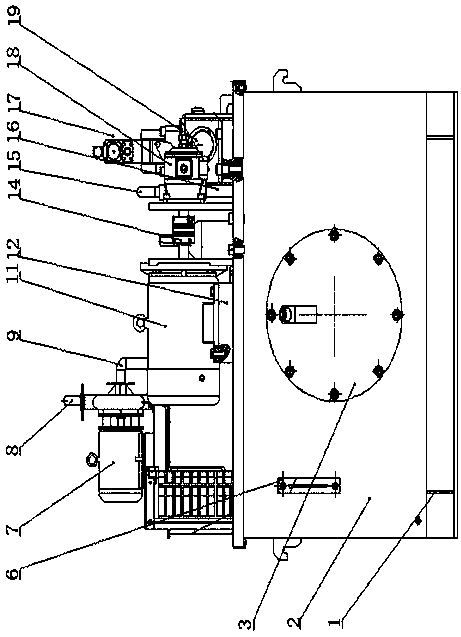

Image

Examples

Embodiment 2

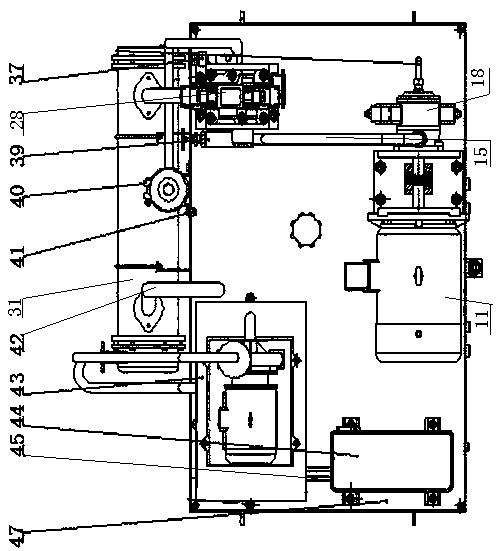

[0030] Example 2, such as Figure 5 As shown, a constant temperature adjustment method of an air-conditioned constant-temperature hydraulic oil tank, the steps are as follows: S1: The evaporator coil of the air-conditioning system of the air-conditioned constant-temperature hydraulic oil tank is connected to the water tank, and the air-conditioning system is based on the oil temperature in the oil tank and the water temperature in the water tank. Perform cooling or heating, and control the temperature of the cooling water in the water tank;

[0031] S2: The water tank is connected to the heat transfer pipe in the heat exchanger through the water inlet pipe, the oil tank is connected to the inner chamber of the heat exchanger through the oil inlet pipe, and the hydraulic oil in the oil tank exchanges heat with the cooling water in the heat exchanger;

[0032] S3: The hydraulic oil that has completed the heat exchange returns to the oil tank through the oil return pipe, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com