Continuous chlorination method for phenol and circulating flow spray type continuous gas-liquid reactor

A gas-liquid reactor, reactor technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, detailed information on chemical/physical/physical-chemical reactors, etc., can solve the problem of low equipment utilization. , low utilization rate of gas phase, long gas-liquid reaction time, etc., to achieve the effects of increasing solubility, increasing utilization rate of gas phase, and increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

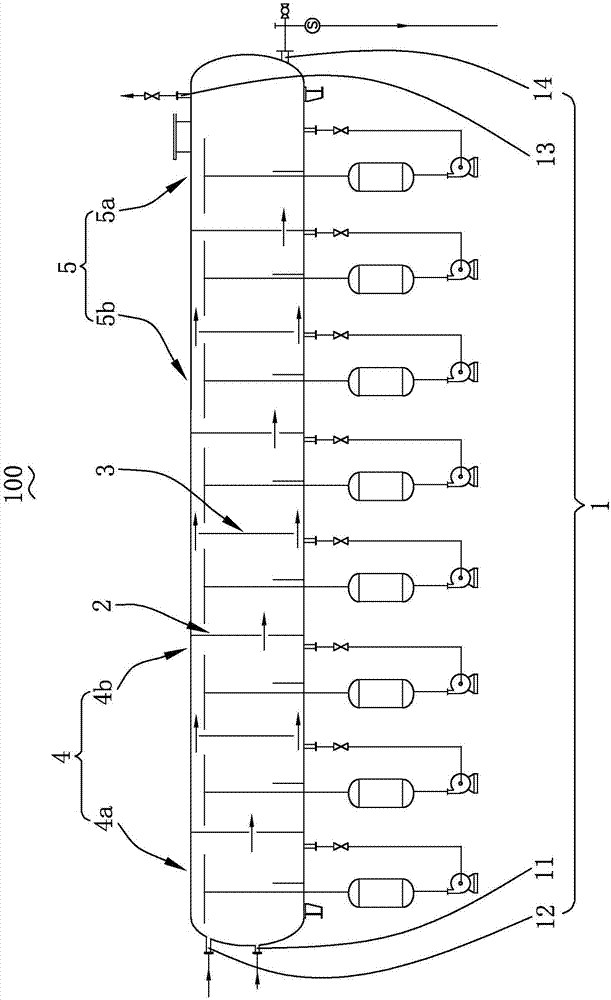

[0058] A method for continuous chlorination of phenol, wherein phenol and chlorine are continuously introduced into the loop continuous gas-liquid reactor 100 in a molar ratio of 1:2, the reaction temperature is controlled to be 50° C., and the reaction pressure is a slight negative pressure; the slight negative pressure is Refers to the reaction pressure slightly lower than the standard atmospheric pressure, such as -50Pa, -20Pa, -10Pa;

[0059] Wherein, the loop continuous gas-liquid reactor 100 is formed by a staggered arrangement of five first single-stage reactors and five second single-stage reactors, that is, the number of the first partitions 2 is five, and the second partitions The number of boards 3 is four. Both phenol and chlorine are introduced from the first-stage first single-stage reactor 4a, and the liquid phase is circulated and transported through the first circulation conveying device, and the gas-liquid mixed phase enters the adjacent middle through the ga...

Embodiment 2

[0061] A method for continuous chlorination of phenol, wherein phenol and chlorine are continuously introduced into the loop continuous gas-liquid reactor 100 at a molar ratio of 1:2.02, the reaction temperature is controlled to be 60° C., and the reaction pressure is 1 standard atmosphere;

[0062] Wherein, the loop continuous gas-liquid reactor 100 is formed by staggered arrangements of three first single-stage reactors and three second single-stage reactors, that is, the number of the first partitions 2 is three, and the second partitions The number of boards 3 is two.

[0063] Phenol is introduced from the first single-stage reactor 4a of the first stage, and the amount of chlorine gas introduced from the first single-stage reactor 4a of the first stage accounts for 60% of the total amount of chlorine gas, and the other 40% is introduced from the remaining stages;

[0064] In the first-stage first single-stage reactor 4a, the liquid phase circulation is realized through th...

Embodiment 3

[0066] A method for continuous chlorination of phenol, wherein phenol and chlorine are continuously introduced into the loop continuous gas-liquid reactor 100 at a molar ratio of 1:2.05, the reaction temperature is controlled to be 70° C., and the reaction pressure is 1.5 standard atmospheres;

[0067]Wherein, the loop continuous gas-liquid reactor 100 is formed by staggered arrangements of 4 first single-stage reactors and 4 second second single-stage reactors, that is, the number of the first partitions 2 is 4, and the second partitions The number of boards 3 is three.

[0068] Phenol is introduced from the first-stage first single-stage reactor 4a, chlorine gas is introduced from the first-stage first single-stage reactor 4a to account for 80% of the total amount of chlorine gas, and another 20% is introduced from the remaining stages;

[0069] In the first-stage first single-stage reactor 4a, the liquid phase circulation is realized through the first circulation conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com