Manufacturing method for semiconductor devices with super junction structures

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the part filled with insulating material cannot be used as a current flow path, the chip area cannot be fully utilized, and the on-resistance of the device can be reduced. , to achieve the effect of simple and easy manufacturing process, reducing on-resistance, and increasing the current flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

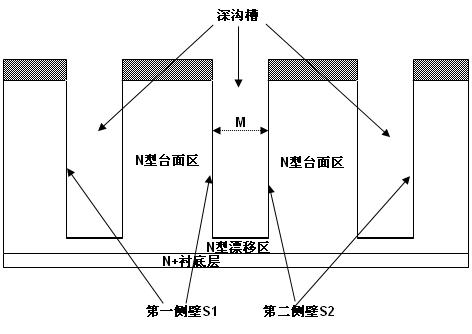

[0040] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] The following embodiments take an N-type superjunction MOSFET device as an example, and the method for manufacturing a semiconductor device with a superjunction structure includes the following steps:

[0042] a. Provide a semiconductor substrate with N-type conductivity (the material includes silicon), the semiconductor substrate has a corresponding first main surface (the upper surface of the semiconductor substrate) and a second main surface (the lower surface of the semiconductor substrate), and the second main surface of the semiconductor substrate An N-type drift region and an N+ substrate layer are included between the first main surface and the second main surface, and the impurity concentration of the N+ substrate layer is greater than the impurity concentration of the N-type drift region; figure 1 shown.

[0043] b. Deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com