Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

313 results about "Chromium sesquioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium compounds. In chromium: Principal compounds …chromium oxide, also known as chromium sesquioxide or chromic oxide, Cr2O3, in which chromium is in the +3 oxidation state. It is prepared by calcining sodium dichromate in the presence of carbon or sulfur.

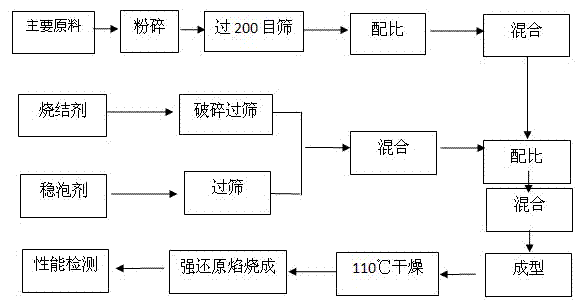

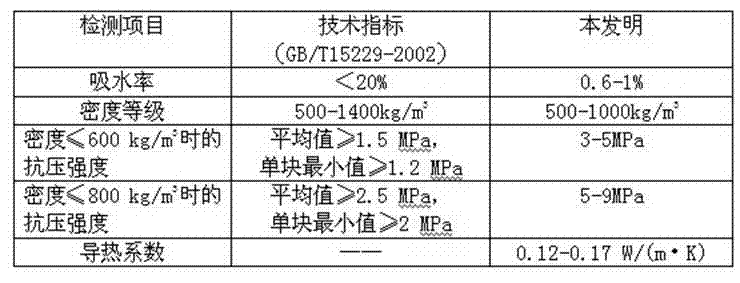

Method for preparing foam ceramic self-insulation wall material by utilizing solid wastes

InactiveCN103396150AReduce manufacturing costRealize comprehensive utilizationSolid waste disposalCeramicwareChromium sesquioxideInsulation layer

The invention relates to a method for preparing a foam ceramic self-insulation wall material by utilizing solid wastes. The wall material comprises a main material and an admixture. The main material is prepared from the following components in proportion: 25% to 35% of chromium slags, 19% to 27% of coal gangue, 20% to 26% of waste ceramic polishing residues, 17% to 25% of albite and 1% to 6% of bentonite. The method comprises the following steps of: adding 16 to 20g of the admixture into every 200g of the main material; evenly mixing and screening the mixture; putting the mixture into a die; molding the mixture in a pressing manner and drying; sintering the mixture under a strong reducing atmosphere at the temperature of 1120-1180 DEG C, thereby obtaining the foam ceramic self-insulation wall material. The carbon in the coal gangue can serve as a foaming agent or a reducing agent, so that hexavalent chromium is reduced into chromium sesquioxide at the high temperature and under the strong reducing atmosphere. Thus, the toxicity of the chromium slags is eliminated. The prepared foam ceramic self-insulation wall material is low in pyroconductivity, small in density and low in water absorption rate; the usage temperature can reach 900 DEG C. In addition, the foam ceramic self-insulation wall material is complete in fire resistance, high in strength and long in service life, and can be used for replacing the existing wall materials and flammable insulation materials. The wall material integrates protection and thermal insulation functions; an exterior wall insulating layer is not required. Thus, the construction cost is lowered.

Owner:HENAN COAL CHEM IND GROUP INST +1

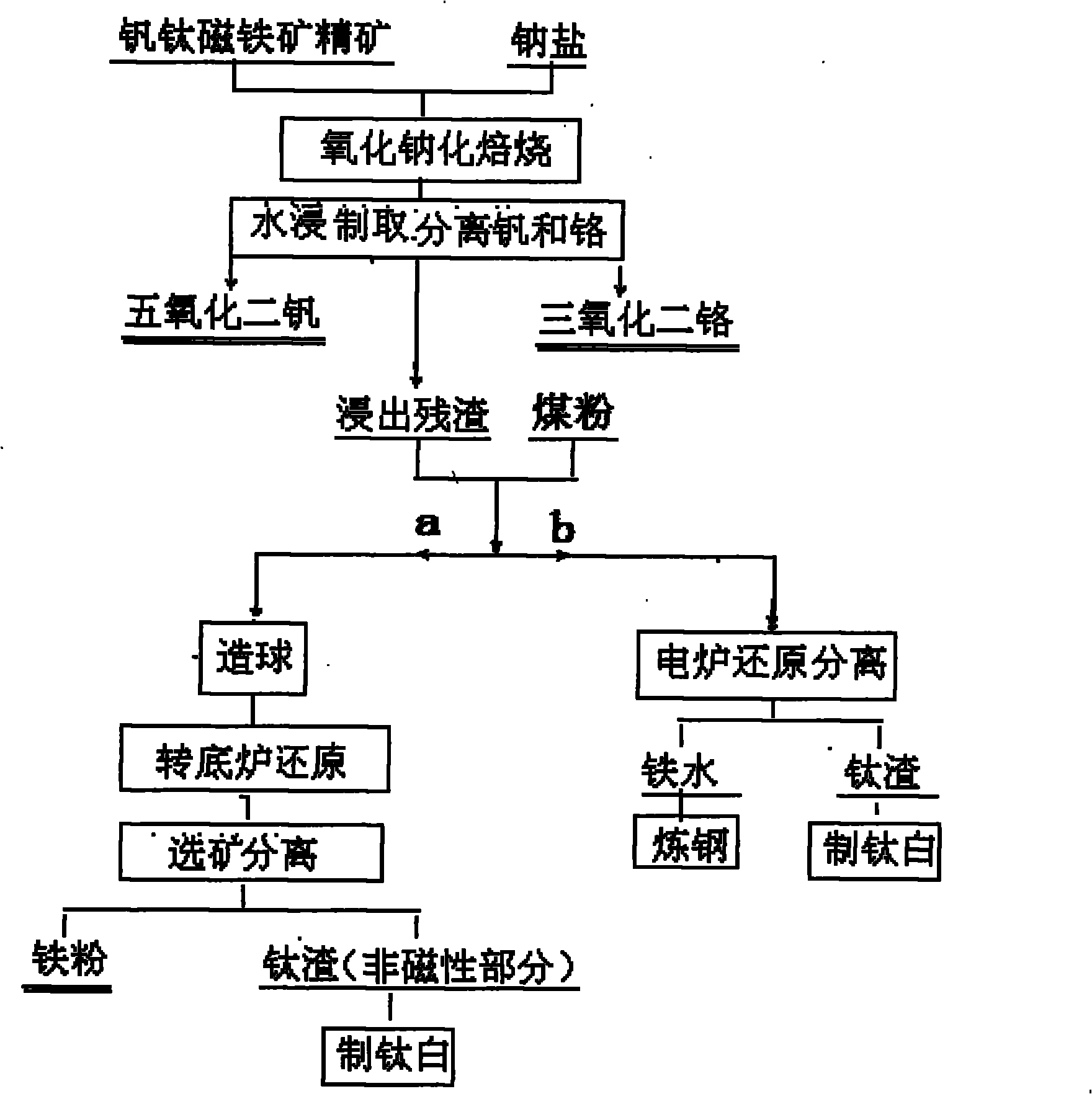

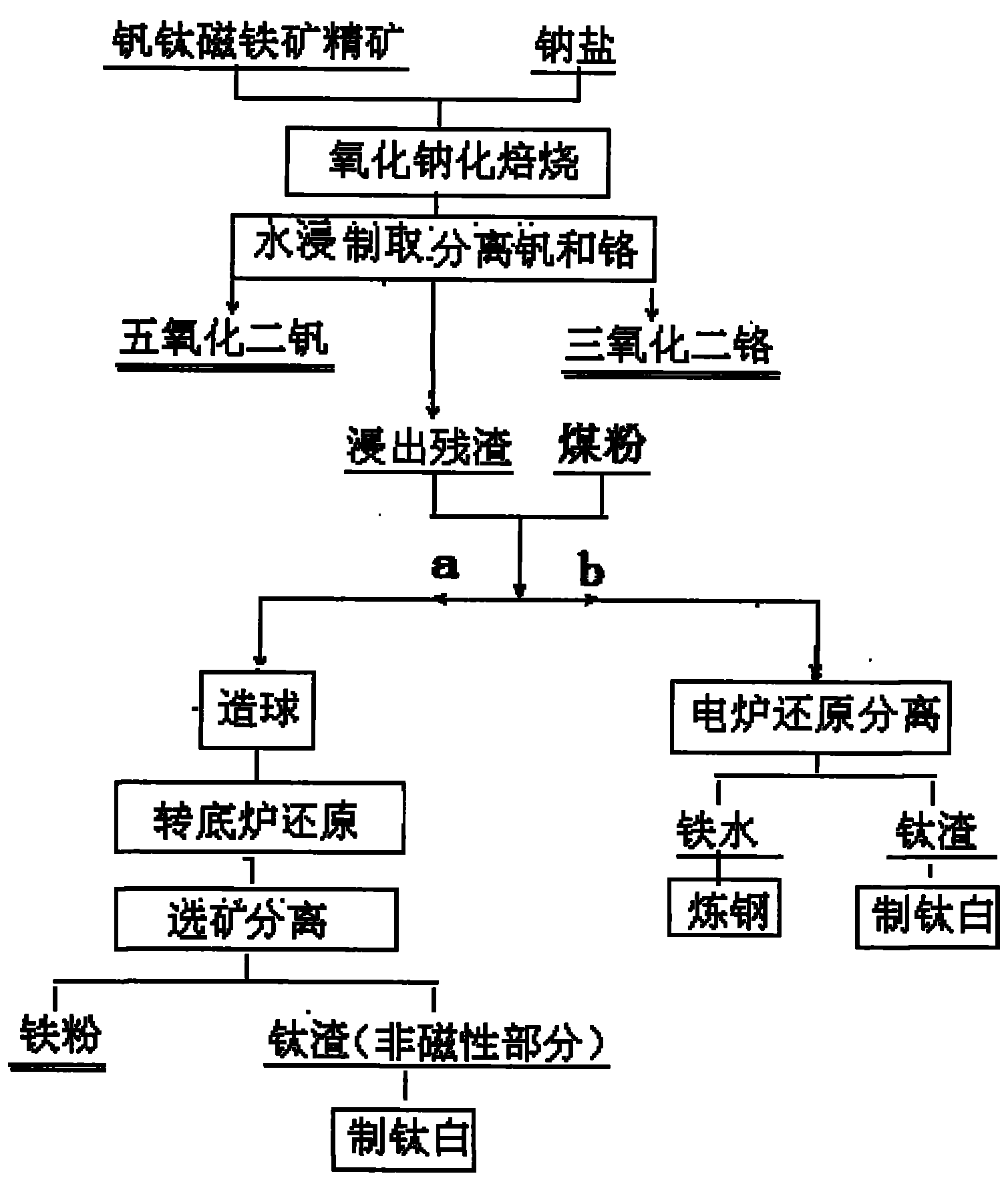

Method for recycling vanadium, chromium, titanium and iron from vanadium-titanium magnetite ore

ActiveCN102061397AHigh recovery rateSimple processProcess efficiency improvementSteelmakingMagnetite

The invention discloses a method for recycling valuable elements from vanadium-titanium magnetite ore, which comprises the following steps of: crushing the ore or concentrate, adding sodium salt, performing oxidizing roasting, converting vanadium and chromium into water-soluble sodium vanadate and sodium chromate, performing water leaching in solution, and separating the vanadium and chromium from the solution to obtain vanadium pentoxide and chromium sesquioxide products; and adding coal dust into the leached residue for pelletizing, reducing in a rotary hearth furnace, magnetically separating iron and titanium, using the obtained magnetic iron powder as a raw material for powder metallurgy or steelmaking, and using a nonmagnetic product containing more than 50 percent of TiO2 as a raw material for extracting the titanium; or reducing iron from the leached residue in an electric furnace, using the obtained molten iron as a raw material for steelmaking and using electric furnace slag containing more than 50 percent of TiO2 as a raw material for extracting the titanium. The method is short in process flow and economical; and the recovery rate of the vanadium, chromium, titanium and iron is high.

Owner:SICHUAN LOMON MINING & METALLURGY +1

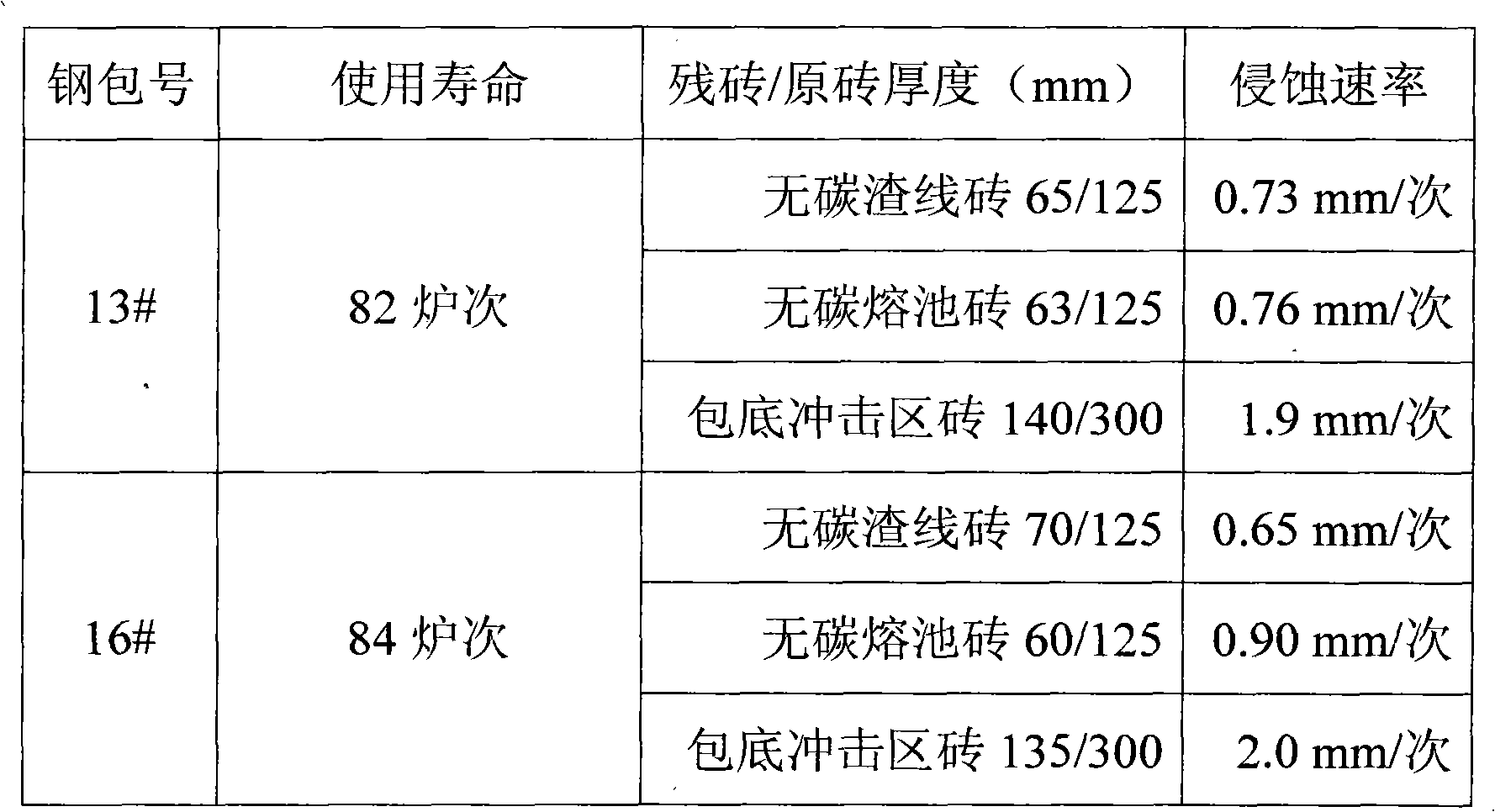

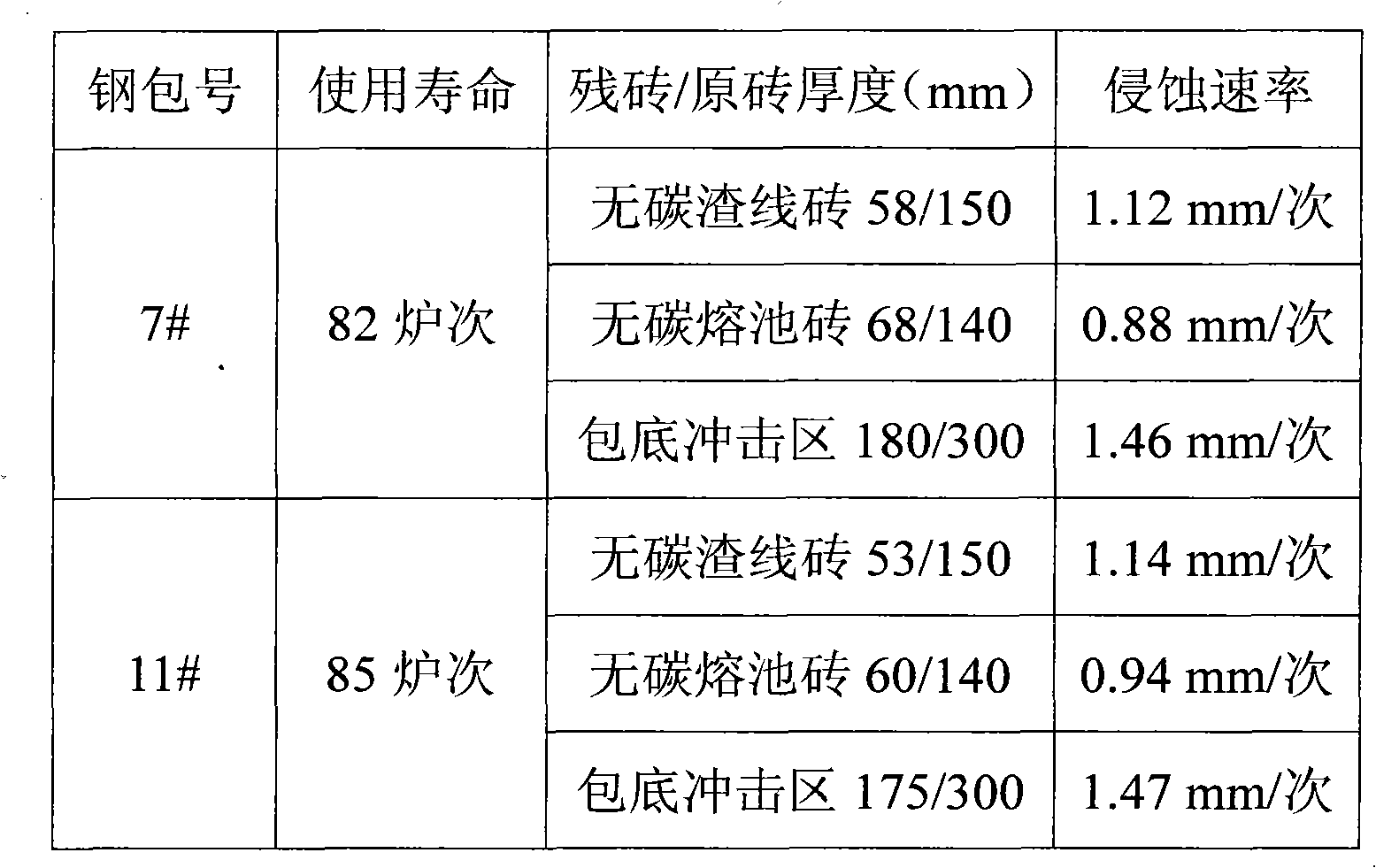

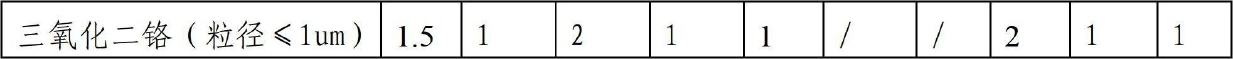

Non-carbon residue feather edge brick for refining steel ladle and preparation method thereof

The invention relates to a refractory and mainly provides a non-carbon residue feather edge brick for a refining steel ladle and a preparation method thereof. The non-carbon residue feather edge brick is formed by taking corundum grains, electrofused spinel grains and electrofused magnesia grains as aggregate, taking corundum fine powder, high-temperature alumina micropowder, electrofused magnesia, chromium sesquioxide, aluminum metal powder and other powders as base components and adopting a mode of compounding and adding inorganic and organic bonding agents and a mode of machine pressing. The obtained non-carbon residue feather edge brick has the advantages of high strength of generated blanks, no firing, favorable thermal shock stability, strong capability of resisting acid and alkali molten slag, no pollution on molten steel and the like and can be applied to residue line parts of the steel ladle under the conditions of RH and specified LF / VD refining.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

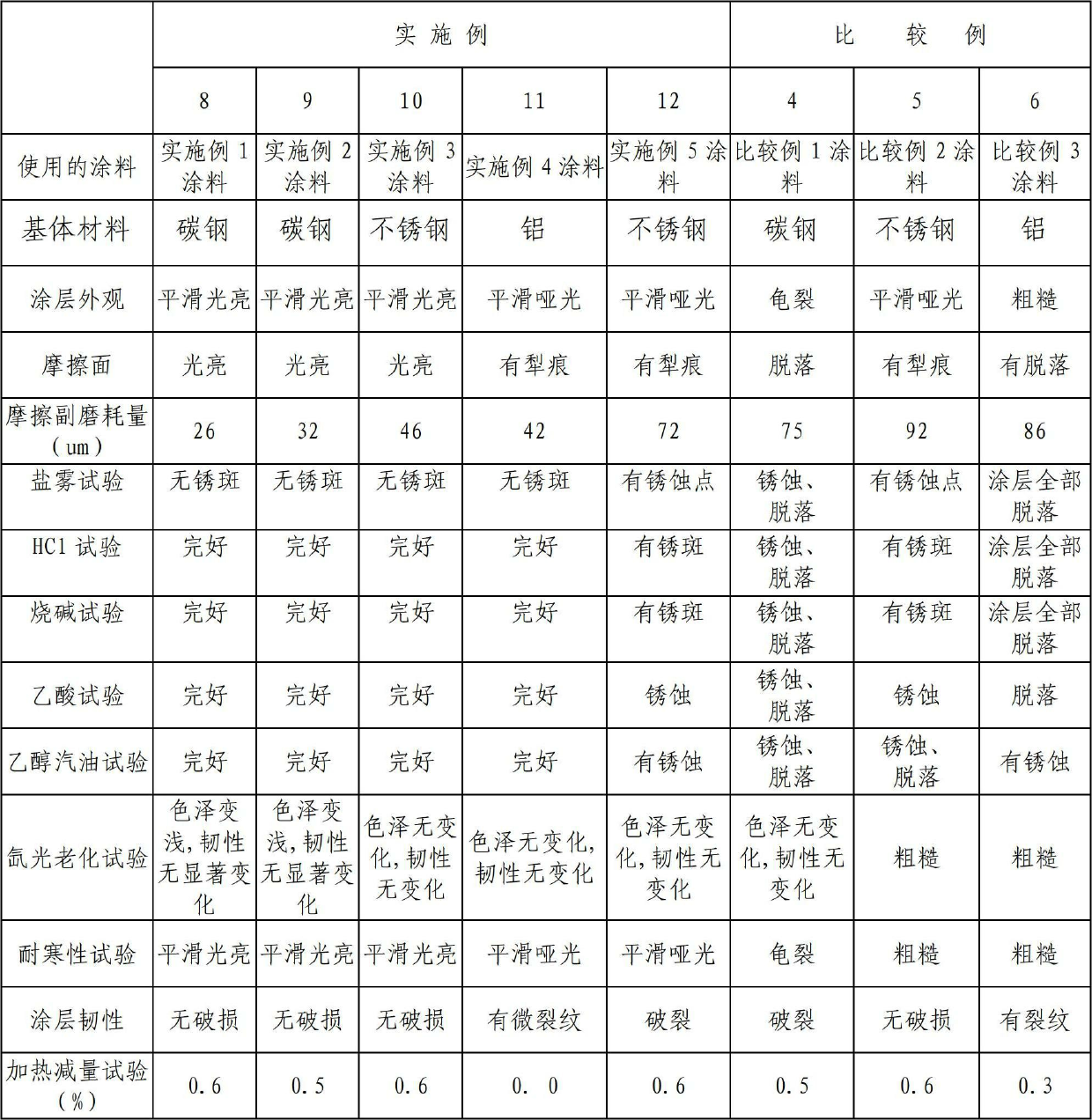

Modified polyphenylene sulfide coating and application thereof

ActiveCN102676048AImprove corrosion resistanceSelf-lubricatingAnti-corrosive paintsWear resistantCorrosion

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Owner:CHENGDU LETIAN PLASTICS

Process for roasting chromite resources in ring kiln through pure oxygen by using low-temperature method and harmlessly and deeply utilizing chromium residue

InactiveCN101824530AImprove resource conversion rateMagnesium carbonatesChromium trioxideSodium bicarbonateSlag

The invention belongs to the field of metallurgy and chemical engineering. The process comprises the following steps of: firstly, crushing chromite, adding sodium hydroxide and a catalyst to be oxidized and roasted by using a low-temperature pure oxygen method; diluting, cooling, extracting and filtering to obtain a sodium chromate crystal and ferrum-magnesium slag; adding an alkali washing solution into a sodium hydroxide solution to back extract to obtain the sodium hydroxide solution for recycling; adding water into the sodium chromate crystal and ferrum-magnesium slag to be dissolved and feeding filtrate into a carbonizer to decompose to extract aluminum; carbonizing, evaporating, condensing and crystallizing the extracted solution to obtain sodium chromate; and carbonizing ferrum-magnesium filter slag to generate sodium bicarbonate, reacting to generate a magnesium hydrogen carbonate solution, heating and cracking to generate a magnesium carbonate product and drying a filter cake to obtain ore refined powder; and secondly, crushing chromium residue, adding sodium bicarbonate in the ration of 1:8, adding a catalyst for calcination, cooling and adding water to soak; adding an aluminum hydroxide crystal into supernatant liquid, carbonizing and decomposing to remove aluminum in a reaction tank; filtering and washing an aluminum hydroxide product; adding a reducing agent into the filtrate to reduce hexavalent chromium to generate anhydrous chromium hydroxide and drying and roasting to obtain chromium sesquioxide; and returning the filtrate to a system for mixing after pyrolyzing and extracting to remove magnesium.

Owner:白向南 +2

Hot-spraying nano composite ceramic coating plastic mold and production method thereof

InactiveCN101249698AEasy releaseRealize easy demouldingMolten spray coatingCeramic layered productsThermal sprayingComposite ceramic

A plastic mold for hot-spray nanometer composite ceramic coating and a production method thereof are provided. The plastic mold is composed of a plastic mold steel basal body, a bottom bonding layer and a nanometer composite ceramic working layer produced by hot-spray technology. The bottom bonding layer adopts any of the Ni / AI, AI / NI or NiCrAl materials. The nanometer composite ceramic working layer adopts the material of granular ball-shaped nanometer composite hot-spray coating powder which is a compound of chromium oxide chromium sesquioxide, titanium dioxide and silicon dioxide. The production method comprises the following steps: firstly, preparing hot-spray coating on mold steel workpieces to be processed according to standard and optimized hot-spray process; secondly, conducting surface grinding and polishing to meet the technical requirements for the size, precision, surface toughness, etc. of the plastic mold. The production method is simple, low in production cost and easy to industrialize, and realizes the high-quality characteristics of the plastic mold such as high rigidity, high wear resistance, high corrosion resistance, long service life, and easiness to de-mould, so that the method has good market application prospect and high commercial value.

Owner:WUHAN YOUKE SURFACE ENG

Boiler coal combustion-improving denitrifying agent composition and preparation method thereof

The invention relates to an additive product suitable for coal-fired boilers in the petroleum, chemical and power industries and provides a boiler coal combustion-improving denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-8 parts of sodium carbonate, 3-7 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 6-15 parts of urea, 4-10 parts of ammonium carbonate, 4-10 parts of ammonium chloride, 3-9 parts of ferric oxide, 7-22 parts of potassium permanganate, 7-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 4-8 parts of chromium sesquioxide, 2-6 parts of manganese oxide, 4-8 parts of zinc oxide, 4-8 parts of copper chloride, 2-6 parts of copper oxide, 2-6 parts of copper carbonate, 3-7 parts of zinc sulfate, 2-5 parts of zinc nitrate, 0.5-1.5 parts of barium molybdate, 1-2 parts of titanium oxide, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of copper sulfate, 0.2-0.5 part of cerium oxide, 1-3 parts of penetrating agent JFC and 0.1-0.2 part of lignosulphonate. The composition is efficient in combustion improving, has high coal saving rate and prolongs the service lives of the boilers.

Owner:GANSU HEIMA PETROCHEM ENG

Method for precipitation separation and recovery of chromium and vanadium in chromium-vanadium solution

ActiveCN103849765AHigh removal rateLow Chromium Loss RateProcess efficiency improvementTwo stepReducing agent

The invention relates to a method for the precipitation separation and the recovery of chromium and vanadium in a chromium-vanadium solution. The method comprises the following steps: regulating the pH (Power Of Hydrogen) of a solution until the solution is acidic; adding an ammonium salt so as to precipitate the majority of vanadium from the solution in a form of ammonium polyvanadate; filtering and adding a certain amount of reducing agent into a vanadium-precipitated supernatant so as to perform reduction and precipitation on the partial vanadium in the solution; stirring and filtering; then adding the certain amount of reducing agent so as to reduce the rest of the vanadium in the precipitation solution; filtering; collecting filter residues obtained by two steps of reduction and precipitation; dissolving out in an oxidization manner and returning to the vanadium precipitation step via the ammonium salt; collecting the supernatants obtained by the two steps of reduction and precipitation; adding the certain amount of reducing agent again and precipitating chromium hydroxide; and filtering and calcining a filter cake so as to prepare chromium sesquioxide, wherein the supernatant after the precipitation of the chromic hydroxide can be taken as a mother liquor of a leaching process to be recycled. The method is simple in process, low in cost, less in equipment and small in reagent adding amount, and realizes the recycling of wastewater.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for separating and extracting vanadium and chromium from vanadium chromium leaching liquor

ActiveCN103276205AImprove oxidation capacityLess reducing doseProcess efficiency improvementChromium sesquioxideSulfite salt

The invention belongs to the field of wet metallurgy, and particularly relates to a method for separating and extracting vanadium and chromium from vanadium chromium leaching liquor. The method comprises the following steps of: adding sodium sulfite into the vanadium chromium leaching liquor, adjusting the pH value to 5 to 5.5; carrying out the precipitation reaction; filtering, calcining filtered solids and cooling; adding the calcination products into NaOH (sodium hydroxide) solution to obtain solid filter residue, i.e. chromium sesquioxide; adjusting the pH value of the liquid filtered after the precipitatio to 2.0 to 2.5, heating the filtered liquid to 90 to 95 DEG C, and adding ammonium sulfate to obtain precipitates, filtering the precipitates, wherein the solid filter residue is ammonium metavanadate. By adopting the moderate reduction, less reduction agent is added, the reduction action is carried out under a normal temperature condition, and the cost is reduced.

Owner:NORTHEASTERN UNIV

Vanadium titano-magnetite tailing glass-ceramic and preparation method thereof

The invention relates to vanadium titano-magnetite tailing glass-ceramic and a preparation method thereof. The vanadium titano-magnetite tailing glass-ceramic takes vanadium titano-magnetite tailings as a main raw material, and takes silica or silica sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), magnesium oxide (MgO), chromium sesquioxide (Cr2O3), calcium fluoride (CaF2) and sodium nitrate (NaNO3) as auxiliary raw materials, wherein the content of vanadium titano-magnetite tailings in all the raw materials of the glass-ceramic is 50.0 to 65.0 percent by weight. The preparation method comprises the following steps: smashing the vanadium titano-magnetite tailings; mixing the vanadium titano-magnetite tailing powder, the auxiliary raw materials and a flexible clarifying agent exactly according to a designed ingredient proportion to obtain a uniform mixture; putting the mixture into a smelter for melting; after homogenizing and clarification of glass melt, preparing a glass board or glass particles through formation or water quenching; conducting crystallization heat treatment on the formed glass board, or carrying out crystallization after a mold is filled with the glass particles; carrying out annealing to obtain a glass-ceramic board. The vanadium titano-magnetite tailing glass-ceramic and the preparation method have the advantages that the production cost of glass-ceramic is reduced; the problems of resource waste and environmental pollution are solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

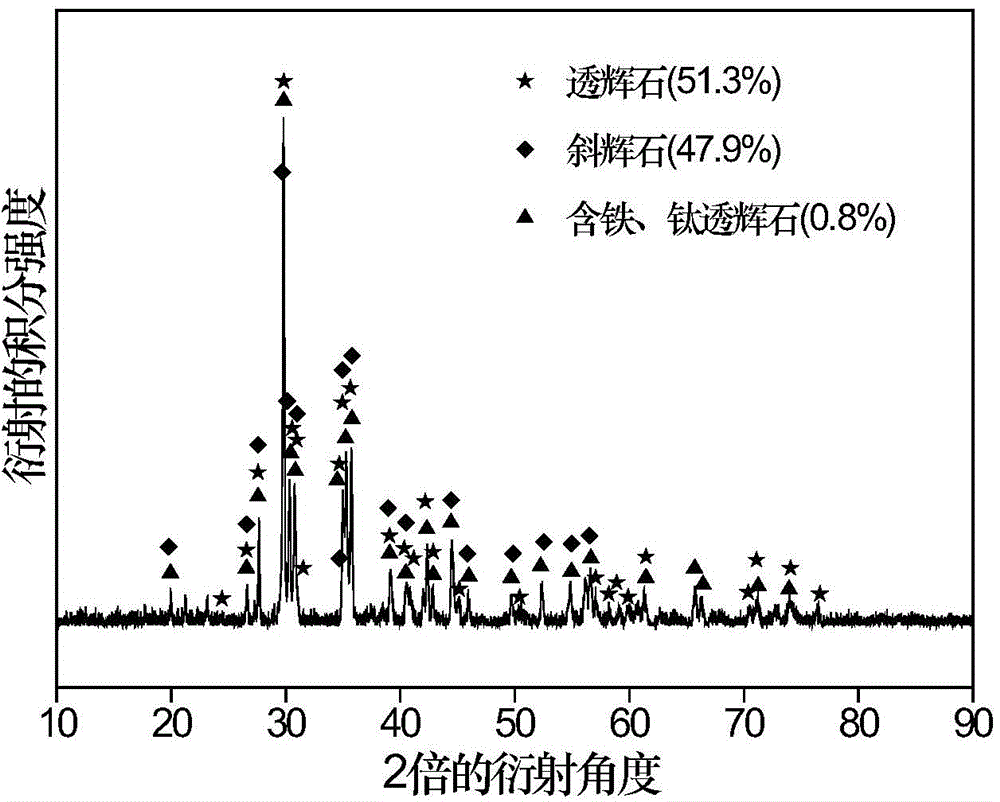

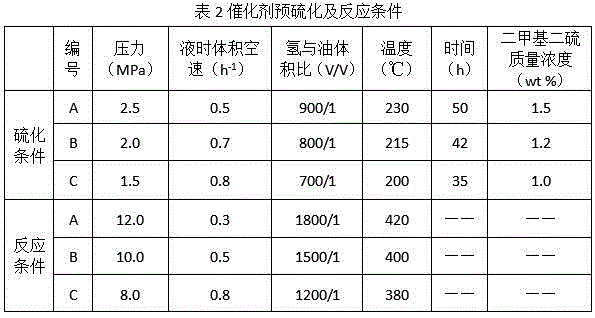

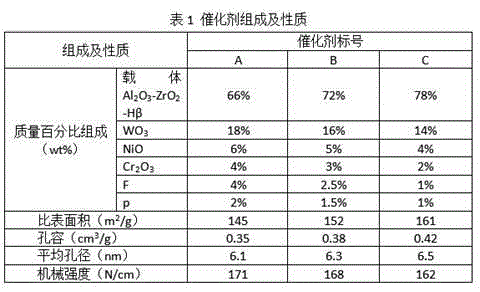

Hydrodenitrogenation catalyst capable of removing nitrogen-containing compound from coal tar, and preparation method and application thereof

ActiveCN102614909AIncreased total phenolic contentImprove water resistanceMolecular sieve catalystsHydrocarbon oils refiningNickel MonoxideChromium(III) oxide

The invention belongs to the technical field of catalysts for hydrodenitrogenation of coal tar. The technical problem to be solved is to provide a hydrodenitrogenation catalyst capable of deeply removing a nitrogen-containing compound from coal tar and provided with high mechanical strength, wear resistance and water resistance, and a preparation method and application thereof. The invention adopts the technical scheme that in the hydrodenitrogenation catalyst capable of removing nitrogen-containing compound from coal tar, active components consist of tungsten trioxide, nickel monoxide and chromium sesquioxide; aids comprise fluorine and phosphorus; and a carrier consists of aluminum oxide, zirconium oxide, a Hbeta molecular sieve, a binder and an extrusion aid. By adopting the hydrodenitrogenation catalyst capable of deeply removing the nitrogen-containing compound from the coal tar, the oil nitrogen content of the hydrogenation product can be reduced to be below 50 micrograms / gram; and the hydrodenitrogenation property is high, so that the oil sulfur content of the hydrogenation product can be reduced to be below 40 micrograms / gram.

Owner:山西中科化美科技有限责任公司

Method for producing chromium metal by using carbon reduction two-step method

ActiveCN101798638AImprove work efficiencyIncrease production capacityChromium sesquioxideHigh humidity

The invention discloses a method for producing chromium metal by using a carbon reduction two-step method, which comprises the following steps: grinding 100 parts of chromium sesquioxide with the purity of 94 to 99.5 percent and 25 to 44 parts of carbon powder, mixing and stirring the ground powder uniformly, pressing the powder to form balls, and putting the balls into a high temperature furnace to perform primary carbon reduction treatment to generate chromium carbon melt; crushing the melt into fine powder of 80 to 200 meshes, measuring the carbon content, adding the chromium sesquioxide into the melt in a ratio of oxygen to carbon of 1: 33, stirring the mixture fully and uniformly, and pressing and drying the mixture; and putting the dried blank into a vacuum high-humidity furnace, keeping the blank wet for 14 to 15 hours under the vacuum of 20 to 200Pa at the furnace temperature of between 1,300 and 1,600 DEG C, or putting the blank into the high temperature furnace filled with argon, heating the blank to 2,000 DEG C to be smelted, preserving the heat for 2 hours, casting the blank to form blocks, and discharging the blocks after cooling. The method can produce chromium metal products of multiple specifications with the purity of 94 to 99.5 percent, and has large production capacity and high work efficiency so as to achieve the purpose of industrialized production.

Owner:LOUDI DAJIN NEW MATERIAL CO LTD

Anti-static zirconia ceramic and preparation process thereof

ActiveCN104341150AGood chemical stabilityHigh hardnessManganous-manganic oxideYttria-stabilized zirconia

The invention discloses an anti-static zirconia ceramic. The anti-static zirconia ceramic is prepared from the following raw materials in parts by mole: yttria-stabilized zirconia, sodium oxide, aluminum oxide, calcium oxide, nickel oxide, chromium sesquioxide, manganous-manganic oxide and conductive carbon black. The preparation process of the anti-static zirconia ceramic comprises the following steps: 1) sufficiently carrying out ball milling on the yttria-stabilized zirconia; 2) mixing the ball-milled yttria-stabilized zirconia, sodium oxide, aluminum oxide, calcium oxide, nickel oxide, chromium sesquioxide, manganous-manganic oxide and conductive carbon black and then sufficiently sanding and mixing; 3) adding a binder in above mixture, and pelleting; and 4) placing above spherical particle in a die at room temperature to perform compression forming, hot-pressing to degrease and sintering; after sintering, naturally cooling to room temperature. The zirconia ceramic product produced by the invention is good in chemical stability, high in hardness, high temperature resistant, abrasion resistant, corrosion resistant, strong in insulation, and obvious in anti-static performance advantage, and has good application prospect.

Owner:李正国

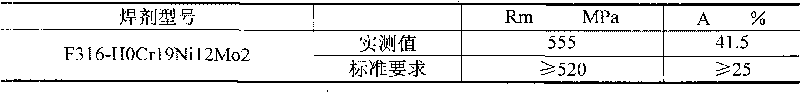

Stainless steel sintered flux

InactiveCN101733587AEasy to remove slagExcellent weld process performanceWelding/cutting media/materialsSoldering mediaChromium sesquioxideMagnesite

The invention introduces a stainless steel sintered flux which is a baking object prepared by mixing a mixture of 20-30wt% of fused magnesite, 20-30wt% of corundum, 10-20wt% of fluorite, 1-5wt% of cryolite, 10-16wt% of aedelforsite, 1-5wt% of zirconia, 3-5wt% of chromium sesquioxide, 1-3wt% of silicoferrite with more than 74 percent of Si, 4-10wt% of quartz powder and 1-5wt% of ferromanganese with more than 78 percent of Mn and 42-45Be potassium-sodium water glass at the temperature of 20 DEG C, wherein the mass of the potassium-sodium water glass accounts for 20-30 percent of that of the mixture. The stainless steel sintered flux of the invention is matched with a corresponding welding core and has excellent weld process performance; when in welding, an electric arc is stable, the surface of a weld is white and light and has no oxidation color, and the detachability in a bevel is good; the weld has attractive molding, and the infiltration angle is moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Antioxidant coating applied to high-temperature alloy heat treatment

InactiveCN101736138ASustained antioxidant effectImprove thermal conductivityChromium sesquioxideSodium polyacrylate

The invention belongs to the technical field of preparing high-temperature antioxidant coating, and develops a high-temperature oxidation resistant coating on the basis of researching steel alloy plate blank heat treatment process, which is especially applicable to high-temperature long-time insulation heat treatment process of silicon steel and the like. The antioxidant coating applied to high-temperature alloy heat treatment is characterized by comprising the following components by mass ratio: solid powder ratio: 85-92% of magnesia, 0.5-5% of chromium sesquioxide, 2-5% of sodium tripolyphosphate, 1-4% of industrial aluminum powder and 0.1-1% of graphite; and sodium polyacrylate accounting for 2-4wt% of the solid powder, ludox solution accounting for 4-5wt% of the solid powder, and water accounting for 15-25wt% of the solid powder. The method has simple process, low cost and good adhesion of the prepared coating, and can further help improve protectiveness on matrix.

Owner:UNIV OF SCI & TECH BEIJING

Conductive coating

ActiveCN103587164AGood film formingImprove securitySynthetic resin layered productsElectrically-conductive paintsPhosphoric acidSulfide

The invention provides a conductive coating which comprises a bottom layer and a surface layer, wherein the bottom layer is prepared by components in parts by weight as follows: 70 parts of polytetrafluoroethylene emulsion, 6.8-7.1 parts of phosphoric acid, 6.8-7.2 parts of chromic acid, 0.7-1.0 part of lauryl sodium sulfate, 1.6-2.0 parts of chromium sesquioxide, 8-9 parts of water, 0.5-0.8 part of polyphenylene sulfide, 5-7.5 parts of graphite and 1-2.5 parts of conductive black; and the surface layer is prepared by components in parts by weight as follows: 90 parts of polytetrafluoroethylene emulsion, 0.7-0.9 part of lauryl sodium sulfate, 10-11 parts of water, 2-2.5 parts of polyphenylene sulfide, 5-7.5 parts of graphite and 1-3 parts of conductive black. The obtained conductive coating has a smooth surface and large adhesive force with a metal mold, and is high in hardness, difficult to scratch and good in conductivity; and the demolding effect is good after the metal mold is sprayed, and the quality of a finished product is guaranteed.

Owner:湖北三江航天江河橡塑有限公司

Ferromagnetic oxide powder for magnetic recording and preparation method thereof

Owner:BGRIMM TECH CO LTD

Monatomic catalyst and application thereof in carbon dioxide hydrogenation reaction

ActiveCN111530458ASelectivity adjustablePromote formationOrganic compound preparationHydroxy compound preparationChromium sesquioxidePtru catalyst

The invention discloses a monatomic catalyst and application thereof in a carbon dioxide hydrogenation reaction, and belongs to the technical field of carbon dioxide conversion. Cerium dioxide, zinc oxide, zirconium dioxide, chromium sesquioxide and the like are used as carriers, and monoatomic Pd, In, Cu and Au are used as active components; the weight of the catalyst carriers accounts for 95-99.9% of the total weight of the catalyst, and the weight of the active components accounts for 0.01-5% of the total weight of the catalyst. The preparation method of the catalyst is simple, methanol orcarbon monoxide can be selectively generated by adjusting reaction conditions, the selectivity of the methanol or carbon monoxide is very high and can reach 90% or above, and the catalyst has wide industrial application prospects.

Owner:JIANGNAN UNIV

Ceramic bond and preparation method thereof

ActiveCN105150122ALower firing temperatureImprove gripAbrasion apparatusGrinding devicesChromium sesquioxideLithium carbonate

The invention relates to a ceramic bond and a preparation method thereof, and belongs to the technical field of grinding wheel bonds. The ceramic bond is prepared from, by weight, 20%-40% of borosilicate glass, 22%-43% of feldspar, 10%-35% of nepheline syenite, 5%-13% of clay, 2%-5% of lithium carbonate and 3%-13% of chromium sesquioxide. According to the ceramic bond, all the components are subjected to a synergistic effect within a limited dosage range, the firing temperature of the ceramic bond is lowered to be 1000 DEG C, high-temperature burning loss of ceramic microcrystal grinding materials is avoided, the revolving strength of a grinding wheel manufactured through the bond is improved, and the grinding linear velocity reaches 80 m / s maximally. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:白鸽磨料磨具有限公司

High-voltage resistant high-stability piezoelectric ceramic

The invention discloses high-voltage resistant high-stability piezoelectric ceramic, comprising the following raw materials in parts by weight: 100 parts of lead tetroxide, 14-17 parts of barium carbonate, 3.5-6.5 parts of strontium carbonate, 28-30 parts of zirconium dioxide, 15-17 parts of titanium dioxide, 9.6 parts of niobium pentoxide, 2.8 parts of nickel protoxide, 0.05-0.07 part of cerium oxide, 0.03-0.05 part of chromium sesquioxide, 0.04-0.06 part of silicon dioxide and 0.02-0.04 part of lithium carbonate. The piezoelectric ceramic is prepared through mixing, pre-sintering, crushing, baking, pulping, cast film forming, isostatic pressing, sintering, electric shock treatment and polarization. A micro unit cell of the piezoelectric ceramic is square unit cell, the included angle between crystal axes is 90 degrees, the unit cell structure is relatively stable, and the electric domain is changed little by high voltage and high temperature shock. A device manufactured by adopting the piezoelectric ceramic is low in performance drift and low in failure rate, the stability and consistency of products are improved, and large-scale application of piezoelectric high-power products is promoted.

Owner:HUNAN JIAYEDA ELECTRONICS

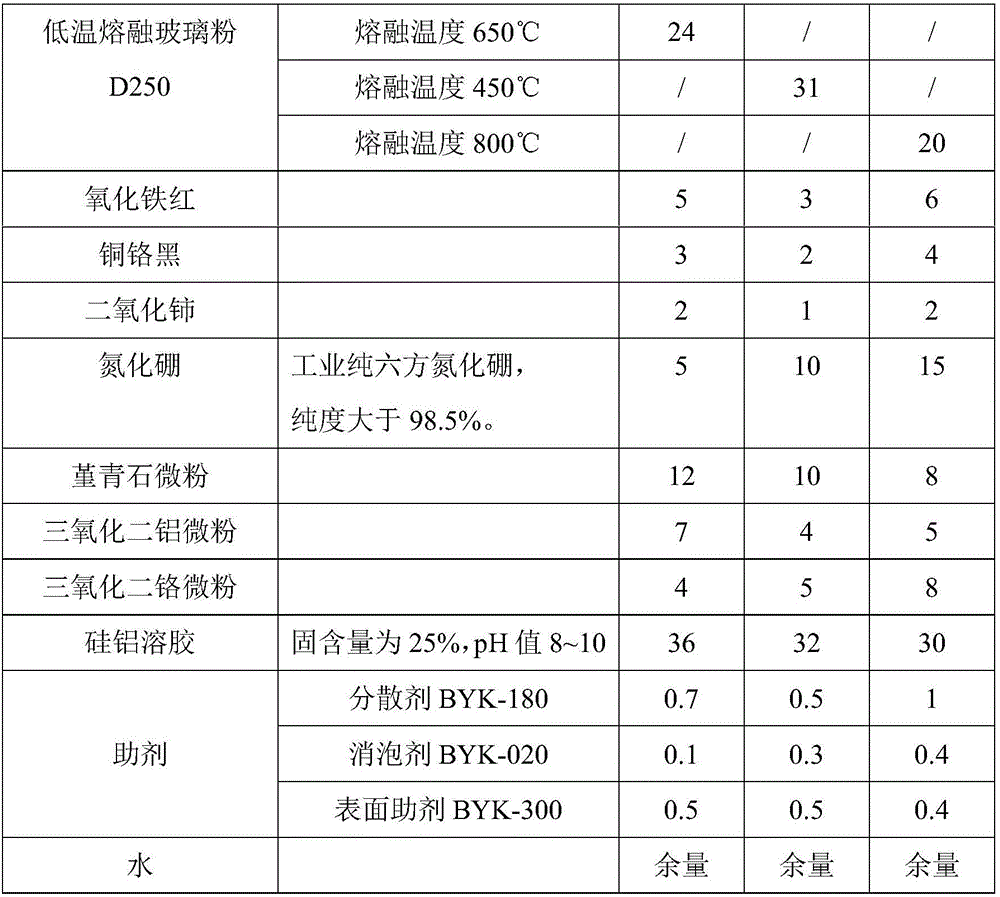

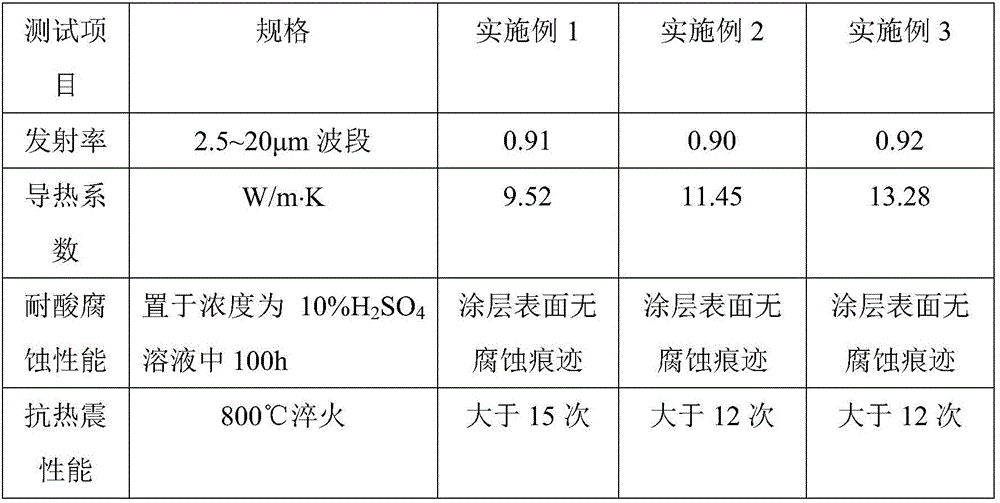

Low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and preparation method and application thereof

The invention discloses a low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and a preparation method and an application thereof. The paint comprises the following raw materials: low-temperature molten glass powder, iron oxide red, copper-chrome black, cerium dioxide, boron nitride, iolite micro powder, alumina micro powder, chromium sesquioxide micro powder, 20-50% of silicon aluminium sol, 0.5-3% of an auxiliary agent, and the balance of water. The method comprises the following steps: a metal matrix is processed, then the surface of the metal matrix is uniformly coated with a paint and dried in shade; and the coated metal matrix is heated at the temperature of 650-900 DEG C to form the low-temperature sintering high-heat conduction ceramic paint. The paint has the advantages of easy acquisition of the raw materials and low cost, is tightly combined with the metal matrix, has effective high temperature oxidation resistance, acid corrosion resistance and abrasion resisting effects of a heating furnace flue heat exchanger on a metal heat exchanger, ceramic coating surface is smooth and clean, slag buildup of the heat exchanger is effectively reduced, the service life of the metal heat exchanger is prolonged, and the heat exchange efficiency effect is increased.

Owner:武汉钢铁有限公司

Green red brown-extracting glaze and ceramic material

Owner:江西欣天利陶瓷有限公司

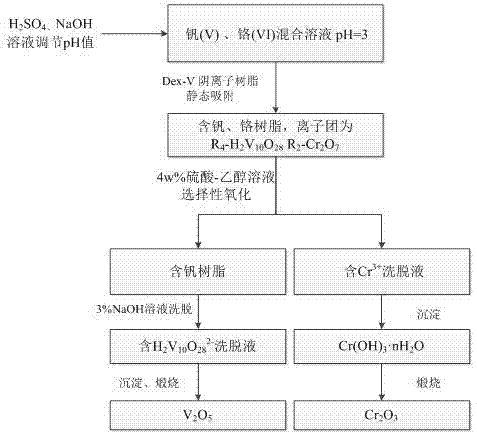

Method for extracting vanadium and chromium from mixed solution containing vanadium and chromium

InactiveCN107190155AEfficient separationHigh purity extractionProcess efficiency improvementChromium sesquioxideAlcohol

The invention discloses a method for extracting vanadium and chromium from a mixed solution containing the vanadium and the chromium. The method comprises the steps that the vanadium and the chromium in the solution are adsorbed with Dex-V large-pore alkalescent anion exchange resin, so that resin adsorbing the vanadium and the chromium is obtained; then, elution is conducted with a sulfuric acid and ethyl alcohol mixed solution with the concentration being 4%, so that a chromium (III) solution and vanadium-containing resin are obtained; neutralizing treatment is conducted on the chromium-containing solution, so that chromium sesquioxide is obtained; and then, the vanadium-containing resin is desorbed with an alkaline solution, vanadium precipitation treatment is conducted on an obtained vanadium-containing desorption solution, so that vanadium pentoxide is obtained. The method is low in raw material and equipment requirement, simple in operation process, high in efficiency and low in cost. According to the method, the vanadium and the chromium are extracted through adsorption; the adsorption rate of the vanadium (V) can reach 98.83%, and the adsorption rate of the chromium (VI) can reach 99.87%; the desorption rate, on the chromium (VI), of the sulfuric acid and ethyl alcohol mixed solution with the concentration being 4% can reach 96.7%; and the final overall recovery rate of the vanadium can reach 90.57%, and the final overall recovery rate of the chromium can reach 96.52%.

Owner:CHONGQING UNIV

Anti-radar coating for air vehicles and preparation method of anti-radar coating

InactiveCN106634283AHigh magnetic lossHigh dielectric lossAnti-corrosive paintsRadiation-absorbing paintsCyclohexanoneEpoxy

The invention discloses an anti-radar coating for air vehicles and a preparation method of the anti-radar coating. The anti-radar coating is prepared from the following raw materials: polyvinyl acetate emulsion, chlorosulfonated polyethylene, epoxy resin, graphite powder, dihydroxymethyl propane, diethanol amine, chromium sesquioxide, diisocyanate, manganese oxide, indene resin, glass powder, cyclohexanone, n-butyl acetate and pigments. The anti-radar coating has the beneficial effects that a product can resist ultrahigh frequency; high strength radar detection is realized, electromagnetic parameters and frequency are good, and the adhesive force is level 1; the magnetic loss and the dielectric loss are high, the corrosion resistance is good, the temperature stability is good, the storage is easy, the heat conduction coefficient is 0.01W / m.k-0.014W / m.k; the anti-radar coating can resist the temperature of 100-400 DEG C, does not fall and does not corrode metal, and the coating density is 0.1g / cm<3>-0.5g / cm<3>; and the hardness is 2H-6H, and the anti-radar coating is high in electromagnetic radiation absorptivity and infrared reflectivity, simple to synthesize and low in cost, can be widely produced and can be used for continuously replacing the existing materials.

Owner:江苏悠谷未来科技有限公司

Aniline formaldehyde resin LED dispersion coating and preparation method thereof

InactiveCN103881436AGood weather resistanceImproves UV resistanceCoatingsCarbon nanotubeRaw material

The invention discloses an aniline formaldehyde resin LED heat dispersion coating which is prepared from the following raw materials in parts by weight: 30-35 parts of aniline formaldehyde resin, 20-25 parts of polyamide imide prepolymer, 6-8 parts of methyl 2-methacrylate, 5-7 parts of tetraethylenepentamine, 15-18 parts of aluminum nitride powder, 1-2 parts of graphene, 1-2 parts of carbon nano tube, 2-4 parts of titanium dioxide, 1-2 parts of barium sulfate, 2-3 parts of zinc oxide, 12-15 parts of ethylene glycol, 2-3 parts of silane coupling agent KH-550, 5-7 parts of phthalate, 1-2 parts of chromium sesquioxide, 20-25 parts of ethyl acetate, 8-10 parts of p-xylene and 4-5 parts of film forming agent. The coating disclosed by the invention has excellent weather fastness, ultraviolet resistance, water resistance, oil resistance and alkali resistance; as aluminum nitride powder, graphene, carbon nano tube, titanium dioxide, barium sulfate and zinc oxide are added, the heat dispersion, the dispersibility and the ageing-resistant performance of the coating are improved and the coating can be used for a long period of time below 200 DEG C.

Owner:程实

Wide-temperature-range low-loss ferrite and preparation method thereof

InactiveCN111039667AHigh initial permeabilityReduce magnetic lossInorganic material magnetismTungstateCerium

The invention provides wide-temperature-range low-loss ferrite and a preparation method thereof, and relates to the technical field of ferrite processing. The wide-temperature-range low-loss ferrite is prepared from the following raw materials in parts by weight: 90-100 parts of ferric oxide, 12-18 parts of nano titanium dioxide, 18-22 parts of magnesium oxide, 6-12 parts of barium oxide, 52-60 parts of manganese dioxide, 6-8 parts of a first mixture and 0.8-1.2 parts of a second mixture, wherein the first mixture is a mixture of chromium sesquioxide, tungsten trioxide, copper oxide and zinc oxide in a mass ratio of 3: 1: 4: 12, and the second mixture is a mixture of lanthanum hexaboride, cerium oxide and ammonium tungstate in a mass ratio of 2: 1: 1. The preparation method overcomes the defects of the prior art, effectively solves the problem of high loss of the traditional ferrite under the conditions of wide temperature and high frequency, effectively saves energy, and is suitable for various environments and fields.

Owner:天长市华磁磁电有限公司

Nitrogen oxide removal process based on hydrogen peroxide catalytic oxidation

InactiveCN106861392AGood dispersionEfficient activationHeterogenous catalyst chemical elementsDispersed particle separationCerium(IV) oxideCatalytic oxidation

The invention relates to the fields of industrial catalysis and environmental management, and particularly relates to a nitrogen oxide removal process based on hydrogen peroxide catalytic oxidation. A hydrogen peroxide solution is directly sprayed into a flue after passing through an atomizer; after the hydrogen peroxide solution is mixed with flue gas, a mixture enters a catalyst layer; the mixture is activated under the contact action of a catalyst; NO in the flue gas is oxidized into high valence lyotropic nitrogen oxides such as NO2, N2O4, N2O5 and the like; absorption processing is carried out by using alkali slurry to remove the nitrogen oxides in the flue gas. The process is simple, easy to operate, compact in device structure, good in economy and flexible to regulate, has various mode configurations, and can implement efficient denitration. Meanwhile, the catalyst used in the technical process uses nano titanium dioxide as a carrier and uses one or more of ceric oxide, cobaltosic oxide, nickel oxide, chromium sesquioxide and manganese dioxide as active ingredients; the catalyst is low in price and simple in preparation process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Resource utilization method for chrome sludge of vanadium extraction waste water treatment sediment

The invention provides a resource utilization method for chrome sludge of vanadium extraction waste water treatment sediment and belongs to the technical field of solid waste treatment and resource utilization. The method includes the steps that (1) the chrome sludge of the vanadium extraction waste water treatment sediment is roasted at a high temperature of 400-1000 DEG C for 0.5-5 h, sodium salt and vanadium remaining in the chrome sludge of vanadium extraction waste water generate a sodium salt roasting reaction again in the roasting process, and a roasted product is obtained; (2) water which is 2-10 times the mass of the roasted product is added into the roasted product, stirring washing is carried out for 0.5-3 h, solid and liquid separation is conducted, and the roasted product obtained after washing is deep green chromium sesquioxide powder; (3) a binding agent is added into the deep green chromium sesquioxide powder, briquetting and drying are carried out, and chromium sesquioxide particles with the effective grain size being larger than or equal to 3 mm are obtained; and (4) chromium containing steel is produced by taking the chromium sesquioxide particles as raw materials. According to the method, high value-added vanadium and chromium resources in the chromium sludge are recycled at low cost, so that remarkable economic benefits, social benefits and environmental benefits are generated.

Owner:NORTHEASTERN UNIV

Method for preparing chromic oxide

InactiveCN102010005AAchieve restorationEfficient productionChromium oxides/hydratesChromium sesquioxideHydrogen

The invention provides a method for preparing chromic oxide. The method comprises the following steps of: introducing reduction gas containing hydrogen into a high-temperature high-voltage reaction kettle to perform a reduction reaction on alkali metal salt of chromic acid or dichromic acid which serves as a raw material; cooling and depressurizing a reacted solution; and performing solid-liquid separation to obtain hydrated chromium sesquioxide and corresponding caustic alkali solution. By the process method provided by the invention, the corresponding caustic alkali product and the hydrated chromium sesquioxide can be prepared at the same time, and series of chromic oxide products can be prepared by further modifying the hydrated chromium sesquioxide; and the high-temperature high-pressure reaction kettle is adopted as a reactor, the reaction efficiency can be improved, and self-heat reaction can be simultaneously implemented by utilizing system reaction heat to achieve the aims of saving energy and reducing carbon emission. No waste water, waste residues or waste gas is generated in the process of preparing the chromic oxide and caustic alkali products, so that high-efficiency, energy-saving and pollution-free production of the chromic oxide can be implemented.

Owner:TIANJIN PAISEN TECH

Anti-cavitation and abrasion-resistant paint for water pump impellers and preparation method of paint

InactiveCN104893451AImprove the level ofFlat surfaceAnti-corrosive paintsEpoxy resin coatingsVinyl etherPolymer science

The invention discloses anti-cavitation and abrasion-resistant paint for water pump impellers and a preparation method of the paint. The paint comprises the following components in percentage by weight: 35-70% of a tetrafluoroethylene-vinyl ether polymer, 5.5-12% of a curing agent, 2-10% of a silane coupling agent and a fluoroalkyl silane coupling agent, 15-30% of silicon carbide, 1-10% of nano-composite particles, 0.03-3% of additives, 20-40% of methyl isobutyl ketone and butyl acetate, and 0.001-1% of a drying agent, wherein the nano-composite particles are a mixture of chromium sesquioxide, zirconia and gas-phase silicon dioxide; the additives comprise a leveling agent, an antifoaming agent, a dispersing agent and an anti-settling agent. The paint adopts a special paint formula; a coating prepared by utilizing the paint has a flat and smooth surface, and the adhesive force, the film coating rigidity, the waterproof performance, the salt-fog resistance performance and the abrasion resistance performance of the prepared coating reach 0 degree, 9 H, 3000 h, 2500 h and 5 times of 20 carbon steel respectively.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com