High-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit and preparation method of high-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit

A technology of high-entropy alloys and integrated circuits, applied in circuits, metal material coating processes, coatings, etc., can solve problems such as low resistivity and high thermal stability, and achieve low resistivity, improved barrier performance, and uniform composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

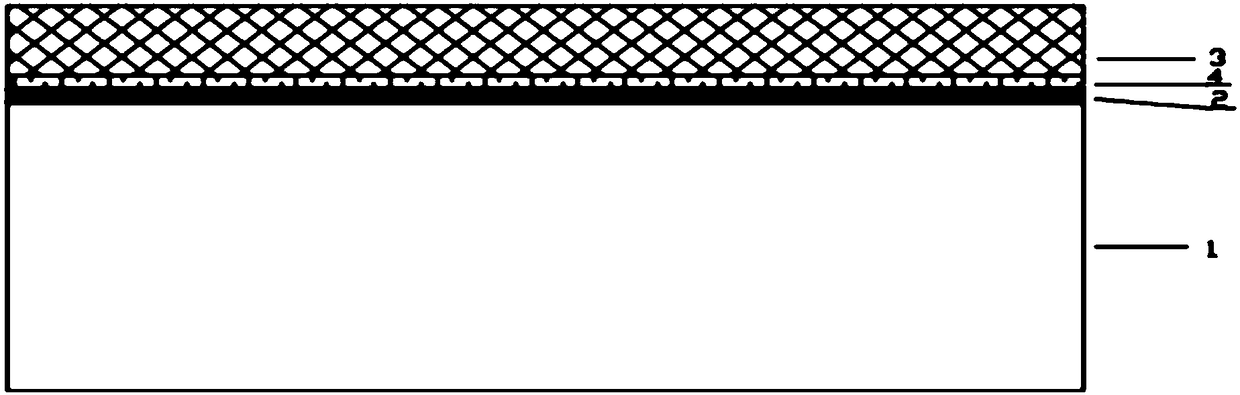

[0036]First, Al, Cr, Ta, Ti, Zr, and Mo are arranged in an equimolar ratio, mixed evenly, and the AlCrTaTiZrMo high-entropy alloy target is prepared by hot isostatic pressing; before sputtering the high-entropy alloy intermediate coating, Use acetone, alcohol, and deionized water to perform ultrasonic cleaning on the Si substrate layer in sequence to remove surface oxides or impurities; then pre-sputter the above Si substrate layer for 15 minutes to remove residual impurities on the substrate surface and increase the bonding between the coating and the substrate Then, using the above-mentioned AlCrTaTiZrMo high-entropy alloy target material, three-layer coatings are sputtered by DC magnetron sputtering to form a laminated diffusion barrier layer. The process parameters for the first layer of sputtering are: Ar flow rate 24sccm, N 2 In an atmosphere where the flow rate is 6 sccm, that is, x=0.2, the sputtering current is 1A, the substrate bias is -100V, the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com