Tensile creep test device and method for high-strength concrete

A high-strength concrete and test device technology, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test material strength, etc., can solve problems affecting the authenticity of test data, limiting the tensile strength of glue, and destroying the overall It can overcome the uneven load application, overcome the instability of the measurement results, and reduce the difficulty of the test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

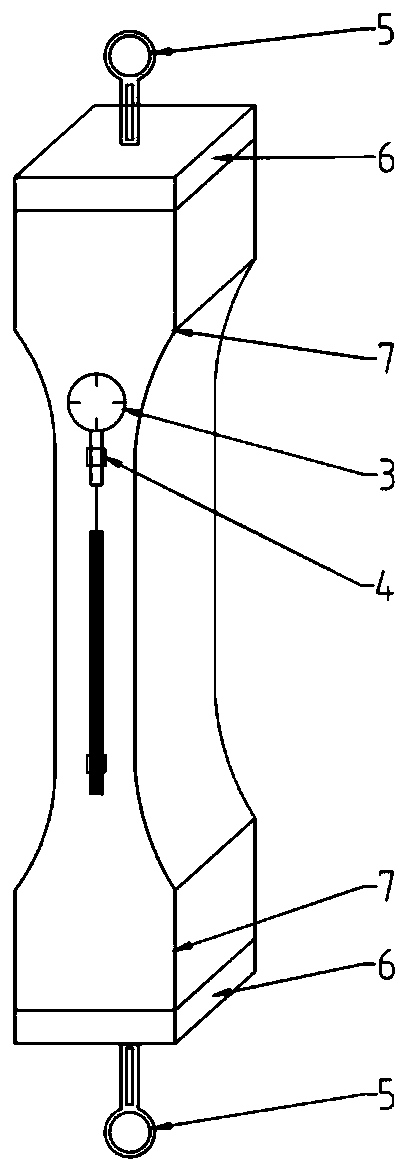

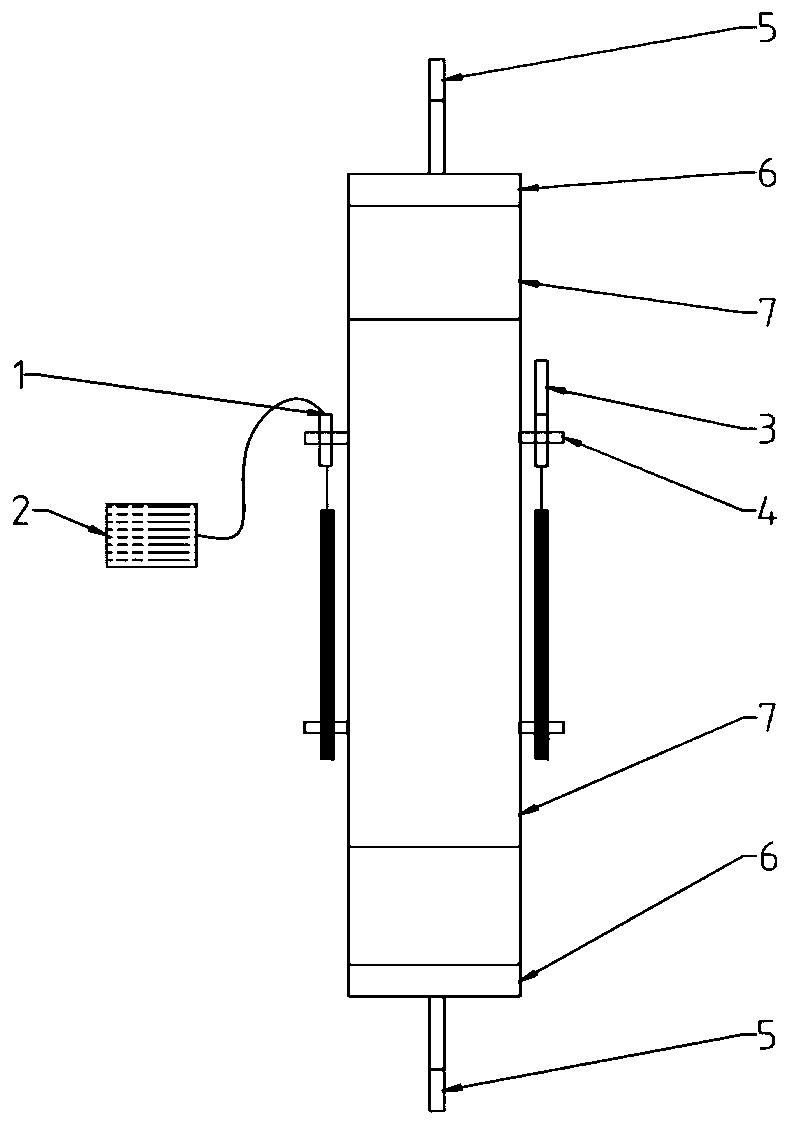

[0059] It can be seen from the accompanying drawings that a tensile creep test device for high-strength concrete includes a loading test device and a concrete test piece, the concrete test piece is connected to the loading test device, and one side of the concrete test piece is provided with A linear differential displacement sensor, the other side of the concrete test piece is provided with a dial indicator detector.

[0060] Described loading test device comprises top plate 9, base plate 19 and three threaded rods 12, and three threaded rods 12 upper ends are all fixedly connected on the top plate 9, and three threaded rods 12 lower ends are all fixedly connected on the base plate 19, and each threaded rod The middle part of 12 is provided with a sleeve 11, a force spring 14 and a stabilizing spring 16 sequentially from top to bottom, and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com