Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215results about How to "Improve assembly rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

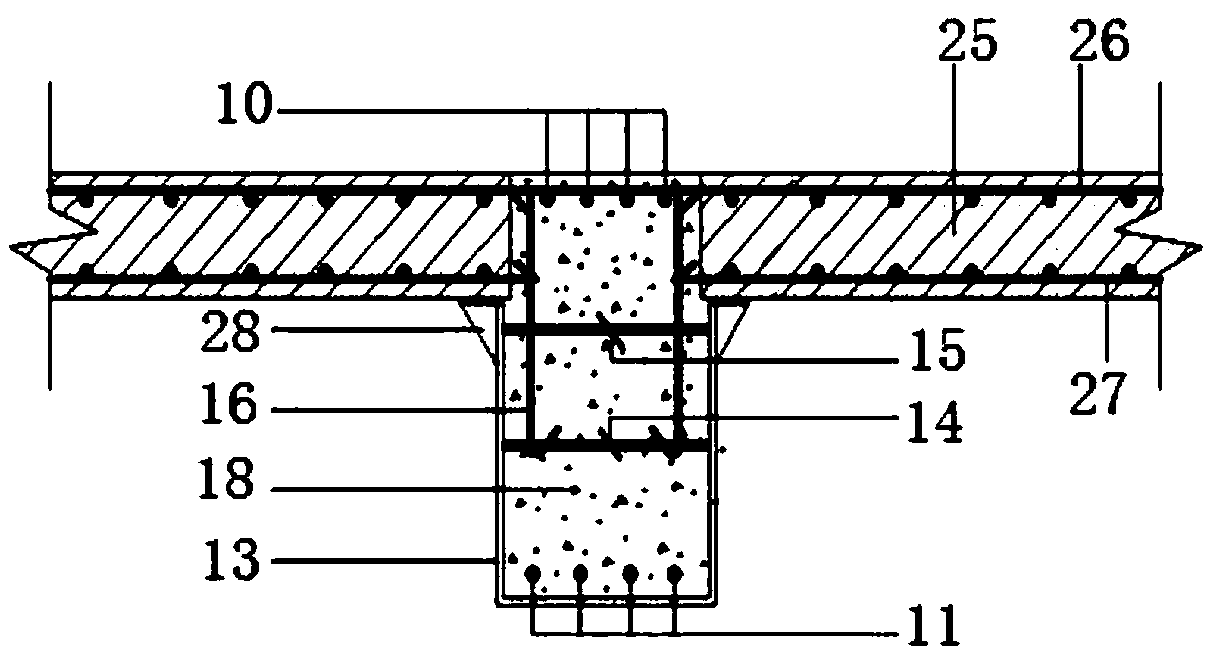

Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination

ActiveCN102808465ASplit location is reasonableEasy to manufactureWallsBuilding material handlingFloor slabRebar

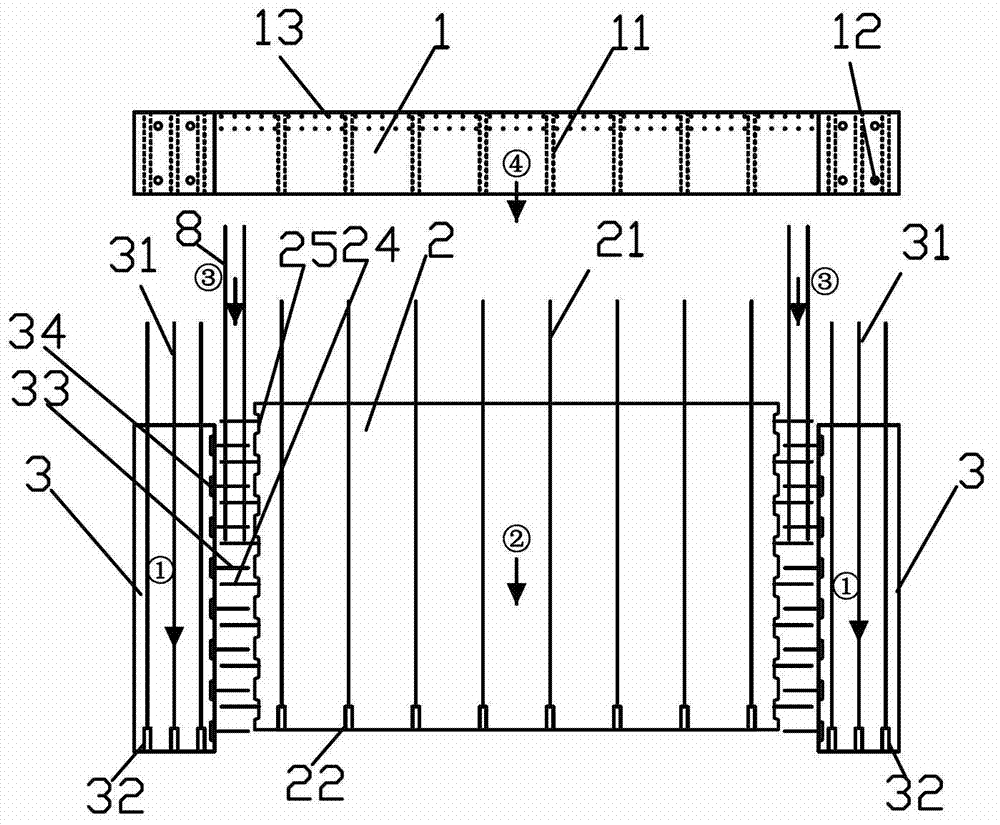

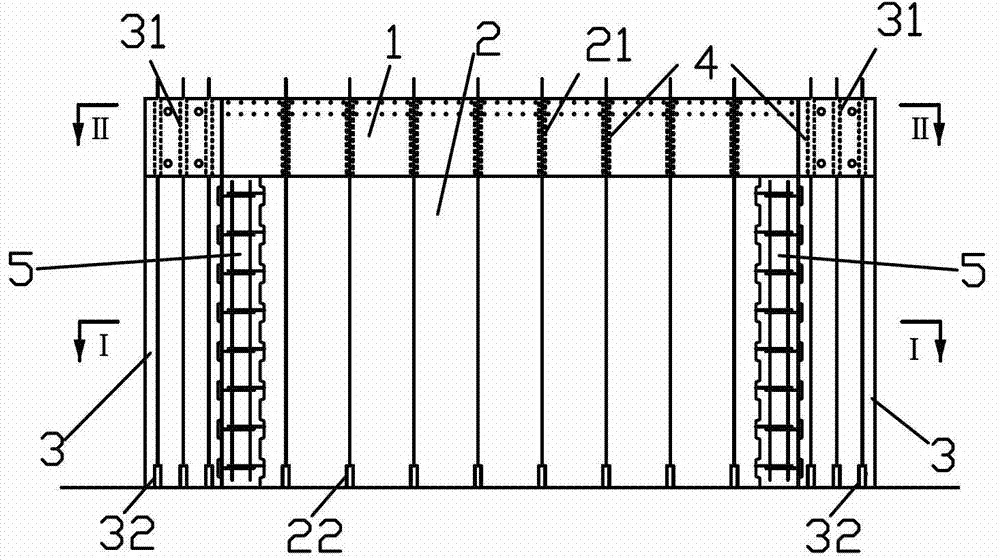

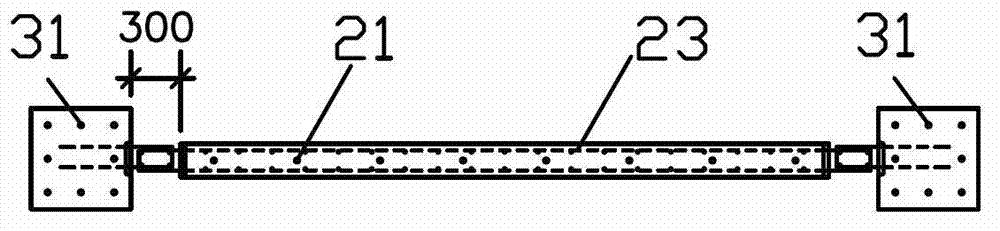

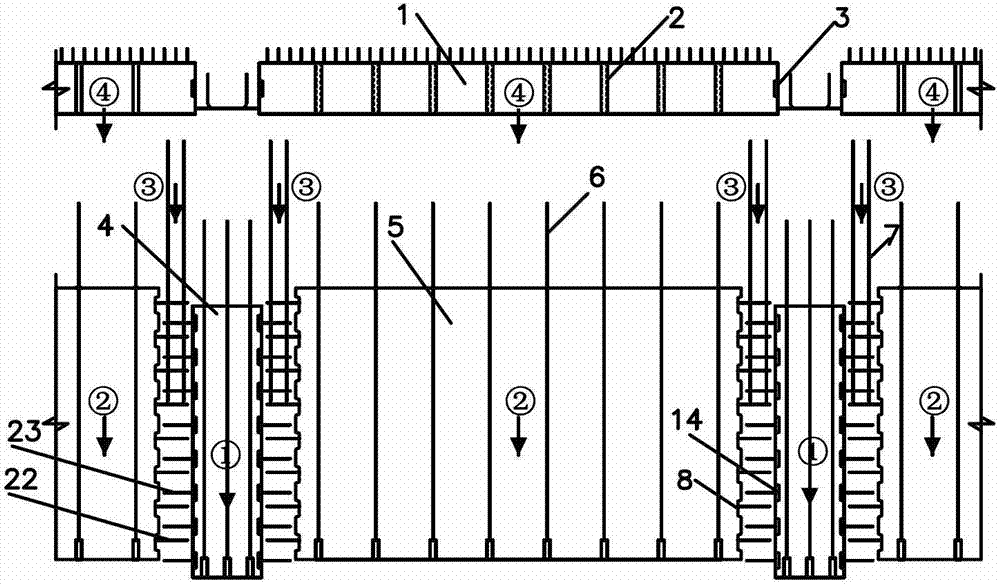

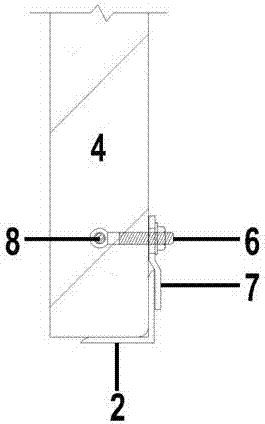

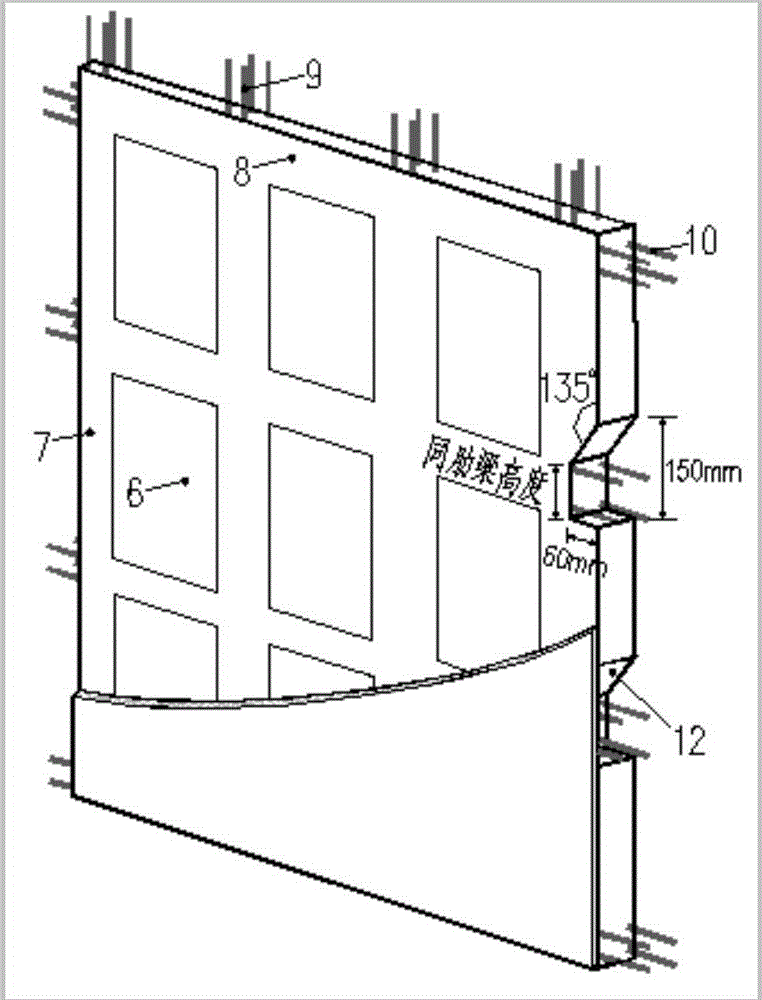

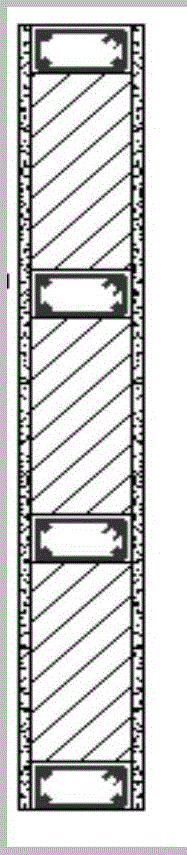

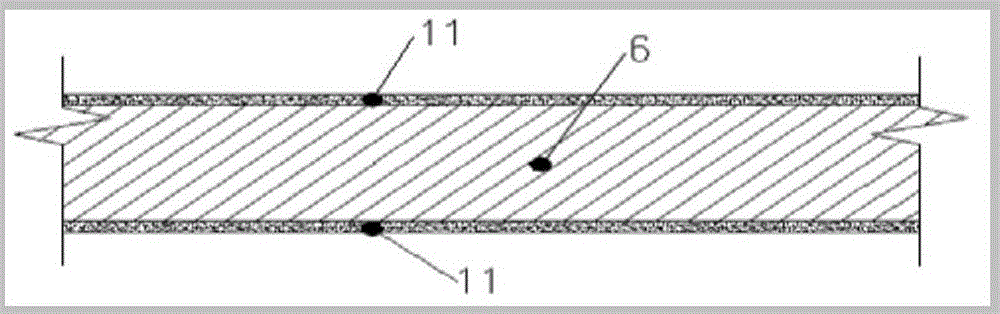

The invention relates to the field of assembled concrete structures, in particular to an assembly connecting structure and an assembly connecting method of an assembled concrete frame and shear wall combination. A cast-in-place strip is disposed between precast columns and precast shear walls to connect column-wall embedded rebars. Vertical through holes are reserved in a precast node-precast beam integrated component to achieve communicated connection of vertical rebars for the upper and lower columns and the upper and lower shear walls. Embedded steel sleeves at the lower ends of the precast columns and the precast shear walls are mutually embedded with projecting rebar segments extending up out of the lower columns and the lower walls, and are integrated with the lower columns and the lower walls through cast mortar. The projecting straight rebars at the upper ends of the precast columns and the precast walls penetrate through the through holes reserved in the precast node-precast beam integrated component and protrude a floor slab, and the precast columns and the precast nodes are firmly integrated with the precast shear walls precast beams by cast mortar. Wet operations such as in-place casting of concrete are reduced to the maximum extent, building quality is improved, construction period is shortened, and energy conservation and emission reduction are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

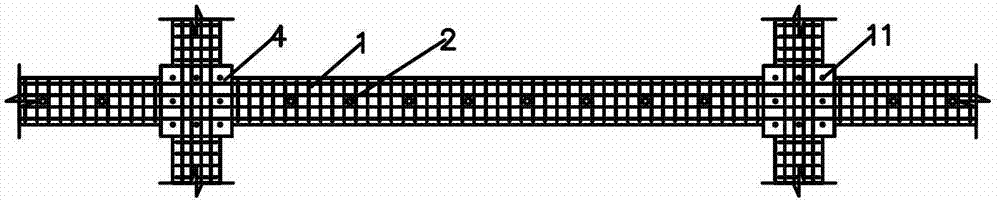

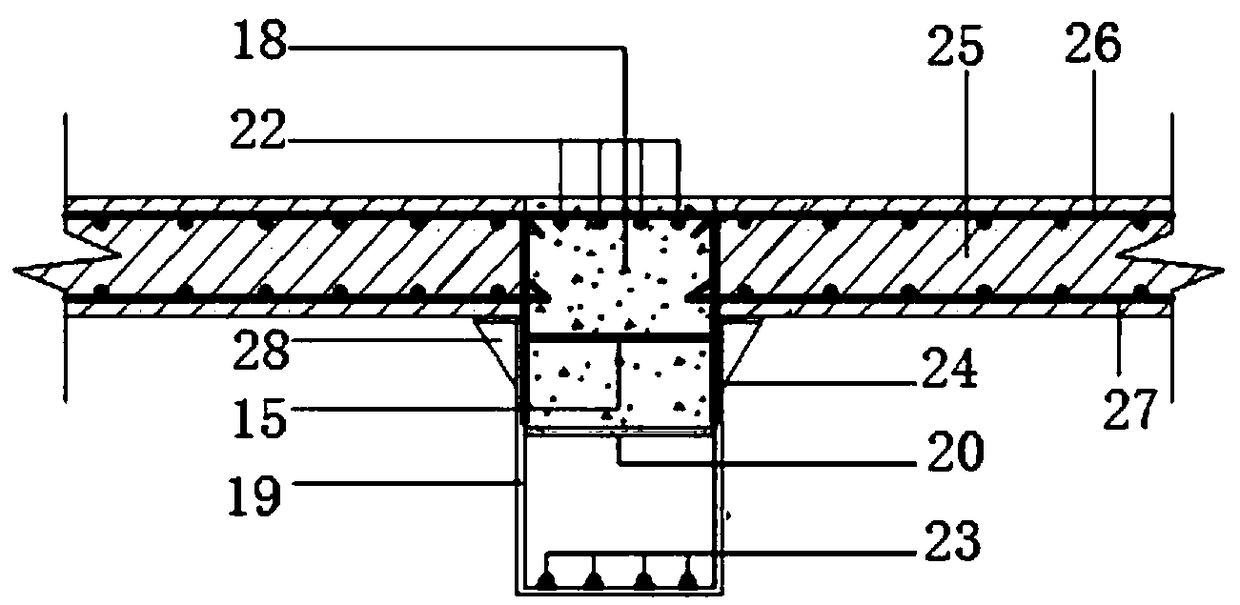

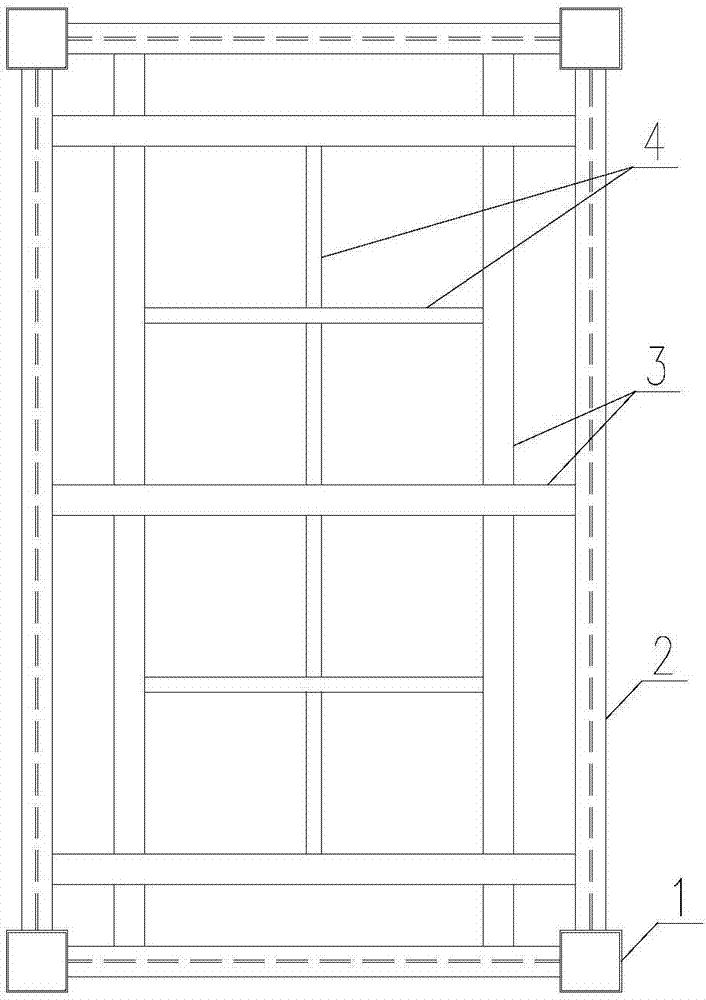

Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

ActiveCN102900168ASplit location is reasonableEasy to manufactureWallsBuilding material handlingSteel barEngineering

The invention relates to the field of concrete structures, in particular to a splitting and assembling structure and an assembling connecting method of an assembled type concrete frame-shear wall. The splitting and assembling structure comprises prefabricated pillars, prefabricated beams, prefabricated shear walls and cast-in-situ joints, wherein sleeves are embedded at the lower ends of the prefabricated pillars, mutually embedded with protruding reinforcing steel bar sections which extend from the upper ends of lower layer pillars and are integrally connected with the lower layer pillars by filling mortar; longitudinal prefabricated beam reinforcing steel bars extend into a joint core area to be anchored or connected with side beam ribs in a mechanical manner; a cast-in-situ zone is arranged between the prefabricated pillars and the prefabricated shear walls so as to carry out the connection of the embedded ribs of the pillars and the walls; and the embedded reinforcing steel bar sleeves at the lower ends of the prefabricated shear walls are mutually embedded with protruding reinforcing steel bar sections which extend upwards from the walls at the lower layer and are integrally connected with the walls at the lower layer by filling the mortar. The through connection of the vertical reinforcing steel bars of the share walls at the upper and lower layers is realized by filling the mortar into the through holes and the sleeves at the upper ends of the prefabricated shear walls and the prefabricated beams, so that the key problem that the vertical reinforcing steel bars of the share walls are hard to be continuous because of the isolation of the prefabricated beams is solved.

Owner:SHENYANG JIANZHU UNIVERSITY

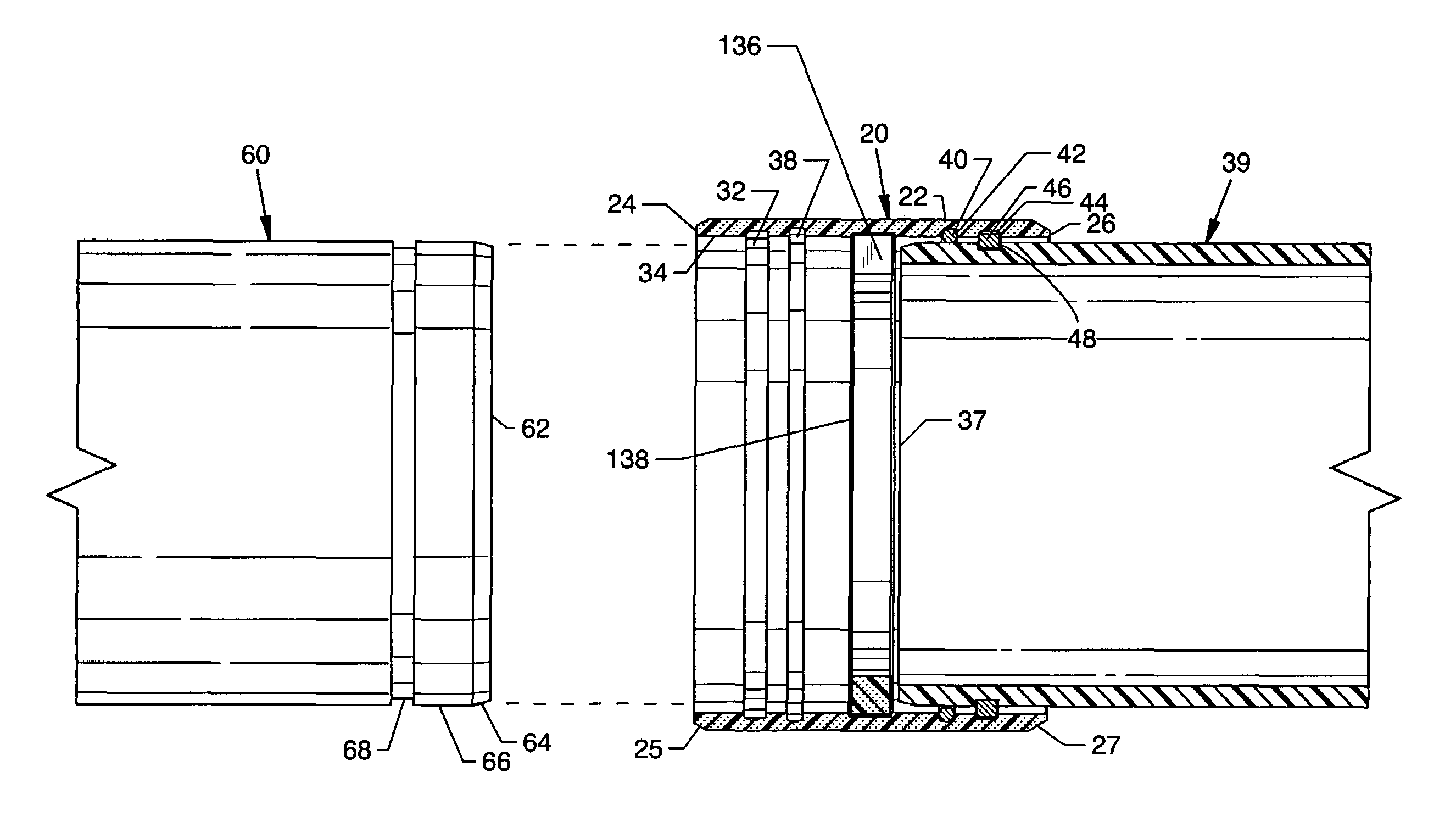

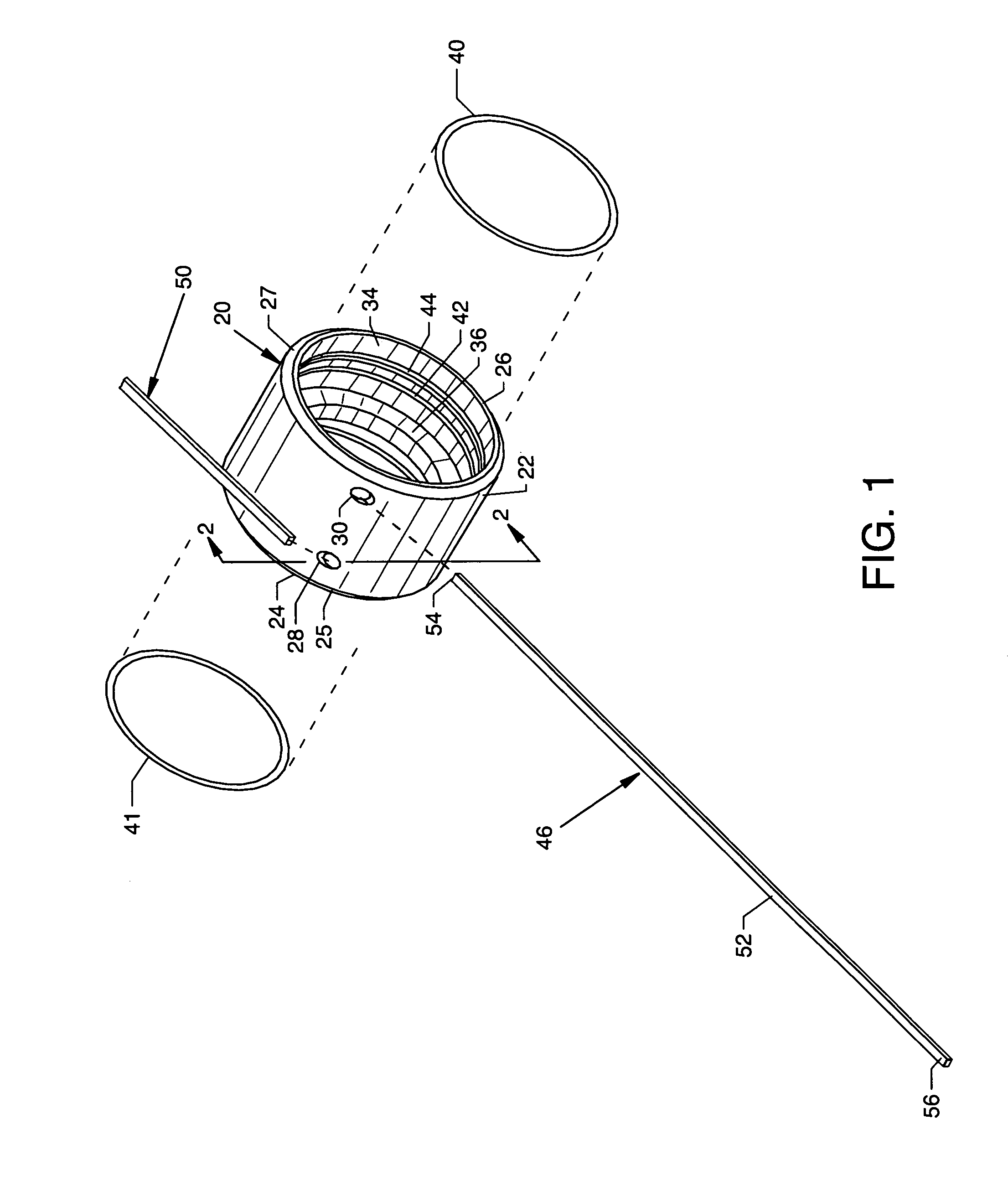

Filament-wound composite coupling

ActiveUS7108295B1The relative position is appropriateLimit depth of insertionVessel manufacturingCouplingsCouplingPolyvinyl chloride

A filament-wound composite coupling for use in assembling a restrained joint between large diameter pipes with complementary retaining grooves, such as 16 inch or larger outer diameter polyvinyl chloride pipes. The coupling has first and second ends and ported retaining grooves associated with each end. Preferably, the coupling also includes O-ring seals and a pipe stop to index the pipes to be coupled. The composite coupling has a cylindrical composite body with a plurality of concentrically arranged layers of wound filaments in a thermoset plastic matrix. Each of the layers is characterized by a winding angle opposing the winding angle of the adjoining layers.

Owner:NORTH AMERICAN SPECIALTY PROD

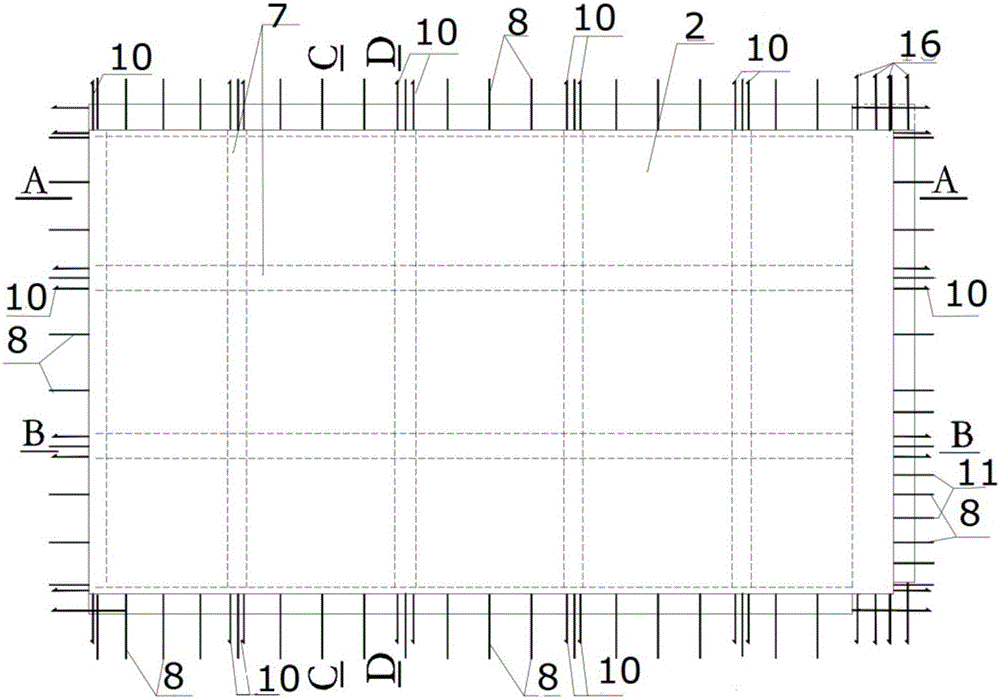

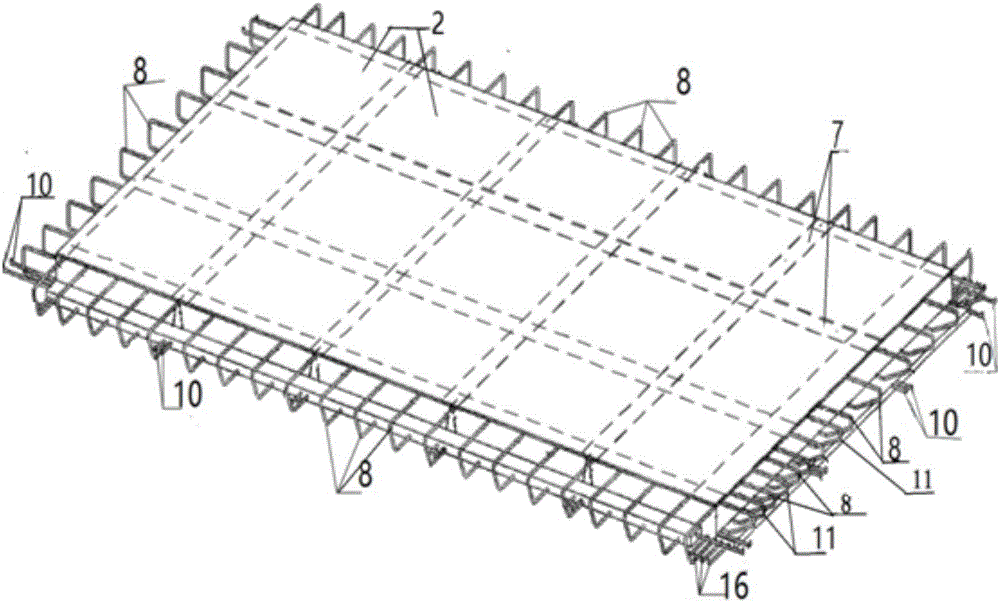

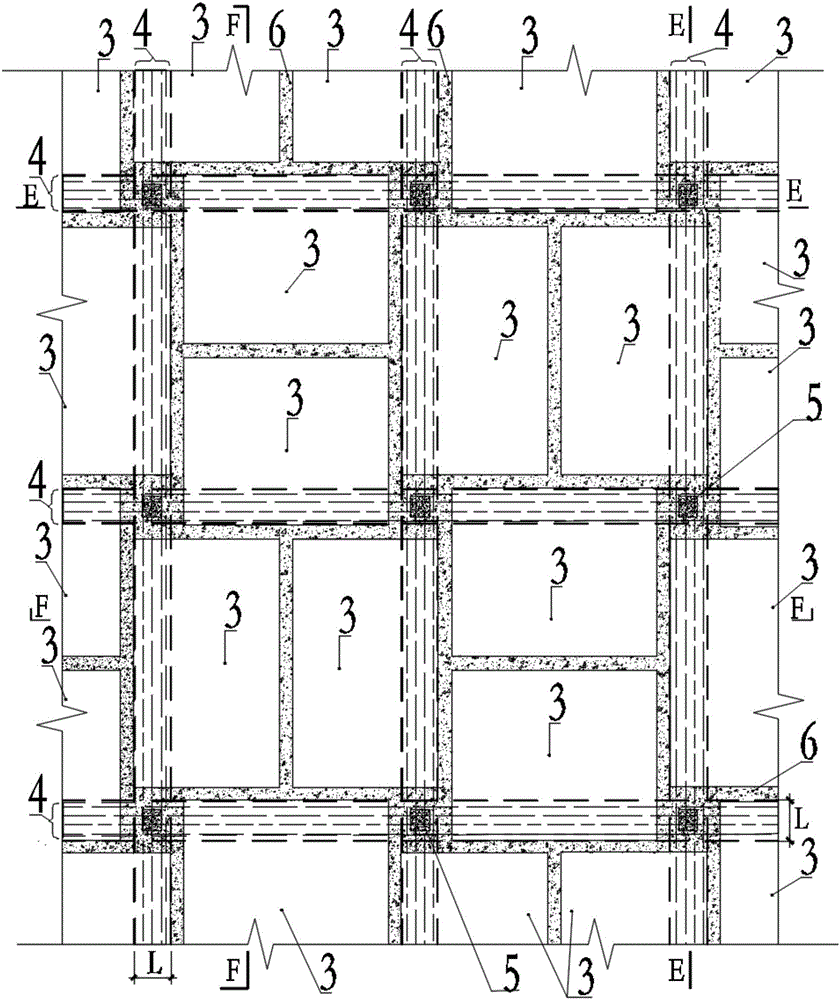

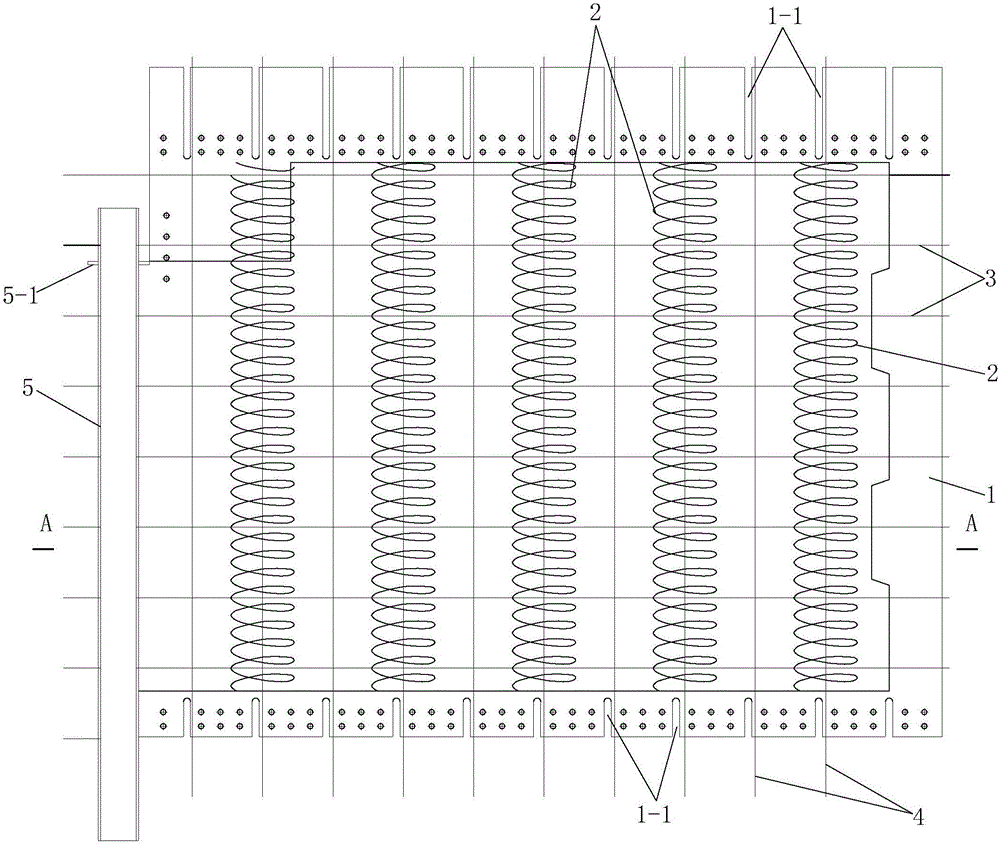

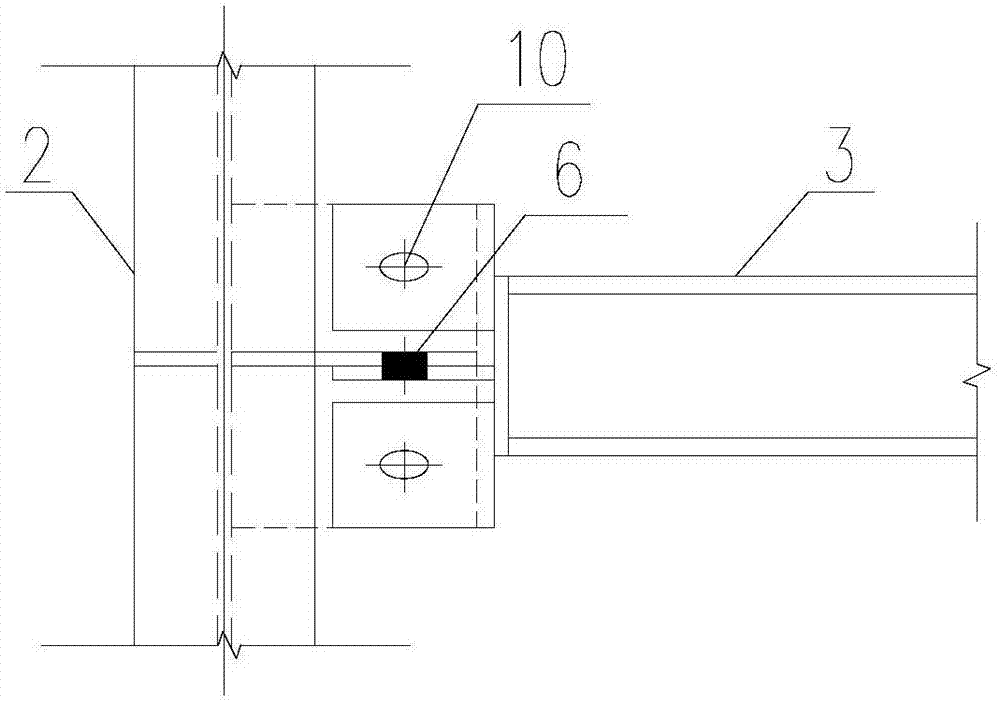

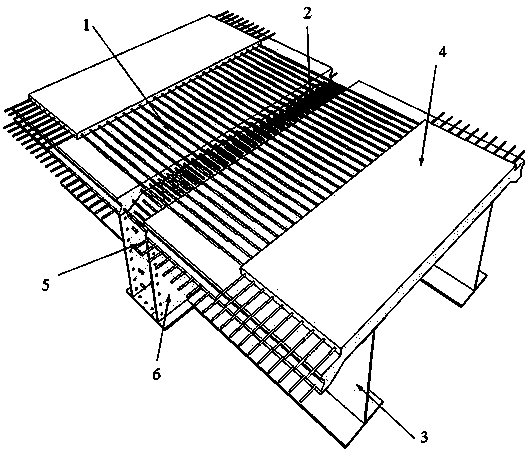

Fully prefabricated reinforced concrete bridge assembly structure and connecting method for same

ActiveCN103741604AImprove assembly rateReduce construction costsBridge erection/assemblyReinforced concreteBridge deck

The invention discloses a fully prefabricated reinforced concrete bridge assembly structure and a connecting method for the same. The fully prefabricated reinforced concrete bridge assembly structure is characterized by comprising prefabricated piles, prefabricated floor collar beams, prefabricated pier studs, prefabricated capping beams, prefabricated longitudinal beams, prefabricated composite bottom plates and prefabricated anti-collision barriers. The connecting method includes connecting the tops of the prefabricated piles with the bottoms of the prefabricated floor collar beams; upwardly connecting the prefabricated floor collar beams with the prefabricated pier studs; upwardly connecting the prefabricated pier studs with the prefabricated capping beams; erecting the prefabricated longitudinal beams on the prefabricated capping beams via bridge supports or fixing ends; supporting the prefabricated composite bottom plates on the prefabricated longitudinal beams, tying reinforcing steel bars of a bridge deck on the prefabricated composite bottom plates and integrally casting concrete on a site to form the bridge deck; mounting the prefabricated anti-collision barriers on the bridge deck. The fully prefabricated reinforced concrete bridge assembly structure and the connecting method have the advantages that components, except for the bridge deck, of the fully prefabricated reinforced concrete bridge assembly structure are of prefabricated structures, so that the bridge prefabricated rate can be greatly increased; common construction labor consumption can be reduced to the greatest extent, and the labor productivity can be improved; the construction period of the fully prefabricated structure can be greatly shortened, the bridge building cost can be reduced, and the bridge construction quality can be improved.

Owner:张利铨

Motor module

ActiveUS7663279B2Improve assembly rateStructure miniaturizationAssociation with control/drive circuitsMechanical energy handlingEngineeringConductor Coil

A motor module includes a bearing housing having a loading base, an electric unit, a bearing, and a magnetic rotor unit disposed on the bearing. In addition, a protruding portion is extending from the loading base, and the electric unit includes a printed circuit board (PCB) and sensing elements, wherein the PCB is utilized for disposing the loading base thereon. Moreover, signal circuits and motor windings are formed on the PCB around the loading base, the sensing elements are disposed around the motor windings, and the bearing is disposed at the protruding portion. Besides, the magnetic rotor unit is disposed on the motor windings, keeping a gap with the PCB; therefore, when electric current passes the motor windings, the magnetic rotor unit and the motor windings generate a flux linkage induction, so as to drive the magnetic rotor unit to rotate relative to the PCB.

Owner:METAL INDS RES & DEV CENT

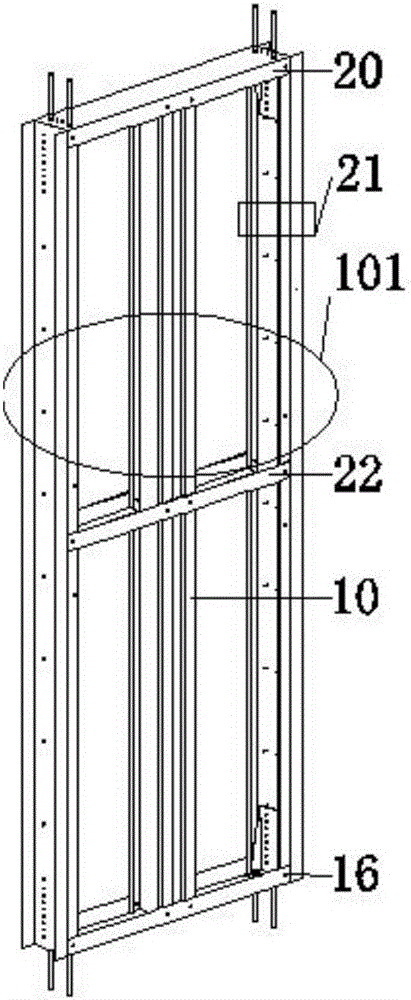

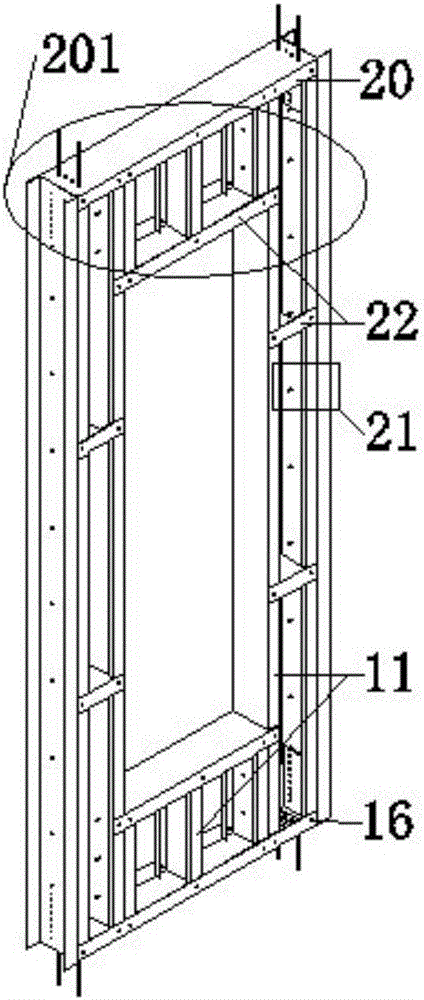

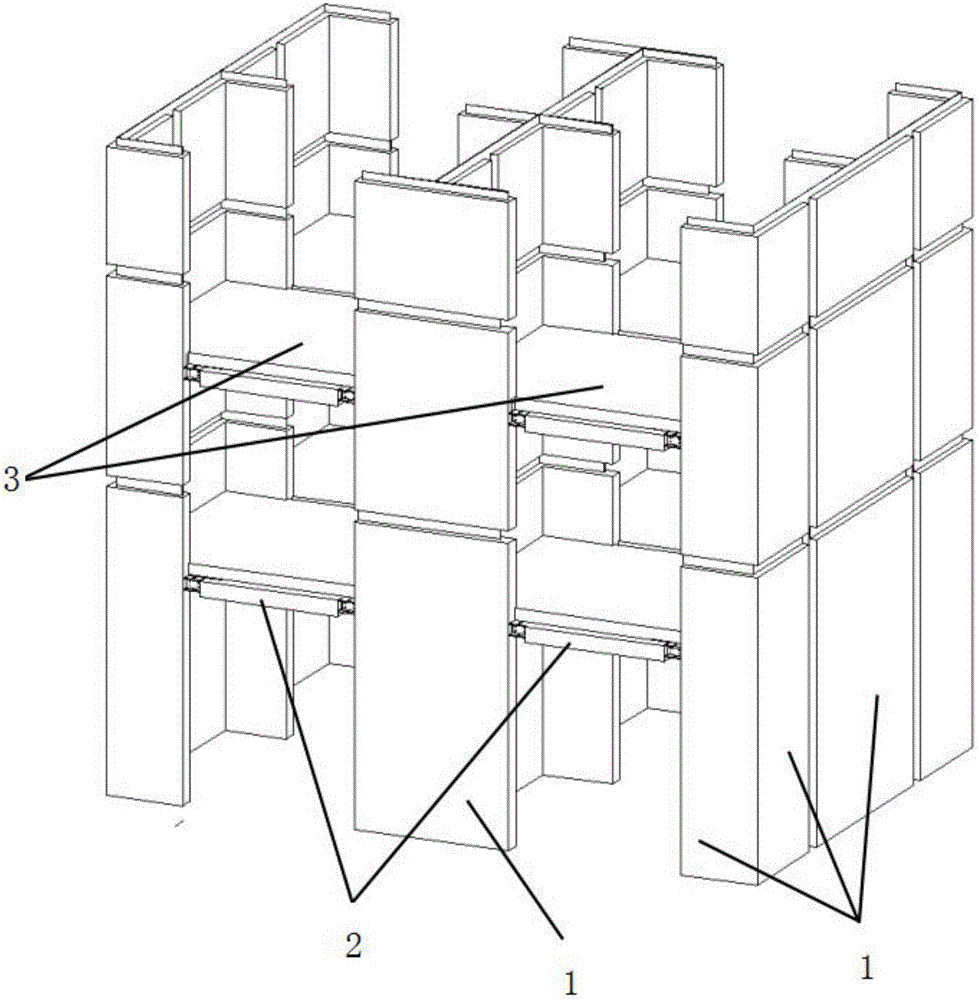

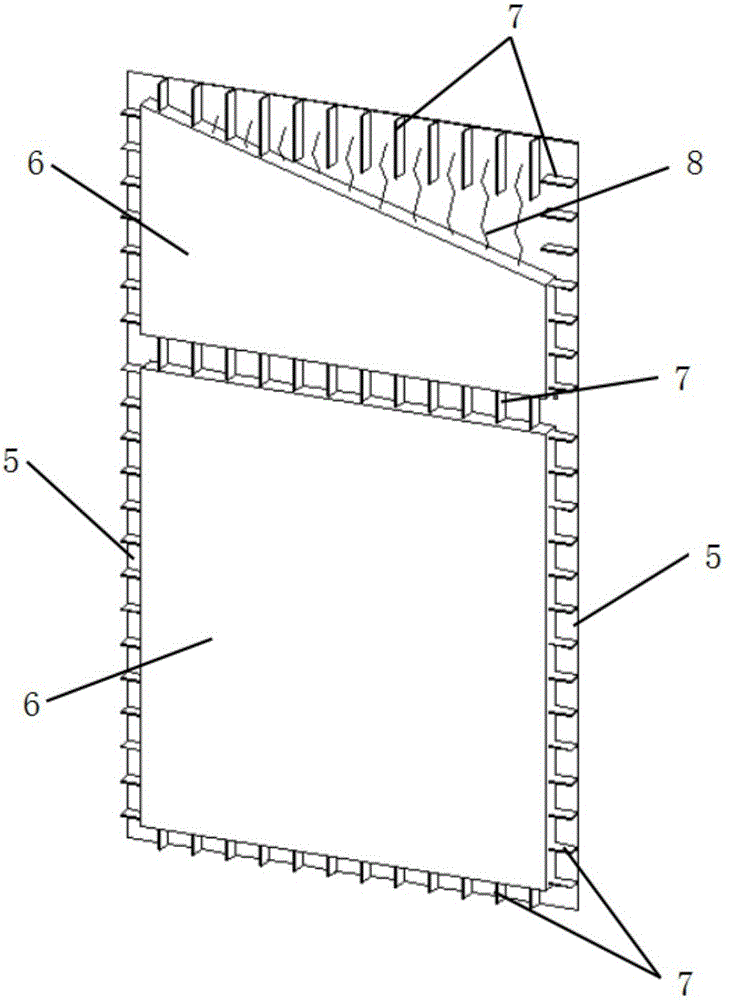

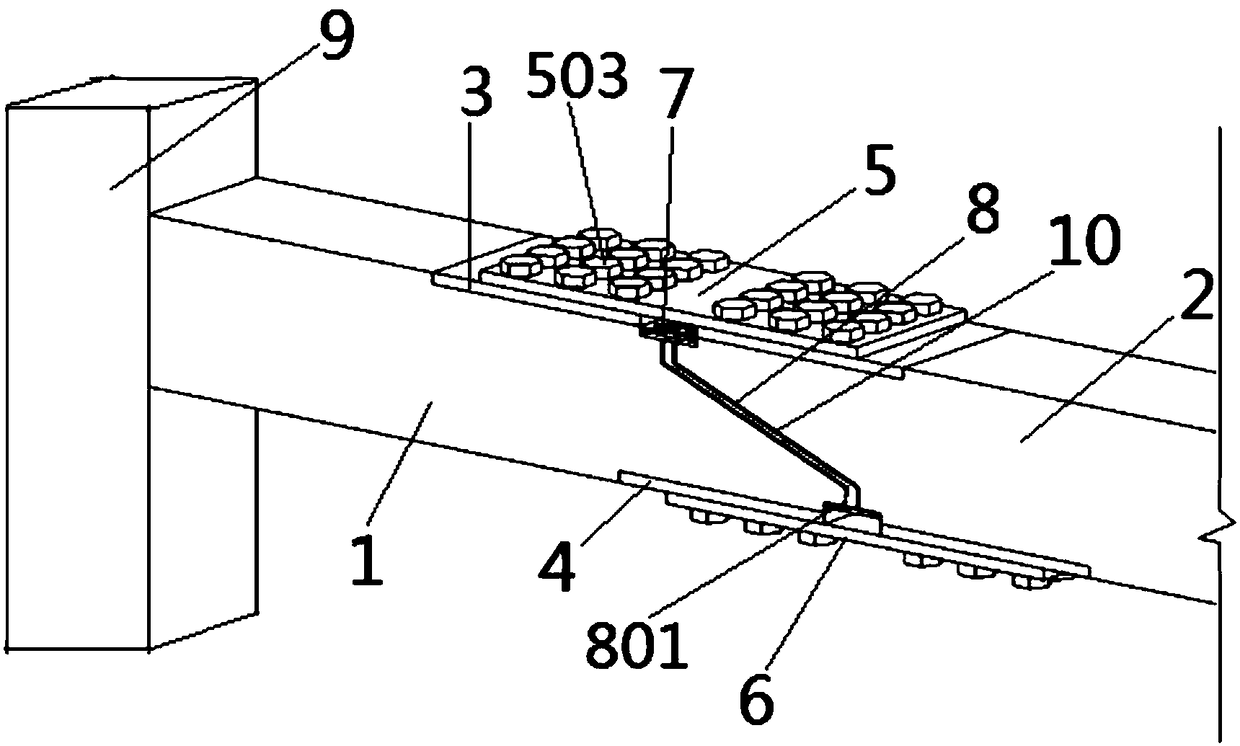

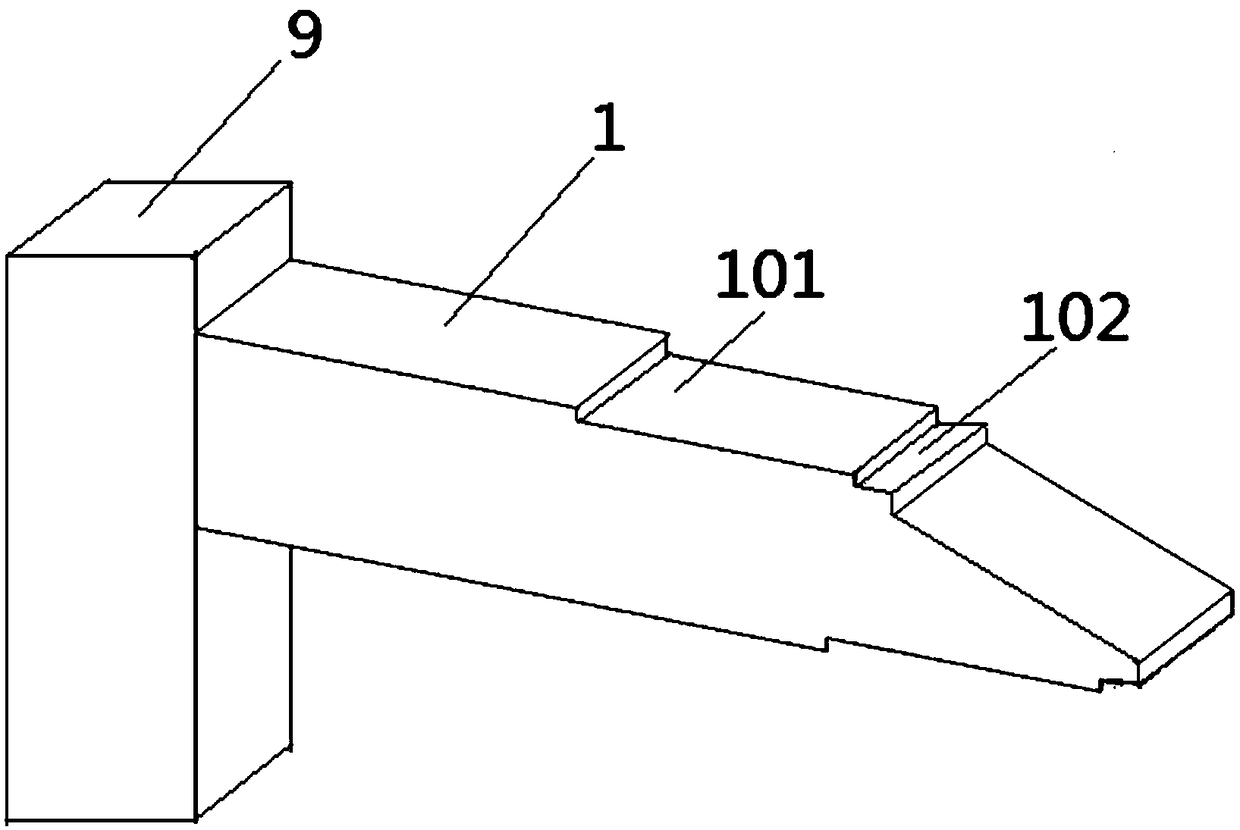

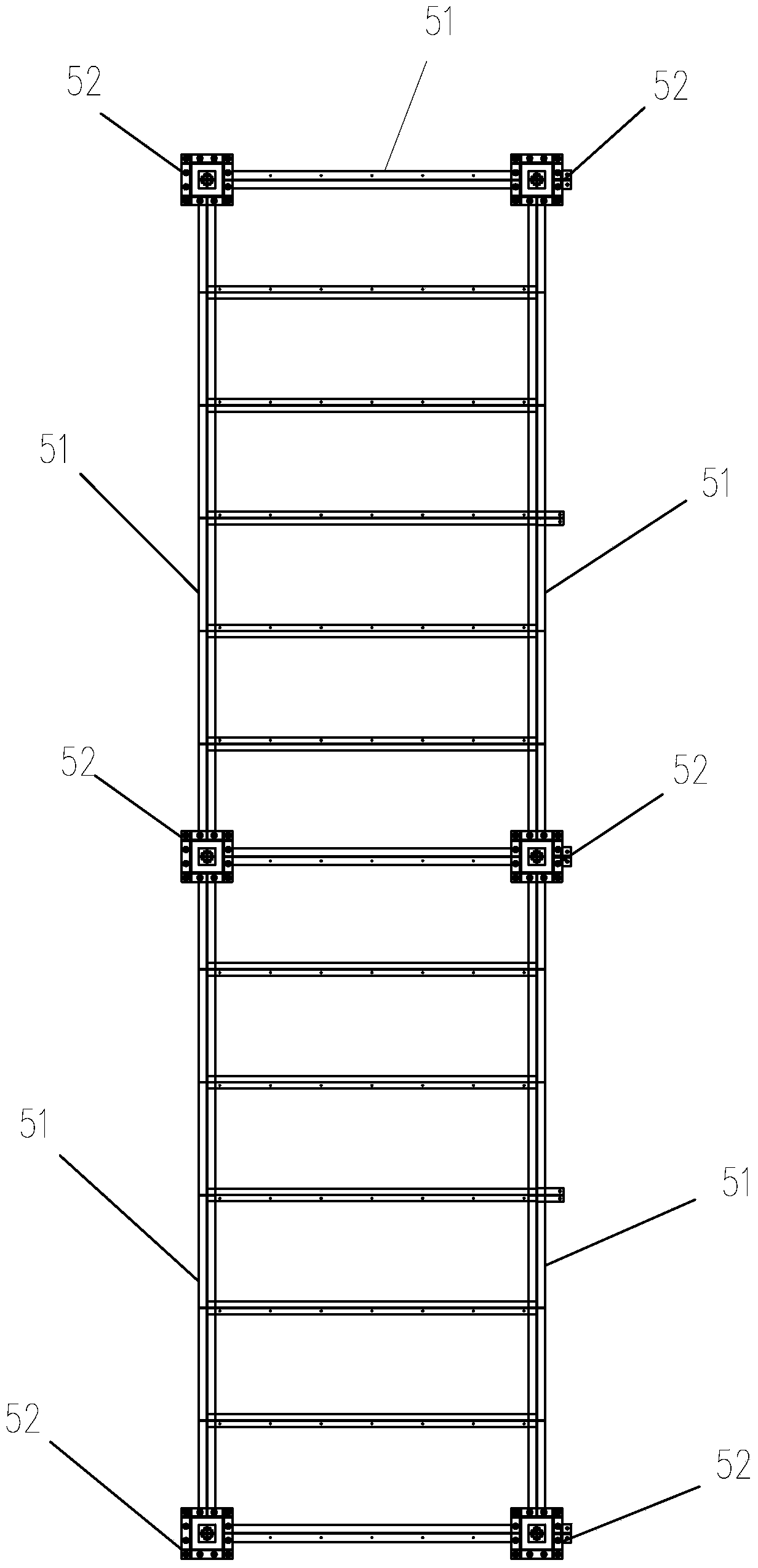

Modular assembling type cold-bent thin-wall type steel wall board structural system

Provided is a modular assembling type cold-bent thin-wall type steel wall board structural system. A vertical body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially connecting a common wall body module, an opened wall body module, an L-shaped wall body module and a T-shaped wall body module. A horizontal body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially splicing slab modules. The slab modules are spliced by being connected. The vertical body structure and the slab modules are connected in the mode that the wall body and the slab module are connected. By optimizing the wall body module connection mode, the slab module connection mode, and the wall body and slab module connection mode, the site assembly difficulty and site construction workload are reduced to a great extent, and the whole structural system can be safer and better in anti-seismic property. The modular assembling type cold-bent thin-wall type steel wall board structural system is low in mass, good in anti-seismic property, capable of preserving heat, insulating heat and saving energy, environmentally friendly, low in manufacturing cost, suitable for mid-rise buildings and low-rise buildings, and high in economic and social benefit.

Owner:BEIJING UNIV OF TECH

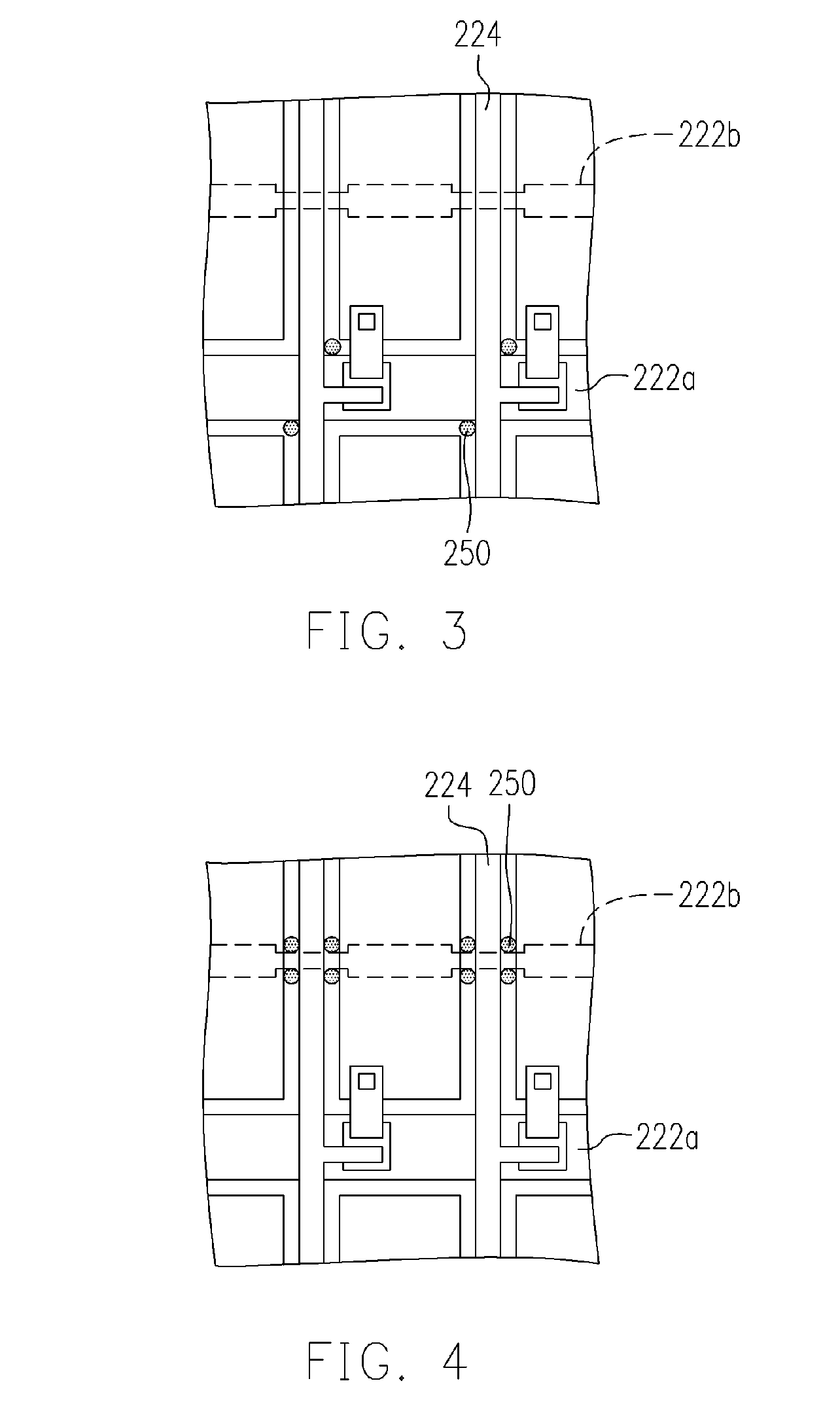

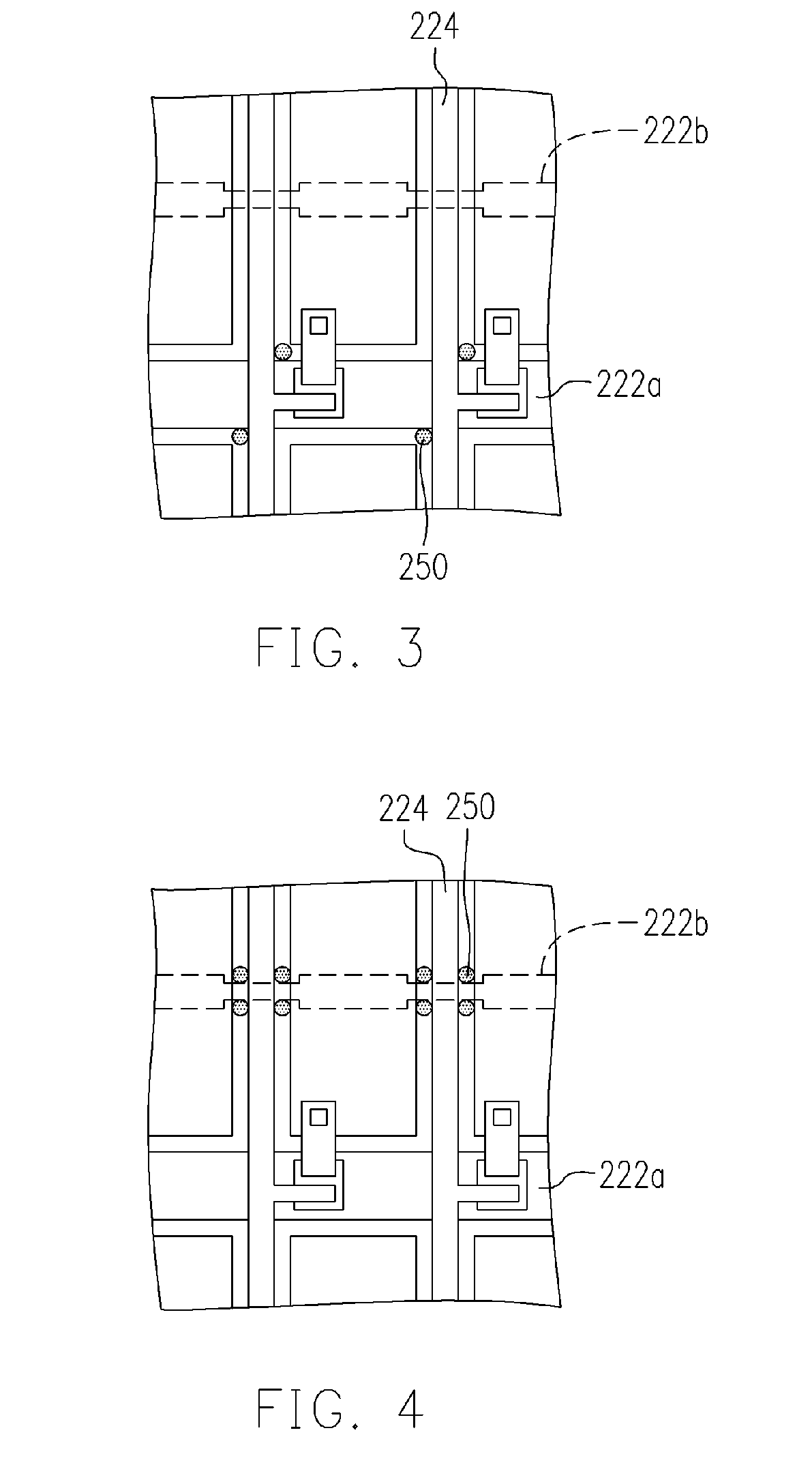

Liquid crystal display panel and manufacturing method thereof

ActiveUS20060066801A1Good adhesionImprove display qualityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises a color filter substrate and a thin film transistor array substrate arranged in parallel and a liquid crystal layer between the substrates. In addition, several spacers are disposed on a black matrix of the color filter substrate. These spacers lean on the edge of at least one of the gate layer lines and source layer lines on the thin film transistor array substrate. The invention increases the bonding stability between the color filter substrate and the thin film transistor array substrate so that the reliability and display quality of the liquid crystal display panel is improved.

Owner:NYTELL SOFTWARE LLC

Factorial construction method for component of total prefabricated assembly integral type shear wall structure system

InactiveCN102296816AReduce usageReduce productionMouldsBuilding material handlingRebarStructure system

The invention discloses a factorial construction method for a component of a total prefabricated assembly integral type shear wall structure system. In the construction method disclosed by the invention, a basic component in the shear wall structure system is manufactured by adopting factorial prefabrication; a grouting pipe and a node reinforcing steel bar are preset in the component; and only the prefabricated component is directly assembled in the shear wall structure system for construction installation in the construction course of the shear wall structure system. In the technical scheme adopted by the invention, the adopted factorial production for producing the prefabricated component is beneficial to reduction of pollution emission, the usage amount of turnover materials such as wood and the like, water consumption, the usage amount of wood templates and the discharge amount of garbage, and is favorable for reducing construction cost whiling meeting the environmentally-friendly requirements.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

Assembly connection structure and method of coupling beams of shear walls of assembly concrete frame shear structure

The invention relates to the field of assembly concrete structures, in particular to an assembly connection structure and method of coupling beams of shear walls of an assembly concrete frame shear structure. Grouting seams and equivalent bars are arranged between prefabricated coupling beams and prefabricated shear walls or between the coupling beams of the shear walls with half-span coupling beams for beam-wall or beam-beam connection. Holes are reserved in the prefabricated coupling beams and the coupling beams of the prefabricated shear walls or the shear walls with half-span coupling beams, spiral stirrups are arranged surrounding the holes in advance, the equivalent bars penetrate through the preserved holes, the reserved horizontal holes and the grouting seams between the beams and walls or between the beams are filled by grouting minimum inflation mortar, therefore the prefabricated coupling beams, the prefabricated shear walls and the equivalent bars, or the coupling beams of the shear walls with half-span coupling beams and the equivalent bars can be firmly integrated, and connection of the prefabricated coupling beams and the coupling beams of the prefabricated shear walls or the shear walls with half-span coupling beams can be achieved. The assembly connection structure and method greatly reduce the project construction cost and reduce site concreting wet construction.

Owner:浙江筑工科技有限公司

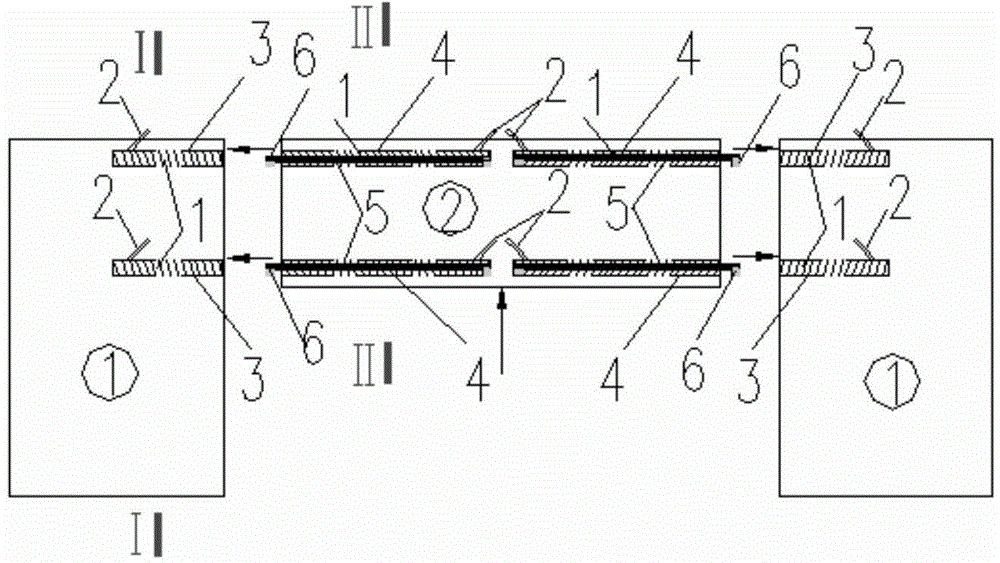

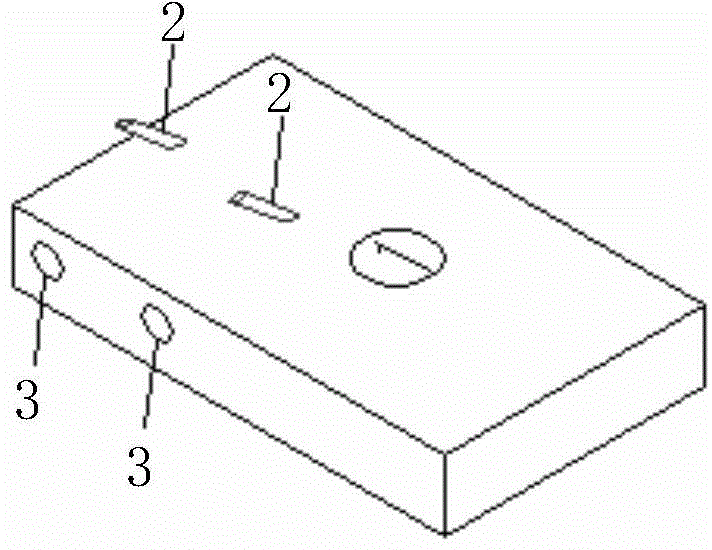

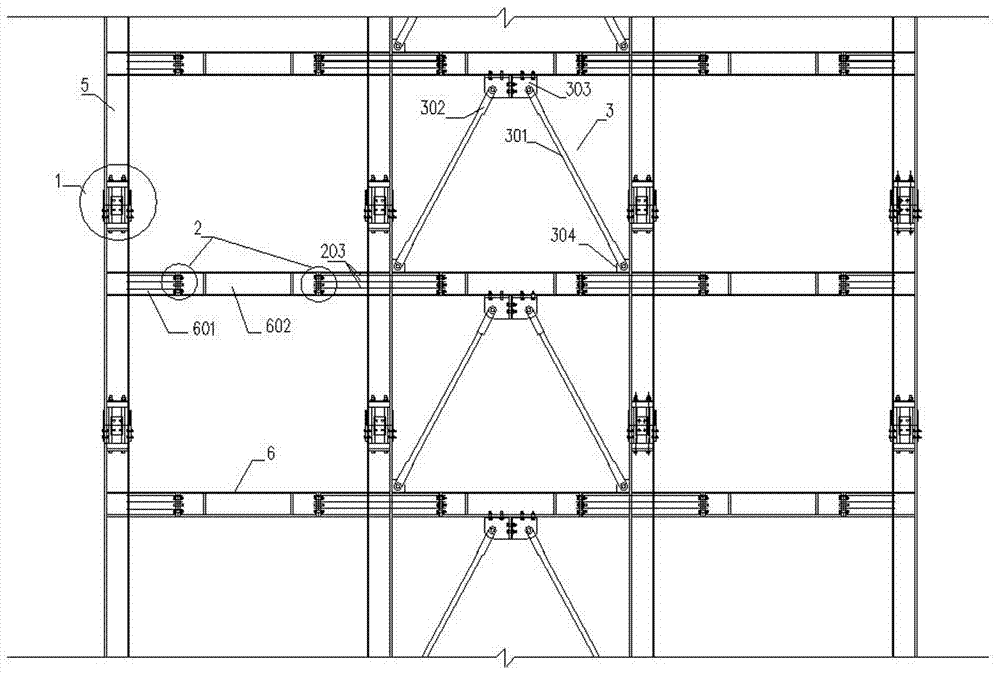

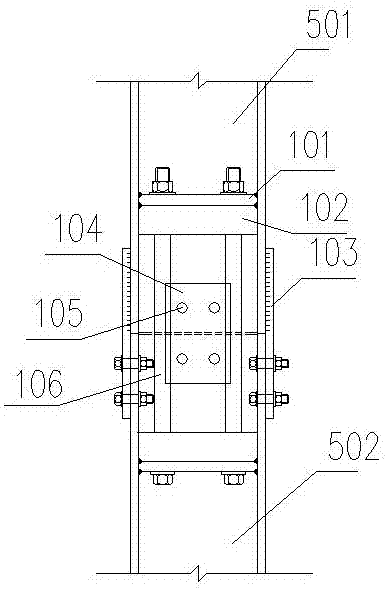

Fabricated recoverable-function steel frame-supporting system connected by prestressed joints

InactiveCN107386435APrevent bucklingGuaranteed continuityBuilding constructionsSupporting systemFloor slab

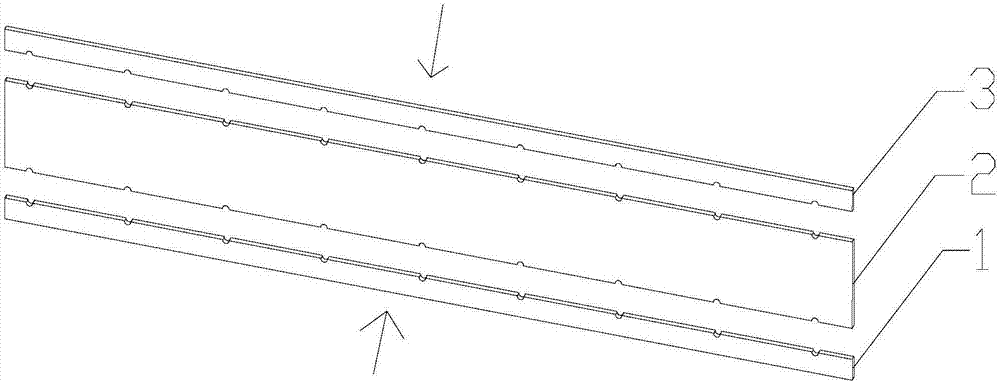

A fabricated recoverable-function steel frame-supporting system connected by prestressed joints is provided. The fabricated recoverable-function steel frame-supporting system connected by the prestressed joints comprises fabricated joints I, fabricated joints II, supporting structures and floor slabs, the fabricated joints I are fabricated prestressed column-column splicing joints and located in inflection points of columns, and the fabricated joints I comprise prestressed pull rod supporting plates, stiffening plates, half-welded lug plates, web splicing plates and prestressed pull rods; the fabricated joints II are fabricated prestressed beam-beam splicing joints and comprise cantilever beam section flange plates, middle beam section flange plates and rear-tensioning prestressed cables; the supporting structures are arranged between every two vertically adjacent steel beams in pairs, and each pair of the supporting structures comprises supporting rods, supporting rod sleeves, lower end connection pieces and upper end connecting pieces; and the floor slabs comprise three types of prefabricated concrete floor slabs, namely the I-type plate, the II-type plate and the III-type plate. According to the fabricated recoverable-function steel frame-supporting system connected by the prestressed joints, novel prestressed steel beam and steel column splicing joints are adopted, the fabricating efficiency of the structure of the fabricated recoverable-function steel frame-supporting system is improved, rapid construction is achieved, and rapid restoration and rapid rebuilding can be achieved after an earthquake.

Owner:HENAN UNIV OF SCI & TECH

NALC (N autoclaved lightweight concrete) large slab component

PendingCN107130757ASave mechanical shiftsSave time for coordinationCovering/liningsSlagStructural engineering

The invention discloses an NALC (N autoclaved lightweight concrete) large slab component. The large slab component is characterized by comprising multiple NALC slabs, wherein slag joints between the adjacent NALC slabs are treated with a crack sealer, angle steel components are arranged around the NALC slabs, mounting joints are arranged at the two ends of the NALC slabs, and the NALC slabs are fixed through fixing components. The technical scheme is compact and ingenious in structural design and high in prefabricating rate and assembling rate, and the whole NALC large slab composite exterior decoration is completely manufactured in a factory; all manufacturing procedures are performed on the ground, so that aloft work is reduced, and the construction risk is lowered.

Owner:南京旭建新型建材股份有限公司

Total-prefabricated rural residential class composite wall structure system and construction method thereof

ActiveCN106522359ASolve the compactness problemImprove integrityWallsProtective buildings/sheltersFloor slabReinforced concrete

Provided is a total-prefabricated rural residential class composite wall structure system, comprising prefabricating a construction main body bearing component and prefabricating an accessory component. The method comprises the steps of when a factory prefabricates a construction main body bearing component and prefabricates an accessory component, pre-burying construction equipment pipelines; during construction on spot, achieving the connection between wallboards by conducting pouring on reinforced concrete connecting columns with small cross sections, and achieving the connection between the wallboards and composite floor slabs by conducting pouring on reinforced concrete constraint hidden beams with small cross sections. All components of the total-prefabricated rural residential class composite wall structure system are produced by prefabrication technology in workshops, which effectively ensures the quality and trait of the components; professional construction installation team command hoisting installation and construction at the construction site, meanwhile little wet connection is adopted and little concrete is poured only at the component key connecting portions and floor slab super-position layers, the overall stability and anti-seismic property of the building is ensured, construction and operation area on spot is saved, meanwhile the main body structure of a set of rural residence can be finished by hoisting installation only in a few days, and the construction period is greatly shortened.

Owner:西咸新区矩阵实业有限公司

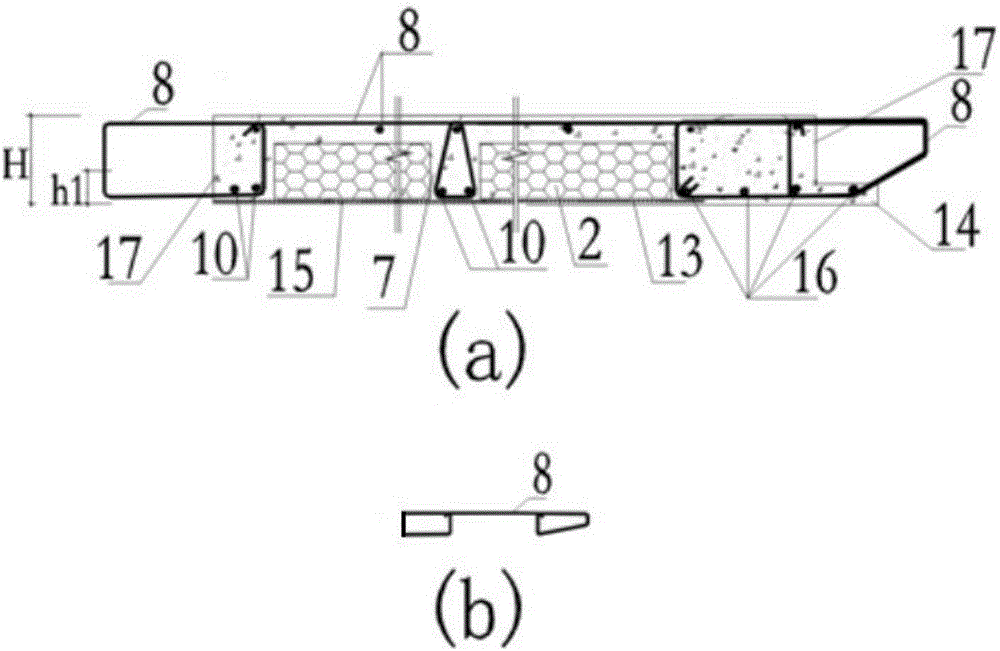

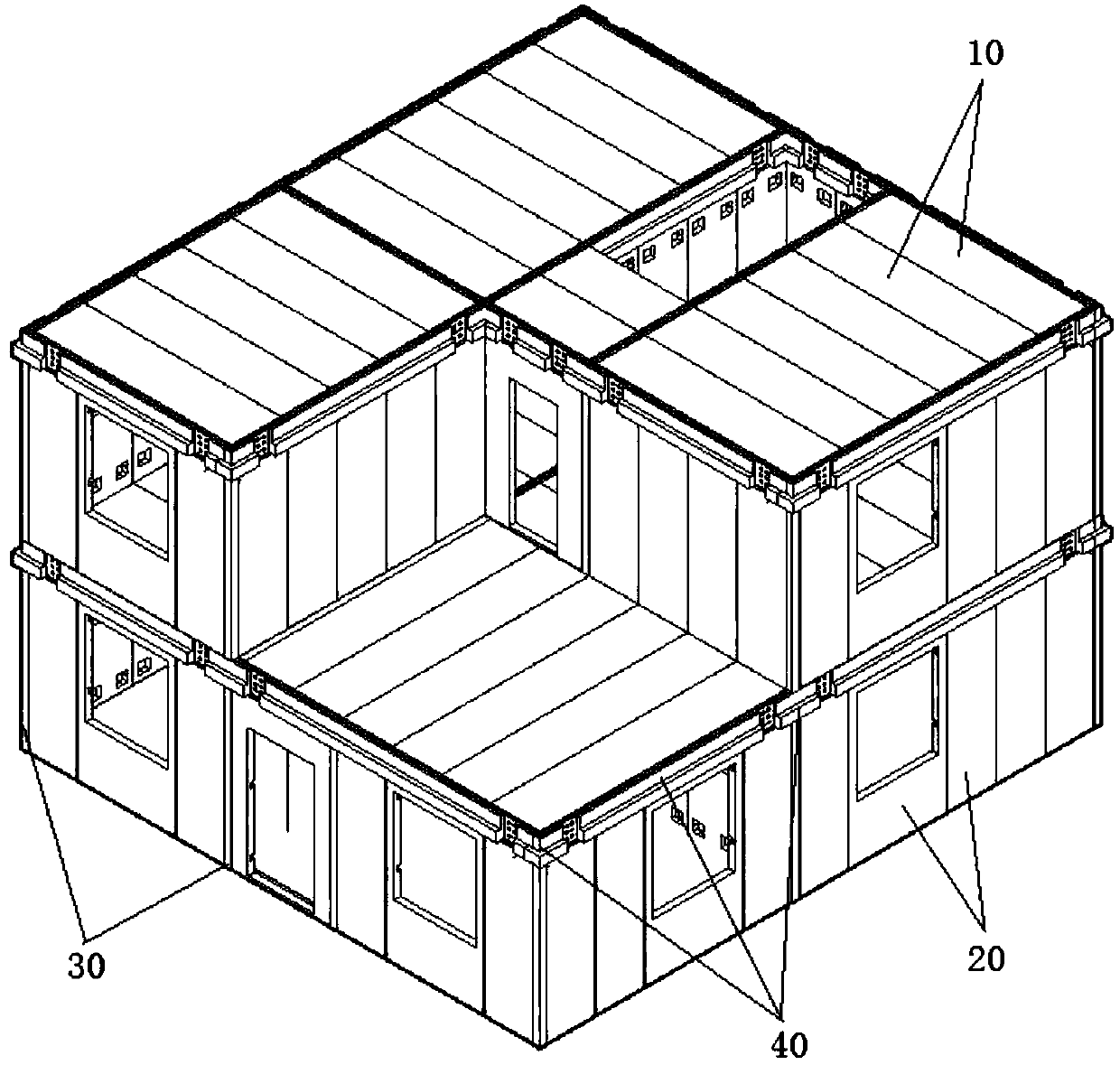

Building method of full-fabricated-type house

The invention provides a building method of a full-fabricated-type house and belongs to the technical field of fabricated-type buildings. The building method comprises the following steps that A, a foundation is treated; B, a first layer wall body system is mounted on the foundation, specifically, wall plates and wall plate auxiliary connecting components are sequentially mounted and tightly connected on the foundation to form the first layer wall body system; C, a first layer connecting beam system is mounted on the first layer wall body system, specifically, connecting beam components with the delta-shaped sections are sequentially spliced on the first layer wall body system and tightly connected to form the first layer connecting beam system; and D, a first layer floor slab system is mounted on the first layer connecting beam system, specifically, floor slabs are set up on the circular bead surfaces of connecting beam components of the first layer connecting beam system and are tightly connected to form the first layer floor slab system. According to the building method of the full-fabricated-type house, the fabricating rate of the house can be greatly increased, the building efficiency is improved, the building period is shortened, and pollution in the building process is reduced.

Owner:河北丽建丽筑集成房屋有限公司

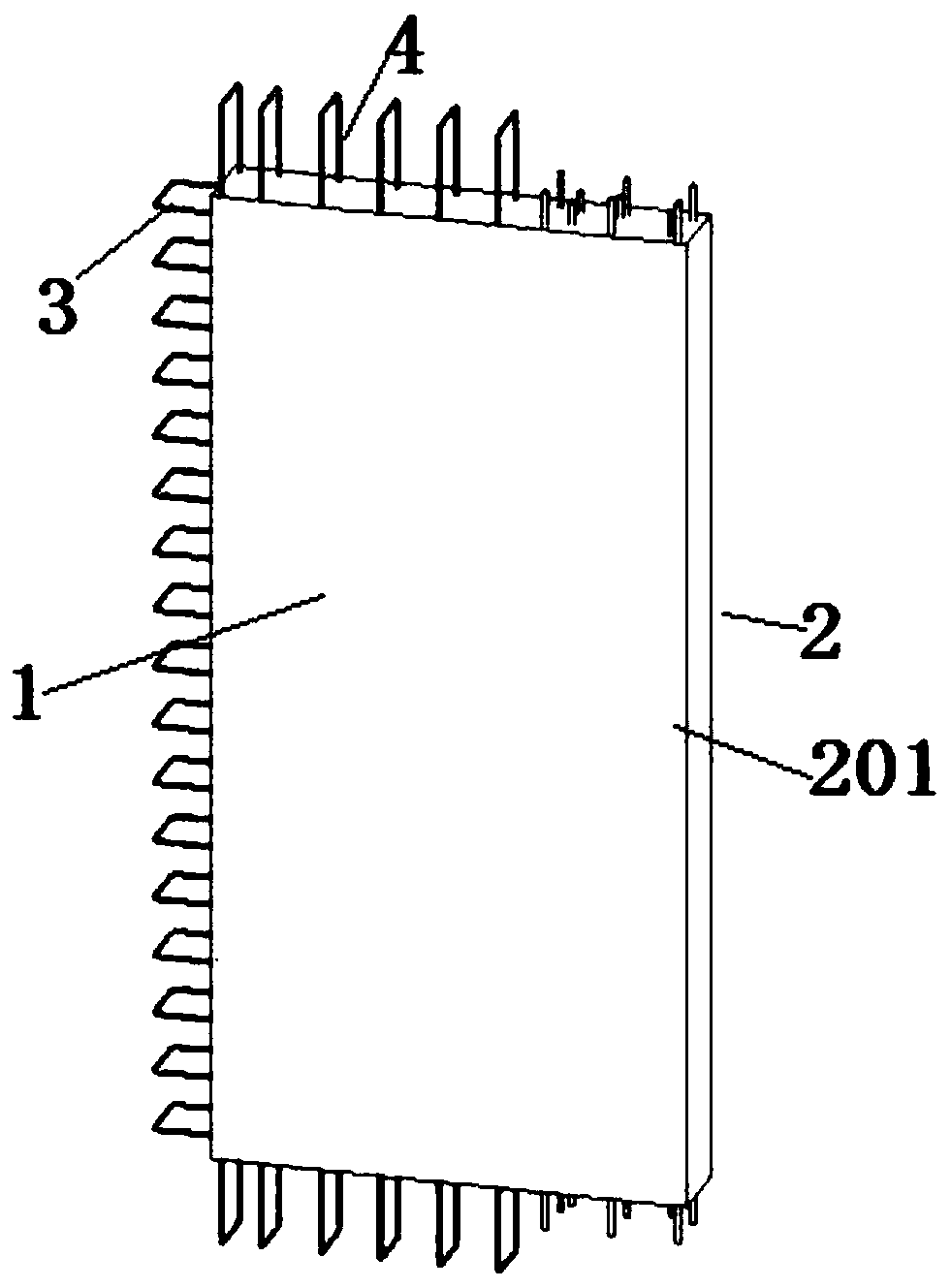

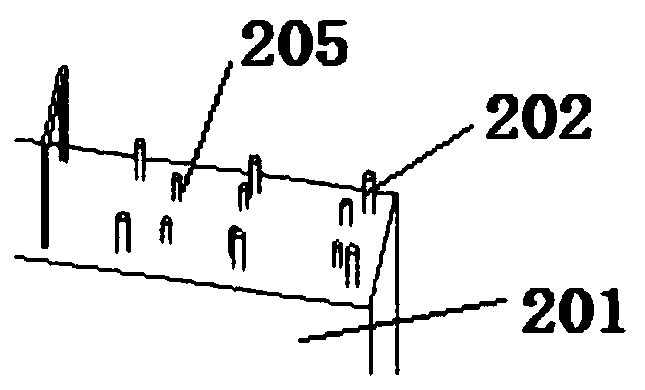

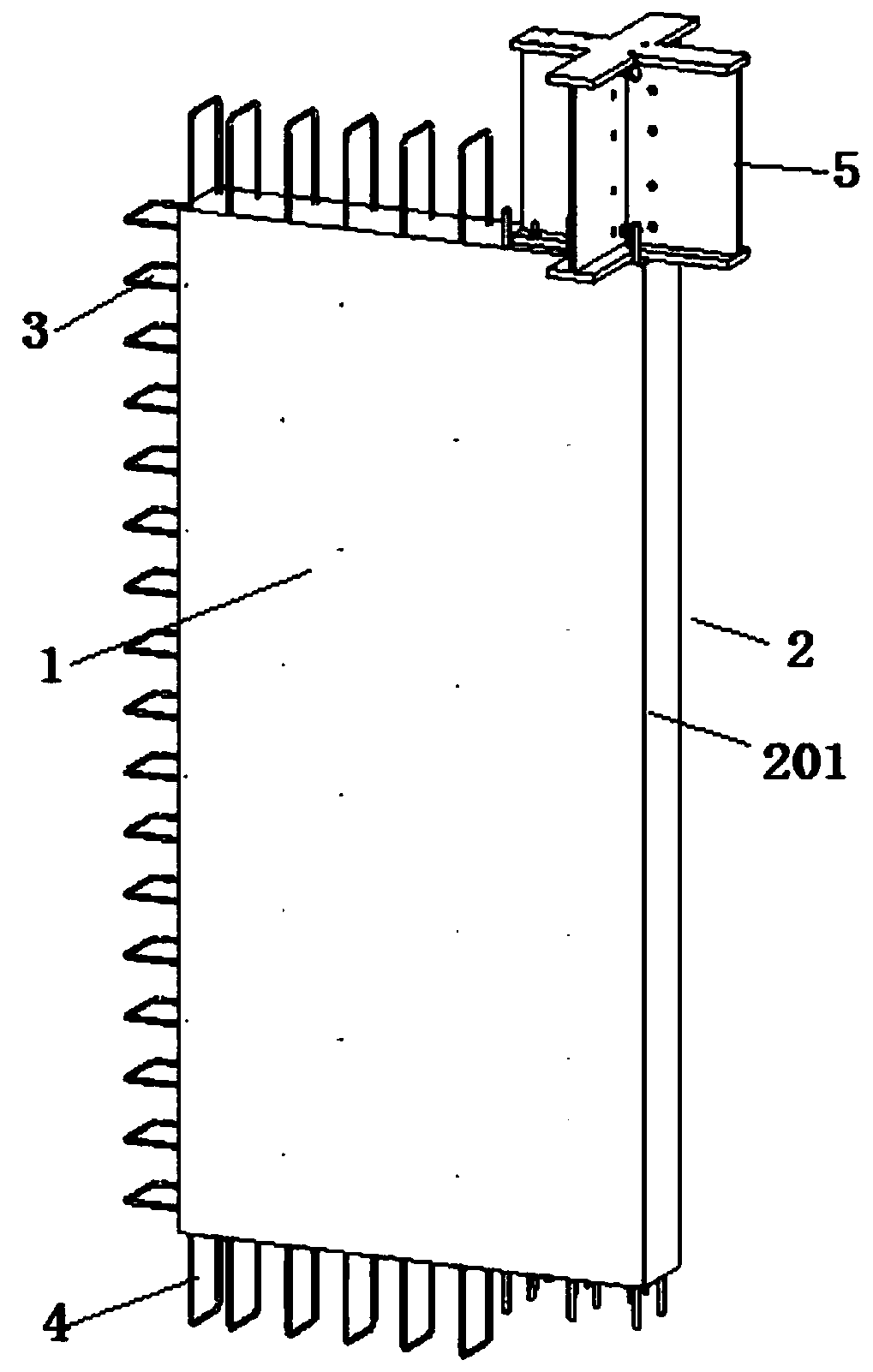

Prefabricated reinforced concrete shear wall convenient to install and construction method

PendingCN111424849AReduce usagePrecise positioningWallsBuilding material handlingReinforced concreteFloor slab

The invention discloses a prefabricated reinforced concrete shear wall convenient to install and a construction method. The prefabricated reinforced concrete shear wall comprises a concrete wall body,wherein an edge component is arranged on the side face of the concrete wall body, and longitudinal ribs vertically protrude out of the end face of the concrete wall body; a steel beam connecting piece is arranged at one end of the edge component; and the steel beam connecting piece comprises two flange plates, and a web is arranged between the two flange plates. The construction method comprisesthe following steps that stirrups and the longitudinal ribs are bound in a horizontal connecting area, supporting pieces and the steel beam connecting piece are arranged on the shear wall, and the steel beam connecting piece is fixed to anchor bolts; hidden beam steel bars and hidden beam stirrups are arranged in a vertical connecting area; hidden column longitudinal ribs are connected through longitudinal rib connectors, and the stirrups are inserted into stirrup penetrating holes; the steel beam connecting piece is connected with a steel beam; and a laminated slab or a floor support plate islaid on the steel beam, floor slab steel bars are bound, concrete is poured, and the wall body is obtained through maintenance. The prefabricated reinforced concrete shear wall has the advantages ofbeing low in manufacturing cost and good in fireproof performance.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

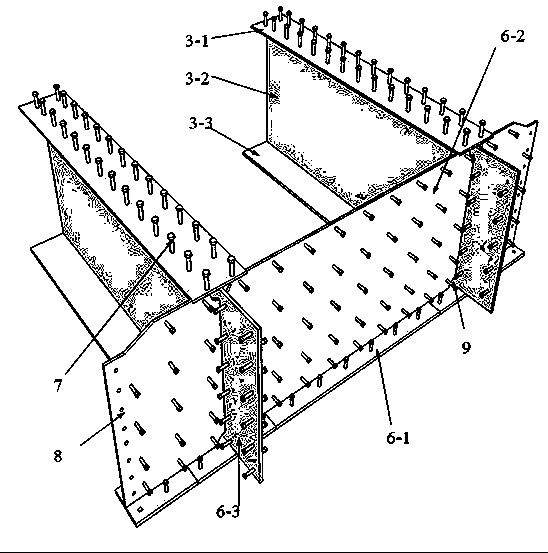

Prefabricated assembly type steel plate-concrete composite shear wall structure system and construction method thereof

Provided are a prefabricated assembly type steel plate-concrete composite shear wall structure system and a construction method thereof. The prefabricated assembly type steel plate-concrete composite shear wall structure system comprises prefabricated steel plate-concrete composite shear walls, prefabricated steel rib-concrete composite beams, composite floor slabs and composite floor slab installation supports; the vertically-arranged prefabricated steel plate-concrete composite shear walls are connected with the prefabricated steel rib-concrete composite beams and the composite floor slabs through the composite floor slab installation supports; and the prefabricated steel plate-concrete composite shear walls are connected through bolted steel plates. Longitudinal stress rebars in components are omitted, so that grouting sleeve connection of the longitudinal rebars in an assembly type concrete structure is avoided, the construction process is simplified, and the structure construction cost is reduced. The outer sides of the steel plates or the steel ribs in the composite structure are all protected by concrete, so that the rust prevention and fire prevention cost caused by exposure of steel in structural steel buildings is avoided, and durability of the structure is improved. The prefabricated assembly type steel plate-concrete composite shear wall structure system is suitable for assembly type high-rise residences, component connection nodes are constructed simply, stress is reasonable, installation is convenient and rapid, the assembly degree is high, and construction is rapid.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

Fabricated prefabricated reinforced concrete beam connection joint and construction method thereof

PendingCN109457801AGuaranteed stability and securityImprove seismic performanceBuilding constructionsSteel platesRebar

The invention discloses a fabricated prefabricated reinforced concrete beam connection joint and a construction method thereof. The connection joint comprises a lower convex prefabricated concrete beam and an upper convex prefabricated concrete beam. First concave openings are formed in the upper and lower end faces of the connection side wall of the lower convex prefabricated concrete beam, and second concave openings are correspondingly formed in the upper and lower end faces of the connection side wall of the upper convex prefabricated concrete beam; upper prefabricated steel plates and lower prefabricated steel plates are arranged inside the first concave openings and the second concave openings; the upper and lower prefabricated steel plates are correspondingly connected with upper and lower reinforcing steel plates; the connection side walls of the two beams are provided with a third concave opening and a fourth concave opening respectively, and load-bearing bars are correspondingly and transversely arranged inside the third concave opening and the fourth concave opening. The method comprises the steps of manufacturing the two beams, prefabricating the steel plates, performing butt connection on the two beams, and connecting the load-bearing bars inside the two beams. Due to the structural design, three-layer energy dissipation is achieved, and the problems that the shockresistance is poor and the ductility deformability is poor between dry type connection beams are solved; after seismic damage, replacement is easy, assembling is convenient, and the assembling rate is high.

Owner:CHANGAN UNIV

Steel structure assembling system for fabricated building and construction method

ActiveCN110306658AAvoid fatigue damageImprove bindingFloorsProtective buildings/sheltersEngineeringJoint spaces

The invention discloses a steel structure assembling system for a fabricated building and a construction method to solve the problem that an existing fabricated system is bad in stress. The steel structure assembling system comprises stand columns, cross beams and brackets, the same sides of every two adjacent stand columns are only provided with one pair of brackets which are arranged linearly, and one cross beam is installed between the two brackets; every two adjacent stand columns are connected only through one cross beam, and the two ends of the cross beam are movably connected with the brackets on the corresponding stand columns; the periphery of every stand column is provided with at least two cross beams in an outward radial shape, the cross beams on the same stand column do not interfere with each other, and the radial directions of the cross beams on the every two adjacent stand columns are opposite; and the cross beams are located on the sides of the corresponding stand columns. According to the steel structure assembling system, the cross beams are overlapped on the periphery of the stand columns and are arranged in an overlaid radial shape, enough overlapping joint space and enough extensible and retractable space are achieved, and a more excellent anti-seismic property is achieved.

Owner:安徽中冶淮海装配式建筑有限公司

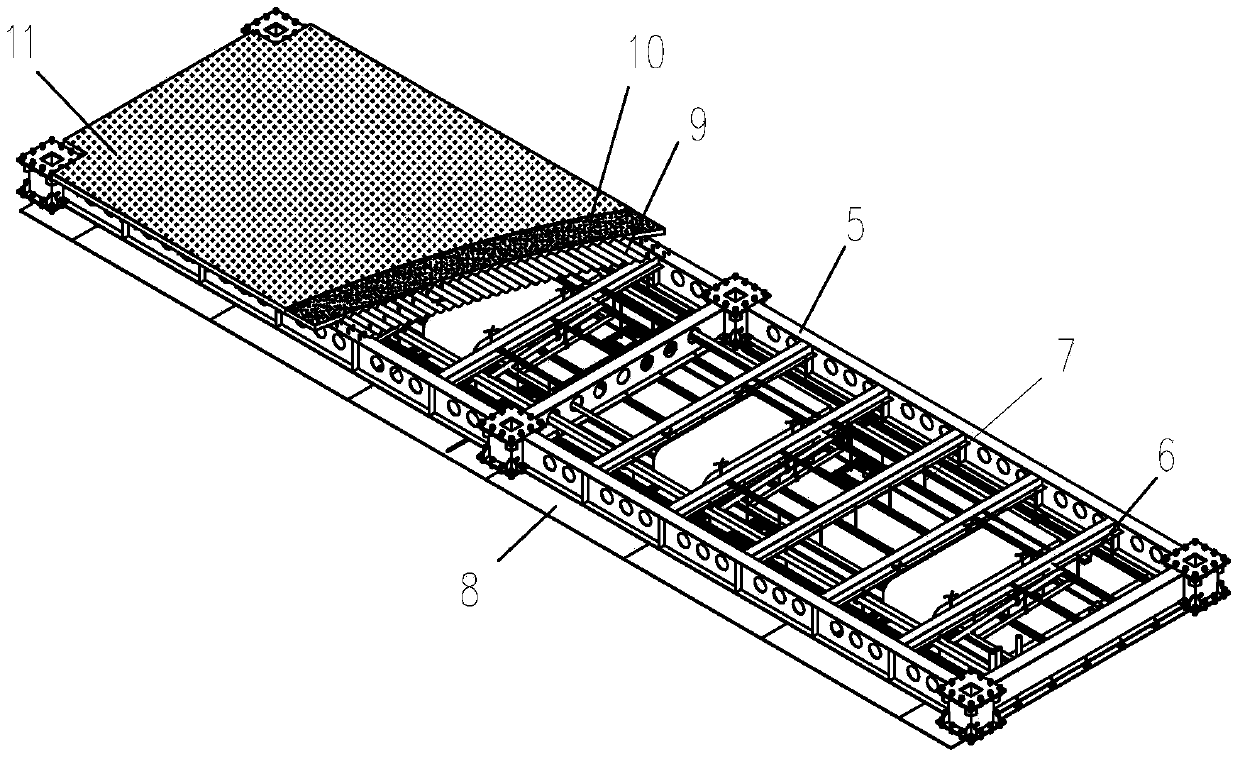

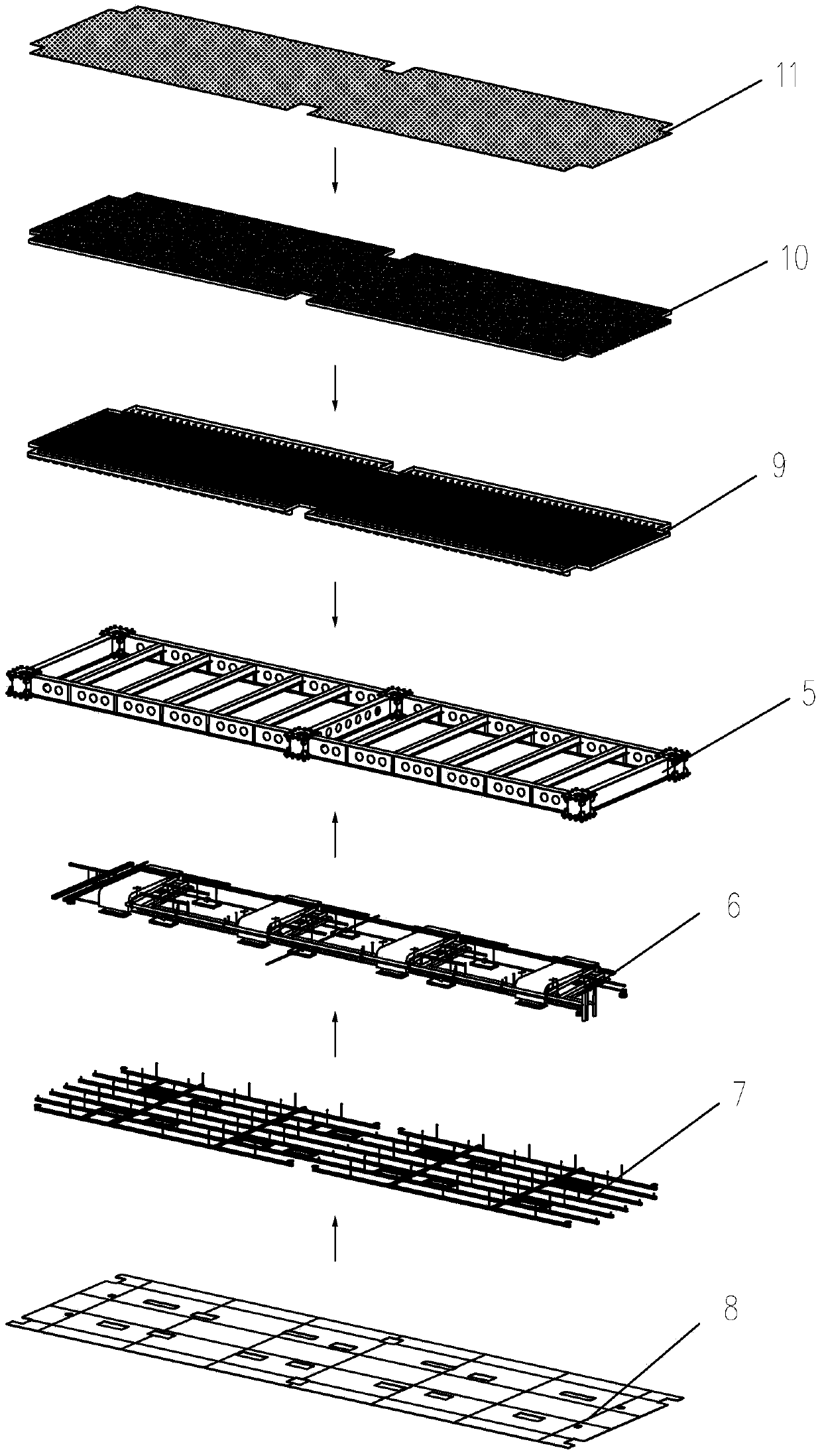

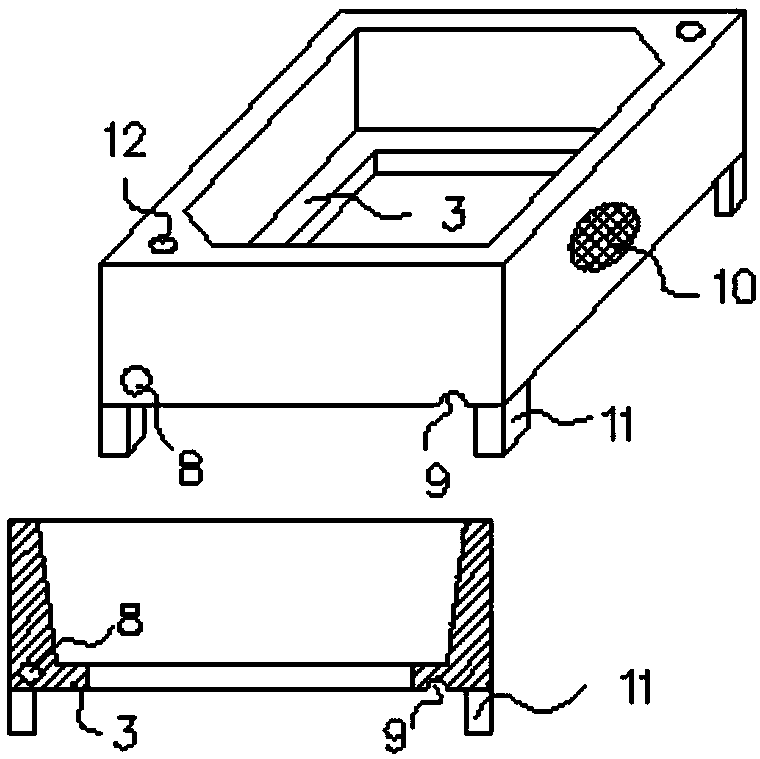

Integrated floor module and assembling method thereof

ActiveCN103993691ARealize industrial productionImprove on-site construction efficiencyFloorsSurface layerJoist

The invention mainly discloses an integrated floor module and an assembling method thereof. The integrated floor module comprises a structure module of floor. Equipment system modules, ceiling joists and suspended ceiling boards are sequentially assembled on the lower surface of the structure module from inside to outside; a profiled steel sheet is installed on the upper surface of the structure module, concrete is poured to the upper surface of the profiled steel sheet on site, a floor surface layer is laid on the surface of the concrete, and a finished product of whole floor system is formed. The assembling method includes the steps that the floor system is prefabricated in a factory firstly, then the finished product of the floor system is carried to a construction site, and the floor system is quickly connected with on-site square columns. According to the integrated floor module and the assembling method, modular production of the floor system is achieved, convenience is brought to quick assembly, and industrialization, assembly and standardization of building industry are propelled.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Cover die for construction of composite-section ribbed floor and construction method thereof

ActiveCN109680929ASolve mold problemsReduce production processForms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a cover die for construction of a composite-section ribbed floor and a construction method thereof. The cover die comprises two cylinders or one cylinder and one box or two boxes, wherein each cylinder is of a cylindrical surrounding body structure of which the upper part and lower part are communicated; the cylinders comprise a cylinder I and / or a cylinder II; each box isof a cavity body structure of which one end is opened and the other end is sealed; the boxes comprise a box I and / or a box II; the cylinder I is sheathed above the exterior of the cylinder II, and / orthe box I is sheathed above the exterior of the cylinder II, and / or the box I is sheathed above the exterior of the box II; a lower flange die cavity of a cast-in-situ concrete rib is formed between the cylinder and / or the box; a web plate die cavity of a cast-in-situ concrete dense rib is formed between the adjacent cylinders and / or the boxes. One of the cover die is reserved in a reinforced concrete prefabricated rib cylinder or box, and the other one is a detachable and repeatedly used cylinder die, or is a prefabricated concrete cylinder reserved in the floor. The cover die is a construction die with the advantages that the production is simple; the construction is convenient; the construction period is short; the manufacturing cost is low; the good use effect is obtained.

Owner:贵州皆盈科技开发有限公司

Liquid crystal display panel and manufacturing method thereof

ActiveUS7345732B2Good adhesionImprove the display effectNon-linear opticsLiquid-crystal displayEngineering

Owner:NYTELL SOFTWARE LLC

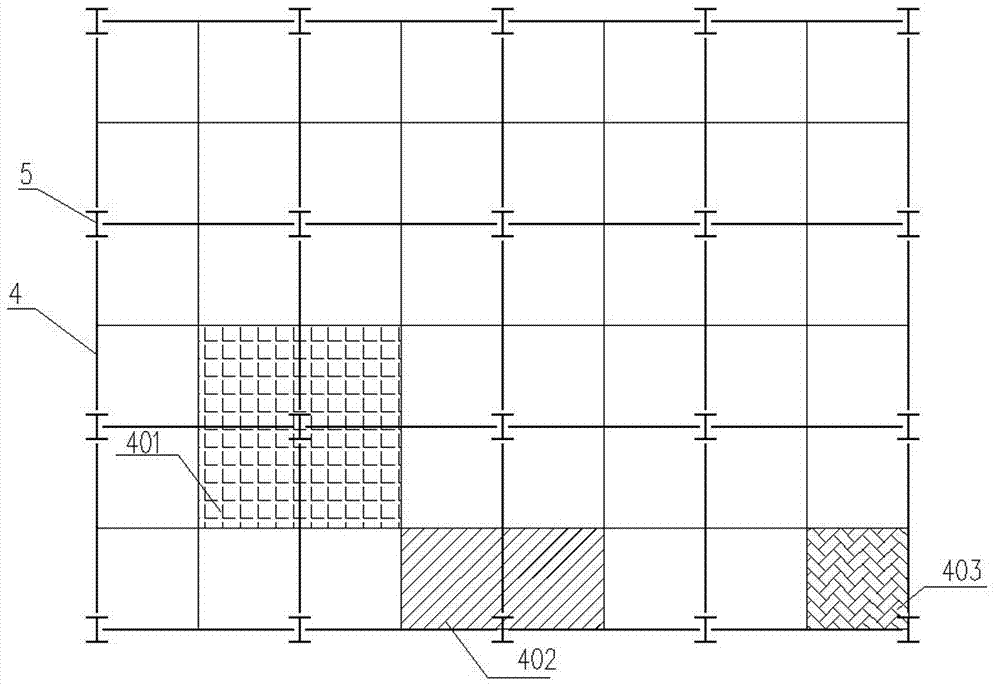

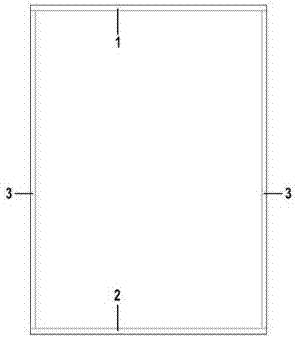

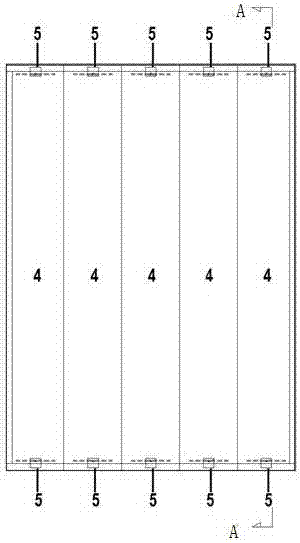

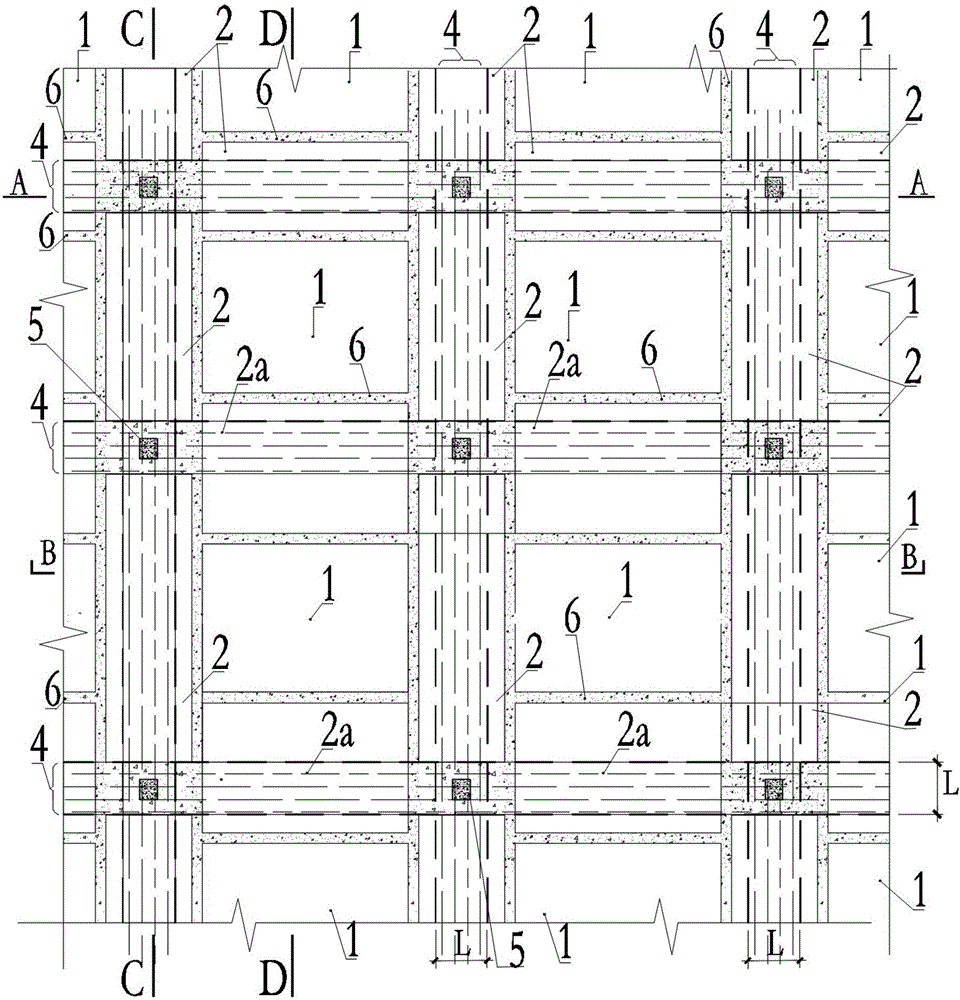

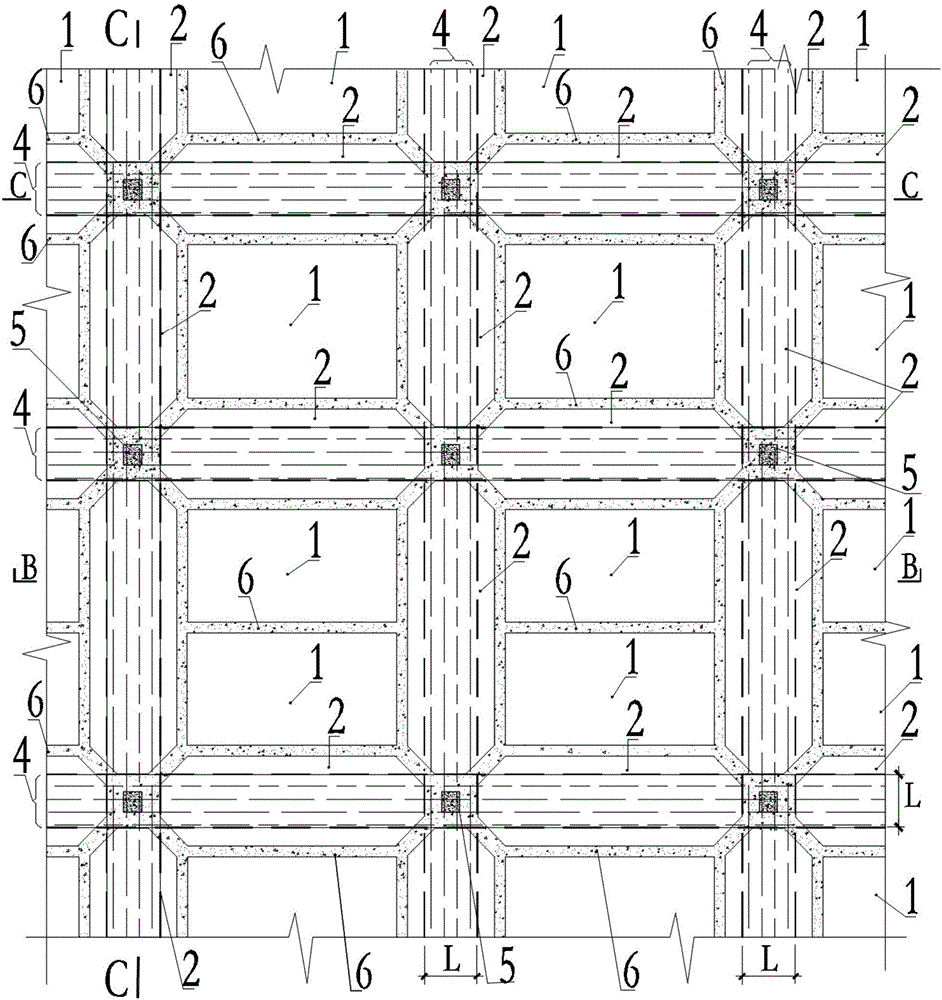

Assembled board-column structure floor slab, dividing method thereof, and floor slab unit components

ActiveCN106522552AImprove reliabilityHigh costFloorsBuilding material handlingAgricultural engineeringFloor slab

The invention discloses an assembled board-column structure floor slab, a dividing method thereof, and floor slab unit components. The assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising adjacent column connection board belts, or the assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising the adjacent column connection board belts, and the multiple conventional prefabricated floor slab unit components. The adjacent column connection board belts in the prefabricated floor slab unit components comprising the adjacent column connection board belts are long-strip-shaped belt boards integrally stretching across every two adjacent columns. The connection line of section centroids of the two adjacent structure columns connected through each adjacent column connection board belt serves as a reference line of the adjacent column connection board belt, and the width of each adjacent column connection board belt is larger than or equal to the longest side length of the connection sides of the two adjacent structure columns connected through the adjacent column connection board belt. The adjacent column connection board belts are provided with direct-through bottom reinforcing bars in the span direction. By the adoption of the technical scheme, cost can be reduced, construction is convenient, and safety and reliability of the board-column structure of the prefabricated floor slab can be improved at the same time.

Owner:刘祥锦

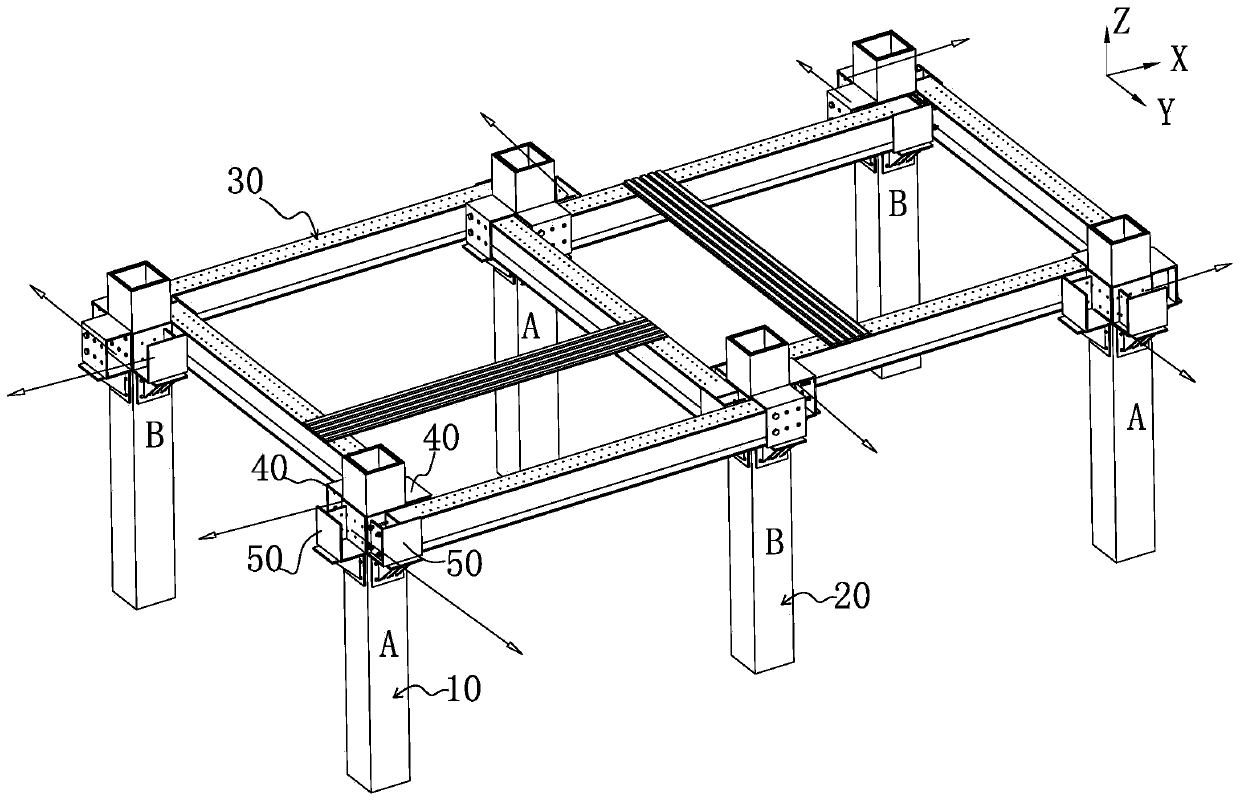

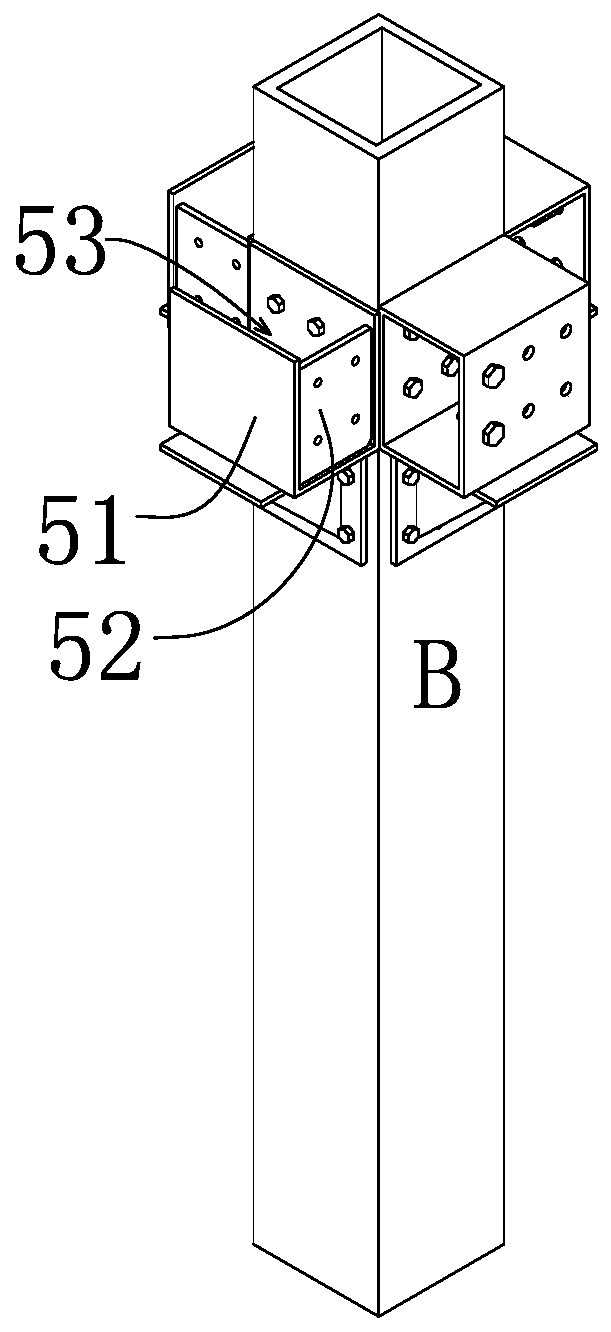

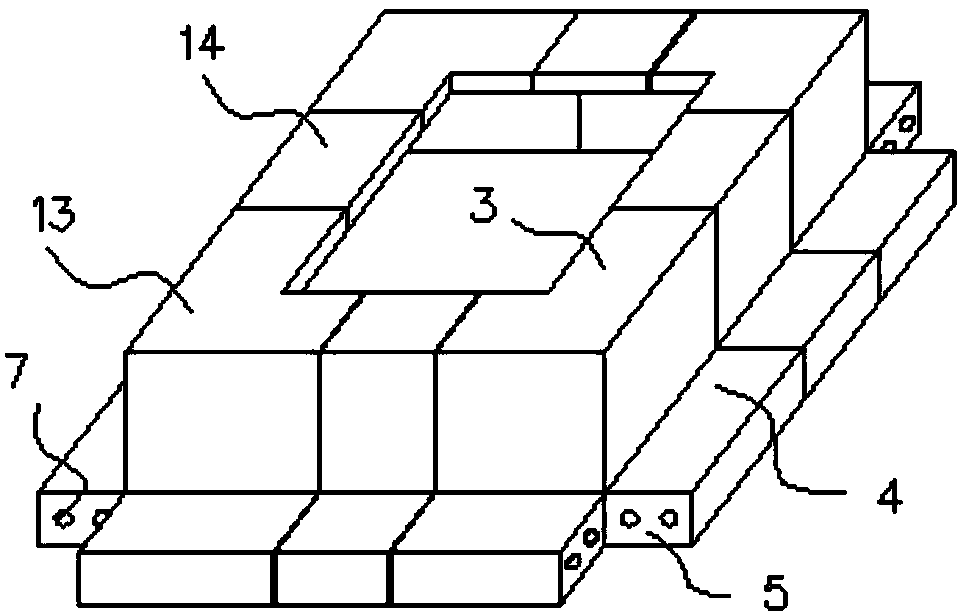

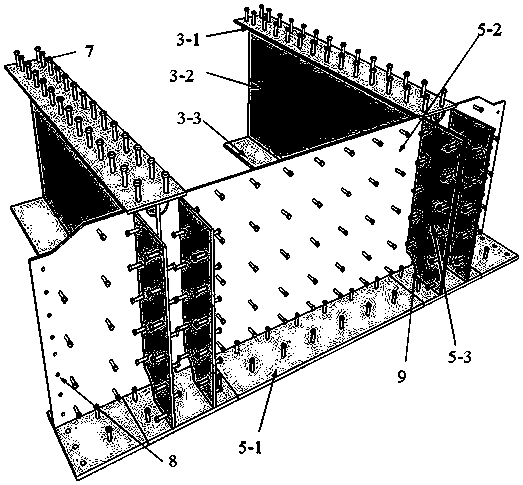

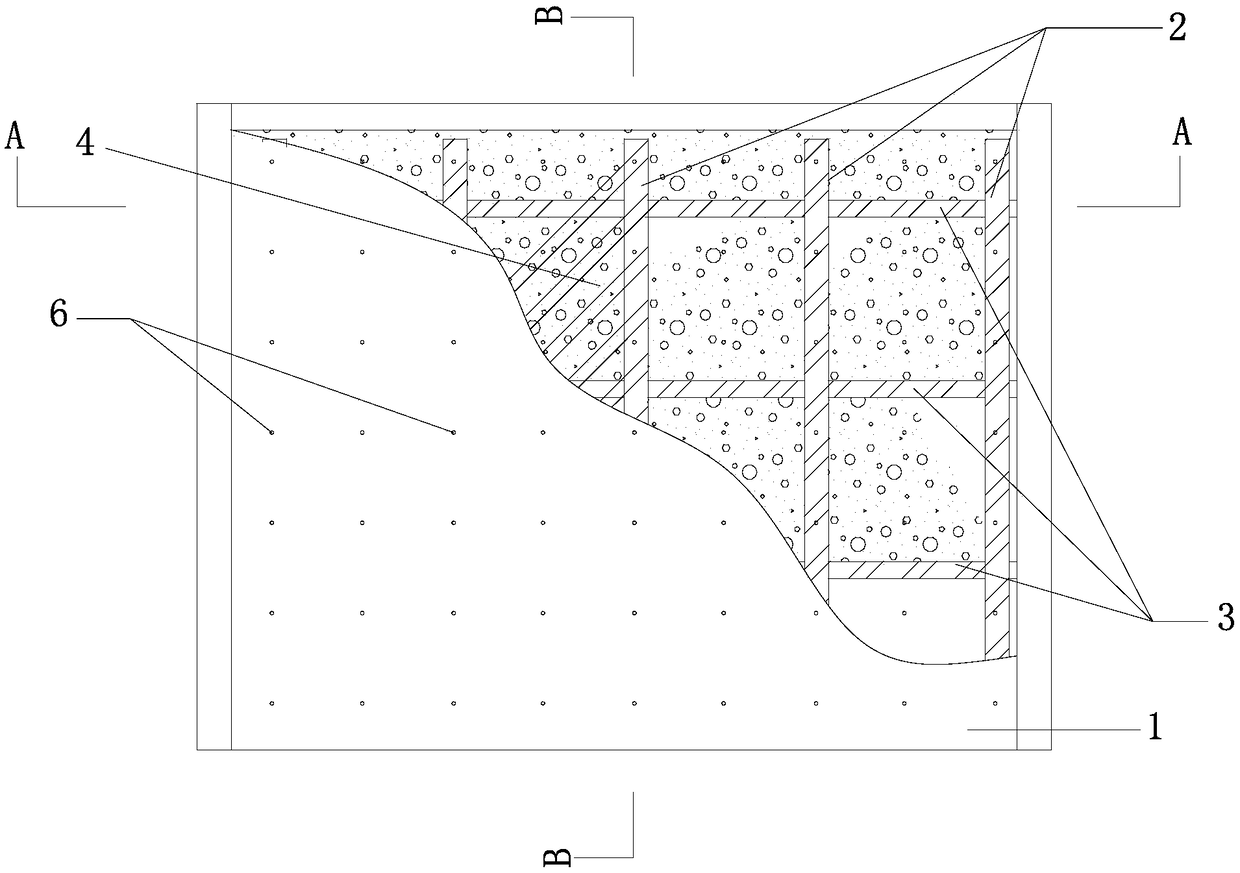

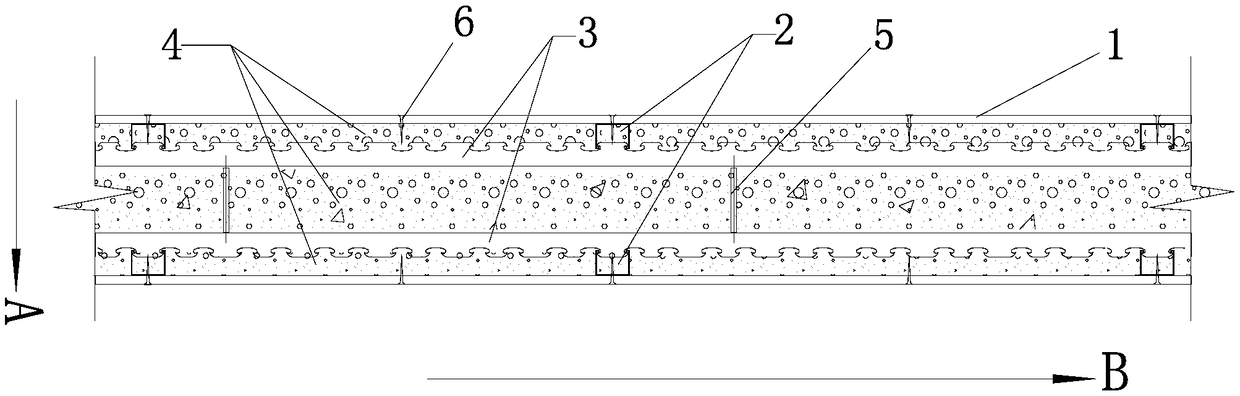

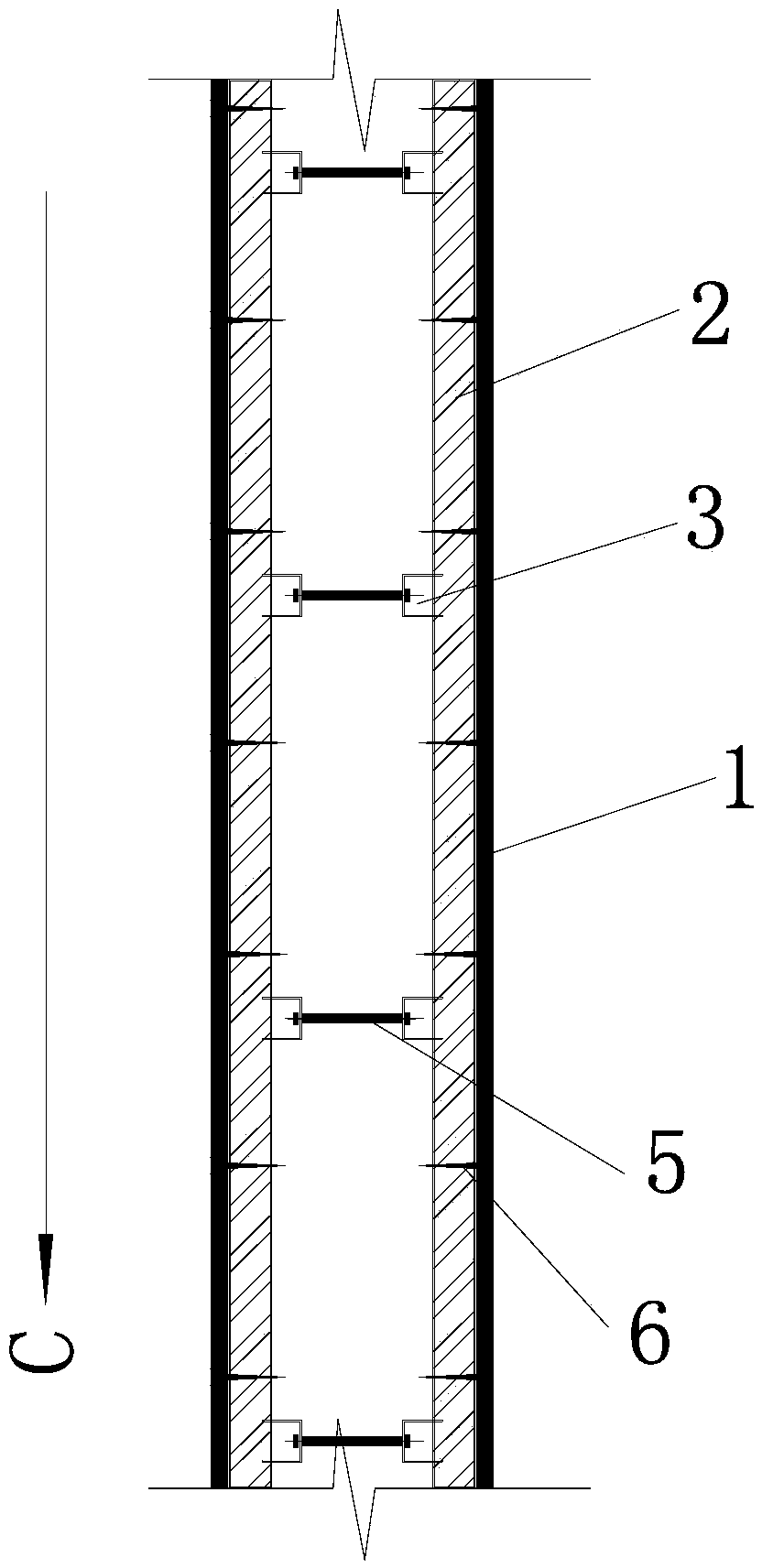

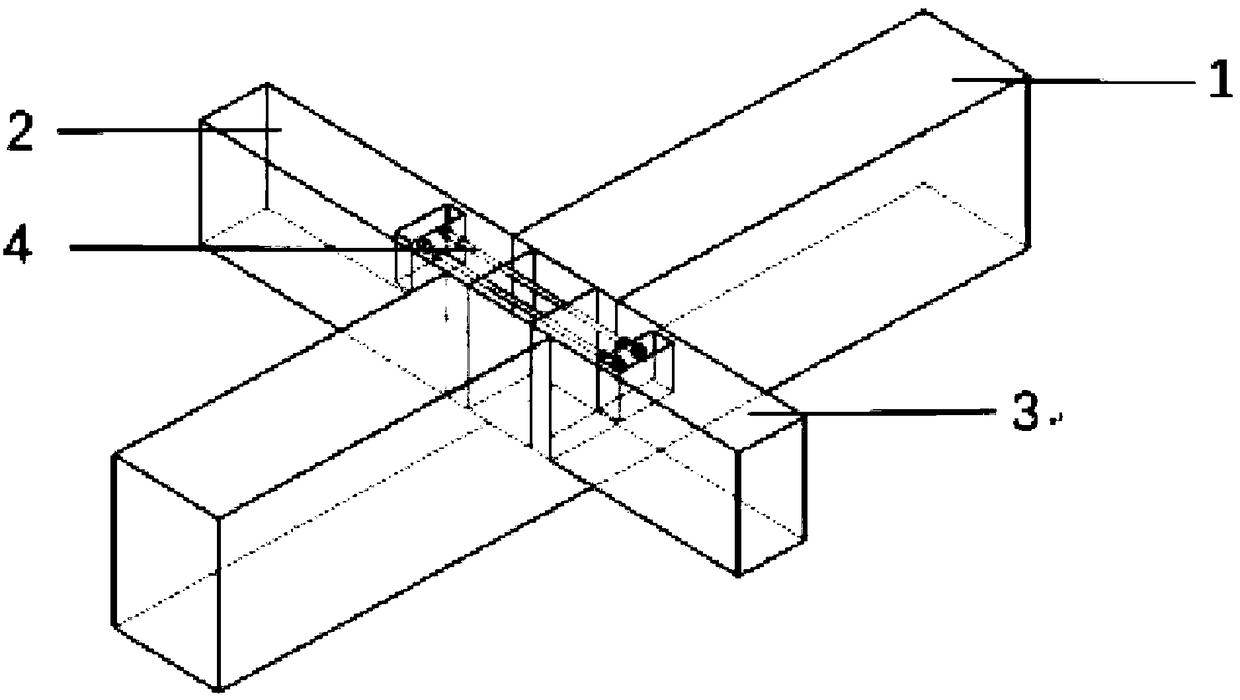

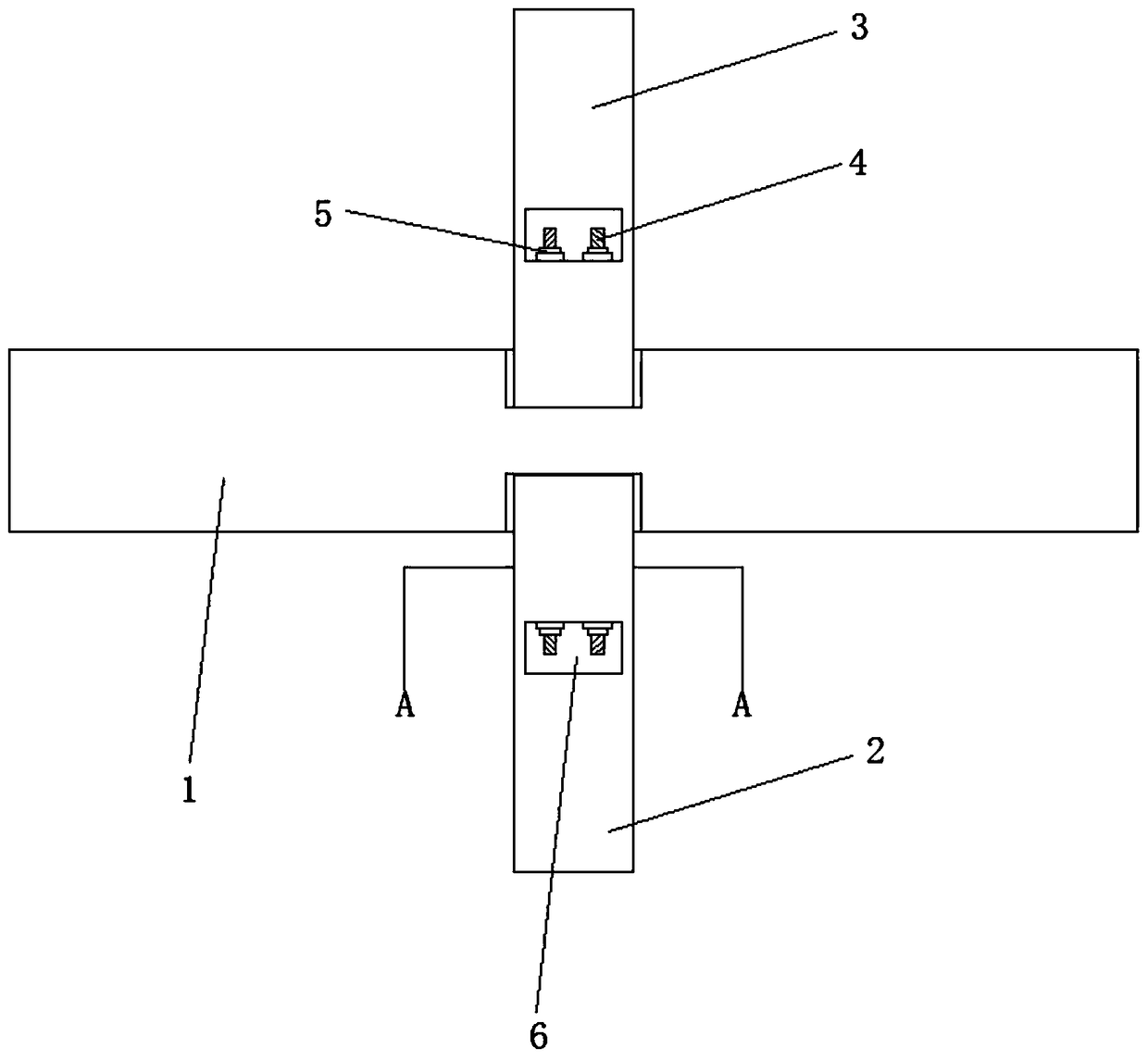

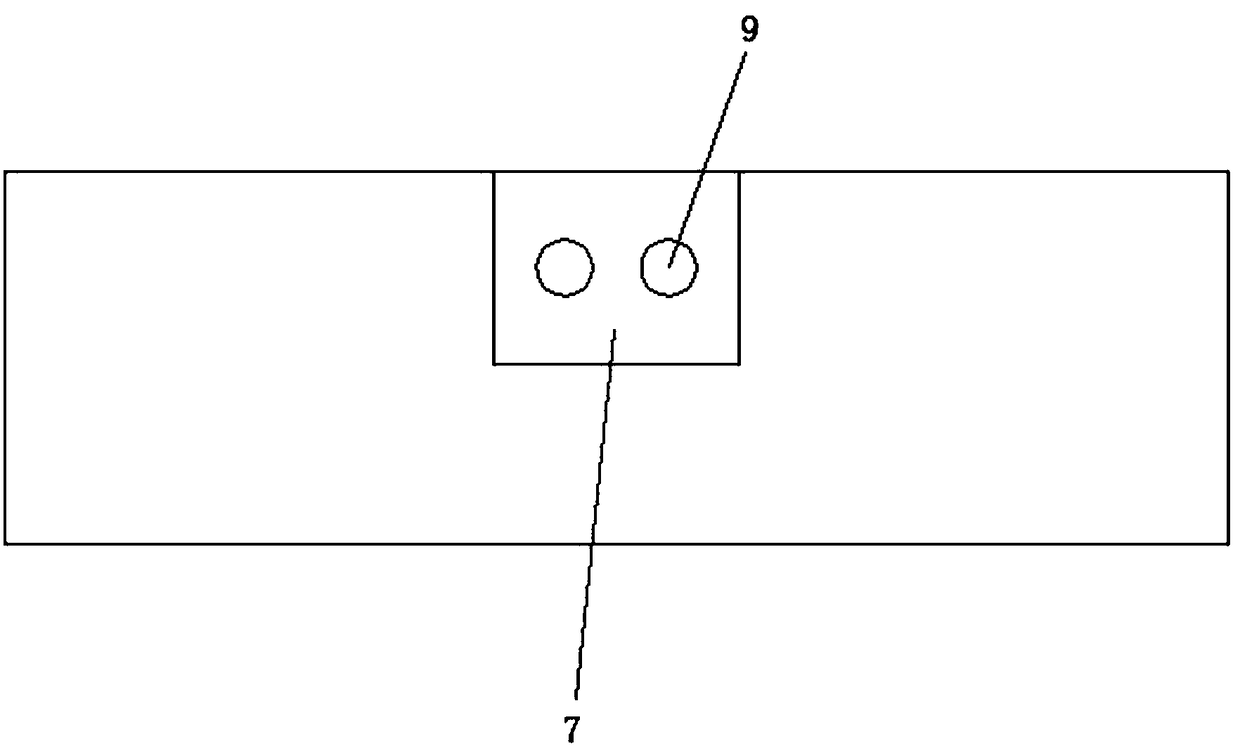

Perforating grout anchoring prefabricated assembly-type concrete-filled steel tubular frame structure

ActiveCN109339229AReduce the amount of pouringImprove assembly rateBuilding constructionsSteel tubeGrout

The invention discloses a perforating grout anchoring prefabricated assembly-type concrete-filled steel tubular frame structure, which comprises a square steel tube concrete lower column, a square steel tube concrete upper column, a semi-open steel box concrete composite beam, a prefabricated slab corner unit, a prefabricated slab edge unit, a prefabricated slab middle unit, column-beam post-pouring joints, column-column bolted connection joints, a prefabricated concrete slab and post-pouring concrete. The square steel tube concrete lower column, the square steel tube concrete upper column, the semi-open steel box concrete composite beam and the prefabricated concrete slab are connected into a whole in a grout anchoring mode, the pouring amount is less, the assembling rate is high, all components are in a prefabricated assembly form, onsite splicing is conducted, the construction speed is high, the construction process is simplified, and the construction environment is optimized; and secondly, the requirements of grout anchoring for the construction precision are low, operation by workers is convenient, the beam-column components are in a combined structural form, the self-weight is low, force bearing is more reasonable, the material property can be exerted sufficiently, the bearing capacity is high, the fire-resisting property is good, and shock resistance is good.

Owner:CHINA MCC17 GRP

Fabricated structural system of steel plate reinforced concrete shear walls and construction method of fabricated structural system

ActiveCN106639052AReduce section loss rateOvercome the technical difficulty of being unable to fix on the vertical steel plateWallsLoad-supporting elementsFloor slabSheet steel

The invention discloses a fabricated structural system of steel plate reinforced concrete shear walls. The fabricated structural system comprises a beam member, the steel plate reinforced concrete shear walls, a floor and a sleeve connecting piece. Each steel plate reinforced concrete shear wall comprises vertical steel plates and continuous spiral stirrups. The structural system is high in assembling rate. The invention further discloses a construction method of the fabricated structural system of the steel plate reinforced concrete shear walls. The construction method comprises the steps that firstly, one prefabricated steel plate reinforced concrete shear wall is manufactured; secondly, the steel plate reinforced concrete shear wall on the lower layer is assembled; thirdly, the sleeve connecting piece is assembled on the steel plate reinforced concrete shear wall on the lower layer; fourthly, the beam member is assembled, and the floor is installed; fifthly, the floor and the beam member as well as the floor and the steel plate reinforced concrete shear wall on the lower layer are connected by pouring concrete, and concrete is poured to the junction of the beam member and the steel plate reinforced concrete shear wall on the lower layer; and sixthly, the steel plate reinforced concrete shear wall on the upper layer is hoisted, and finally concrete is poured to the junction of the steel plate reinforced concrete shear walls on the upper layer and the lower layer in situ. By adoption of the fabricated structural system of steel plate reinforced concrete shear walls and the construction method of the fabricated structural system, construction can be completed with the high assembling rate.

Owner:陕西省建筑设计研究院(集团)有限公司

Concealed beam type connecting fully-prefabricated concrete plate structure and manufacturing and assembling methods

PendingCN107975185AReduce wet work loadEasy to assemble on siteConstruction materialCeramic shaping apparatusLap jointRebar

The invention relates to the field of prefabricated assembly type concrete structure buildings, in particular to a concealed beam type connecting fully-prefabricated concrete plate structure and manufacturing and assembling methods. Fully-prefabricated concrete plates are formed in the mode that concrete is poured into formwork structures; longitudinal steel bars and transverse steel bars are arranged in the fully-prefabricated concrete plates horizontally and are each of the structure with the two ends being bent on the inner side of the corresponding fully-prefabricated concrete plate; and vertical sections between the bottom edges of the longitudinal steel bars and the transverse steel bars and the bent sections of the longitudinal steel bars and the transverse steel bars are arranged on the outer sides of the fully-prefabricated concrete plates. According to the concealed beam type connecting fully-prefabricated concrete plate structure, concealed beam longitudinal steel bars penetrate through closed hoops formed by lap joint of the exposed steel bars of the two prefabricated concrete plates, then, concrete is poured, and thus the plates are connected; the concealed beam longitudinal steel bars penetrate through the closed hoops formed by lap joint of in-beam reserved connecting steel bars and the exposed steel bars of the prefabricated concrete plates, then, the concrete is poured, and thus fixing of the plates on beams is completed; and the requirement for plate and beam connection in actual engineering is completely met.

Owner:SHENYANG JIANZHU UNIVERSITY

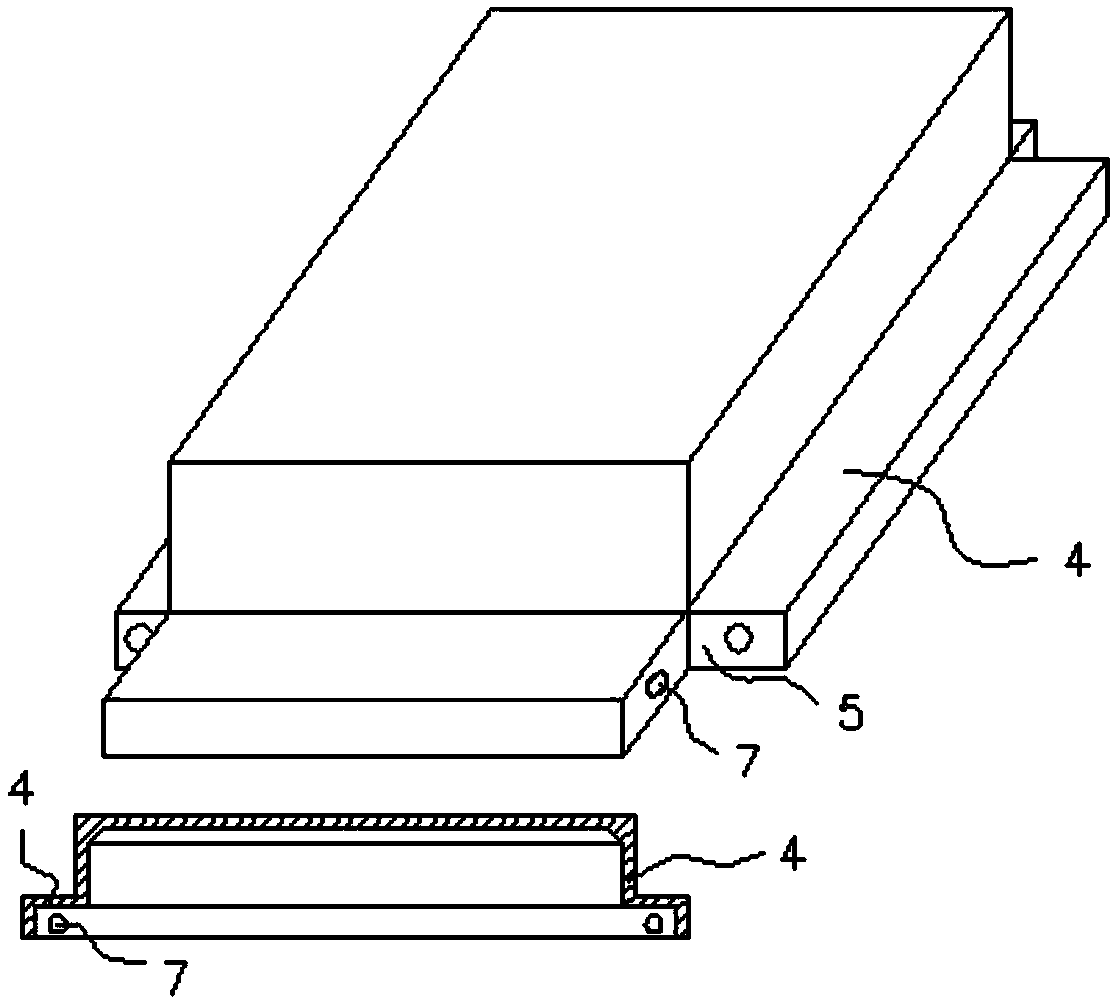

Integrated assembly type light floor and construction method thereof

The invention discloses an integrated assembly type light floor and a construction method thereof, and belongs to the field of building materials. According to the integrated assembly type light floor, the stress system of a main structure is not damaged, factory modular production is adopted for the whole integrated floor, and the assembly rate is increased; the integrated floor is in bolted connection with steel structure main beams, and repeated use is facilitated. The welding quantity is small, the overall height of the integrated floor is small, and the interior net storey height is effectively increased. Meanwhile, the steel consumption of the floor is small, and thus the construction cost is effectively reduced.

Owner:ZHONGTIAN CONSTR GRP ZHEJIANG STEEL STRUCTURE

Superimposed fabricated pipe gallery structure system component industrialization construction device and method

InactiveCN108193712AGood lookingReduce usageArtificial islandsUnderwater structuresIntelligent managementRebar

The invention relates to a superimposed fabricated pipe gallery structure system component industrialization construction device and method. The superimposed fabricated pipe gallery structure system component industrialization construction device comprises a production intelligent management system. The superimposed fabricated pipe gallery structure system component industrialization constructionmethod comprises the steps that a, edge formworks are manufactured, pre-buried components are mounted on manufactured steel reinforcement frameworks, and the steel reinforcement frameworks and the edge formworks are subjected to formwork assembly operation on a formwork table; b, by adopting a distribution machine, concrete is poured onto the steel reinforcement frameworks and the edge formworks which are subjected to formwork assembly, and vibrated, and thus concrete components are obtained; c, the concrete components are cured in a curing kiln through steam; d, single sided boards loaded with superimposed-type double-layer boards are superimposed and sent to the curing kiln for secondary curing; e, the components are subjected to formwork release and stored on a component stacking field,and in the storing process, the superimposed-type single-layer boards and the superimposed-type double-layer boards are subjected to water spraying curing through a spraying system; and f, the components are conveyed to a site to be assembled and mounted. According to the superimposed fabricated pipe gallery structure system component industrialization construction device and method, on-site construction is easy, energy saving and environmental friendliness are achieved, long-time exposure of a foundation pit is reduced, the influence of weather on construction is small, and pollution emission and cost are reduced.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

Fabricated light composite beam simply-supported variable-structure continuous structure and construction method thereof

PendingCN108385503AImprove integrityReduce dosageBridge structural detailsBridge erection/assemblyBridge deckContinuous beam

The invention provides a fabricated light composite beam simply-supported variable-structure continuous structure and a construction method thereof. The fabricated light composite beam simply-supported variable-structure continuous structure comprises two oppositely-arranged span steel-ultrahigh performance concrete light composite simply-supported beam prefabricated units, and a cast-in-place ultrahigh performance concrete pier top crossbeam arranged between the two oppositely-arranged span steel-ultrahigh performance concrete light composite simply-supported beam prefabricated units; the prefabricated units comprise a plurality of I-shaped steel beams, bridge deck slabs arranged on the I-shaped steel beams, and connecting parts arranged at the ends of the I-shaped steel beams; each connecting part comprises a first connecting part body arranged at the end of one prefabricated unit, and a second connecting part body arranged on the other prefabricated unit; and ultrahigh performance concrete is poured at the matched areas of the first connecting part bodies and the second connecting part bodies in place to form the pier top crossbeam. According to the fabricated light composite beam simply-supported variable-structure continuous structure and the construction method thereof, the problem that a traditional steel-concrete composite continuous beam hogging-moment-area bridge deckslab is prone to cracking when being pressed, and steel beams are prone to losing stability due to being pressed is solved; a continuous bridge is better in durability and longer is service life, meanwhile, on-site zero welding can be achieved, the on-site operation amount is reduced, the fabricating efficiency of the structure is improved, and fabricated and rapid construction is facilitated.

Owner:HUNAN UNIV

Foamed concrete thermal insulation composite wall

The invention discloses a foamed concrete thermal insulation composite wall. The foamed concrete thermal insulation composite wall comprises two wall skeletons arranged in the direction of the thickness of the wall at intervals, wherein the two wall skeletons are both fixed to a building main structure. The wall skeletons comprise panels and keel assemblies, a pouring space is formed between the inner surfaces of the two panels and the outer surface of the building main structure, and the keel assemblies are arranged in the pouring space. The keel assemblies include a plurality of vertical keels and a plurality of transverse keels, the vertical keels are fixedly erected on the building main structure, the vertical keels are sequentially arranged at intervals in the length direction of thewall, and the panels are fixed to the corresponding vertical keels. The transverse keels are vertically connected with the corresponding vertical keels and arranged parallel to the corresponding panels, and the transverse keels are sequentially arranged at intervals in the height direction of the wall. Foamed concrete is poured into the pouring space so that the foamed concrete, the two panels andthe keel assemblies form the integrated foamed concrete thermal insulation composite wall. The composite wall has the advantages of good thermal insulation performance, high degree of industrialization, high universality, easy assembly and the like.

Owner:湖南睿盾新材料科技有限公司

Novel fabricated primary and secondary beam connecting node and connecting method thereof

PendingCN108999297AImprove prefabrication rateImprove assembly rateBuilding material handlingMechanical engineeringPrefabrication

The invention discloses a novel fabricated primary and secondary beam connecting node and a connecting method thereof, which comprises a primary beam. Two sides of the middle position of the primary beam are respectively provided with beam grooves. Two sides of each beam groove are uniformly provided with connecting jacks. A first secondary beam and a second secondary beam are respectively arranged in the beam grooves. The middle positions of the first secondary beam and the second secondary beam are respectively provided with a mounting groove. The inside of one side, close to the primary beam, of each of the first secondary beam and the second secondary beam are uniformly provided with bolt jacks. One end of each bolt jack penetrates the corresponding mounting groove. A bolt penetrates each bolt jack. The middle position of each bolt penetrates the corresponding connecting jack. Two ends, located in the corresponding mounting groove, of each bolt are in threaded connection with nuts.The invention relates to the technical field of building beams. According to the novel fabricated primary and secondary beam connecting node and the connecting method thereof, the purpose of improving the bearing capacity and integrality thereof, improving the primary and secondary beam node connecting efficiency, further improving the prefabrication rate and fabrication rate of the connecting node, and promoting modernization development of the construction industry.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com