Fabricated recoverable-function steel frame-supporting system connected by prestressed joints

A technology of node connection and recovery function, which is applied in the direction of architecture and building construction, can solve the problems of inability to meet industrialized efficient installation, large steel consumption, etc., and achieve the effects of saving assembly time, small deformation, and easy positioning and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

[0041] The used steel column 5 and steel beam 6 of the steel frame of the present invention are I-beams;

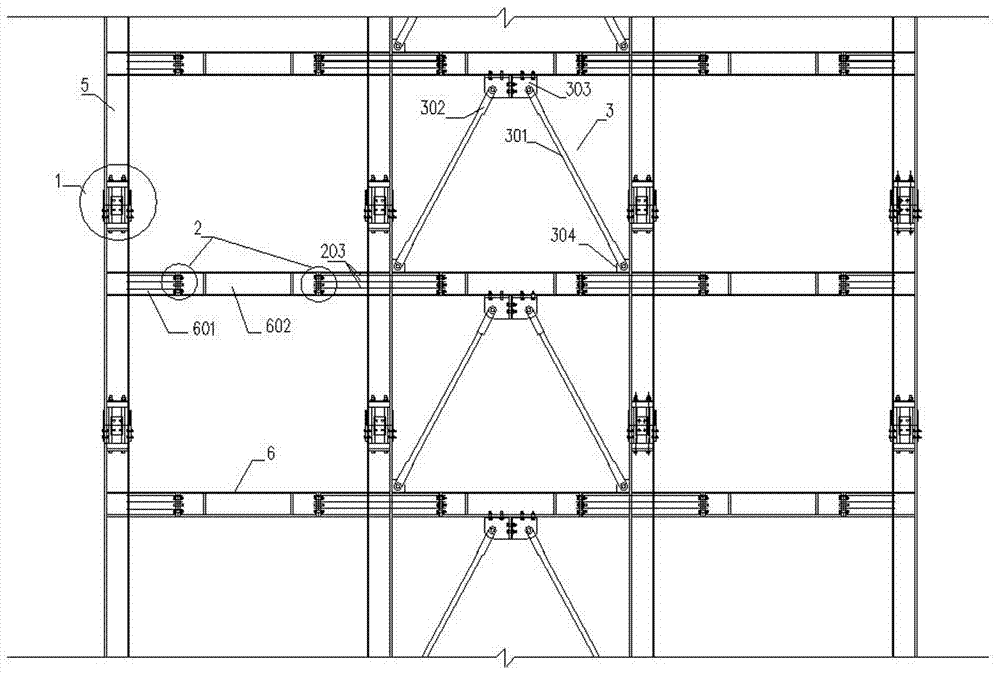

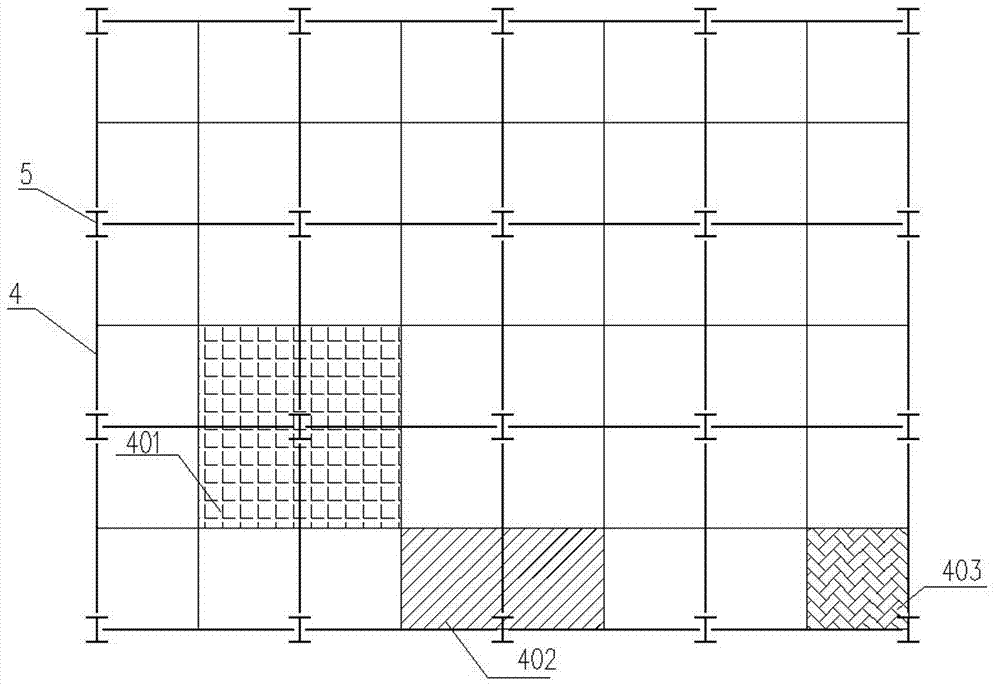

[0042]like figure 1 , figure 2 As shown, the assembled recoverable functional steel frame-support system connected by prestressed joints is composed of assembled joints I1, assembled joints II2, support structure 3 and floor 4, and floor 4 includes type I slab 401 and type II slab 402 Three types of prefabricated concrete slabs are Type III and Type 403.

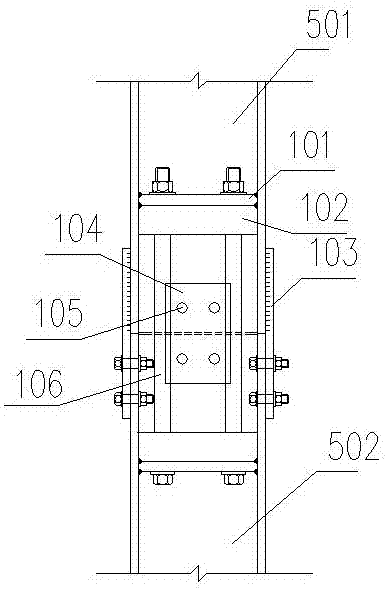

[0043] like image 3 , Figure 4 , Figure 5 As shown, the fabricated node I1 is a fabricated prestressed column-column splicing node to connect two adjacent steel columns 5 above and below, and is located at the inflection point of the column, which is about 1 / 3 to 1 / 4 of the storey height place; including prestressed tie rod support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com