NALC (N autoclaved lightweight concrete) large slab component

A technology of air-entrained concrete and slab components, which is applied in the direction of covering/lining, construction, building construction, etc., which can solve the problems that are not conducive to the promotion of autoclaved light-weight aerated concrete, the inability to ensure a good stress-bearing area for the keel installation, and the unfavorable assembly In order to achieve the effect of compact and ingenious structural design, superior seismic performance and reduced construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

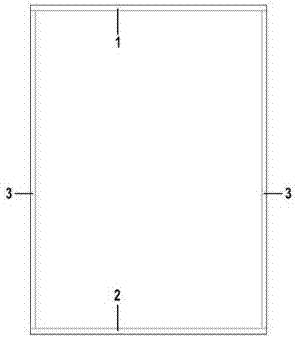

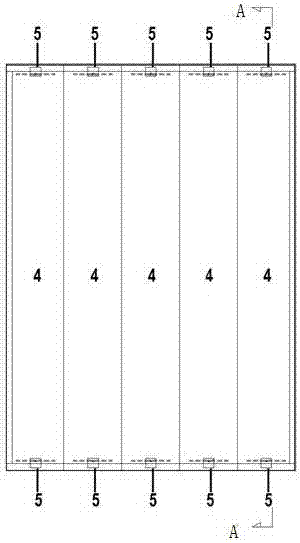

[0022] Embodiment 1: see figure 1 , figure 2 , an autoclaved lightweight aerated concrete large slab assembly, the large slab assembly includes a plurality of NALC panels 4, the joints between adjacent NALC panels are treated with a jointing agent, and the surroundings of the NALC panels are set There are angle steel components, and the two ends of the NALC plate are provided with installation nodes 5, and the NALC plate is fixed by the fixing component. The autoclaved lightweight aerated concrete slab is completed in the factory. After the overall hoisting on site, the decorative panel can be directly hung on the outside, which reduces the installation process of the on-site external keel, shortens the construction period, and reduces labor costs.

Embodiment 2

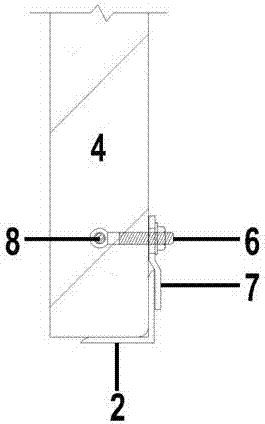

[0023] Example 2: see Figure 1-Figure 3 , as an improvement of the present invention, the angle steel assembly includes a top angle steel 1, a bottom angle steel 2 and an edge angle steel 3, and the top angle steel 1, the bottom angle steel 2 and the edge angle steel 3 are respectively arranged at the bottom, bottom and sides. Used to correct verticality and flatness errors during installation, the fixing assembly includes installation node pressure plates 7 , screw sets 6 and anchoring steel bars 8 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0024] Embodiment 3: see Figure 4-Figure 6 , as an improvement of the present invention, the large panel assembly also includes a decorative panel keel assembly, the decorative panel joist assembly is arranged on the NALC board, and the decorative panel joist assembly includes a decorative panel main joist 9 and / or a decorative panel The secondary keel 10 is fixed by the hook bolt 11. The hook bolt includes a hook part and a straight part. The hook bolt passes through the NALC plate. Extend the sheet. Composite exterior decoration materials on the slab components, that is, paint, ceramic tiles, veneer materials and other decorative materials can be used on the slab components, and the autoclaved lightweight aerated concrete slab composite external decorative keel is completed in the factory and hoisted as a whole on site After that, the decorative board can be directly hung outside, which reduces the on-site hanging keel installation process, improves work efficiency, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com