A construction method for large-diameter coke oven gas pipelines passing through railway culverts

A technology of coke oven gas and construction method, which is applied in the directions of pipe laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of low efficiency, affecting the normal operation of railways, long construction period, etc., and achieves high efficiency and structure. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

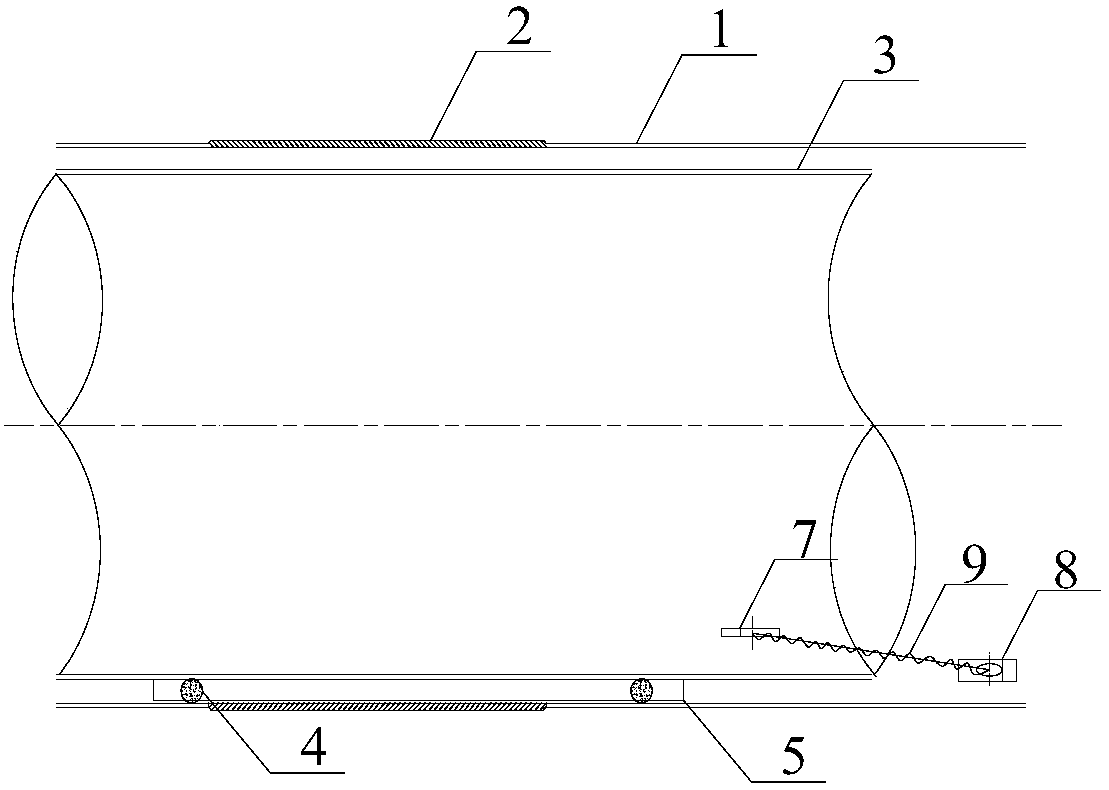

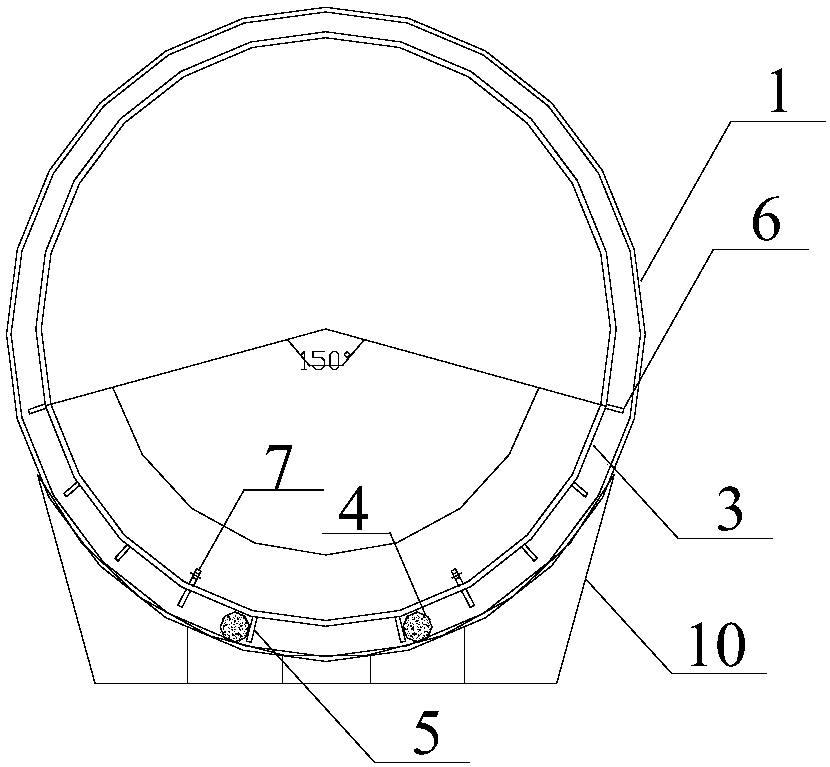

[0034] Such as figure 1 As shown, a construction method for a large-diameter coke oven gas pipeline to pass through a railway culvert includes the following steps:

[0035] (1) Build an operating platform with a width of 5m and a length of 15m on both sides and the middle of the railway culvert, and set up several inverted chains on both sides and the middle of the railway culvert, and construct from both ends of the culvert to the middle at the same time;

[0036] (2) Assemble and weld a thick-walled casing 2 with a length of 2m and a tube wall thickness of 28mm and two sections of a thin-walled casing 1 with a length of 5m and a tube wall thickness of 16mm to obtain a 12m length from outside to inside. The casing module of the wall casing 1, the thick wall casing 2 and the thin wall casing 1, in which the thick wall casing 2 and the thin wall casing 1 are welded on one side outside the V-shaped groove;

[0037] (3) Lay roller bars on the track where the casing passes through the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com