Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349results about How to "Reduce working at heights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

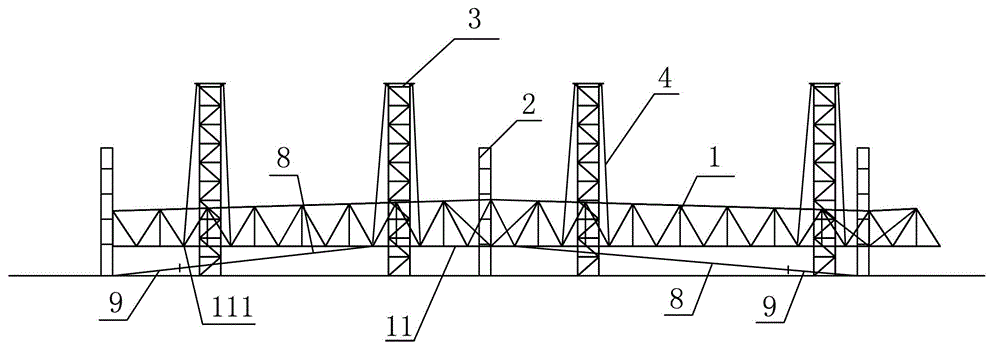

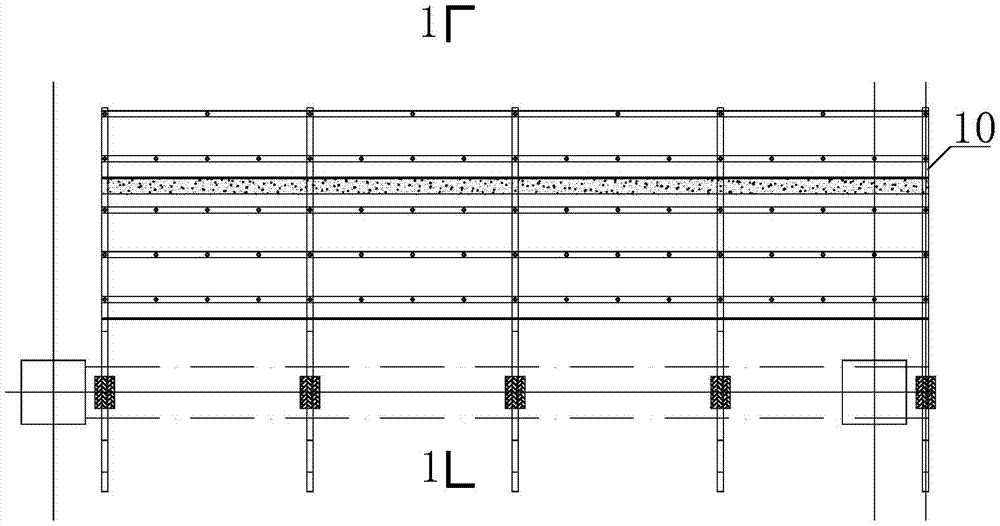

Space truss structure aerial pairing integral slide installation method

InactiveCN101775907AStructural solutionQuick pairBuilding material handlingFalseworkBuilding construction

The invention relates to a space truss structure aerial pairing integral slide installation method, which belongs to the installation technical field of an aerial steel structure. The invention relates to an aerial space truss steel structure installation method. Scaffolds are arranged outside a house to pair a platform, after each pairing, the pair of platforms slide into the house, the splicing continues until all platforms slide in place, and slide rails are disassembled after supports are installed. The method has the advantages that the difficulty that the span of the space truss is large and no large-sized hoisting device exists on the spot can be solved; during the construction period of the roof space truss, the lower part of the civil work can be alternatively carried out; the expense for establishing the spliced platform is saved by 60 percent or more compared to an all-round scaffold aerial scattered installation method; and moreover, the peripheral land occupation of the building is less, and only one construction field is required.

Owner:BEIJING SHOUGANG CONSTR GROUP

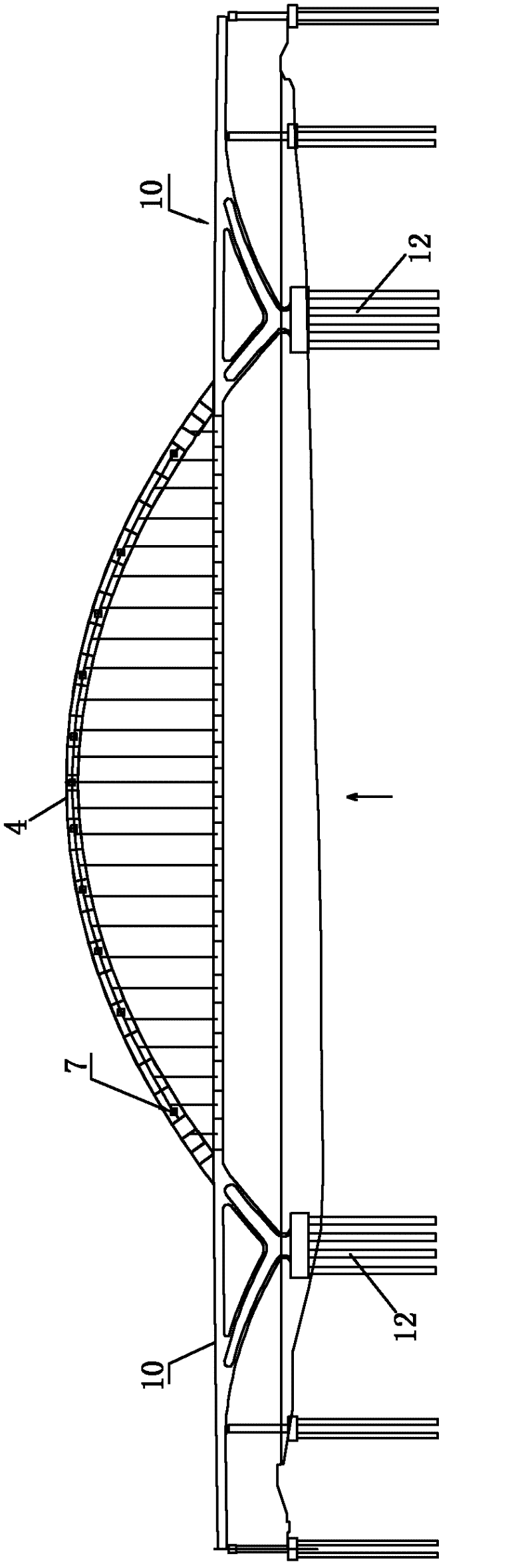

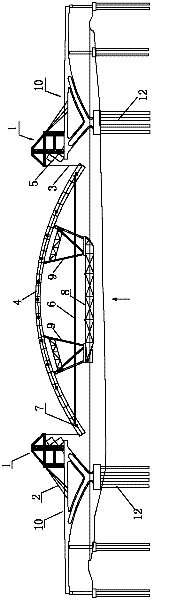

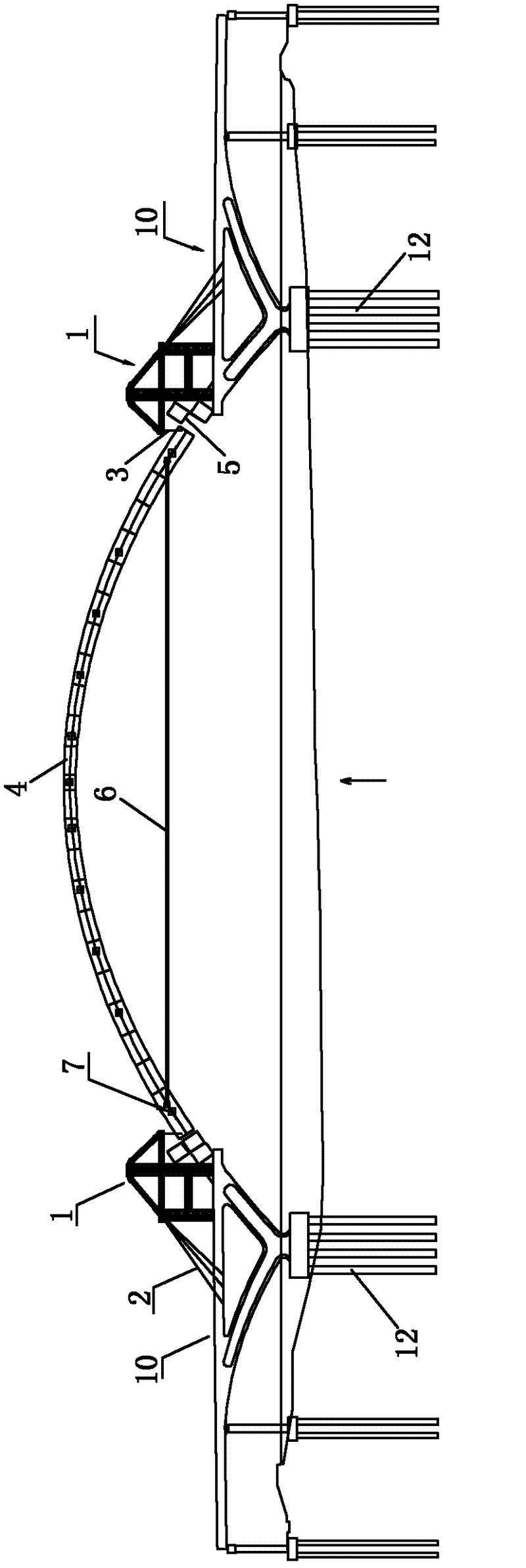

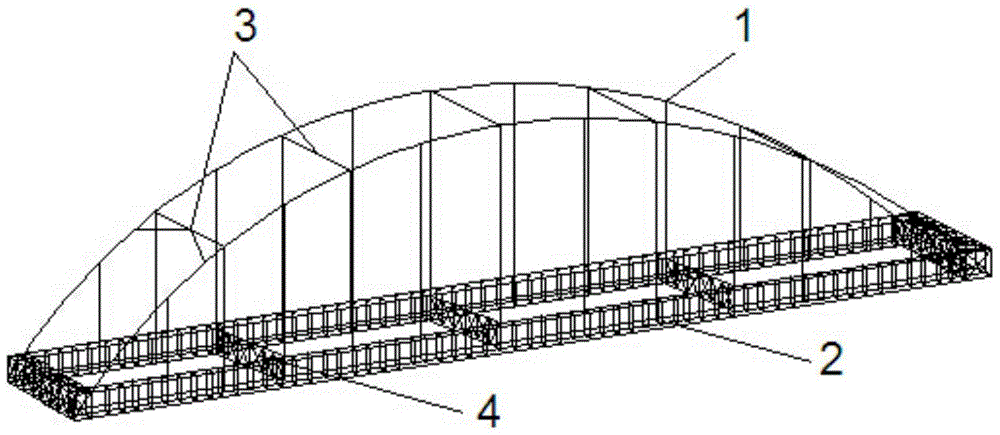

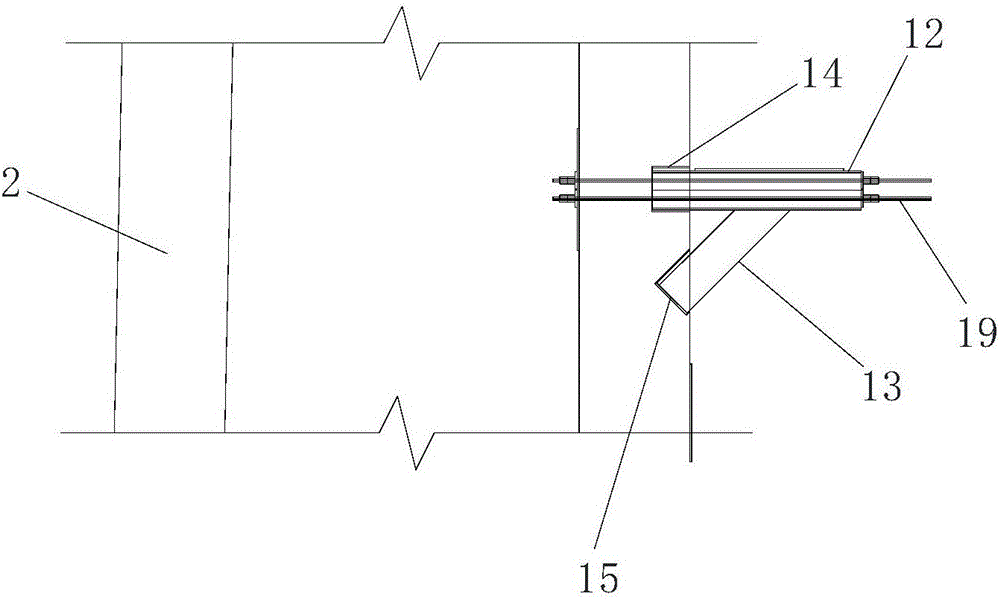

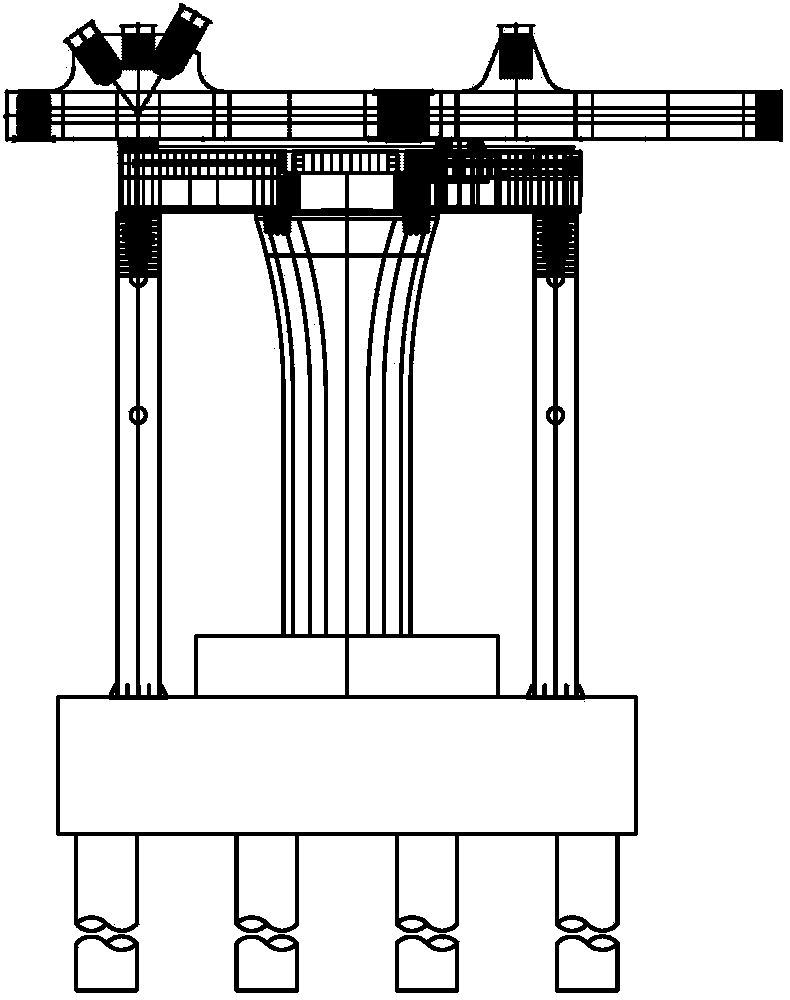

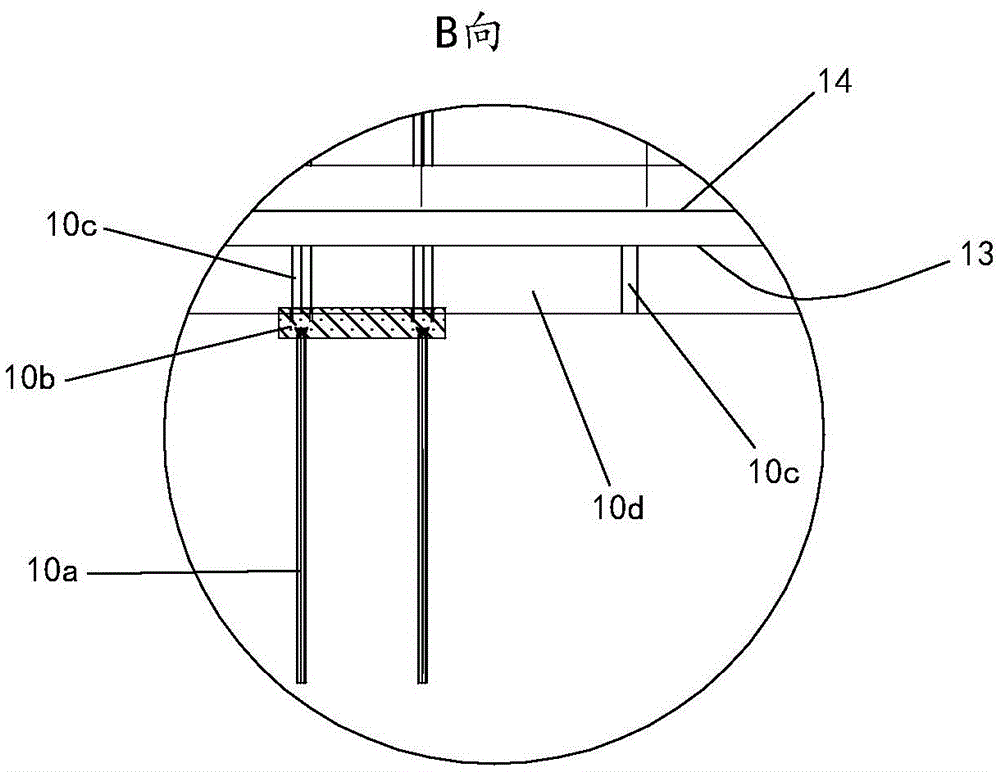

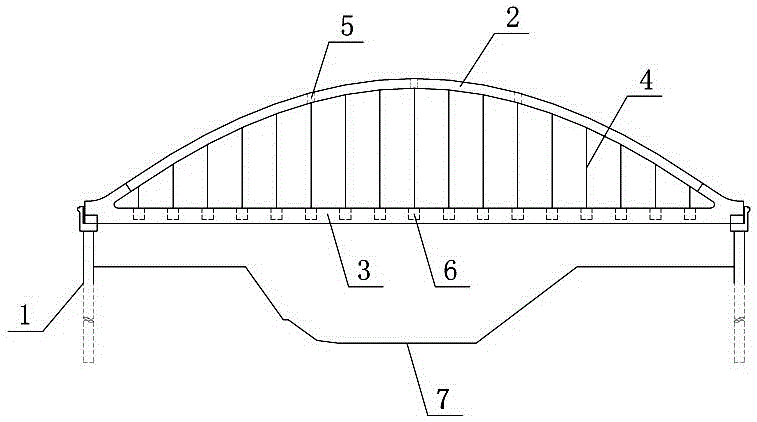

Integral lifting system and construction method for arch bridge ribs

InactiveCN102561191AReduce difficultyReduce working at heightsBridge erection/assemblySteel frameArch bridge

The invention discloses an integral lifting system and a construction method for arch bridge ribs. The integral lifting system comprises a pair of triangular steel frames, two lifting stations, arch rib brackets and an integral arch rib of an arch bridge, and a barge for conveying the integral arch rib. The triangular steel frames are fixedly rested on bridge piers and symmetrically disposed on two sides of main span of the arch bridge, an arch rib closure section in closure with the integral arch rib is disposed on the inner side of the arch bridge main span and close to the corresponding triangular steel frame, the lifting stations are disposed on the triangular frames respectively, the arch rib brackets are rested on the barge and support the integral arch rib, the lifting stations are connected with the integral arch rib through lifting steel stranded wires, the integral arch rib which is lifted up is in fixed closure with the arch rib closure sections, and accordingly the integral arch bridge is formed. The integral lifting system is adaptable to severe construction environments, and accordingly construction progress is quickened. The invention further provides the construction method for integral lifting of the arch bridge rib.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

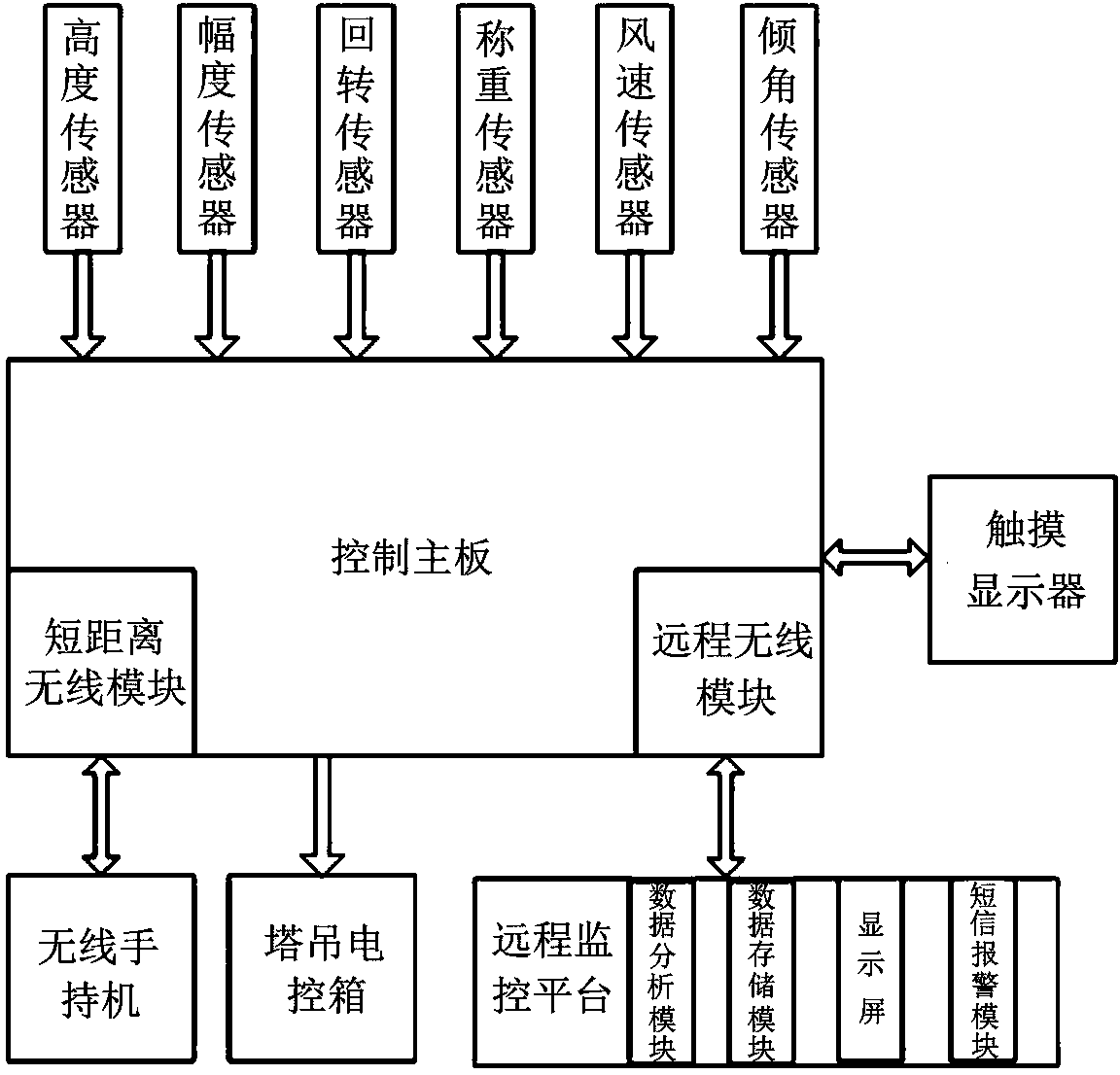

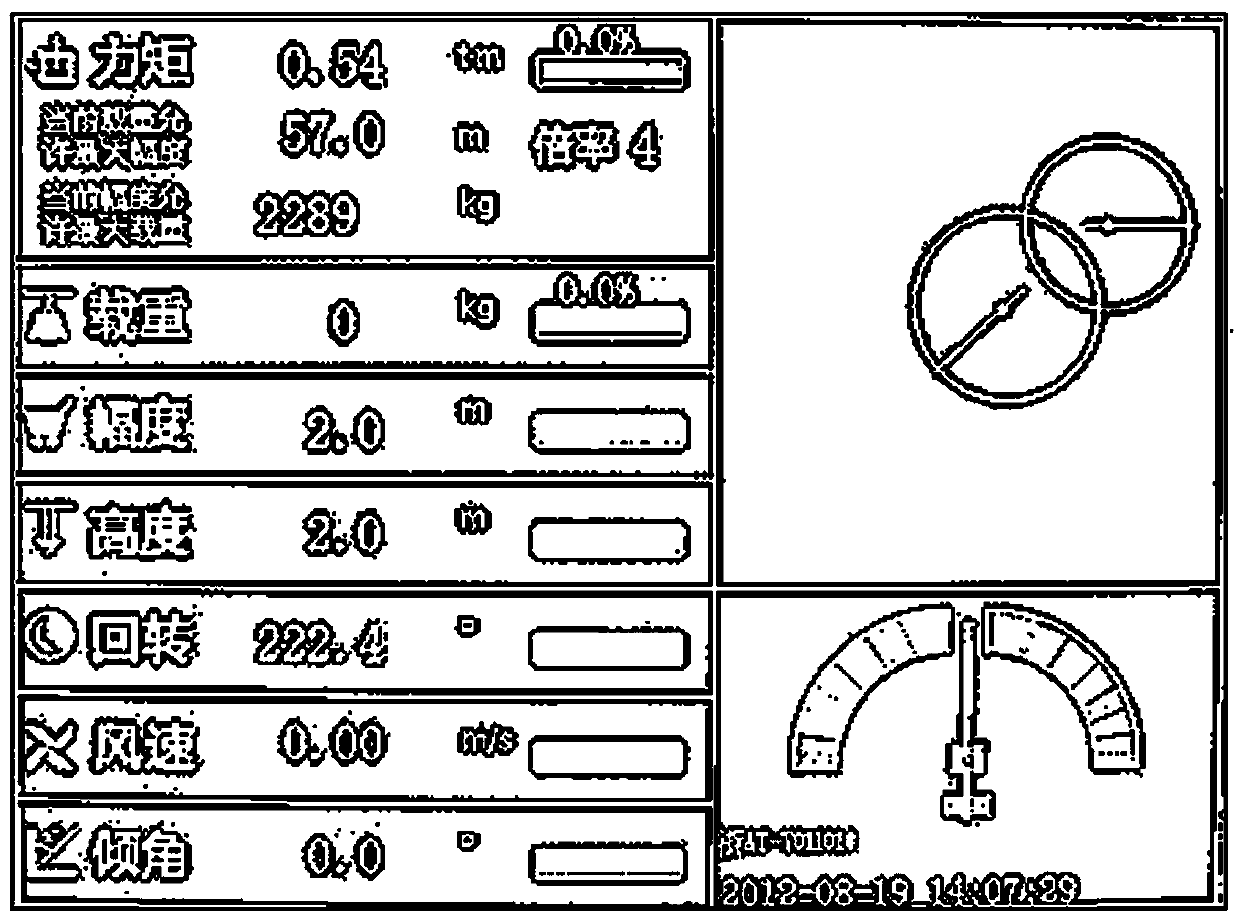

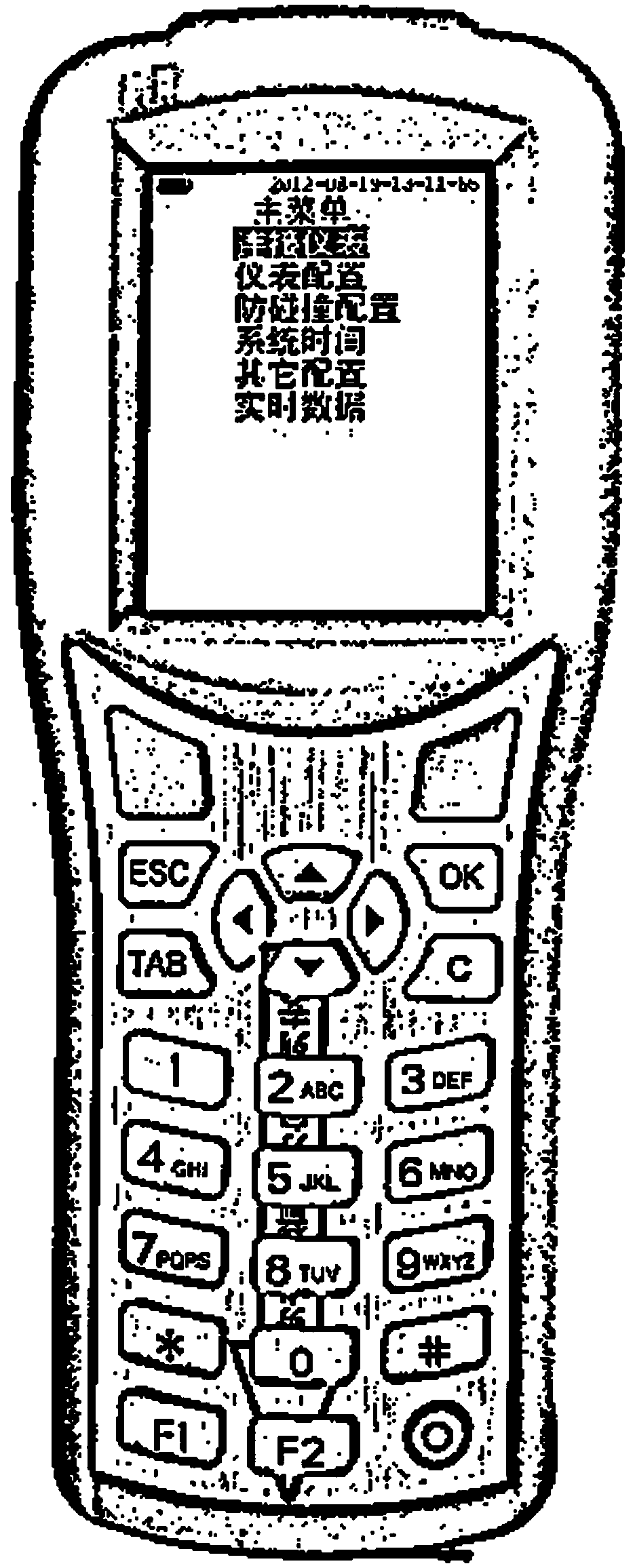

Tower crane safety monitoring system capable of carrying out remote parameter diagnosis

InactiveCN103420291AReduce working at heightsProtection securityCranesLoad-engaging elementsSystems designShortest distance

The invention relates to a safety monitoring system, in particular to a tower crane safety monitoring system capable of carrying out remote parameter diagnosis. The tower crane safety monitoring system capable of carrying out remote parameter diagnosis comprises a control mainboard, a sensor, wireless modules, a remote monitoring platform, a displayer, a tower crane electric cabinet and a wireless hand set, wherein the wireless modules comprise a short-distance wireless module and a remote wireless module. The tower crane safety monitoring system capable of carrying out remote parameter diagnosis has the advantages that due to the fact that the wireless hand set is designed, debugging and maintenance of the tower crane safety monitoring system are convenient, the frequency of aloft working of workers is reduced, and safety of the workers is protected; the remote monitoring platform can carry out analysis on reported false alarms and missed alarms, and can timely send alarm information to related personnel through a short message platform; the control mainboard can detect abnormal signals of the sensor, and can timely discover a fault of the sensor; the remote monitoring platform can carry out diagnosis to judge whether parameters of the control mainboard are falsified, and can effectively prevent man-made amplification of an alarm threshold value.

Owner:浙江海康科技有限公司

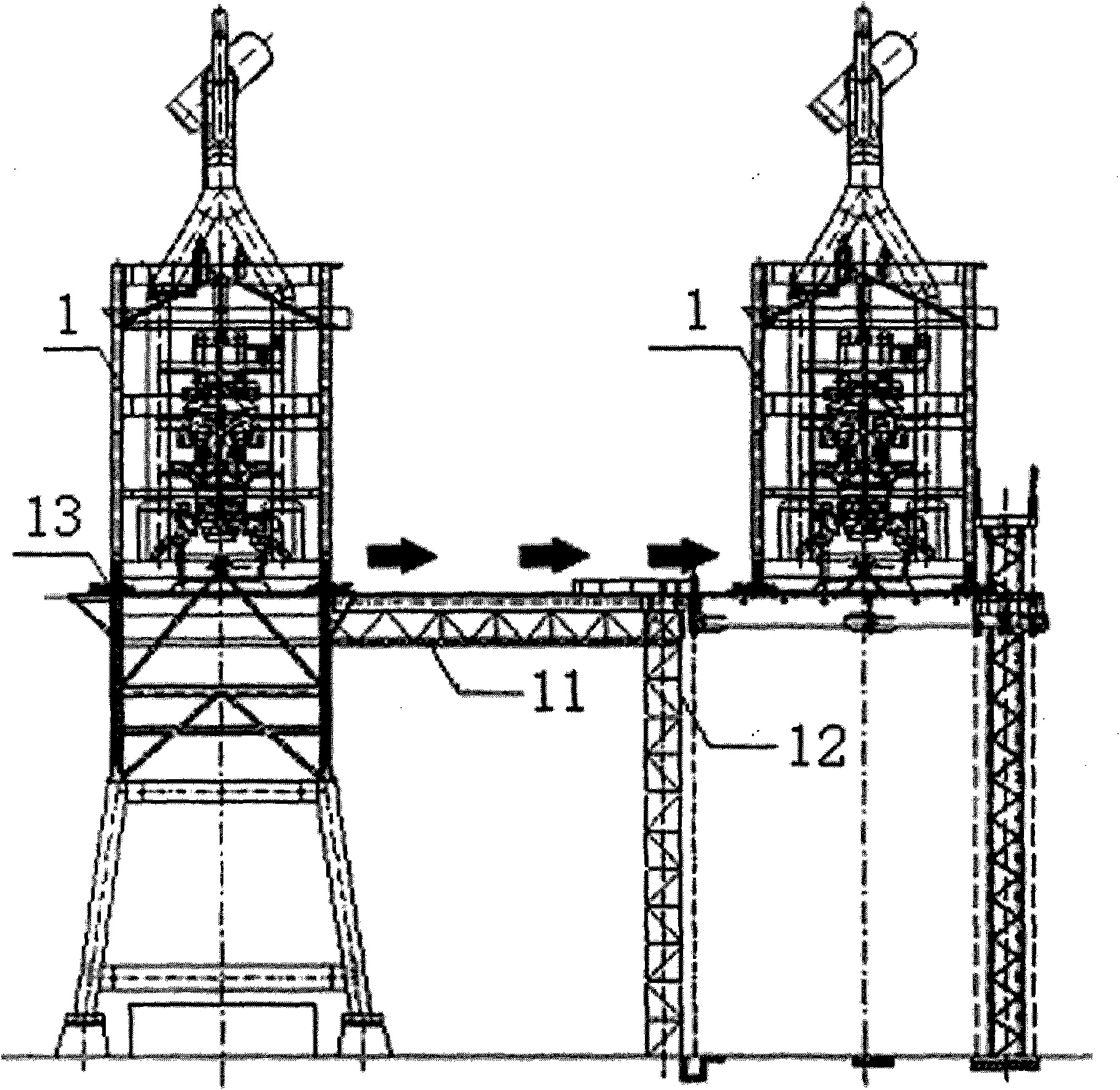

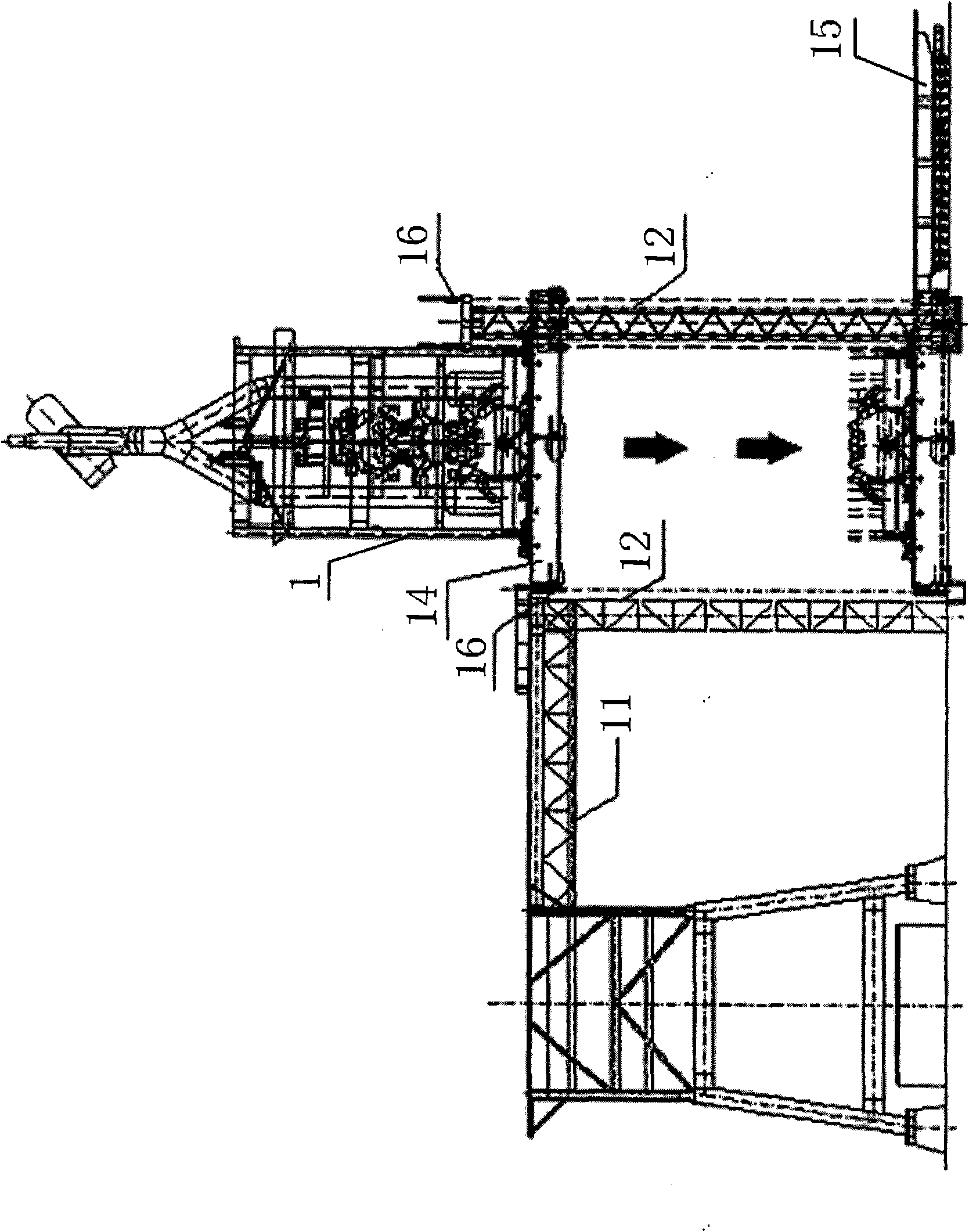

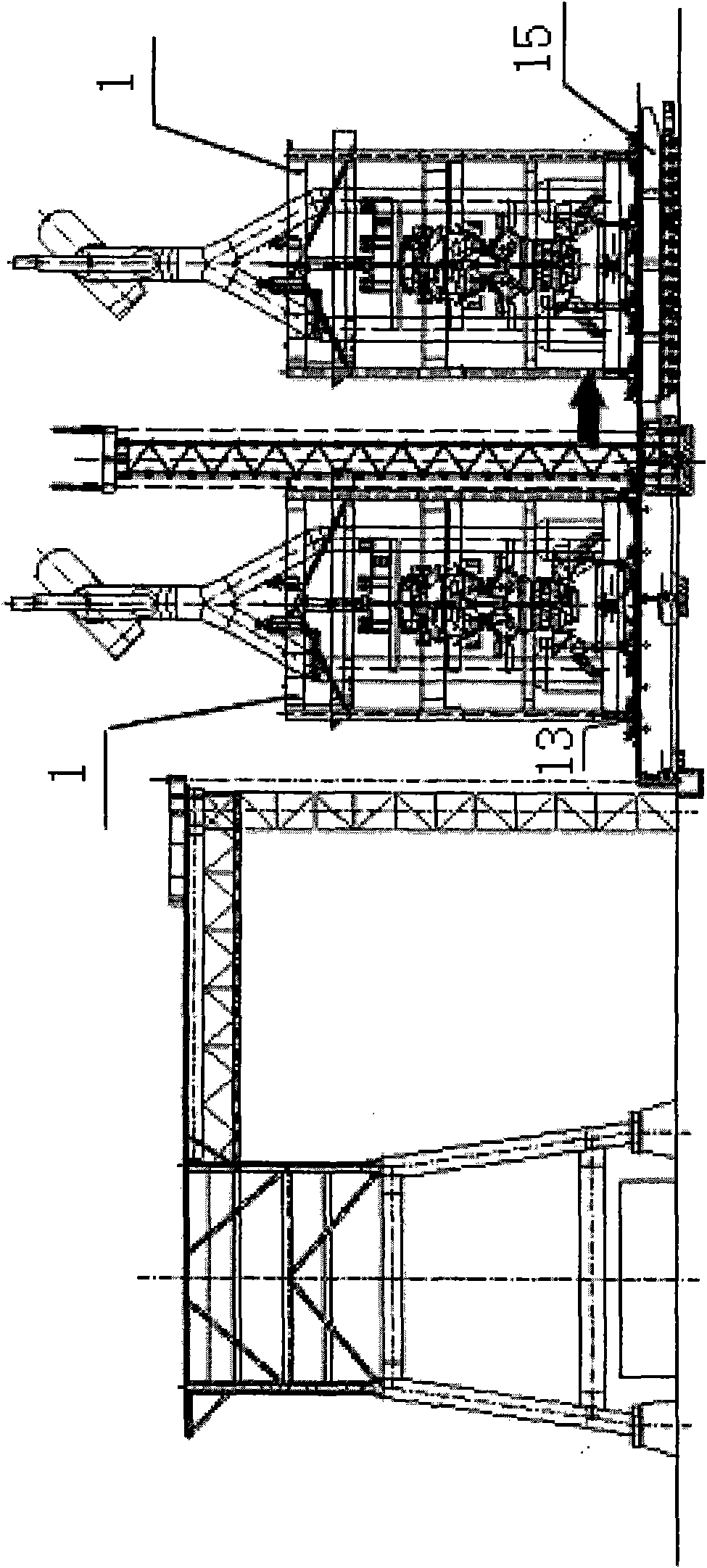

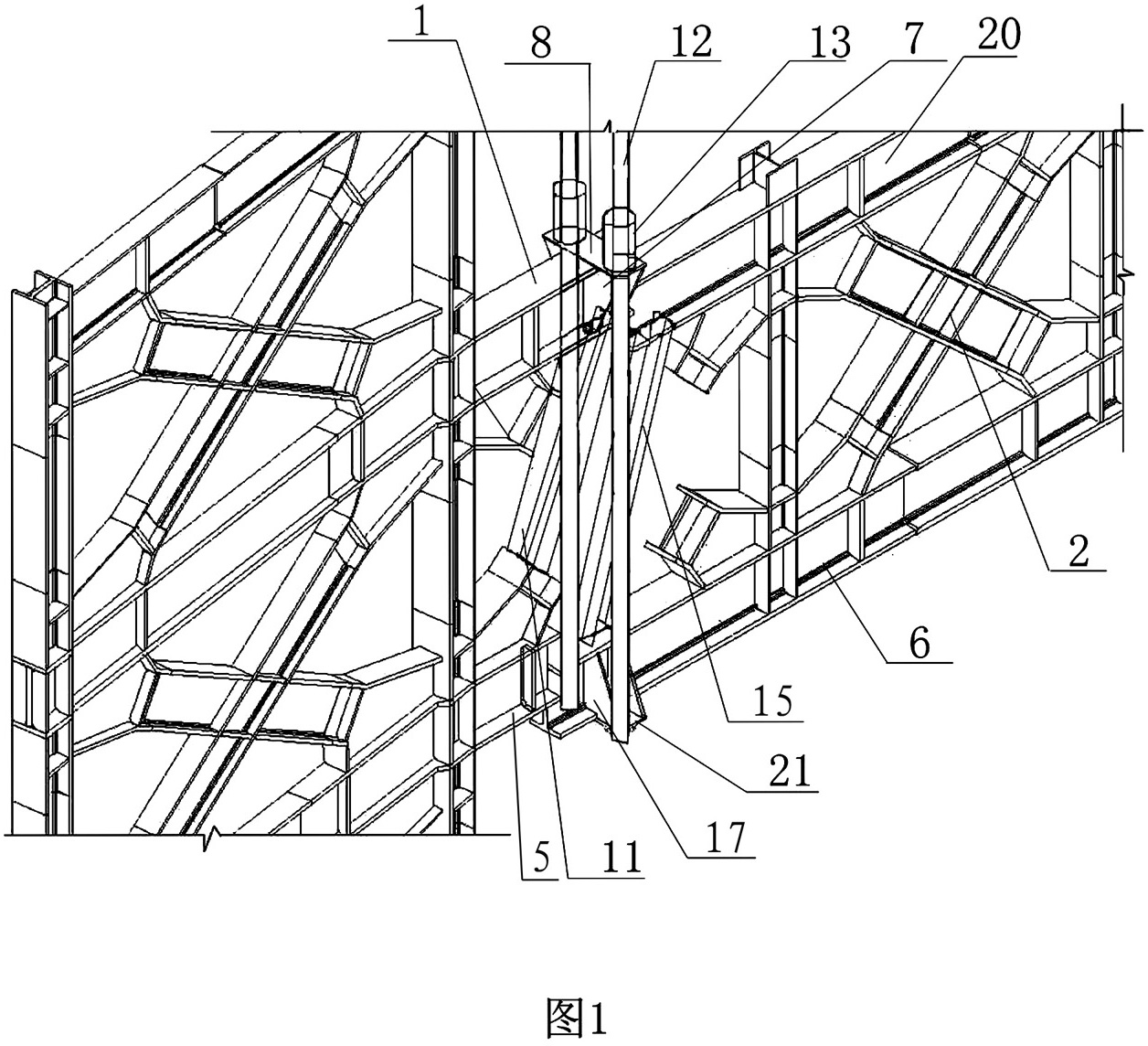

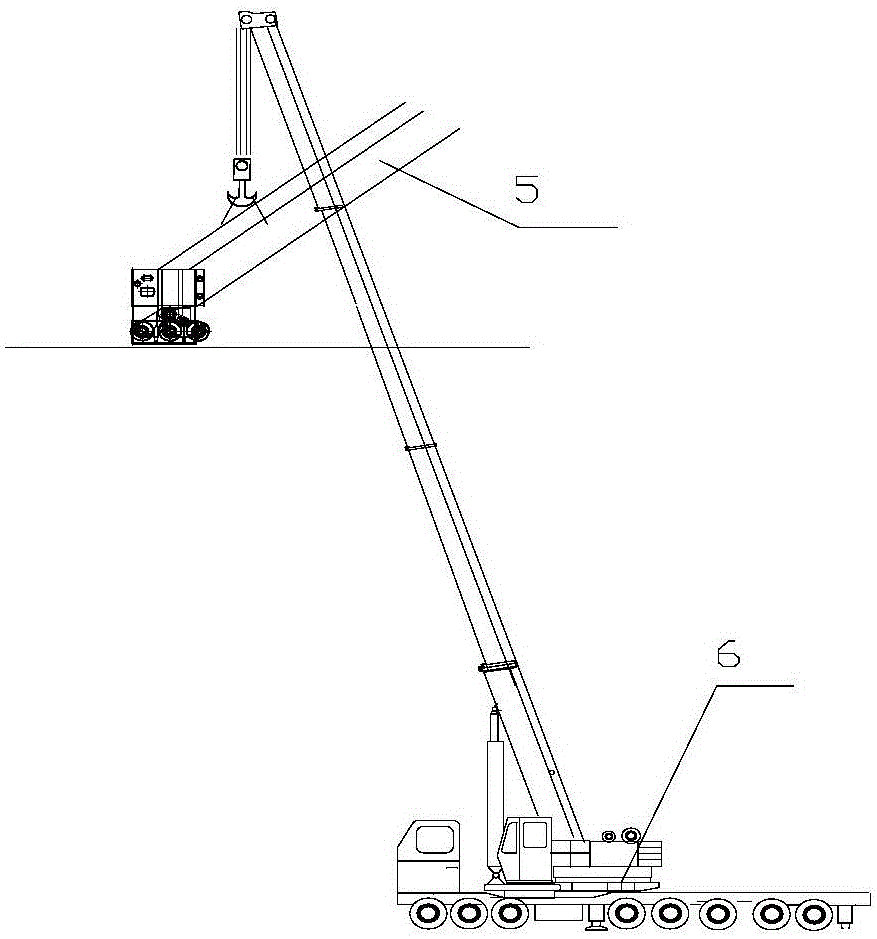

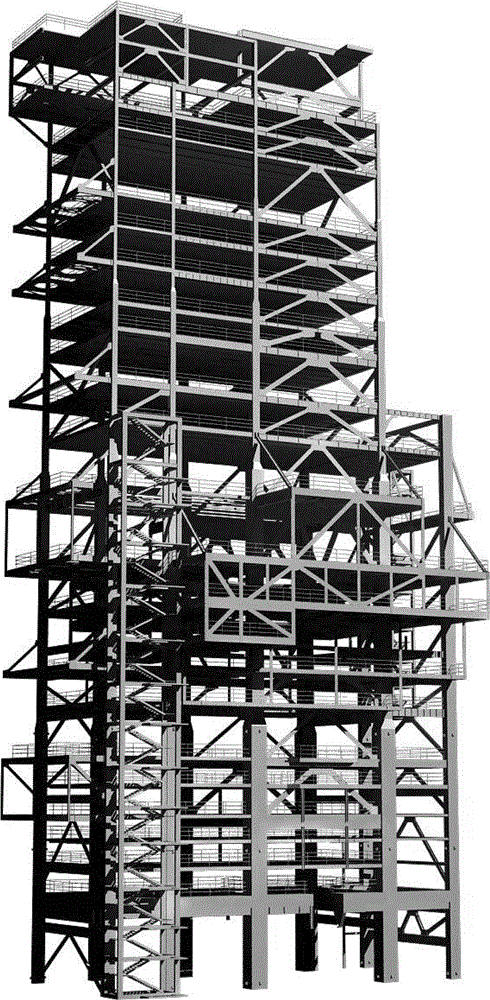

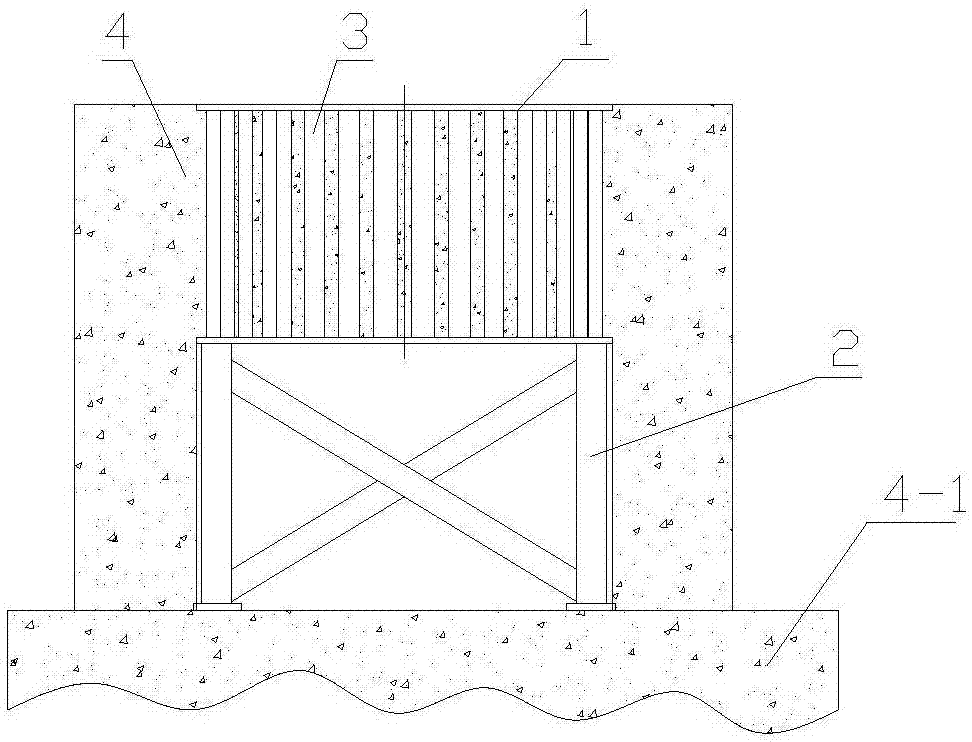

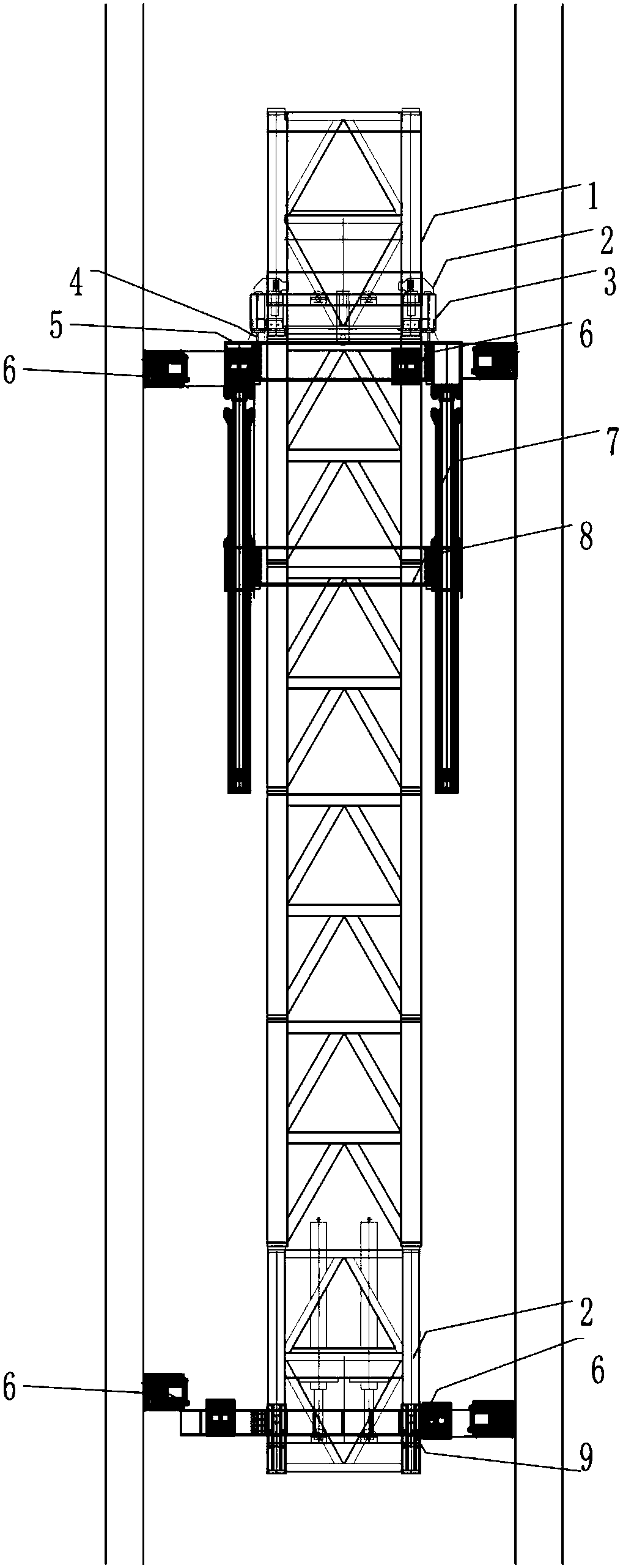

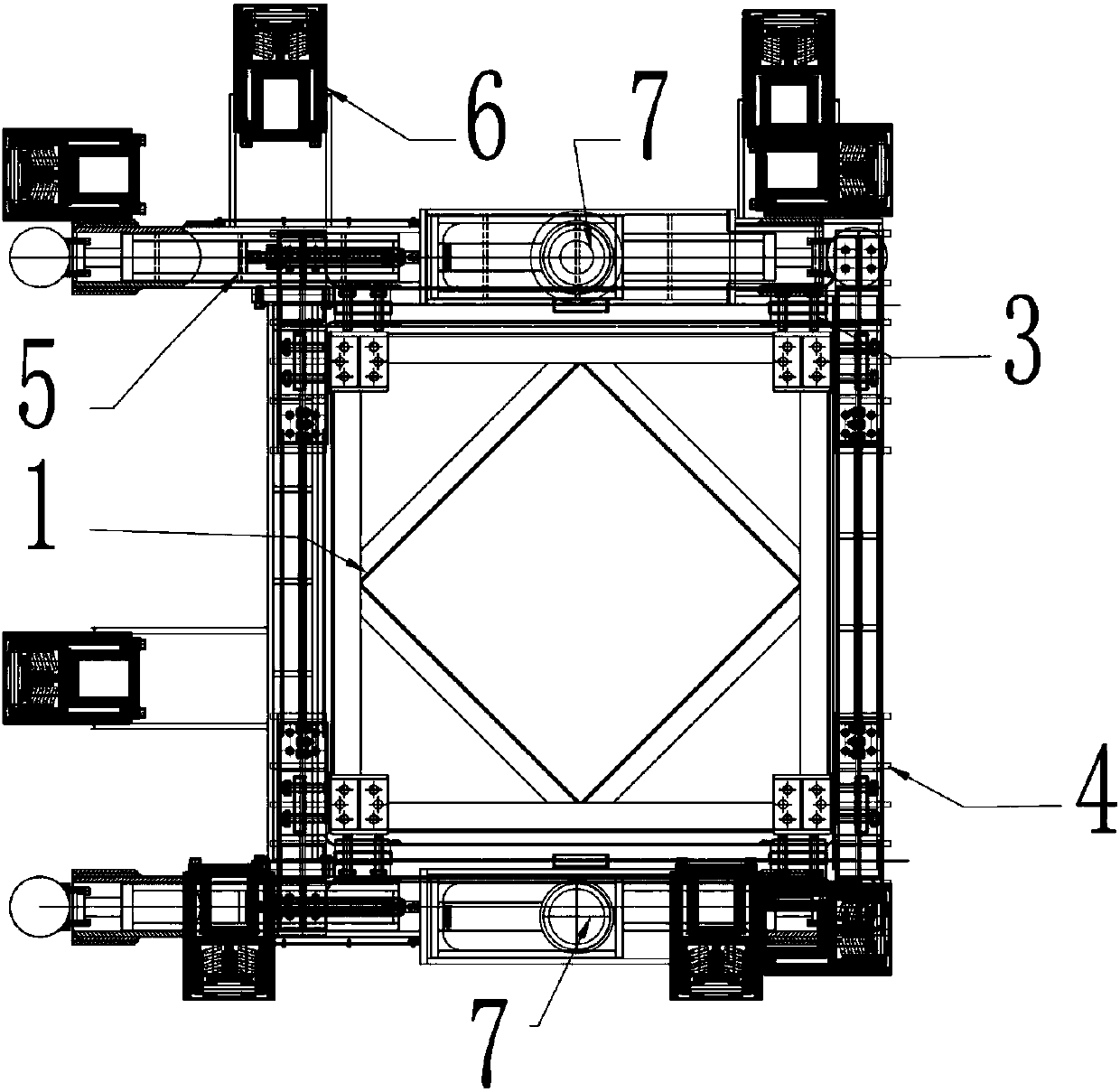

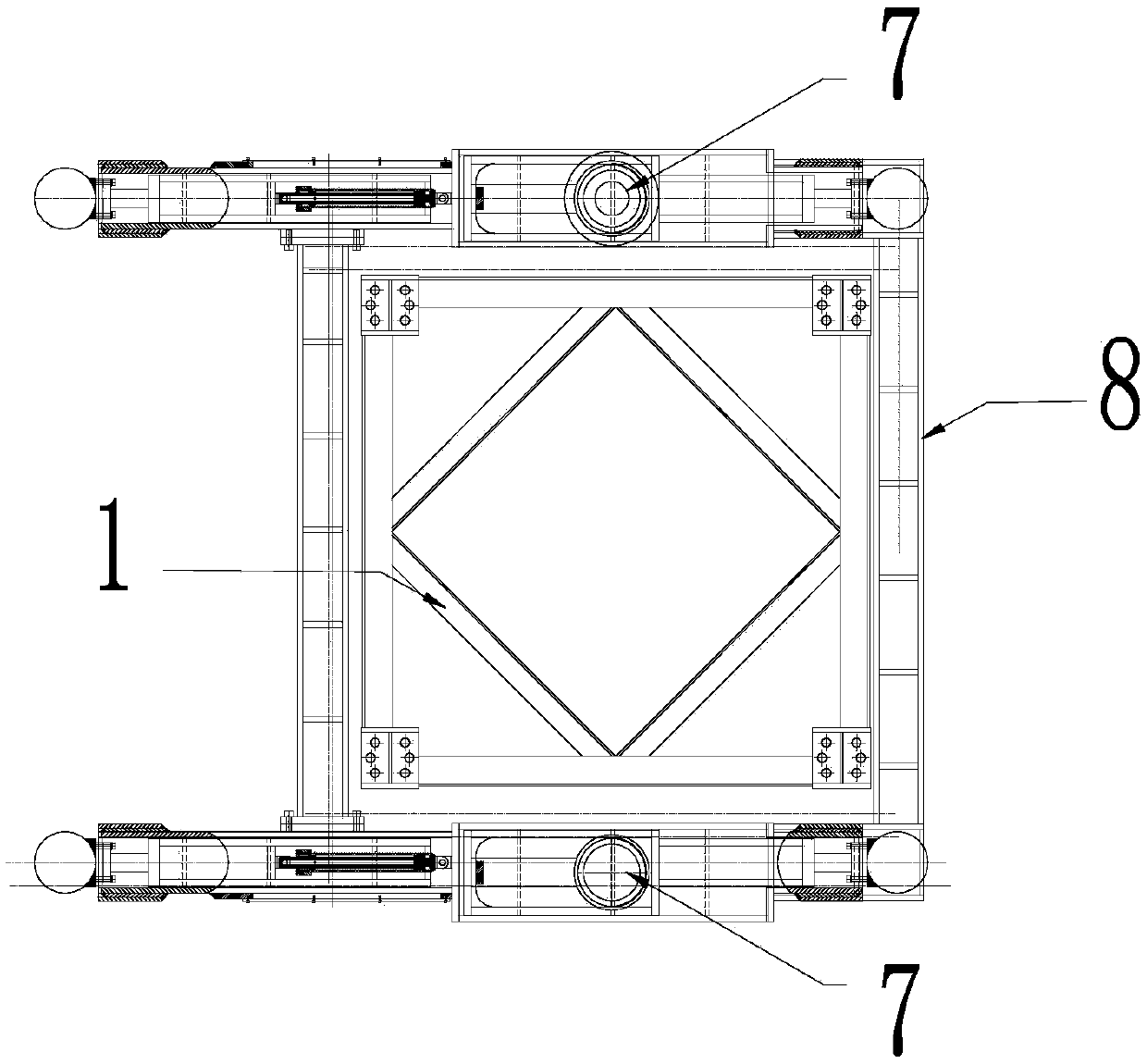

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

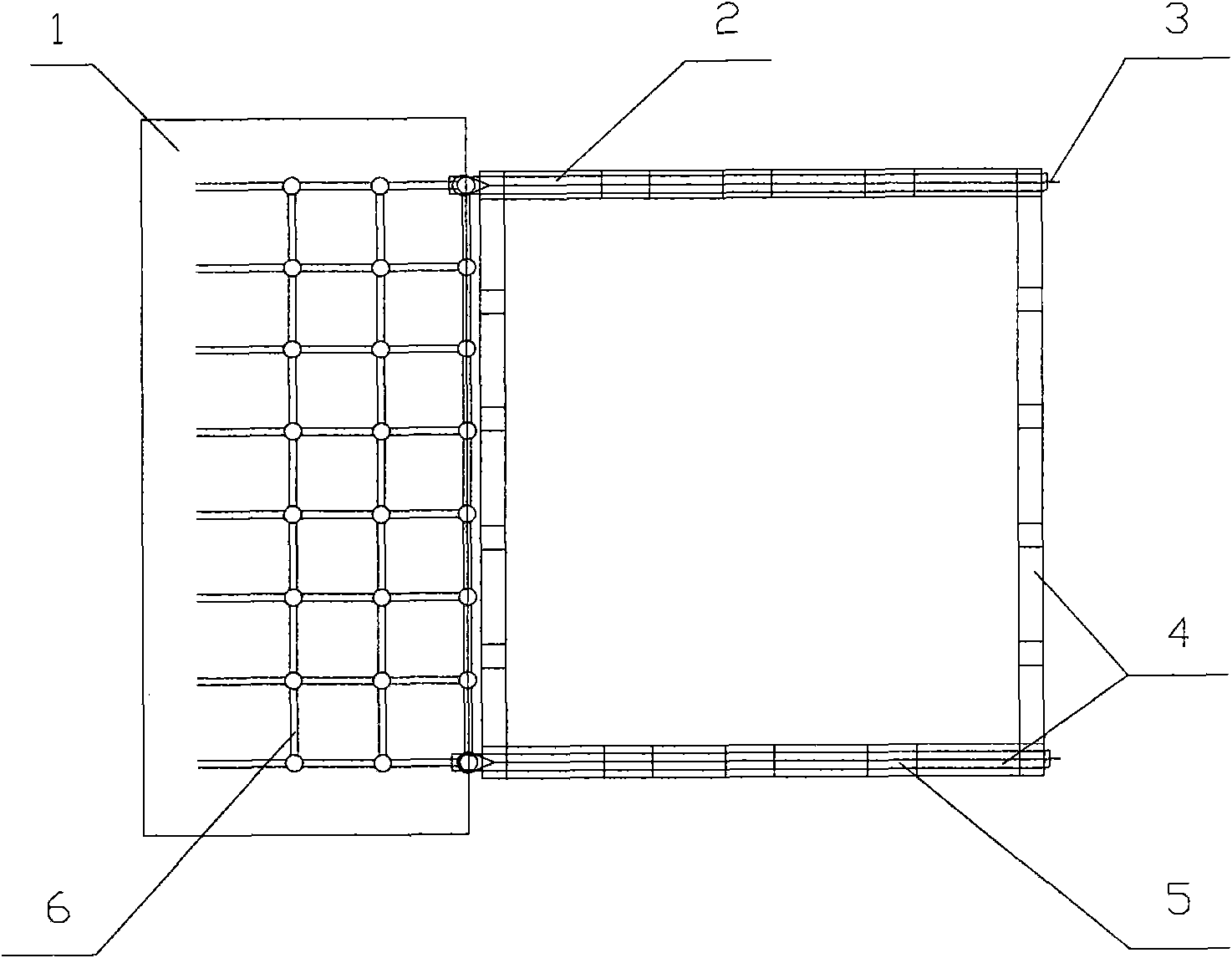

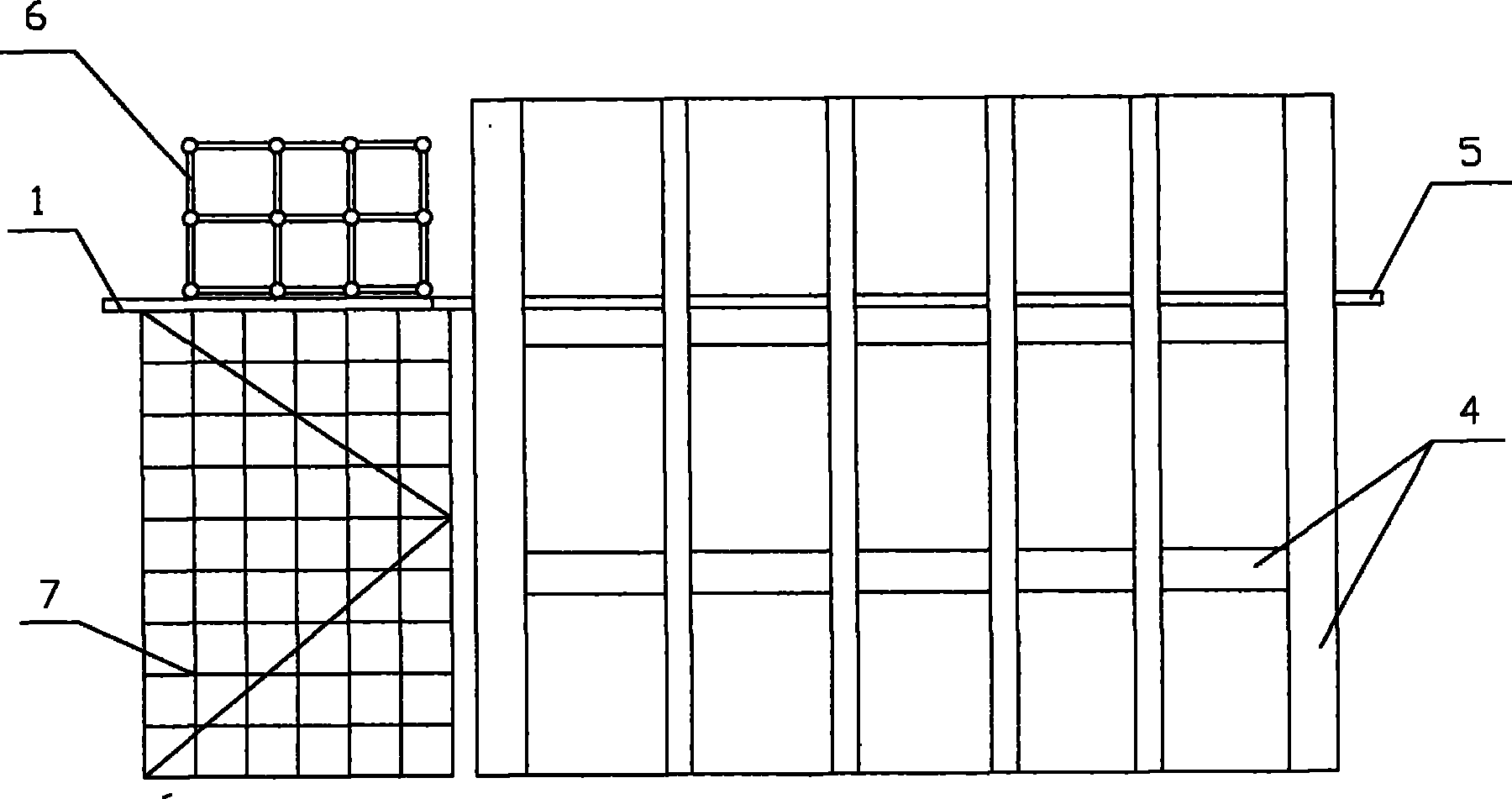

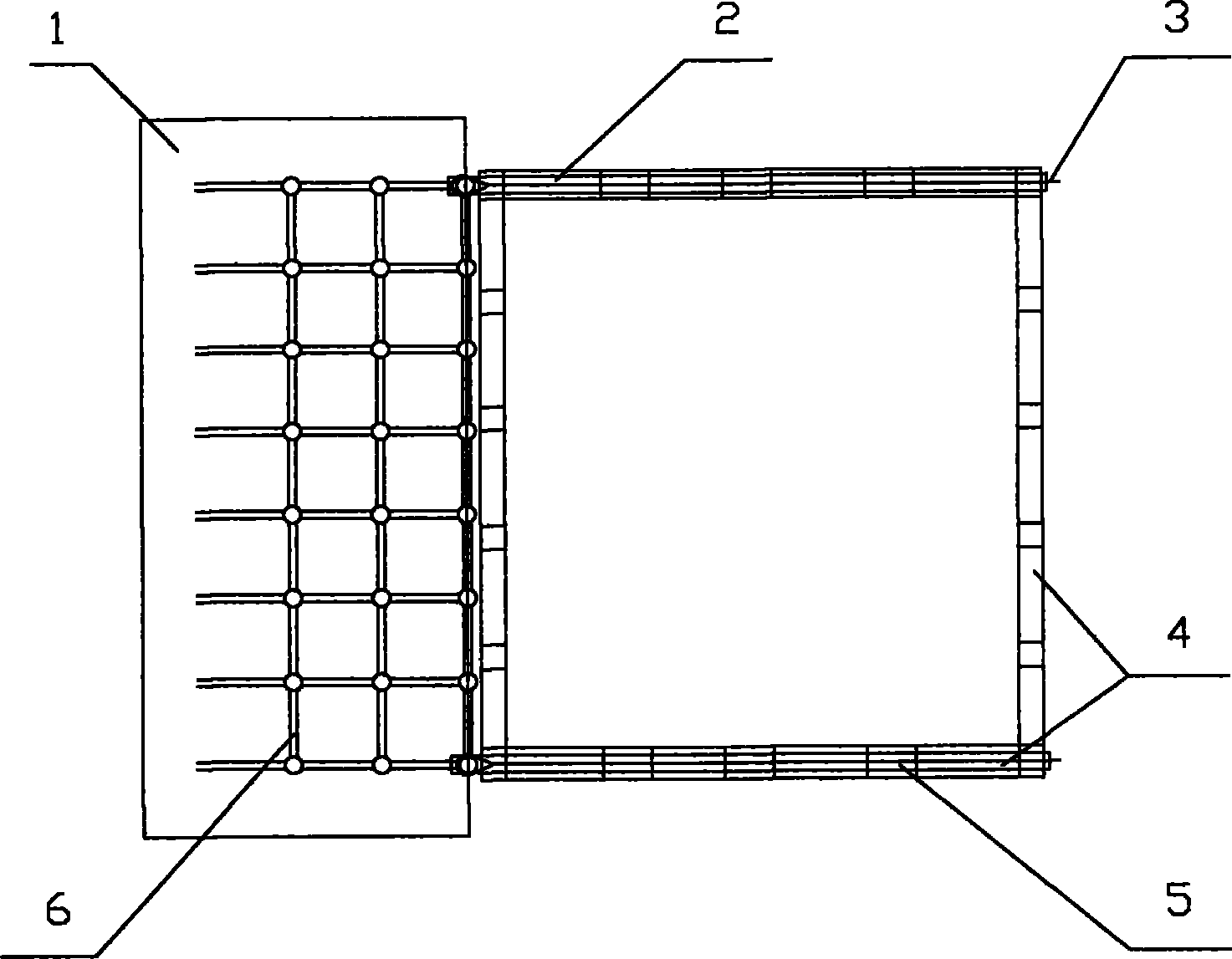

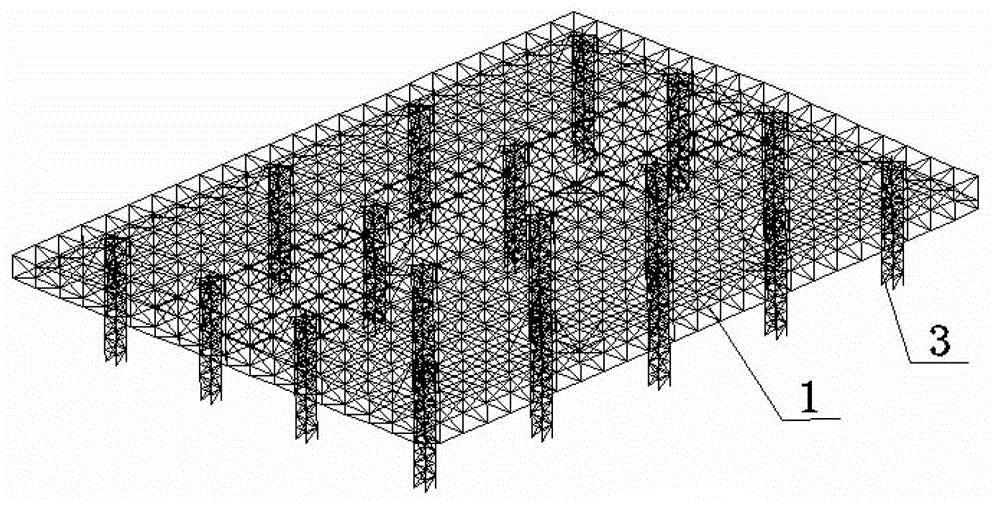

Steel net rack installation method for integrally improving high-altitude moving and positioning

ActiveCN102877547ASmall change in bending momentSmall amount of deformationBuilding constructionsEngineeringBuilding construction

Owner:北京市机械施工集团有限公司

Through concrete-filled steel tube tied-arch bridge erection construction method

InactiveCN105672134ALittle impact on navigationEasy constructionBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a novel through concrete-filled steel tube tied-arch bridge erection construction method. A through concrete-filled steel tube tied-arch bridge is constructed in the mode that steel tube arches and tie bar stiff frameworks are spliced and welded on site and the bridge is hoisted integrally. The construction method comprises the following steps that site selection is conducted in a position close to the bridge site, and scaffolds are subjected to high-precision setting-out and on-site splicing; steel-pipe arch ribs and the tie bar stiff frameworks are spliced on the scaffolds on site, two arches and tie bars are welded into a whole through wind braces and temporary crossbeams, and a temporary steel tube tied-arch bridge is formed; the temporary steel tube tied-arch bridge which is spliced integrally is hoisted in place through a floating crane; and the tie bars, arch supports and end crossbeam concrete are poured in batches, lifting rods are installed in batches, middle crossbeams are installed in batches, and tie bar prestressing tendons and all the prestressing tendons of the end crossbeams are tensioned. By the adoption of the scheme, a conventional construction method that steel tube arc ribs are hoisted in segments and deck beams are hoisted through temporary cables or supports is replaced, and the construction method has the advantages that construction is convenient, high-altitude work is reduced, structure shapes and construction quality are easy to control, and the influences to the surrounding environment and channel navigation are small.

Owner:HOHAI UNIV +1

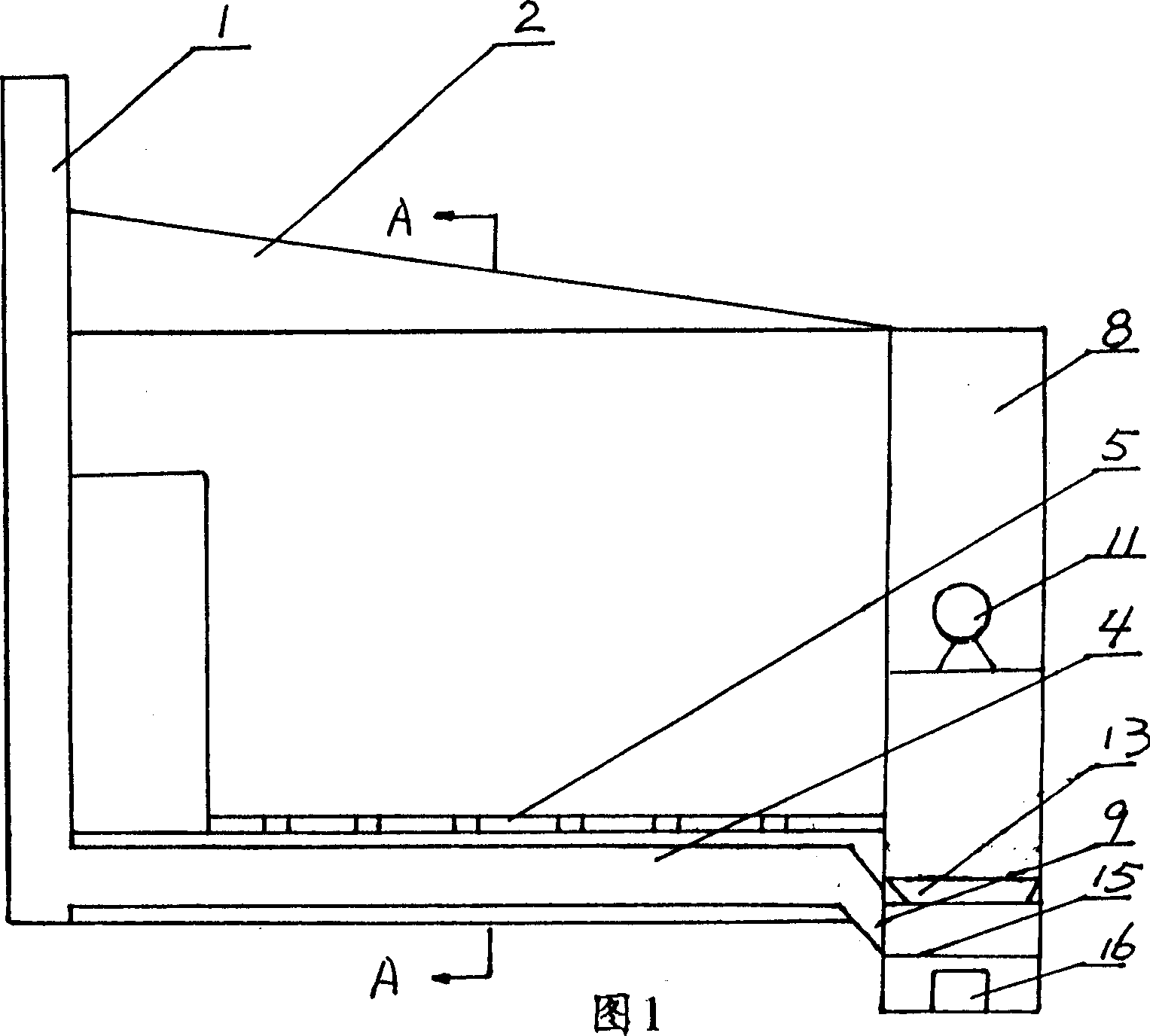

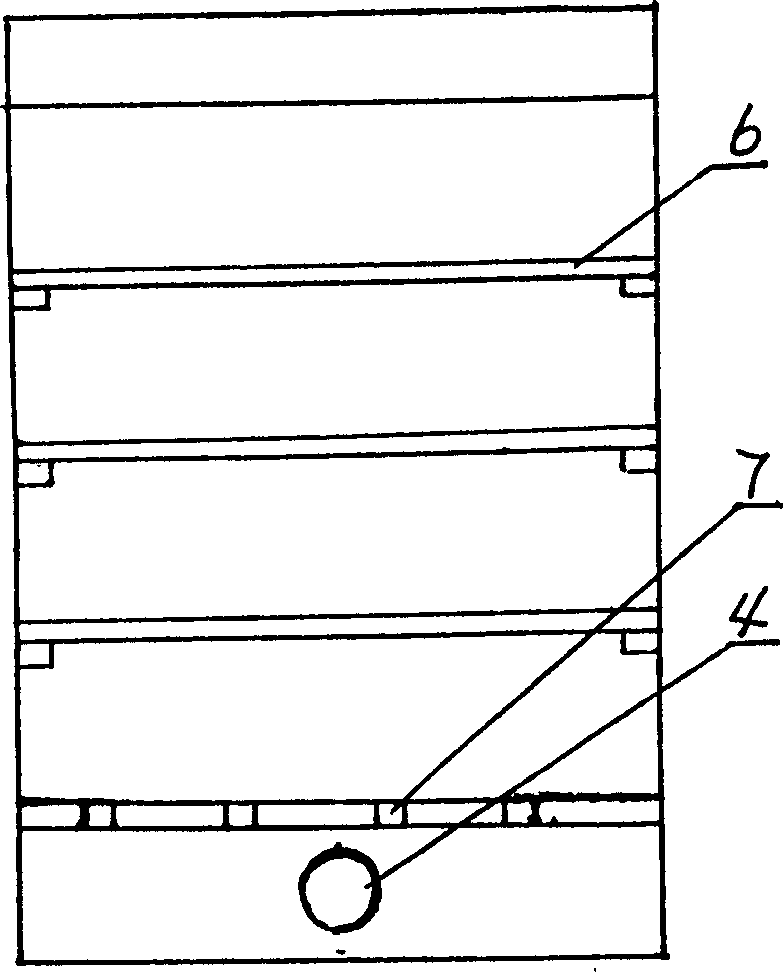

New-type tobacco flue-curing room and the tobacco flue-curing process

InactiveCN1403035ACompatible with growth physiological characteristicsSelection quality improvementTobacco preparationThree stageSmall footprint

Owner:刘志峰

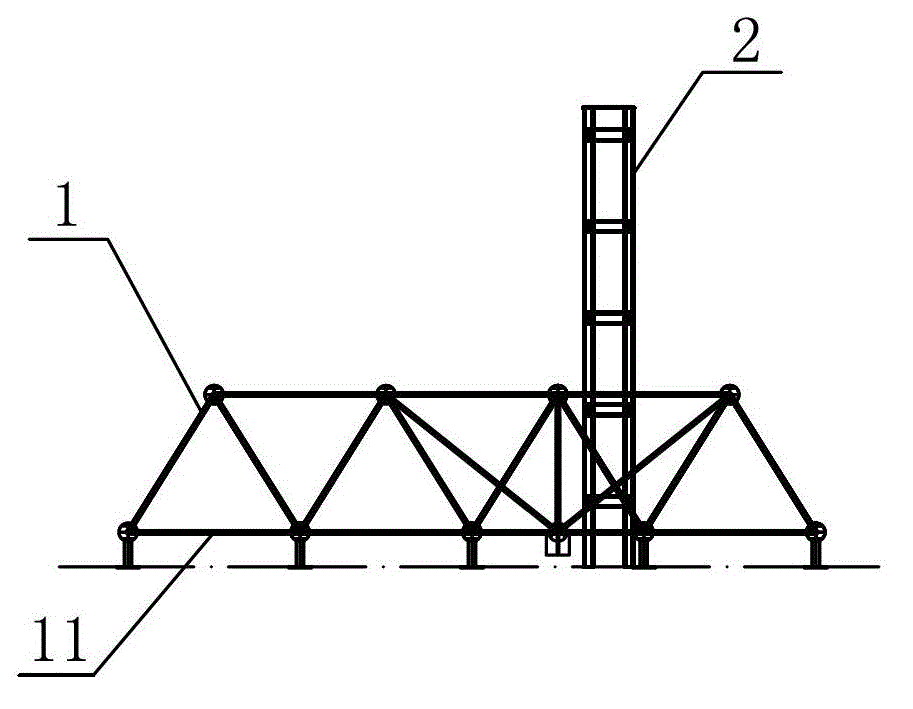

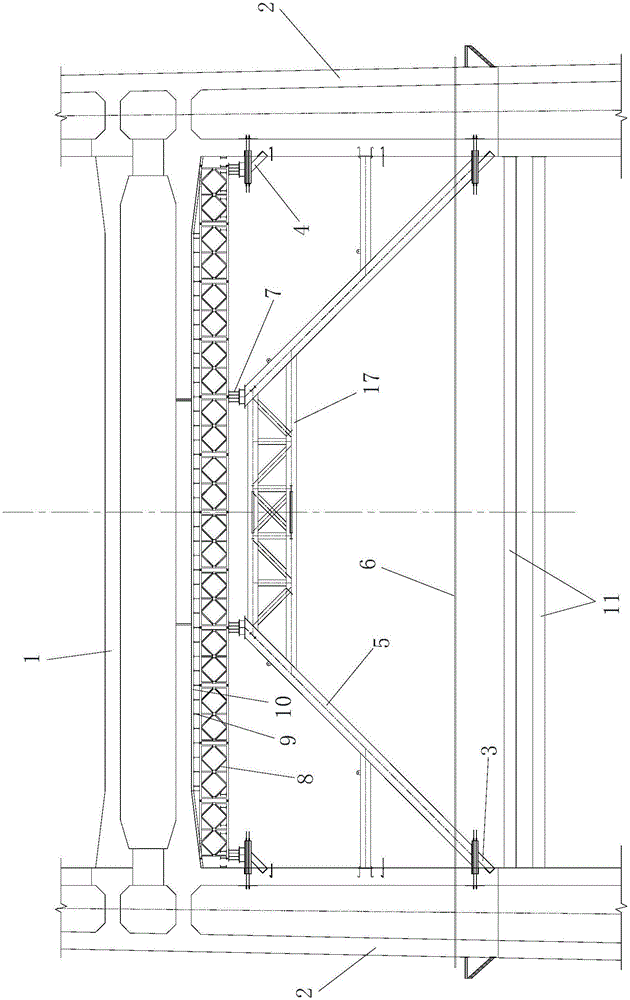

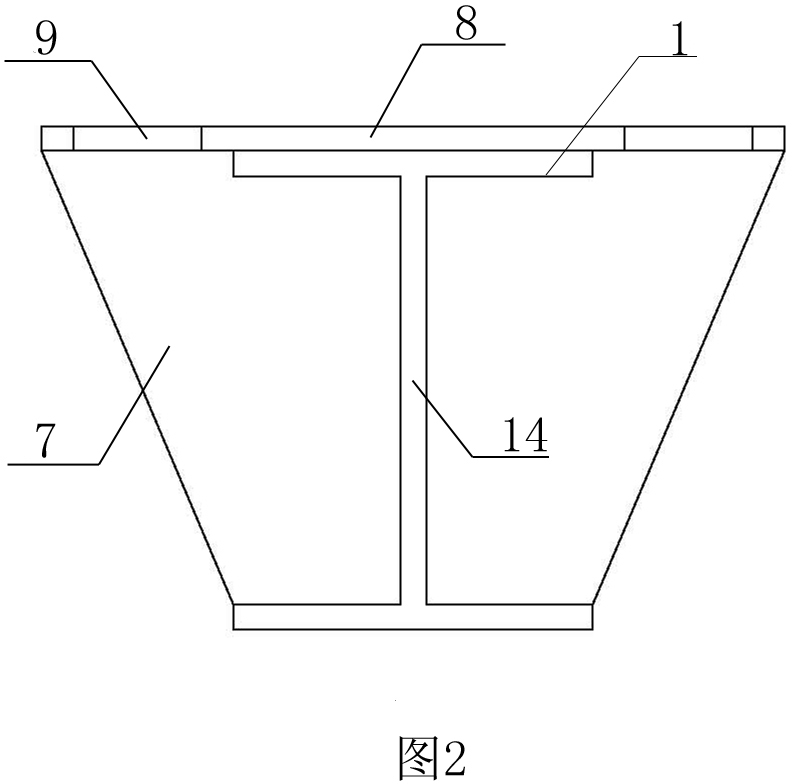

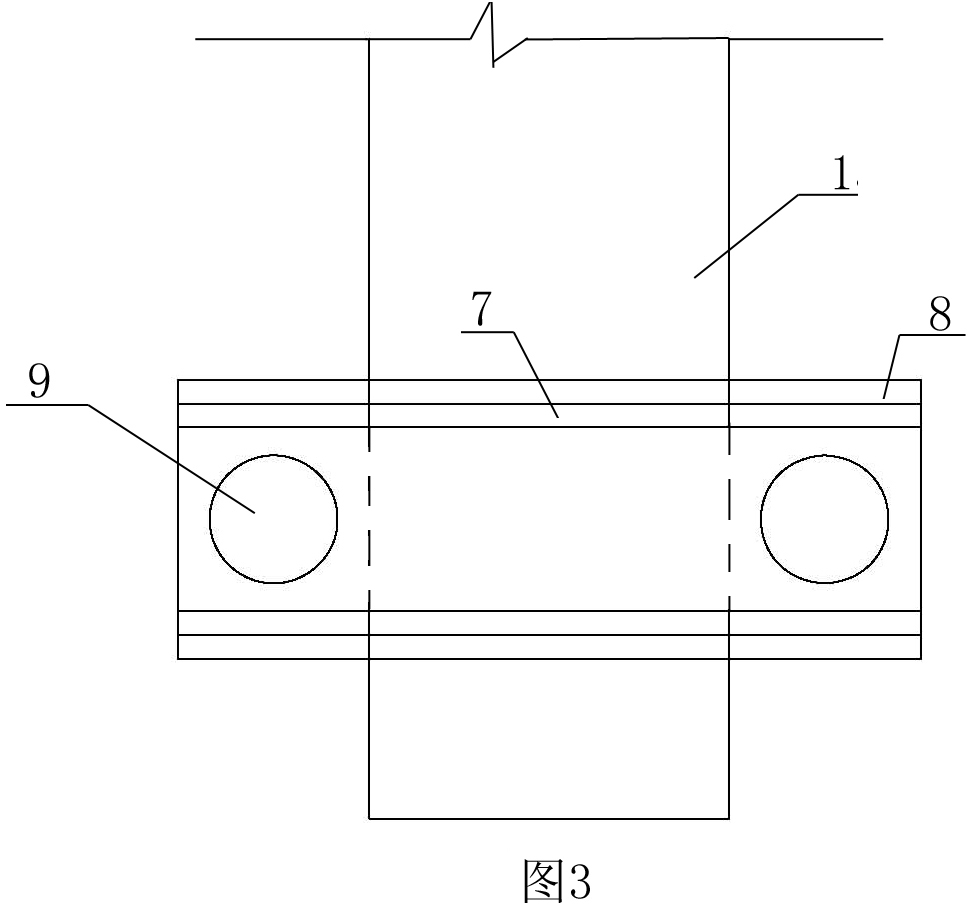

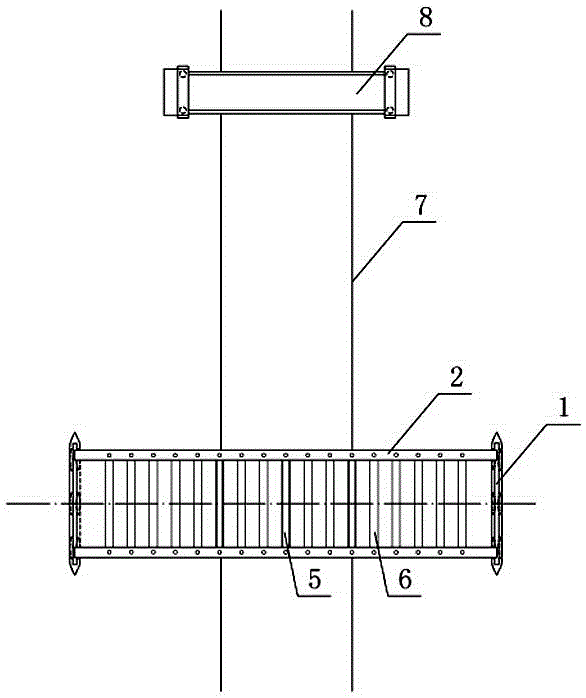

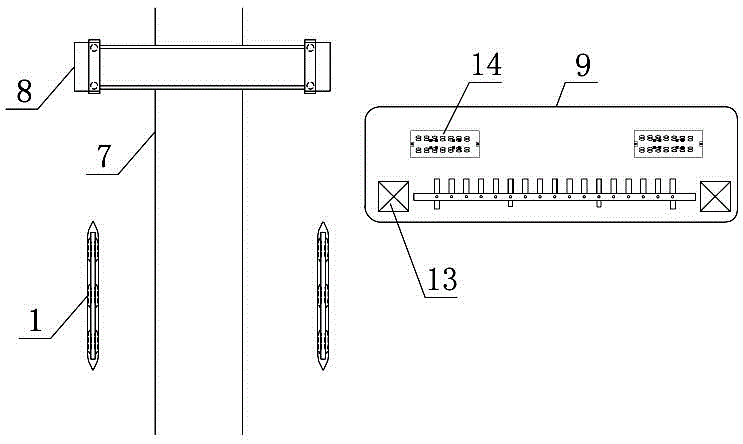

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

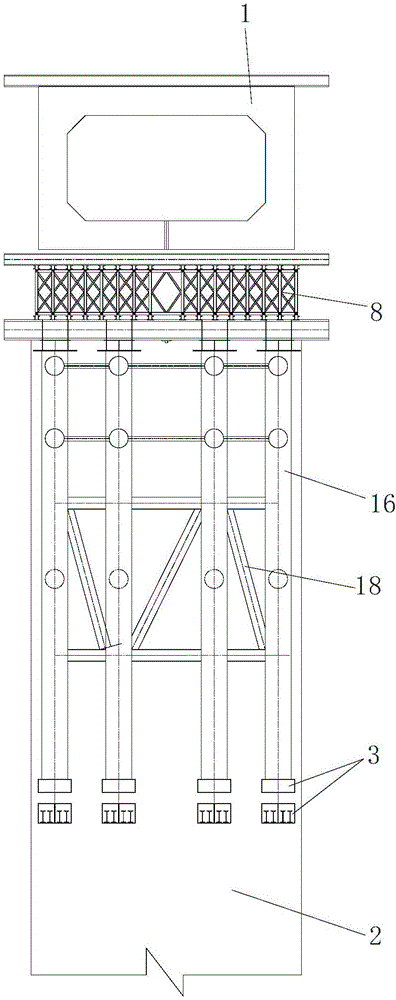

High-rise long-span door type truss integral lifting device and construction method thereof

InactiveCN102071814ASimple structureEasy to implementBuilding repairsLifting devicesEngineeringLong span

The invention relates to a high-rise long-span door type truss integral lifting device and a construction method thereof. The device comprises a run-through jack, a steel strand and an anchoring structure, wherein the anchoring structure consists of an upper anchoring structure which is fixed on an arranged upper truss bracket and a lower anchoring structure which is fixed on a lifted truss; the run-through jack is fixed on the upper anchoring structure and is symmetric on the two sides of the arranged upper truss bracket; and the run-through jack and the steel strand integrally lift the lifted truss to a position which is flush with the arranged upper truss bracket. A whole-course dynamic stress monitoring mode is adopted for monitoring while the integral lifting is performed by a lifting unit. In auxiliary measures of the method, an operating scaffold for ground assembly and an overhung scaffold at a lifting point position are only required to be erected, so the measures are extremely few; and the integral lifting process is controlled by a jack travel control computer; and the conventional measurement monitoring and the stress strain monitoring are performed, so the construction safety and the structural safety are guaranteed. The device can be widely applied to door type truss integral lifting construction.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

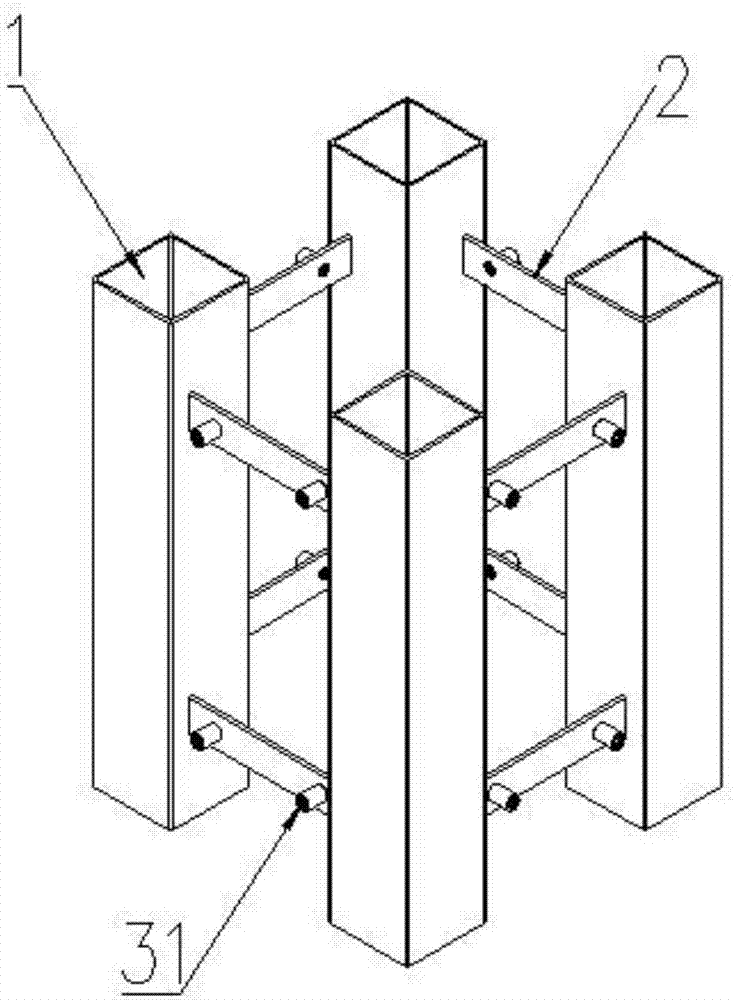

Steel pipe-batten plate combined building column and construction technology thereof

PendingCN107227822AReduce steel consumptionImprove economyStrutsBridge structural detailsReinforced concrete columnArchitectural engineering

The invention provides a steel pipe-batten plate combined building column and a construction technology thereof. The steel pipe-batten plate combined building column comprises a column skeleton and formworks detachably mounted outside the column skeleton, wherein the column skeleton comprises square steel pipes arranged at corners of the column skeleton and batten plates arranged between adjacent square steel pipes; the batten plates are arranged in the vertical directions of the square steel pipes according to certain intervals. The square steel pipes and the batten plates are combined to form the column skeleton, the steel pipe is arranged at each corner of the whole column skeleton, the formworks are arranged among the steel pipes, and then concrete is cast in place to form the steel-concrete combined column; the steel pipes are arranged at the corners of the column skeleton, while only batten plates are arranged at the middle positions of the column skeleton, so that when a beam is connected with an independent column, steel bars can freely extend into the column body and thus a fighting phenomenon of steel bars in the conventional reinforced concrete column is avoided; after the concrete is poured, a whole is formed, so that the rigidity in a node area is better.

Owner:SHANGHAI OPEN STEEL JOIST

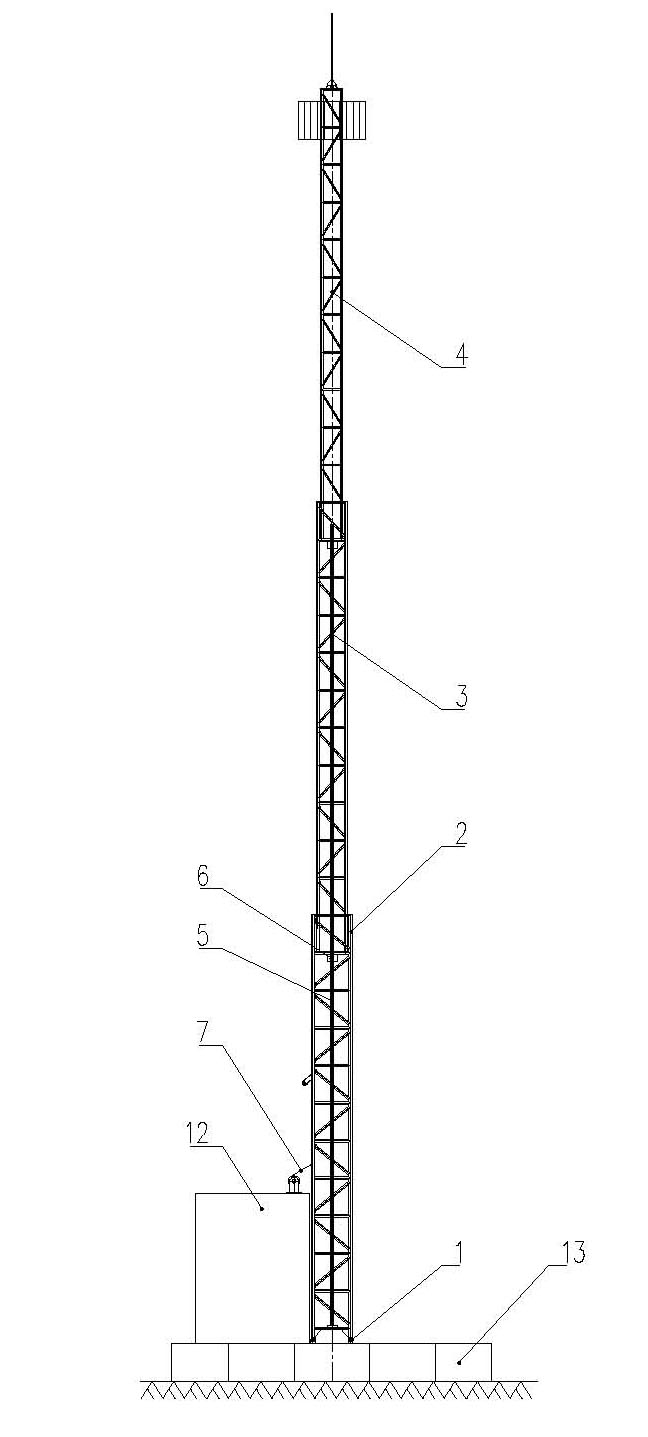

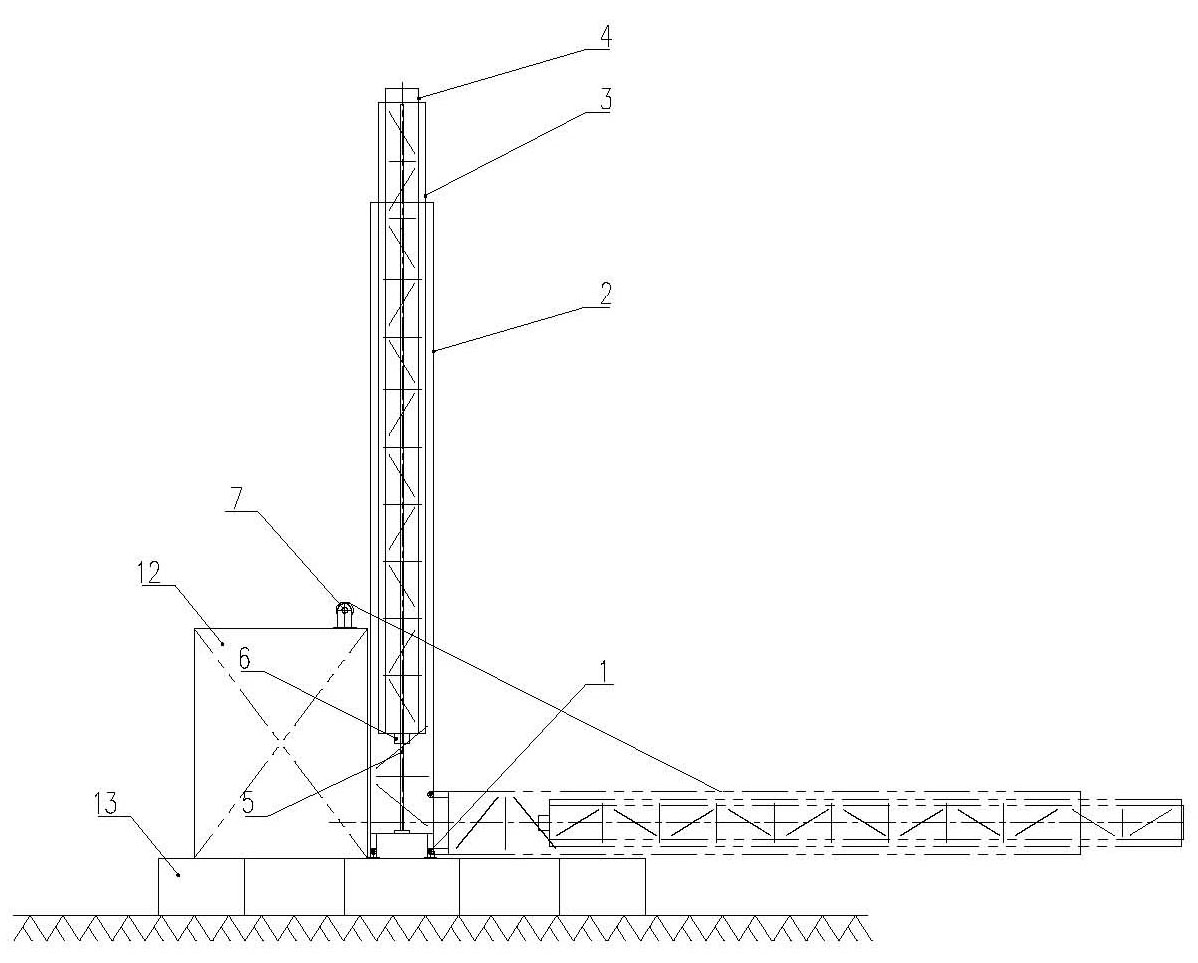

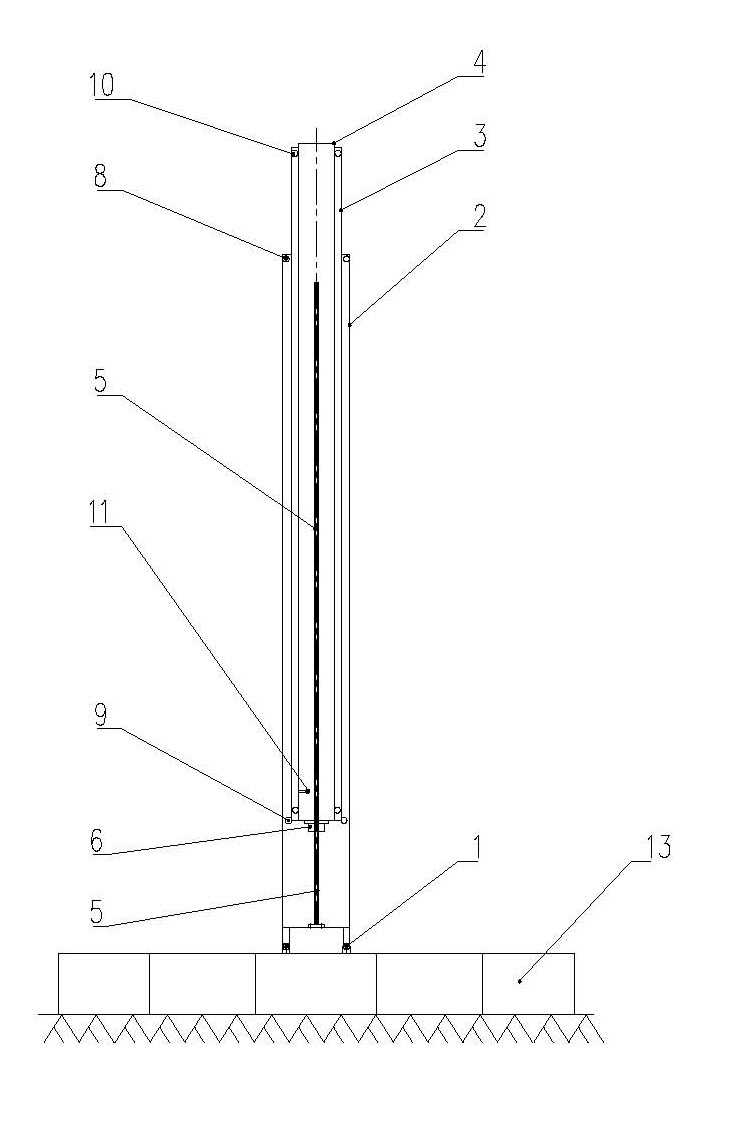

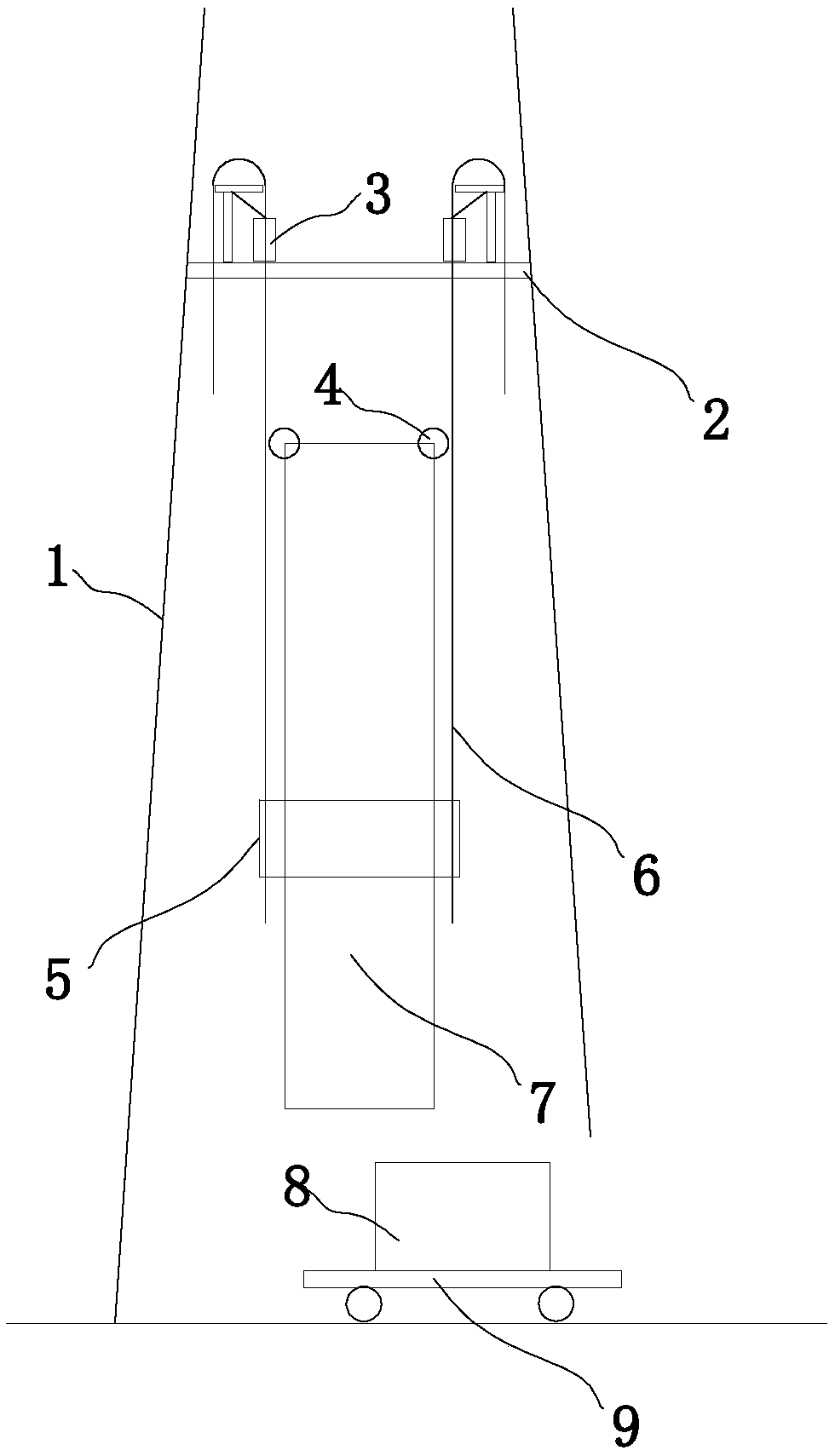

Elevator socket-type tower body, mobile communication base station and mounting method for tower body

InactiveCN101915007ALifting is safe and reliableEasy to moveTowersIndustrial buildingsReducerEngineering

The invention relates to an elevator socket-type tower body and a mobile communication base station. The tower body is formed by connecting a plurality of sockets; a lifting device lifts the sockets of the tower body; the lower part of the tower body is connected with an integrated combined machine room or is connected with a standardized container type machine room; and a foot hinged support on the lower part of the tower body and the machine room are fixedly connected with the base. The elevator socket-type tower body, the mobile communication base station and a mounting method for the tower body have the advantages that: the tower body is a folded lifting tower body which is formed by connecting the plurality of sockets, and can be erected by using a starting device after being assembled on site, so that the assembly is convenient and aerial work is reduced; the sockets of the tower body are lifted by using the lifting device which consists of a lifting screw rod, a lifting nut, a worm speed reducer and a motor, so safety and reliability are achieved; the tower body and the integrated combined machine room are connected into a whole so as to increase the rigidity and stability of the whole; and by using the modularized detachable movable base, the whole communication tower is convenient to move without the fixed site and has low manufacturing cost.

Owner:上海同演建筑科技有限公司 +1

Continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires

InactiveCN102723679AControl loss and wasteGuaranteed crimp qualityApparatus for overhead lines/cablesArchitectural engineeringAluminium

The invention discloses a continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires. The method includes the steps: 1) calculation of the length of a strain section of a wire; 2) calculation of the manufacturing wire length; 3) utilization of strain hardware; and 4) an assembly type wiring process. By the method, wire loss and waste are effectively controlled, compression quality is guaranteed, and aloft operation is reduced. Further, the method is an accurate, efficient and safe construction method.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +2

Method for lifting whole steel structure to top of concrete cabin through slip form and low-altitude modular assembly

InactiveCN103510736AIncrease the construction work areaShorten assembly cycleBulk storage containerFalseworkEngineering

The invention discloses a method for lifting whole steel structure to the top of a concrete cabin through a slip form and low-altitude modular assembly. The method comprises the steps of assembling oblique beam units, assembling steel ring beams, assembling a slip form device, erecting a support ring beam scaffold platform, hoisting the steel ring beams, mounting the oblique steel beams, mounting a structure on a cabin top ring beam, hoisting the slip form system, and the like. As module units are assembled on the ground at the same time, the construction working area is increased, the assembling period is shortened, and the constriction duration is effectively shortened. Temperature and wind load influences when the unassembled large steel structure is assembled and measured at high altitude are reduced, the assembling precision is improved, and the engineering quality is ensured. As a great quantity of scaffolds are reduced duo to low-altitude assembling, and only a small quantity of simple scaffolds are needed to be erected, the mounting requirements can be met; meanwhile difficulty in high-altitude working, assembling and hoisting are reduced, and the security risk is effectively lowered.

Owner:成军

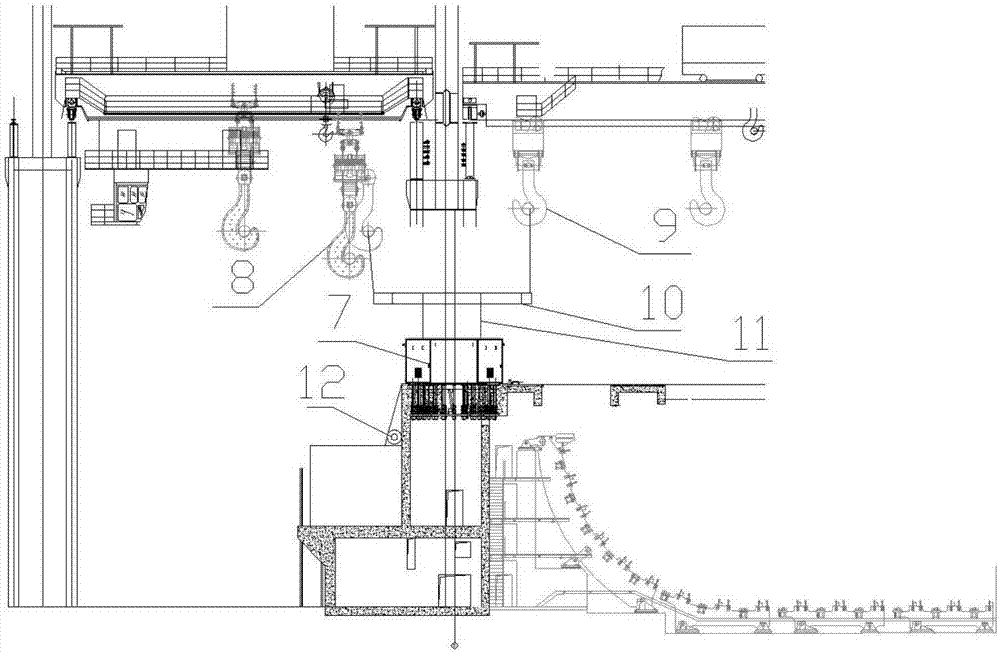

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

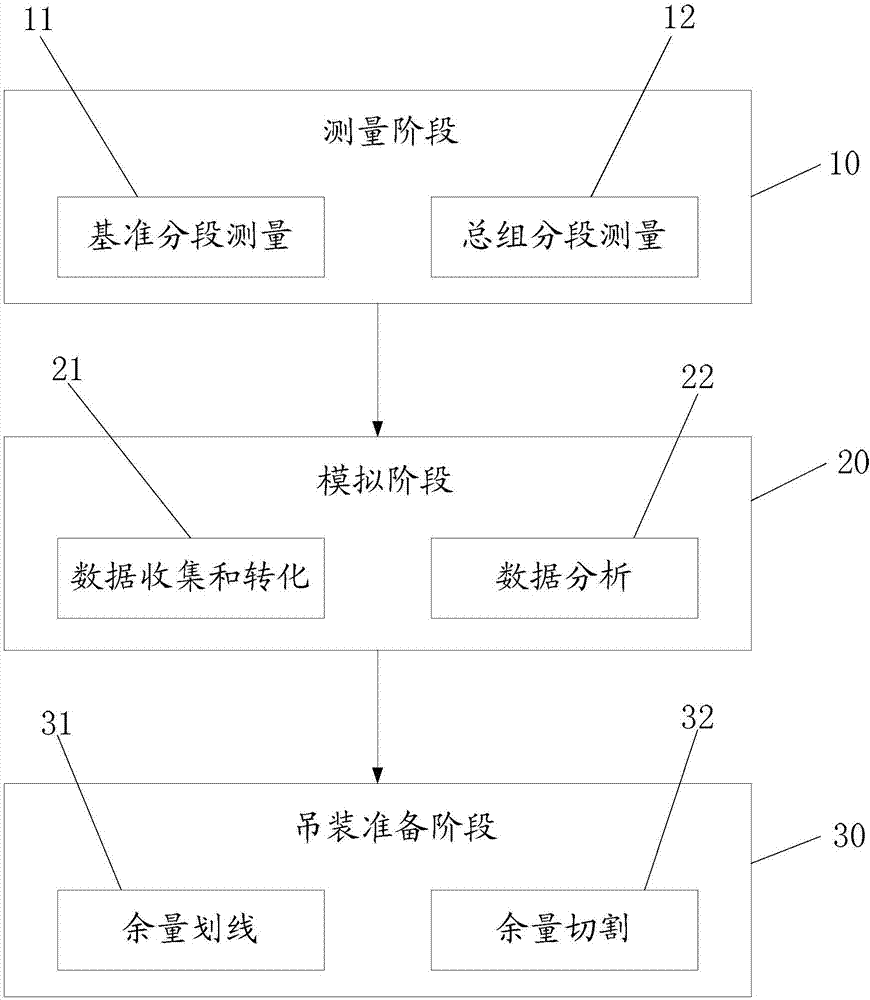

Control method for ship-body section carrying accuracy based on OTS

The invention discloses a control method for the ship-body section carrying accuracy based on OTS. The control method includes the steps of a measurement stage, a simulation stage and a lifting preparation stage, wherein the measurement stage includes the steps of data collection and conversion and data analysis; when the data collection and conversion step is carried out, actually-measured data is guided into a computer to generate a measurement file, and then a deviation value of the actually-measured data and theoretical data is calculated; when the data analysis step is carried out, a total-group section and a basic section are simulated and carried in the computer, a deviation value appears when the total-group section is in place to be in the best form, and margin data of the total-group section is obtained; the lifting preparation stage includes the steps of margin marking and margin cutting; when the margin marking step is carried out, margin lines are marked off on the total-group section according to the margin data; when the margin cutting step is carried out, margins on the total-group section are cut off along the margin lines, and the total-group section is margin-free carrying. According to the control method, sections are successfully lifted and carried one time, and resetting time is shortened.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

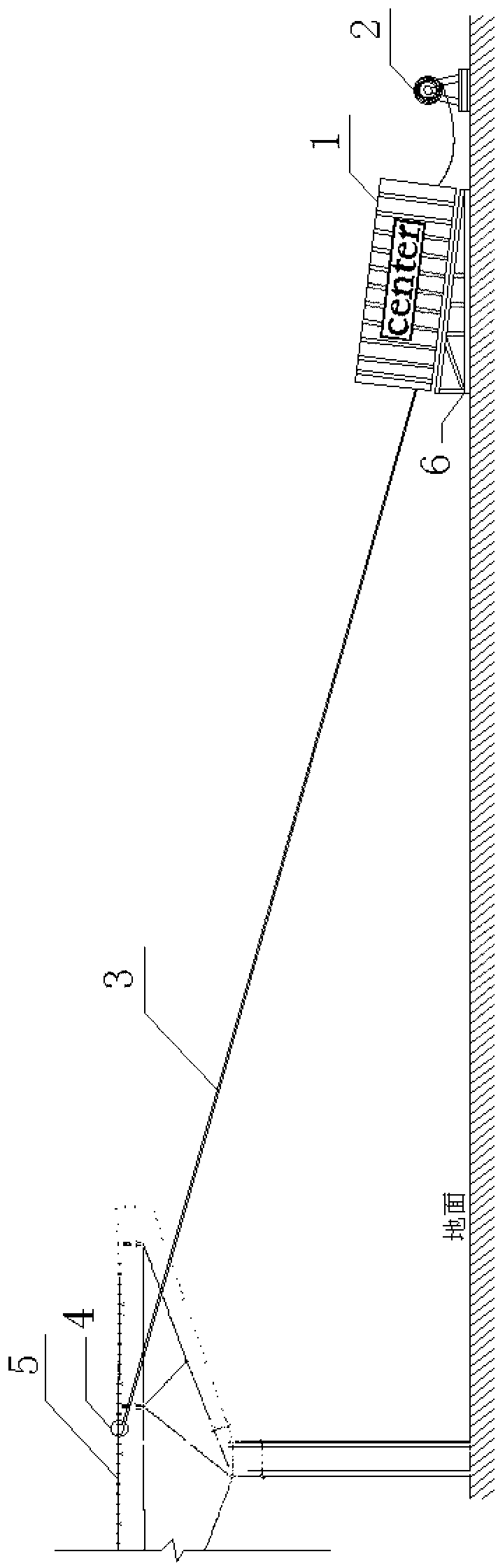

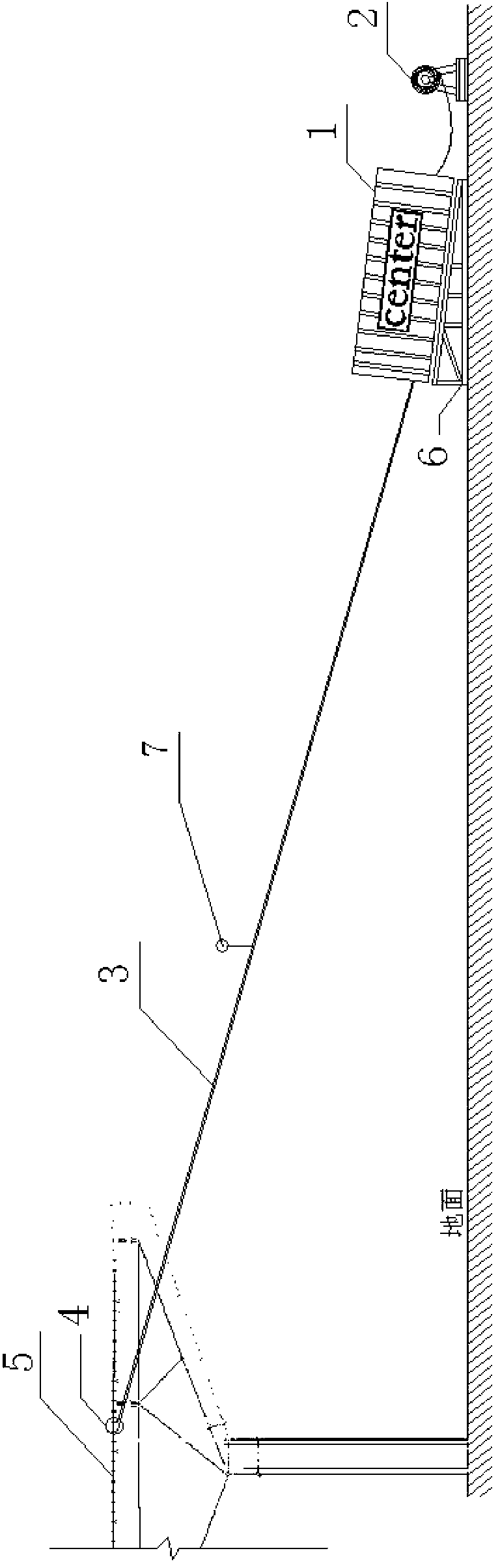

Hydraulic lifting and upside-down construction method for internal steel tube of chimney

The invention provides a hydraulic lifting and upside-down construction method for an internal steel tube of a chimney. The hydraulic lifting and upside-down construction method includes the steps of S1, installing a computer control cabinet, hydraulic pump stations and hydraulic jacks on a steel platform; S2, manufacturing standard sections of the internal steel tube; S3, laying two rails on site and installing a transport trolley on the rails; S4, welding first lifting points and installing anchorage devices and steel stranded wires at the top of the first standard section; S5, lifting a first standard section to a proper height, and transporting a second standard section to an assembly position for assembly and welding; S6, sequentially installing subsequent standard sections, enabling the internal steel tube to descend to the ground when the internal steel tube is lifted to a specific height, and switching to a second lifting point; S7, sequentially installing subsequent standard sections till lifting the internal steel tube is completed. The hydraulic lifting and upside-down construction method has the advantages of high precision, safety, reliability and lower construction cost.

Owner:MCC TIANGONG GROUP

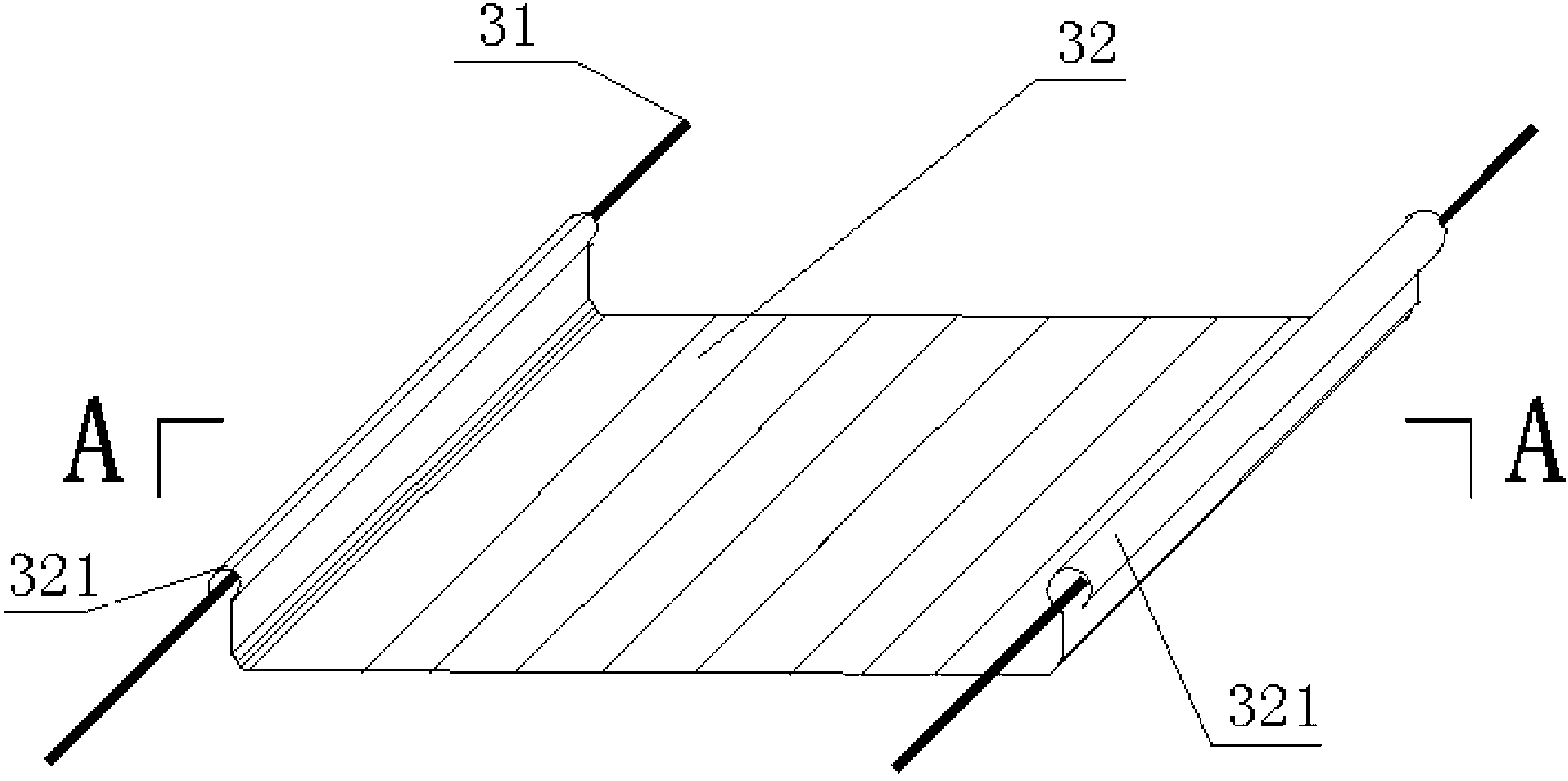

System and method for transporting roof board in air

ActiveCN103233559AShorten the transportation distanceFew linksRoof toolsBuilding constructionCivil engineering

The invention discloses a system for transporting a roof board in the air. The system comprises a sheet metal roll, a forming machine and a transporting device, wherein the forming machine is connected with the sheet metal roll and is used for manufacturing the sheet metal roll into a roof board in a required shape; the transporting device transports the manufactured roof board to a roof on which the metal roof board is to be mounted, and adopts a roof board conveying guide track; one end of the transporting device is connected with a reserved upper board opening on the roof, and the other end of the transporting device is arranged below a board outlet of the forming machine; a board outlet angle of the forming machine tends to be in accordance with an inclined angle of the roof board conveying guide track; and the roof board output by the board outlet of the forming machine falls on the roof board conveying guide track, board outlet thrust of the forming machine drives the roof board to be transported upwards along the roof board conveying guide track. According to the system and the method, the filed roof board manufacture in a construction site is realized, the air transportation is not affected by the building roof height, the length of a single rood board and an on-site condition, the transporting efficiency of the roof board is improved, and the manual labor and the hoisting device cost are reduced.

Owner:CENT INT GROUP

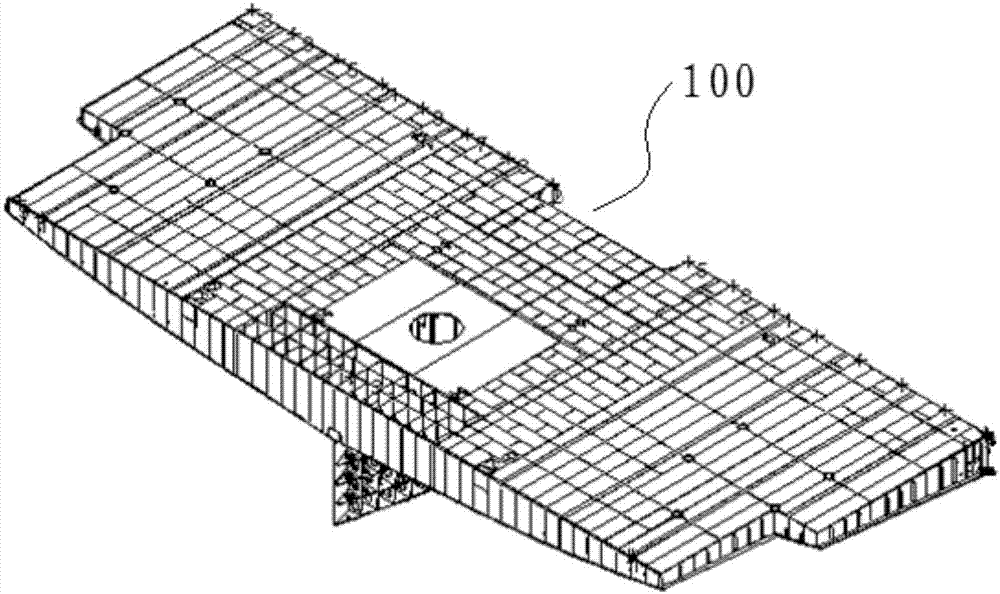

Overall manufacturing process for anchor platform of drilling ship and structure of anchor platform

InactiveCN103057662AImprove working environmentOptimize the installation structureVessel partsStructure of the EarthMarine engineering

The invention discloses an overall manufacturing process for an anchor platform of a drilling ship. The process includes: step A, manufacturing an assembly jig, and marking a center line of the assembly jig and an assembly line of a structure of the anchor platform on the assembly jig ; step B, marking a center line and an assembly positioning base line of a hawse pipe on a prefabricated hawse pipe; step C, assembling the hawse pipe on temporary tools, and calculating an included angle between the hawse pipe and a shell plating of a ship body; and step D, setting a structure base point on the hawse pipe, and assembling a shell plating of the anchor platform and an anchor mouth. Through the overall manufacturing process for the anchor platform of the drilling ship and a structure of the anchor platform, working environment of manufacturing and assembling the anchor platform is greatly improved, assembling and welding of the structure of the anchor platform are benefited, working aloft is reduced, personal safety is benefited, production efficiency and welding quality are improved, and production cycle is shortened.

Owner:COSCO DALIAN SHIPYARD

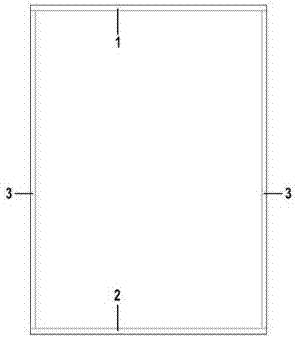

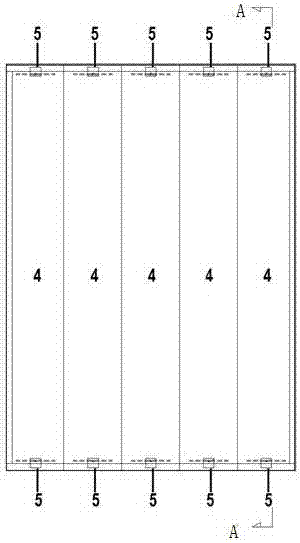

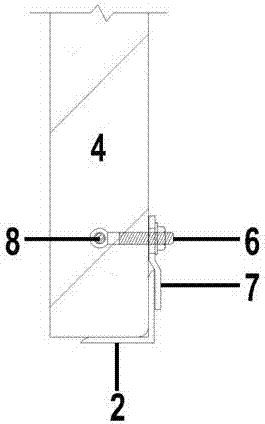

NALC (N autoclaved lightweight concrete) large slab component

PendingCN107130757ASave mechanical shiftsSave time for coordinationCovering/liningsSlagStructural engineering

The invention discloses an NALC (N autoclaved lightweight concrete) large slab component. The large slab component is characterized by comprising multiple NALC slabs, wherein slag joints between the adjacent NALC slabs are treated with a crack sealer, angle steel components are arranged around the NALC slabs, mounting joints are arranged at the two ends of the NALC slabs, and the NALC slabs are fixed through fixing components. The technical scheme is compact and ingenious in structural design and high in prefabricating rate and assembling rate, and the whole NALC large slab composite exterior decoration is completely manufactured in a factory; all manufacturing procedures are performed on the ground, so that aloft work is reduced, and the construction risk is lowered.

Owner:南京旭建新型建材股份有限公司

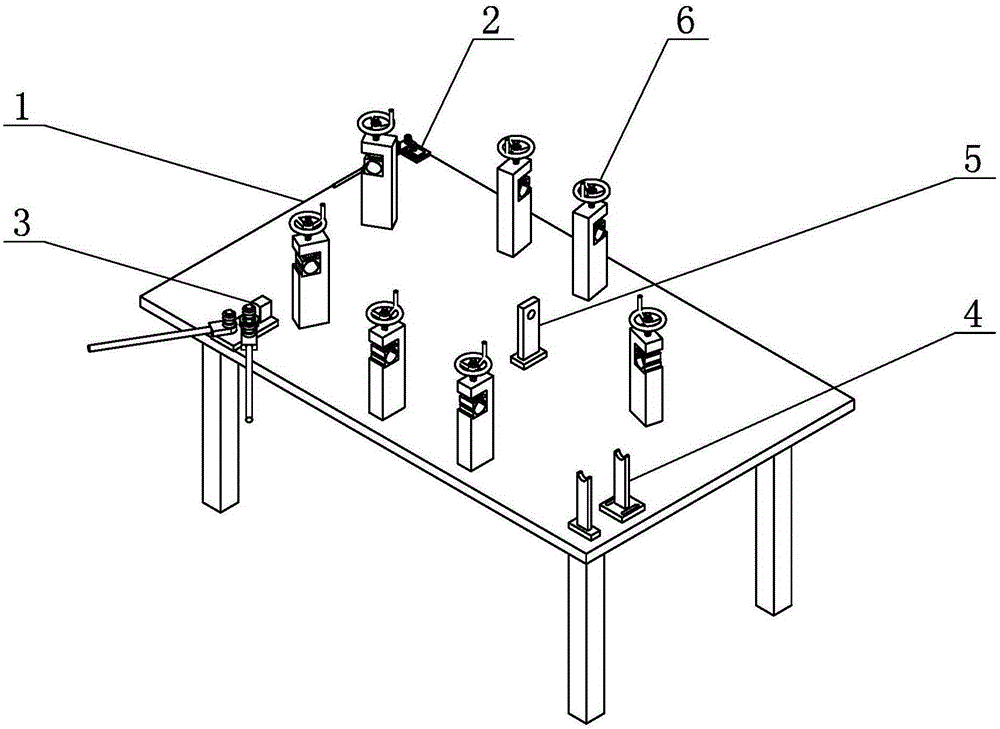

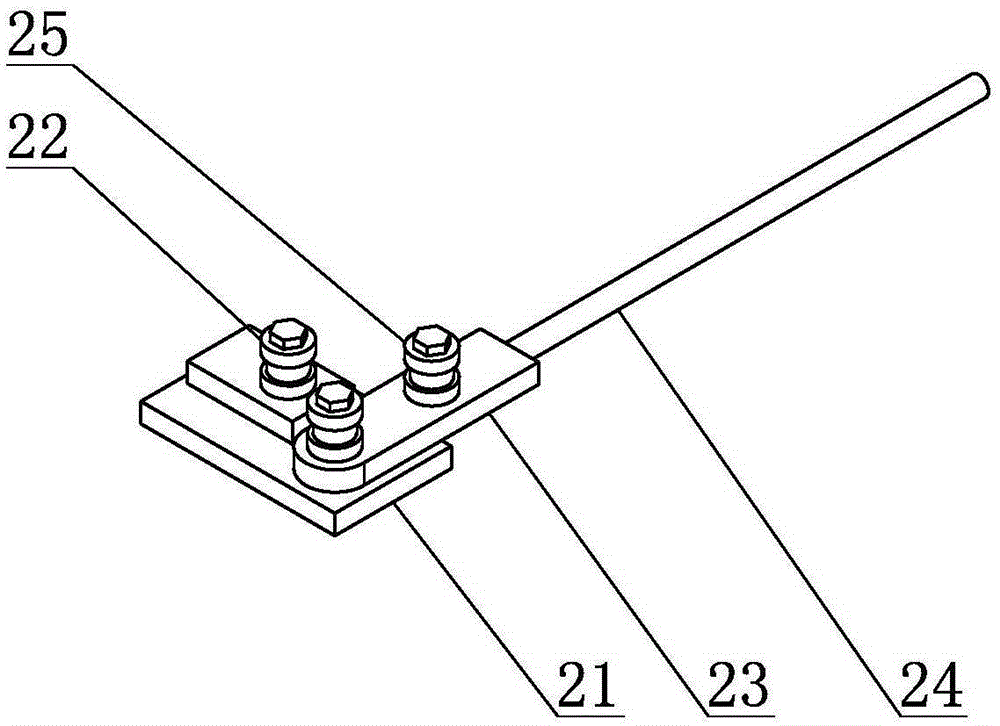

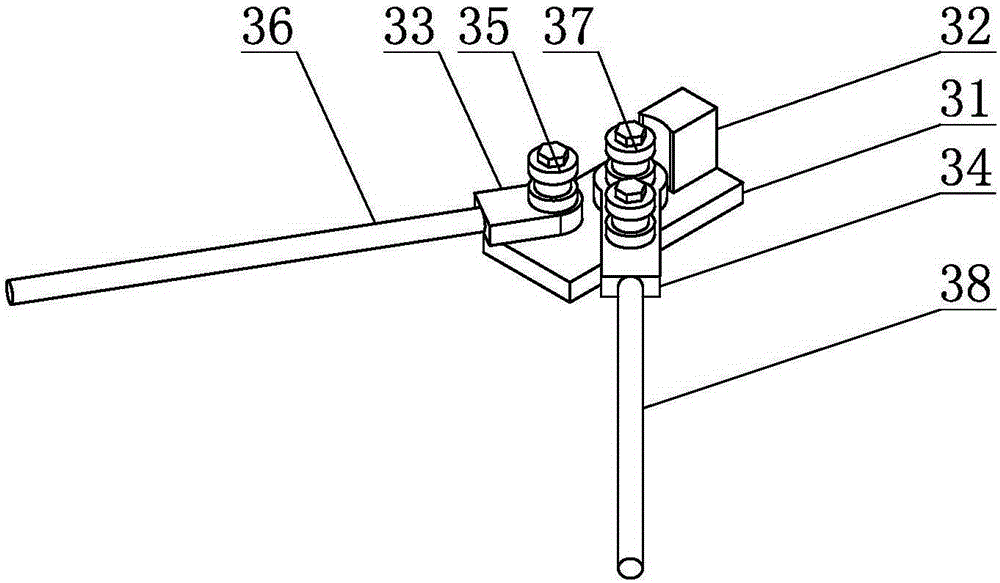

Manufacturing process and manufacturing apparatus for high-voltage lead wires of transformer

ActiveCN105185566ARealize factoryReduce working at heightsTransformers/inductances coils/windings/connectionsCoils manufactureTransformerManufactured apparatus

The invention discloses a manufacturing process and a manufacturing apparatus for high-voltage lead wires of a transformer, and mainly relates to the field of electric power engineering construction processes. The manufacturing apparatus for the high-voltage lead wires of the transformer comprises a worktable, wherein a curve device, a curve shaper, an insulator bracket, a lightning arrester fixing bracket and an insulated wire bracket are arranged on the worktable. The manufacturing process and the manufacturing apparatus have the beneficial effects that the high-voltage lead wires of the transformer are assembled and manufactured on the manufacturing apparatus for the high-voltage lead wire of the transformer and then are transported to a construction site in a unified way for installation, so that excessive overhead work can be reduced, the construction difficulty can be lowered, the field operation progress can be accelerated, the potential safety hazards can be reduced, the manufacturing process can be standardized, the assembly quality can be effectively controlled, and the material waste can be avoided.

Owner:国网山东夏津县供电公司

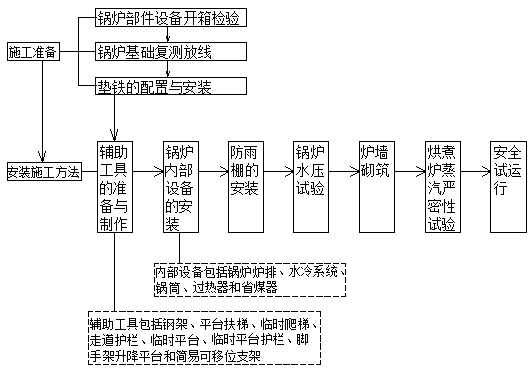

Installation and construction method of mechanical grate type waste incineration boiler

InactiveCN109000261AGive full consideration to reuseReduce the amount of work at heightIncinerator apparatusSteel frameSuperheater

The invention discloses an installation and construction method of a mechanical grate type waste incineration boiler. The installation and construction method includes the following specific steps ofconstruction preparation, specifically, unpacking inspection of boiler parts and equipment, retesting and paying off of boiler foundation, and configuration and installation of parallels; and installation and construction method, specifically, preparation and manufacturing of auxiliary tools, installation of boiler internal equipment, installation of rainproof shed, hydrostatic test of boiler, installation of boiler wall, steam tightness test of drying and boiling boiler, and safe trial operation, wherein the auxiliary tools includes a steel frame, a platform escalator, a temporary climbing ladder, an aisle guardrail, a temporary platform, a temporary platform guardrail, a scaffold lifting platform and a simple removable support, and the internal equipment includes a boiler grate, a watercooling system, a drum, a superheater and an economizer. The installation and construction method of the mechanical grate type waste incineration boiler is applicable to installation of the mechanicalgrate type waste incineration boiler with a daily garbage disposal of about 500t / d by a single unit in a domestic garbage power plant, the degree of mechanized construction is improved, the labor intensity is reduced, the project quality is guaranteed, the construction period is shortened, and the productivity and economic benefits are improved.

Owner:POWER CHINA HENAN ENG CO LTD

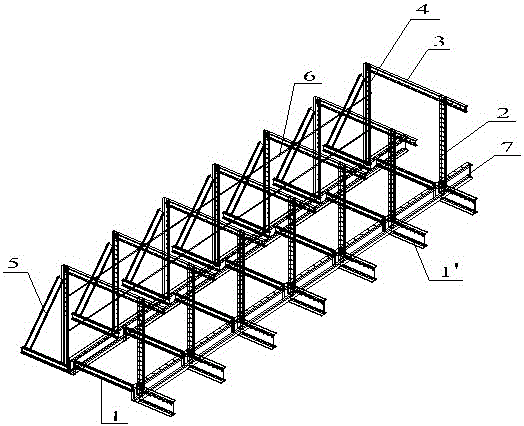

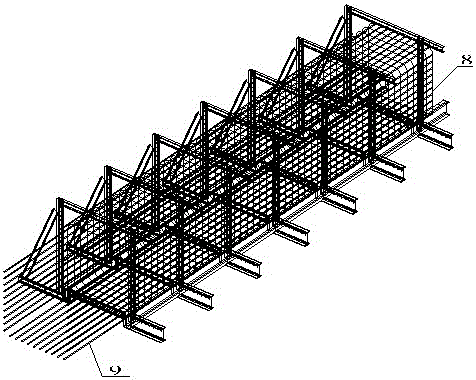

Erecting method of cantilever structure formwork bent

InactiveCN105442839AIncrease spacingReduce deflectionForms/shuttering/falseworksEngineeringCantilever

The invention relates to an erecting method of a cantilever structure formwork bent and belongs to the technical field of building construction. The problem that an existing cantilever structure formwork bent is difficult to erect and high in construction cost is solved. The erecting method comprises the steps that a cantilever platform steel supporting structure is spliced and welded on the ground at first; an embedded part is arranged on a building structure beam in the high altitude; the steel supporting structure is hoisted and is welded and fixed to the embedded part, thereby being fixed to a building structure floor beam; a reinforcing measure is provided, a hoisting ring is embedded on a sealing beam above the cantilever main steel beam to fix an upper pull rod, and the lower end of the upper pull rod is connected with the cantilever main steel beam in the steel supporting structure; auxiliary beams are laid above the cantilever main steel beam at intervals, finally, the gaps between the auxiliary beams are filled with square pillars and covered with a formwork, and therefore construction of a cantilever platform is completed; an operator erects a bent system composed of horizontal rods and vertical rods on the cantilever platform and carries out reliable pulling, and therefore the cantilever structure formwork bent is formed.

Owner:SHANGHAI NO 7 CONSTR

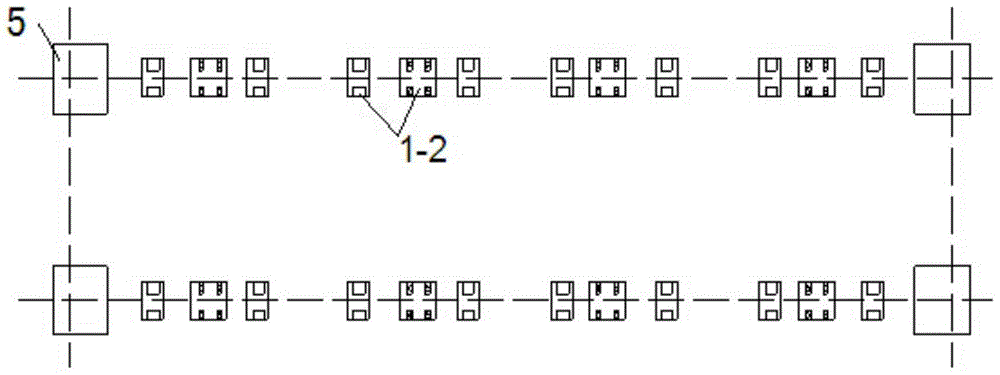

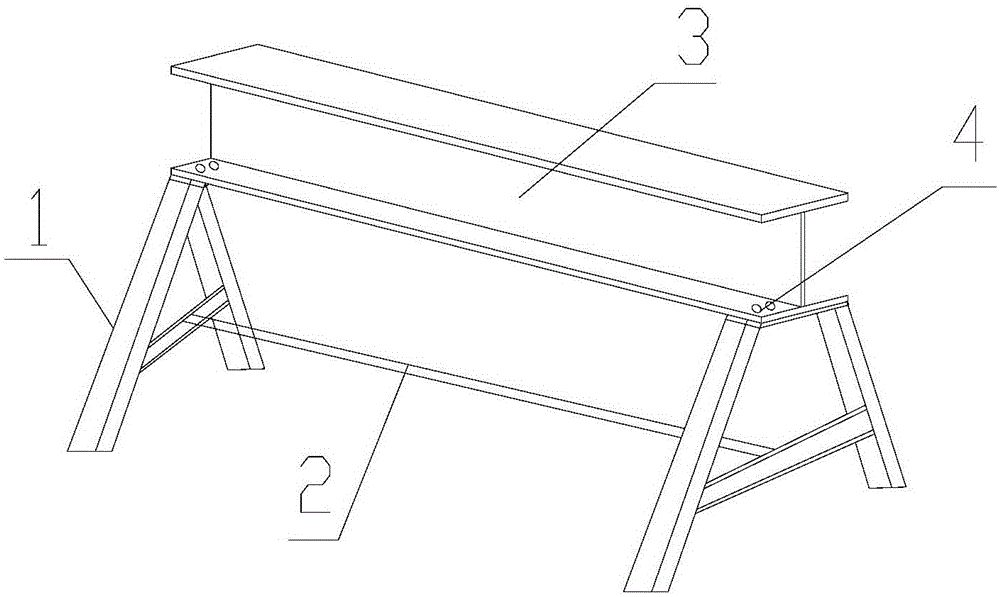

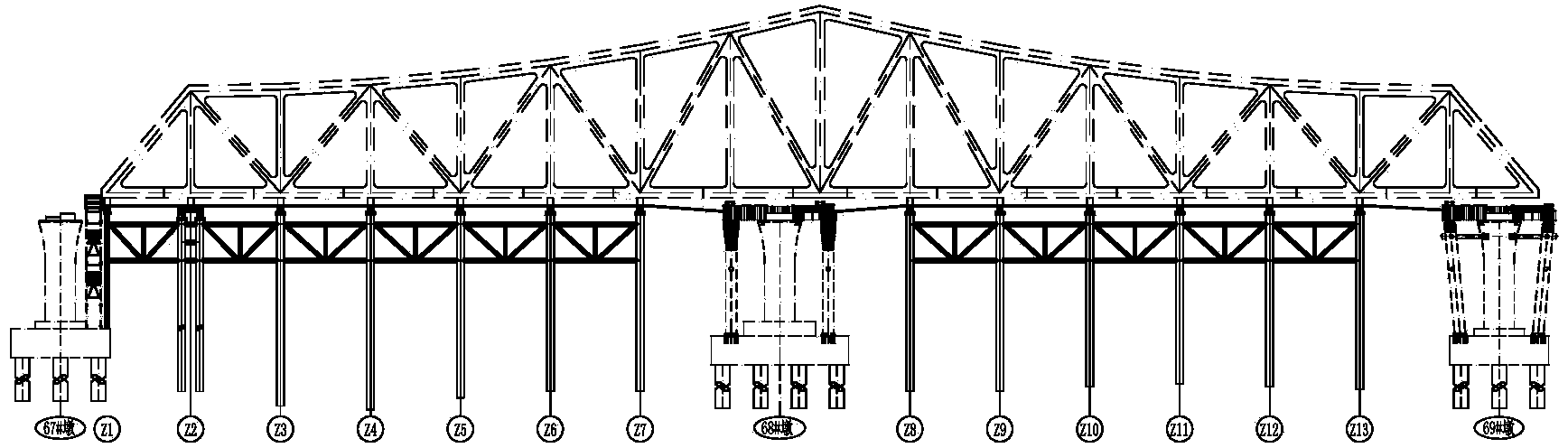

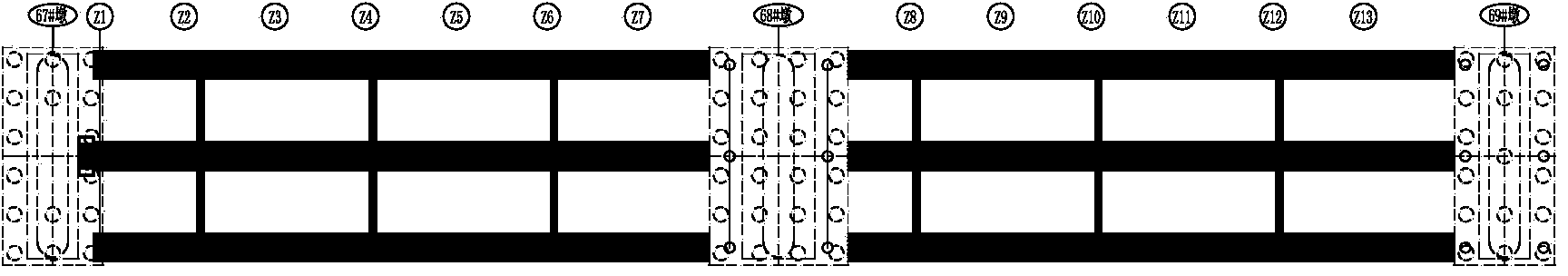

Long-distance pushing construction method of thee-main-truss steel truss beam in single-connection and double-span modes without guide beam

ActiveCN103510475ASave human effortSave moneyBridge erection/assemblyControl equipmentBuilding construction

The invention discloses a long-distance pushing construction method of a thee-main-truss steel truss beam in single-connection and double-span modes without a guide beam, and relates to the field of bridge construction. The method comprises the steps of setting up an assembly support and supporting brackets beside piers, and mounting slide way beams, steel strand anchoring devices and horizontal deflection correction devices. After steel connection truss beams are assembled on the assembly platform, top steel truss beams are arranged on the supporting brackets beside the piers, the upstream and the downstream of the tail end of each steel truss beam are respectively provided with a horizontal continuous jack anchoring counter-force support, steel strands penetrate through the counter-force supports for pre-tensioning, and horizontal jack debugging is carried out. A jack is vertically ejected, a sliding lock is dragged to a designed position and then the jack falls down to start pushing, after pushing between sections is finished, the jack is vertically ejected, the sliding block is moved backwards to a section until the designed position and then the jack falls down, and the action is repeated. Cost of horizontal continuous jacks, vertical falling jacks and control device of the jacks can be reduced, temporary connection and guide beam expense between a large number of steel truss beams and joints is eliminated, the pushing construction of the long-distance steel truss beams is accurately controlled, construction is quick, and safety and reliability are achieved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

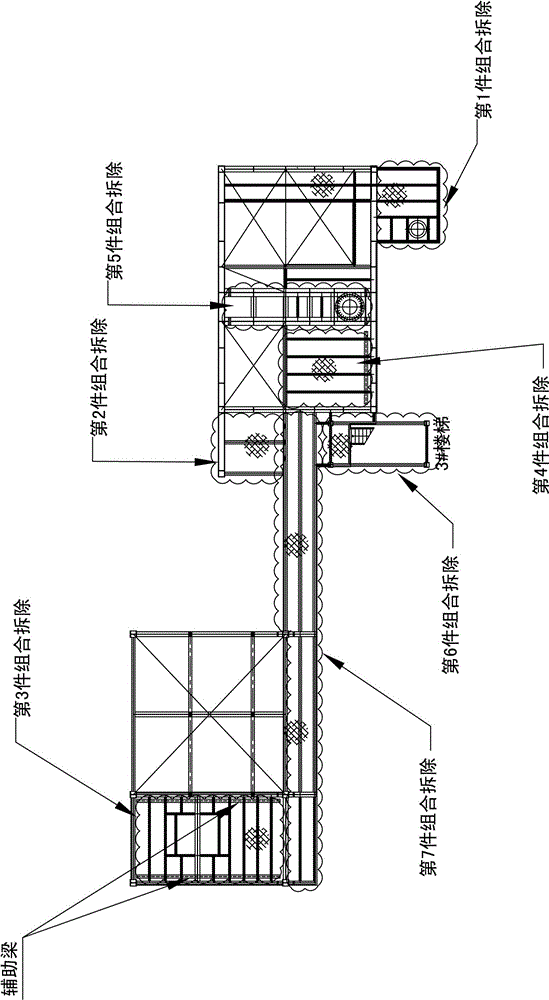

Protective dismantle and assembly method for large-scale towering steel structures

The invention relates to the field of hoisting and hauling operations and especially relates to a protective dismantle and assembly method for large-scale towering steel structures. The protective dismantle and assembly method for large-scale towering steel structures is characterized by following steps which are carried out sequentially: A. dismantling segment by segment; B. marking by drawing lines; C. numbering; D. lifting lug assembling; E. operating by two combined operation modes; F. pre-hoisting; G. cutting segment by segment; H. combined dismantling piece by piece; I. dismantling integrally. The operation by the invention is safe and reliable and the device utilization rate is high.

Owner:SHANGHAI BAOYE GRP CORP

Integral erecting system for large sea-crossing arch bridge and construction method thereof

ActiveCN105603881AImprove constructabilityImprove construction qualityBridge erection/assemblyArch-type bridgeLinear regulatorStructural engineering

The invention discloses an integral erecting system for a large sea-crossing arch bridge and a construction method thereof. The integral erecting system comprises a semi-submerged ship, a tugboat, modular temporary pier sections, modular temporary support sections, a beam bottom temporary supporting docking bayonet, an arch beam temporary stiffening support, an arch rib assembling support, an arch rib linear regulator, a main beam assembling support and a trestle, wherein the main beam assembling support and the arch rib assembling support are used for integral assembly of a whole arch beam on the bank, the modular temporary pier sections are supported by the trestle, the modular temporary support sections are supported by the semi-submerged ship, and alternate jacking support of the modular temporary pier sections and the modular temporary support sections is achieved by means of the semi-submerged ship through pressurized drainage and tidal fluctuation. According to the integral erecting system, after the whole arch beam is jacked to a designed elevation through pressurized drainage of the semi-submerged ship and tidal fluctuation, the whole arch beam is transferred to a bridge site through floating to be directly erected in place. The invention further discloses a large sea-crossing arch bridge integral erecting construction method.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

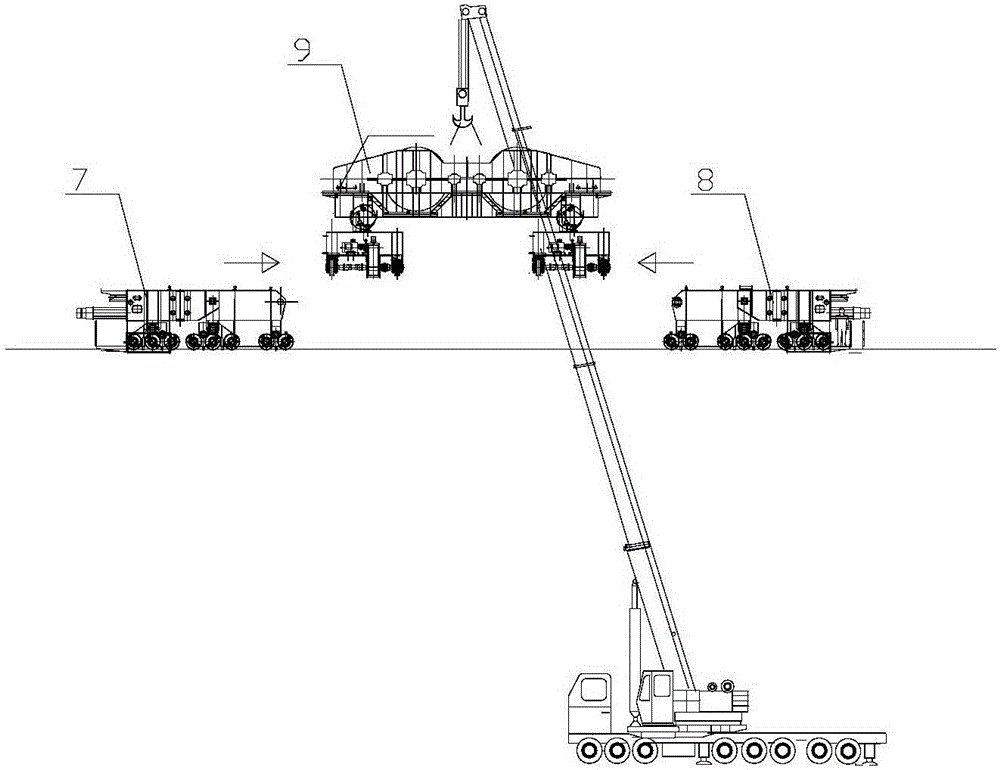

Combination hoisting mounting method of continuous casting ladle turret

The invention belongs to a building construction method, and discloses a combination hoisting mounting method of a continuous casting ladle turret. The combination hoisting mounting method is characterized in that by employing the advantage that the ground in a factory building is wide, a part of components of the continuous casting ladle turret are assembled on the ground off-line, the components of the continuous casting ladle turret are transferred by adopting a sliding device, and are hung by a shoulder pole for hoisting, concrete is prevented from leaking into sleeves of foundation bolts by adopting an anti-leakage device, and a travelling crane of a molten steel receiving bay and a travelling crane of a casting bay that are arranged in the factory building are used jointly to hoist the various components of the continuous casting ladle turret in position. The combination hoisting mounting method comprises the following steps: one, a fixing bracket is arranged and anchor pieces are mounted; two, slurry of a foundation seat is prepared, and the sliding device is arranged; three, a base of the continuous casting ladle turret is hoisted; four, a revolving body is mounted; five, an upper part revolving support body is assembled and mounted; and six, accessories are mounted. The combination hoisting mounting method is fast in progress and high in precision, the construction efficiency is improved, and the construction cost is reduced.

Owner:CHINA MCC17 GRP

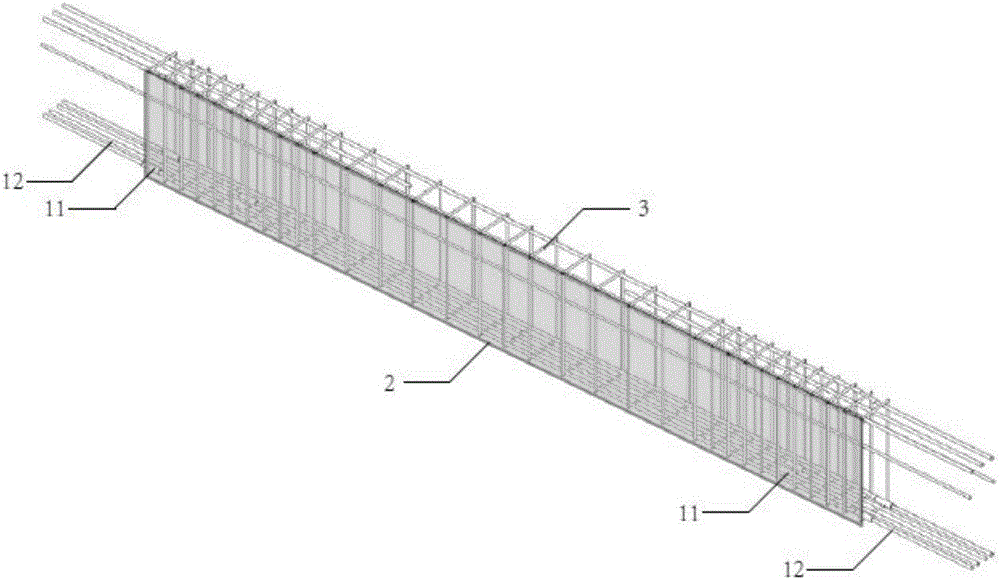

Precast beam reinforcement cage component and assembling method thereof

InactiveCN105952060AMeet construction requirementsEnables step-by-step installation combinationsBuilding reinforcementsBuilding material handlingReinforced concreteRebar

The invention discloses a precast beam reinforcement cage component and an assembling method thereof. The precast beam reinforcement cage component comprises a reinforcing steel bar assembly and a disassembly-free mould connected with the reinforcing steel bar assembly, wherein the reinforcing steel bar assembly is formed by connecting a horizontal reinforcing bar and a stirrup, and the disassembly-free mould is laid along the front side surface, the rear side surface and the bottom surface of a precast beam and is connected with the reinforcing steel bar assembly into a whole by virtue of a locating fixed part. The precast beam reinforcement cage component has the advantages that a large component and a reinforced concrete large-structure-space civil building can be realized, a working procedure is simplified, high-altitude operation is reduced, and current national reinforced concrete reinforcing bar specification can be met; meanwhile, cost is reduced, locating and supporting precision, assembling efficiency and quality of a structural component are improved, site construction is convenient, and a technology is controllable.

Owner:SOUTHEAST UNIV

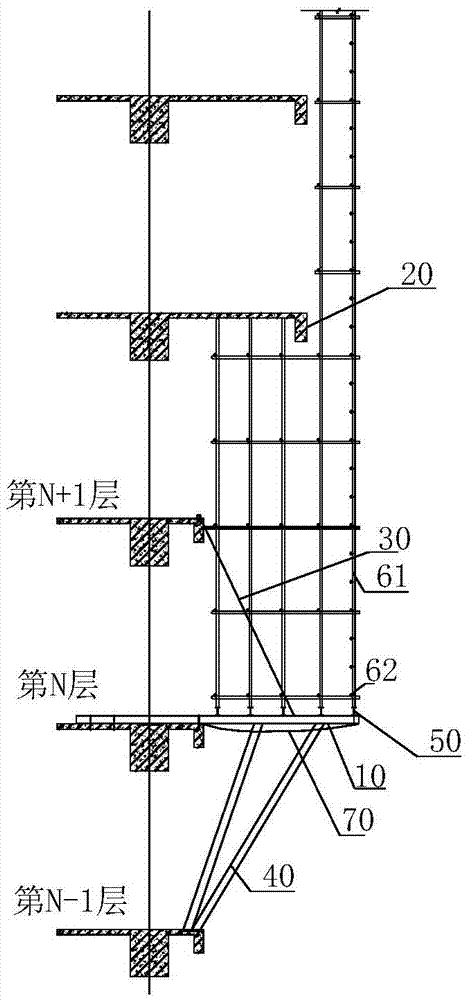

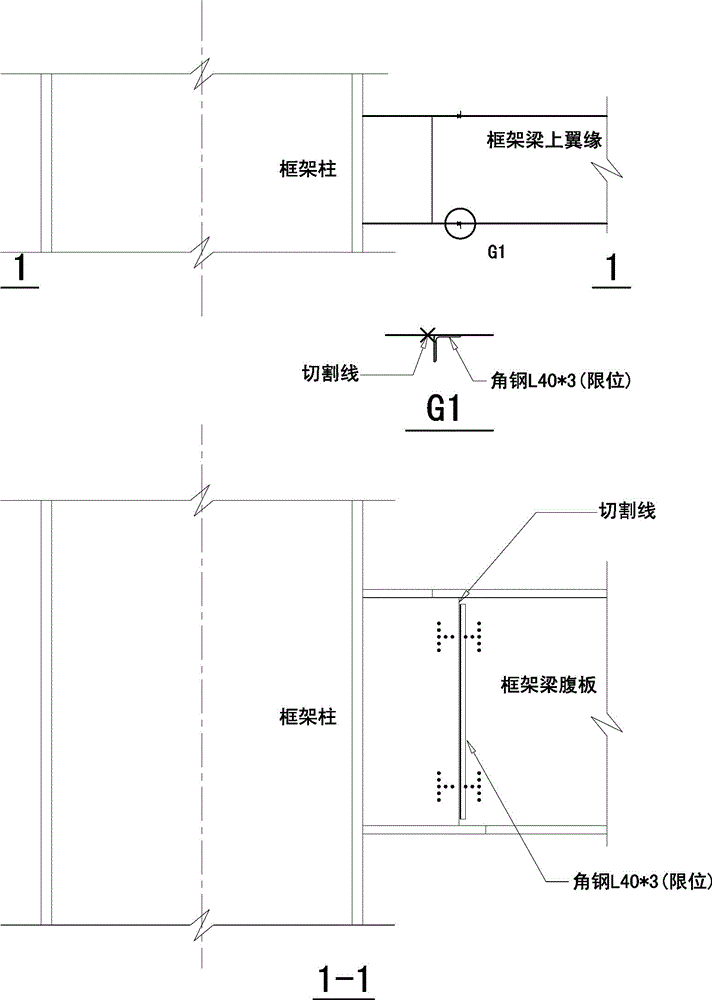

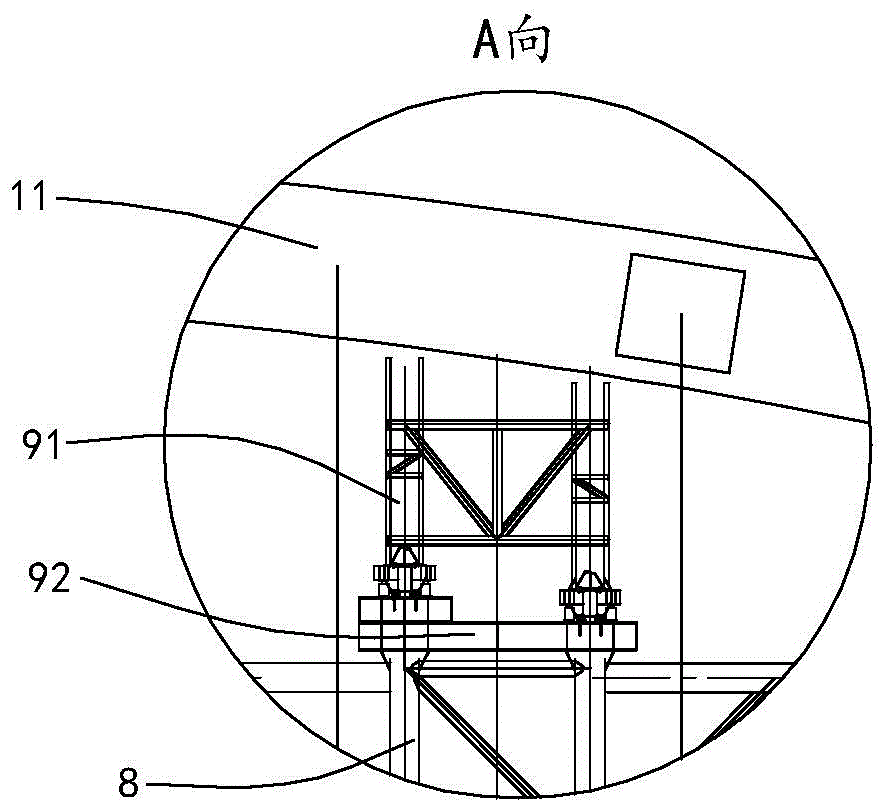

Internal climbing tower crane climbing method without using inverted beam method

The invention relates to an internal climbing tower crane climbing method without using an inverted beam method. Through arranging three support beams and two lifting oil cylinders, an internal climbing tower crane climbs without inversely transporting the support beams. An implement device comprises the tower crane upper beam, the tower crane middle beam, the tower crane lower beam, a climbing frame, the two lifting oil cylinders, a limiting and guiding device, a climbing joint and a hydraulic control system. The method mainly comprises the following steps of balancing a tower crane, and supporting the tower crane middle beam on a main structure; operating the hydraulic control system, stretching the lifting oil cylinders for lifting the tower crane upper beam to lift up, driving the tower crane to lift up at the same time, separating the tower crane upper beam from the main structure, solidifying the tower crane lower beam and the climbing joint, and synchronously lifting the tower crane lower beam and the tower crane; and connecting the tower crane upper beam with the main structure after lifting the tower crane upper beam in place, bearing a load of the tower crane through thetower crane upper beam, separating the tower crane middle beam from the structure, operating the hydraulic control system, contracting the lifting oil cylinders, lifting the tower crane middle beam, and accomplishing one-time climbing after lifting the tower crane middle beam in place.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

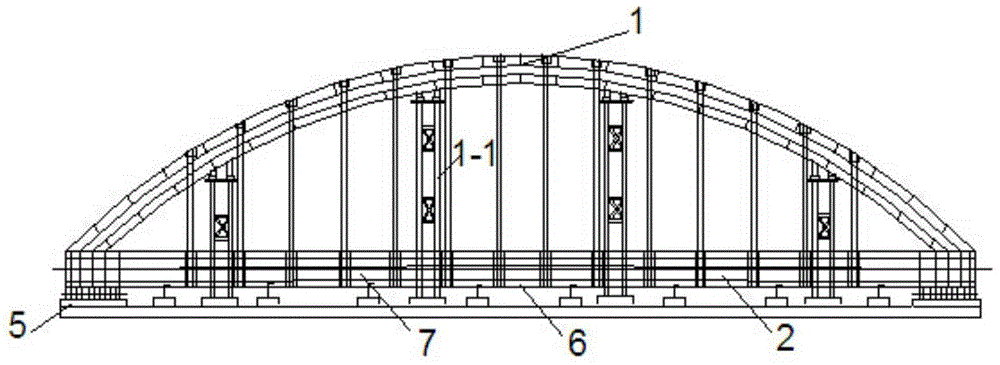

Through tied arch bridge and construction method thereof

ActiveCN106592406AReduce investmentAvoid high-altitude constructionBridge erection/assemblyArch-type bridgeBridge deckEngineering

The invention discloses a through tied arch bridge and a construction method thereof. The through tied arch bridge is composed of two single-piece arch rib units. Each single-piece arch rib unit comprises an arch rib and a tie beam, wherein a hanger rod is arranged between the arch rib and the tie beam. The two arch ribs are connected as a whole through transverse supports. The two tie beams are connected as a whole through transverse beams. A bridge deck slab is erected on the transverse beams. Each arch rib is formed by connecting arch rib sections, each tie beam is formed by connecting tie beam sections, and the arch-shaped arch rib sections and the tie beam sections are arranged correspondingly. Each transverse support is formed by connecting two transverse support sections, wherein the two transverse support sections are fixedly connected on the arch ribs of the two single-piece arch rib units correspondingly. Each transverse beam is formed by connecting two transverse beam sections, wherein the two transverse beam sections are fixedly connected on the tie beams of the two single-piece arch rib units correspondingly. By connecting each group of transverse beam sections and each group of transverse support sections on bridge location construction site, the erection work of a bridge main body can be completed, so that the construction period is shortened effectively, capital investment is reduced, and the construction method is especially suitable for bridge construction of crossing important riverways or important lines.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

Positioning frame for prefabricated pier column reinforcing bar cages and construction method of pier column reinforcing bar cages

ActiveCN105908902APrecise positioningMade preciselyBuilding reinforcementsBuilding material handlingRebarPrefabrication

The invention discloses a positioning frame for prefabricated pier column reinforcing bar cages and a construction method of the pier column reinforcing bar cages, and belongs to the technical field of construction of municipal works. The positioning frame disclosed by the invention can accurately position the positions of main reinforcing bars in pier column reinforcing bars and the positions of hoop reinforcing bars in the pier column reinforcing bars, and a reinforcing bar framework is rapidly and accurately manufactured; during manufacturing of the reinforcing bar framework, bearing platform reinforcing bars are manufactured, and steel plates are arranged on the bearing platform reinforcing bars; control points are arranged on the steel plates to accurately position the reinforcing bar framework. The positioning frame and the construction method disclosed by the invention have great superiority; the bearing platform reinforcing bars and the pier column reinforcing bars can be in line production in parallel; the positions of the main reinforcing bars in the pier column reinforcing bars and the positions of the hoop reinforcing bars in the pier column reinforcing bars are accurately controlled and are convenient to control, so that the construction schedule and the project quality can be doubly increased; the construction safety is guaranteed; after the prefabrication is completed, the reinforcing bar framework is integrally hoisted, so that the time for working high above the ground and crane working is shortened, and the construction cost is reduced.

Owner:JINAN URBAN CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com