Erecting method of cantilever structure formwork bent

A structural formwork and cantilever technology, applied in formwork/formwork/work frame, on-site preparation of building components, building construction, etc., can solve the problems of high difficulty and high construction cost, reduce construction cost and reduce high-altitude The effect of working and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

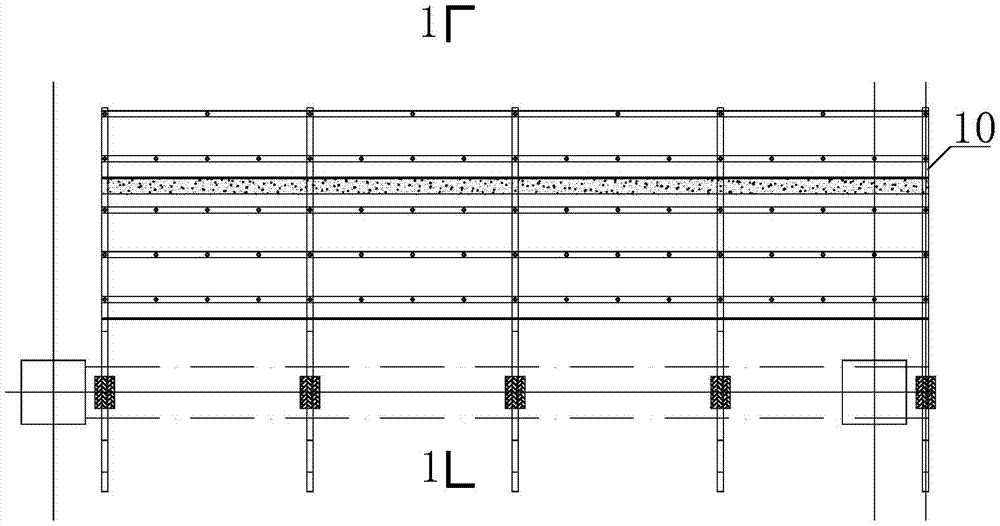

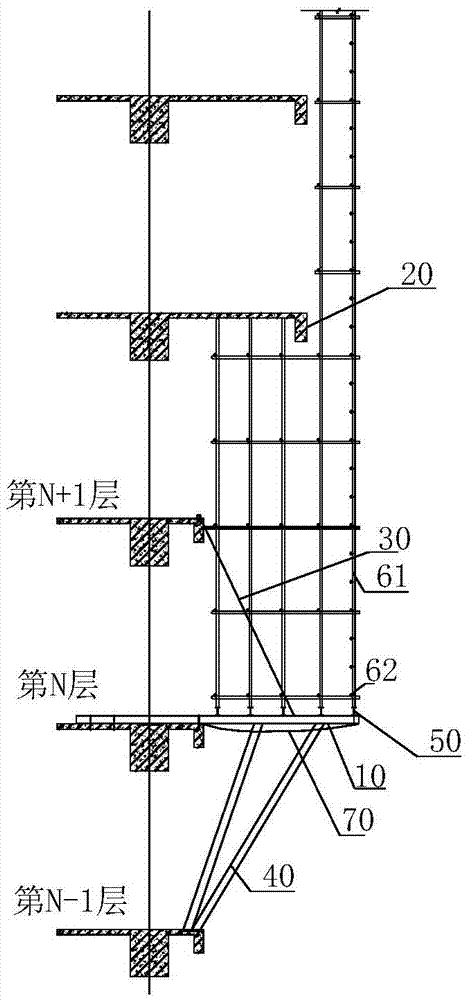

[0032] Such as figure 1 and figure 2 As shown, a method for erecting a formwork bent frame of a cantilevered structure comprises the following steps:

[0033] S001: The steel support structure is spliced on the ground, and each steel support structure includes a cantilevered main steel beam 10 and two diagonal braces 40.

[0034] S002: Install embedded parts on the structural beams of the Nth and N-1st floors of the building structure, where N is a natural number greater than 1. In the erection construction of the cantilevered formwork in this embodiment, N is equal to 12.

[0035] S003: Hoist the steel support structure, weld and fix the steel support structure with the embedded parts in step 2, one end of the diagonal brace 40 is fixedly connected with the cantilevered main steel beam 10, and the other end of the diagonal brace 40 is connected with the The structural beam embedded parts are fixedly connected.

[0036] S004: Embedding lifting rings (not shown) on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com