Manufacturing process and manufacturing apparatus for high-voltage lead wires of transformer

A technology for making devices and technological processes, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of difficult control of transformer lead assembly quality, slow on-site work progress, and difficult construction, and achieve effective control. The effect of improving assembly quality, improving the progress of on-site operations, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

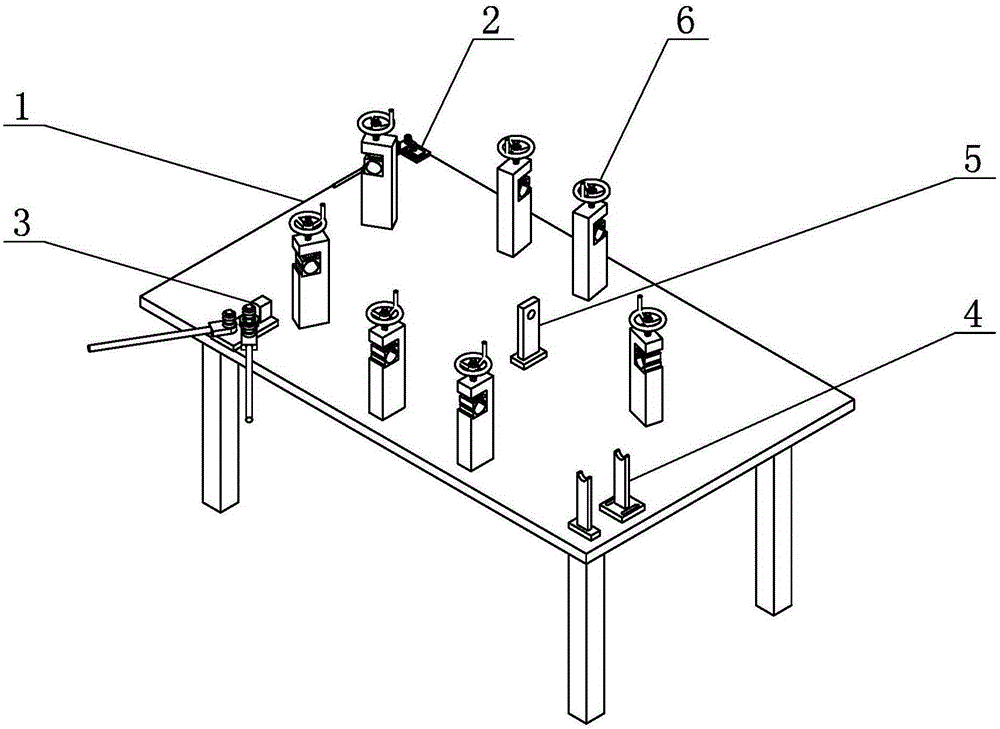

[0071] Embodiment: The present invention describes the production process of transformer high-voltage lead wires. It completes the production of transformer high-voltage lead wires on the transformer high-voltage lead wire manufacturing device, realizes the industrialization of transformer lead wire production, and can reduce excessive high-altitude operation, reduce the difficulty of construction, improve the progress of on-site operations, and reduce potential safety hazards. Specifically follow the steps below:

[0072] Step 1. Select a 10kV single-core insulated wire of 95 square millimeters, intercept a transformer lead wire of 4.3 meters, and a lead wire of a lightning arrester of 0.95 meters;

[0073] Step 2. Make a mark at 1.12 meters of the lead wire of the transformer, and have 2-3 people hold the wire by hand. At this time, pay attention to the natural bending end of the wire facing upwards, and use a curve tool to make an arc on the wire at the mark;

[0074] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com