System and method for transporting roof board in air

A transmission system and transmission method technology, which is applied in the field of large-scale steel structure roofing engineering, can solve the problems of high site conditions, damage loss, and high cost, and achieve the effect of reducing the roof handling distance, less site requirements, and less workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

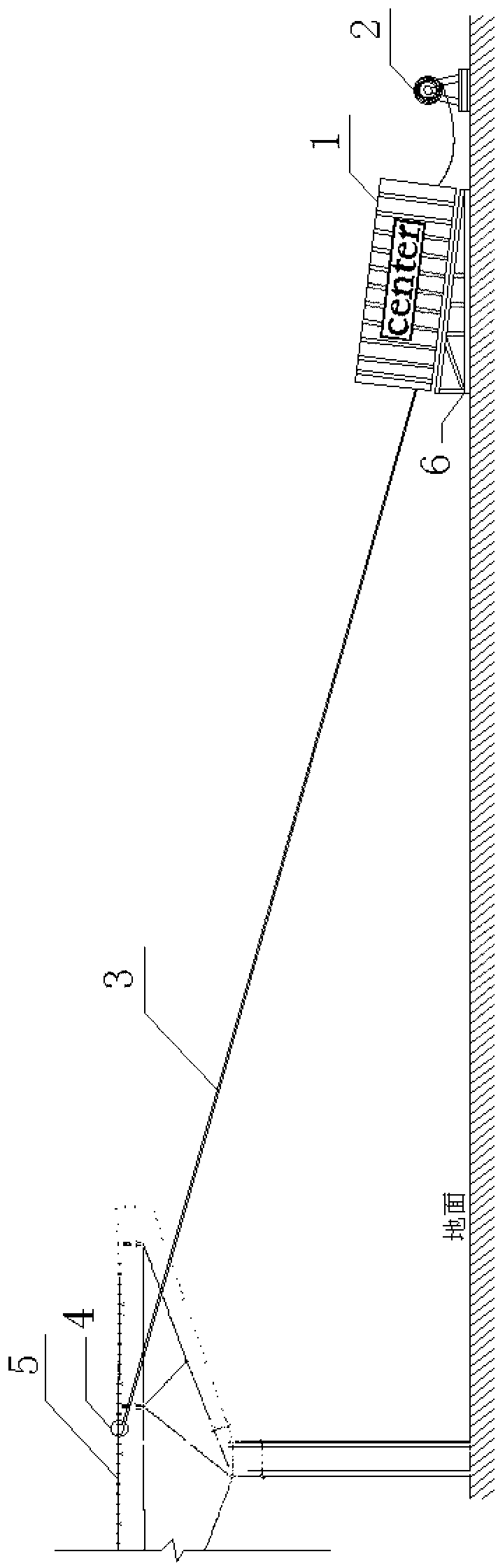

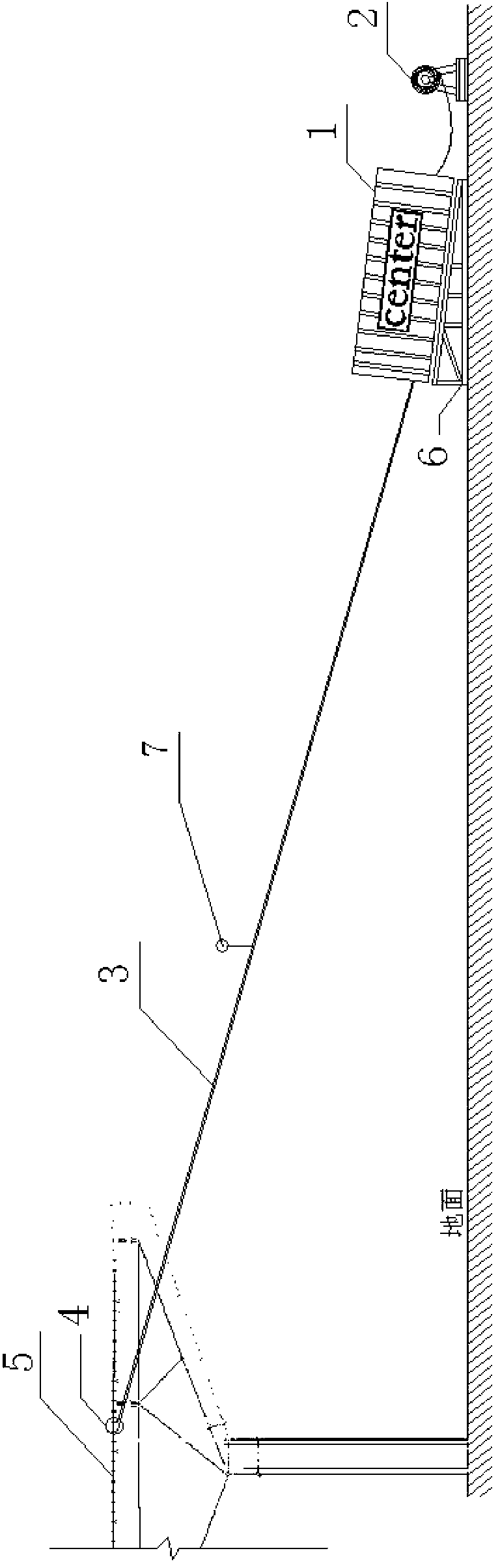

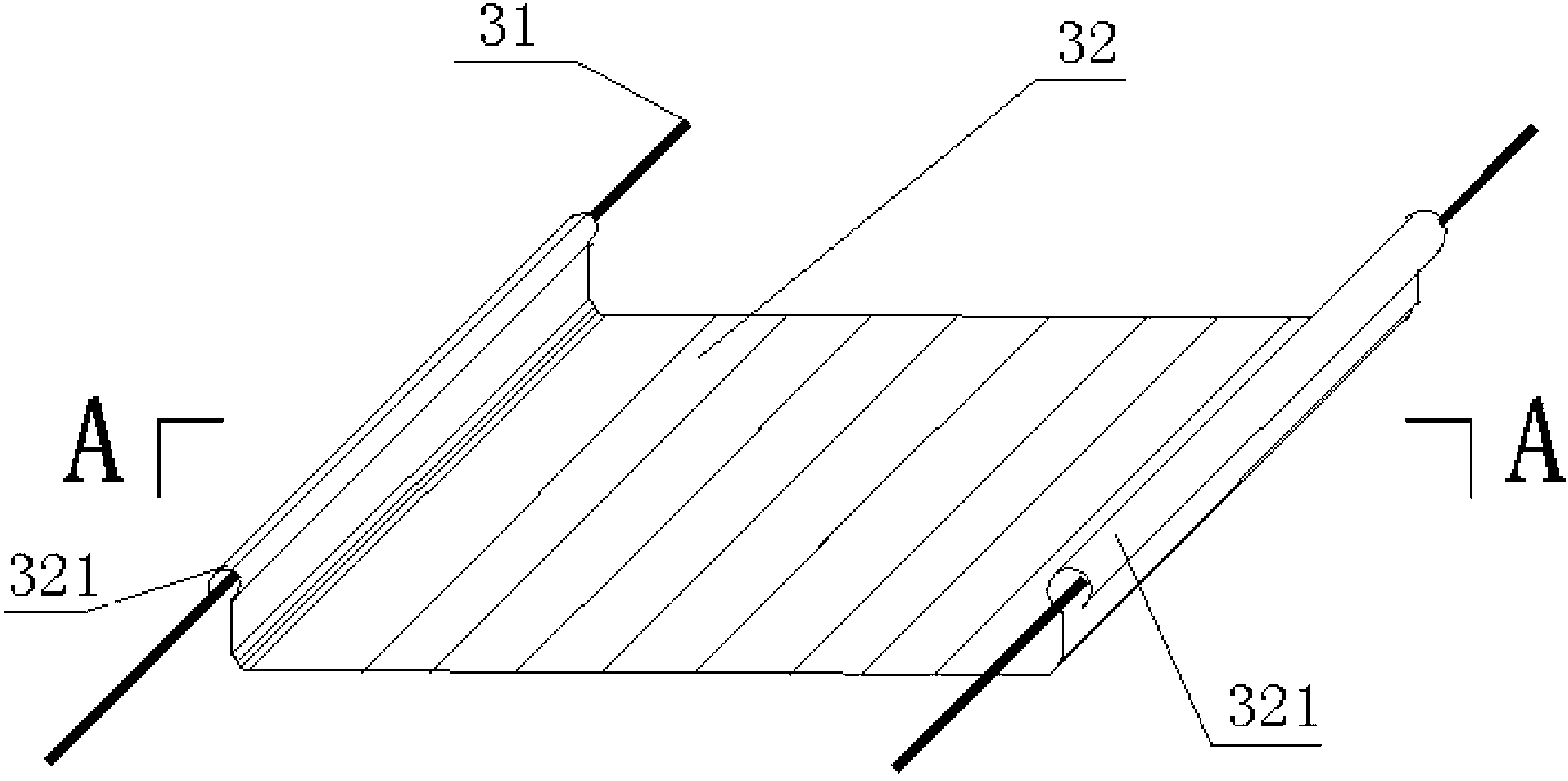

[0048] figure 1 The structure shows a kind of high-altitude transmission system for roof panels, including: metal sheet coil 2, forming machine 1 and transmission device, wherein the metal sheet coil 2 can be steel coil or aluminum coil, etc., which provides sheet material for forming machine 1, The forming machine 1 directly makes the metal coil into the roof panel of the required shape; and the transmission device is used to transfer the made roof panel to the roof 5 where the metal roof panel is to be installed, which is a roof panel conveying guide rail 3, which One end is connected to the reserved upper plate opening 4 on the roof 5, and the other end is arranged below the plate outlet of the forming machine 1. The plate output an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com