Method for conveying coal in end slope laneway in open pit coal mine

A technology of open-pit coal mines and roadways, which is applied in open-pit mining, earthwork drilling, special mining, etc. It can solve problems that affect the economic benefits of enterprises, increase transportation distances, and increase operating costs, so as to shorten transportation distances and reduce pollution. , the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

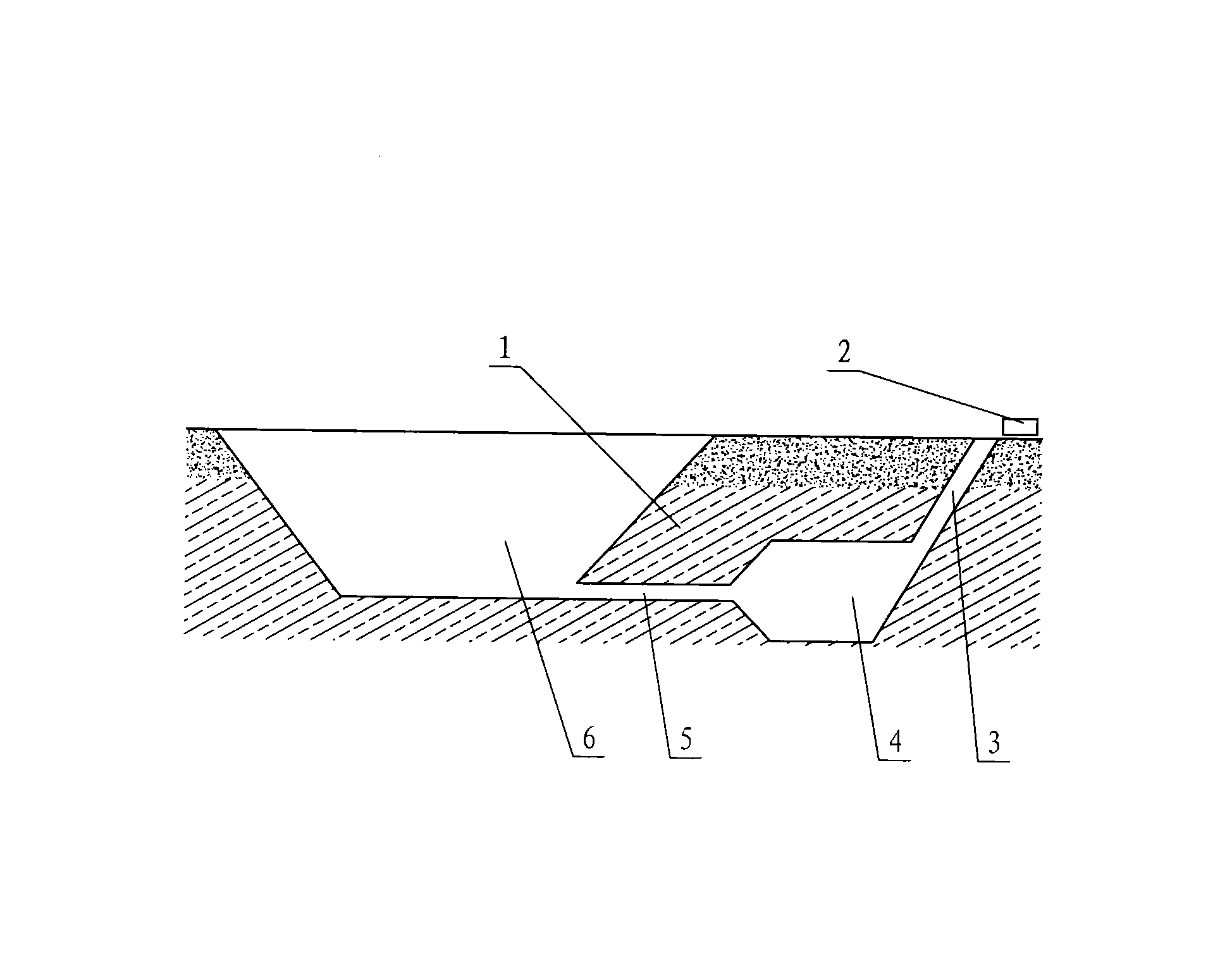

[0011] In the coal seam where the end side 1 of the open-pit pit is located, a transport roadway is continuously extended with the advancement of the stripping working face to become the side side roadway 2. It is connected with the ground transportation system 6, that is, the open-pit, the connecting roadway, the side roadway, the inclined shaft, and the ground transportation system are connected in sequence. Determine the belt conveyor with the corresponding bandwidth, and the cross-sectional dimensions of the connecting lane, side lane and inclined shaft are determined according to the technical parameters of the belt conveyor with different bandwidths. The coal transportation process is as follows: After the coal is crushed by the crushing station in the pit → the shaft or connecting lane → the side roadway → the inclined shaft → the ground transportation system. Coal is collected by single-bucket excavator and transported by dump truck to the crushing station in the pit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com