Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Orderly cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

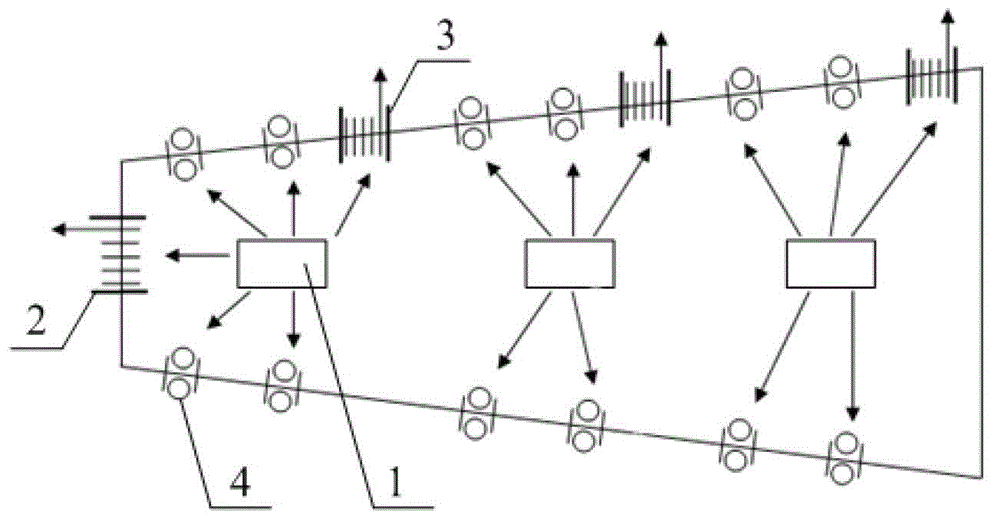

Control method and device for station train running operation

ActiveCN106218671AAvoid the build processSent to preventRailway traffic control systemsComputer moduleControl principle

The invention relates to a control method and device for station train running operation during the railway transportation. The control method for station train running operation is characterized in that the current station site lines, equipment and train running static basic data is used as train route inherent card control principles and conditions; through the train plan planning, dispatching command processing and flow process operation setting, the train card control conditions are enriched and refined; the route integral card control condition of each train is formed; in addition, one-by-one checking and rechecking are performed on various card control conditions before the train route building; route handling is performed after the errorless condition is confirmed. The control device for station train running operation provided by the invention comprises a plurality of function modules; the method provided by the invention is realized through each functional module; the timeliness and the comprehensiveness of the card control condition inspection are ensured; the correctness of the route building is ensured; the occurrence of wrong route handling problem is fundamentally avoided.

Owner:中国铁路兰州局集团有限公司 +1

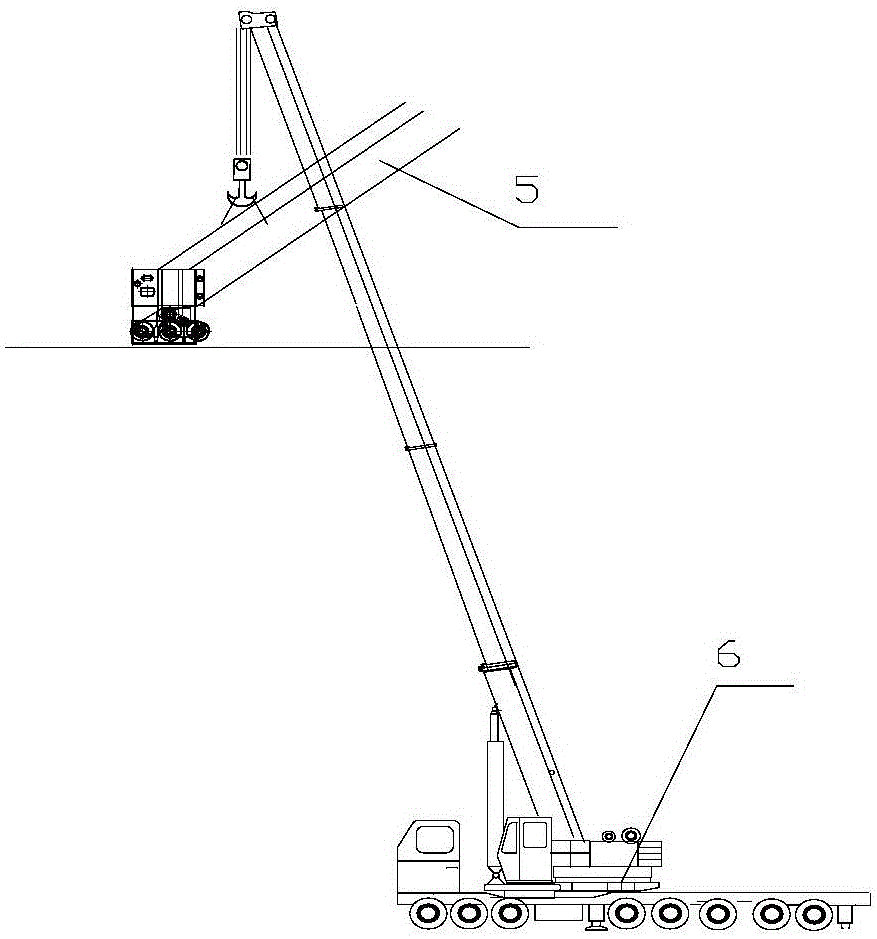

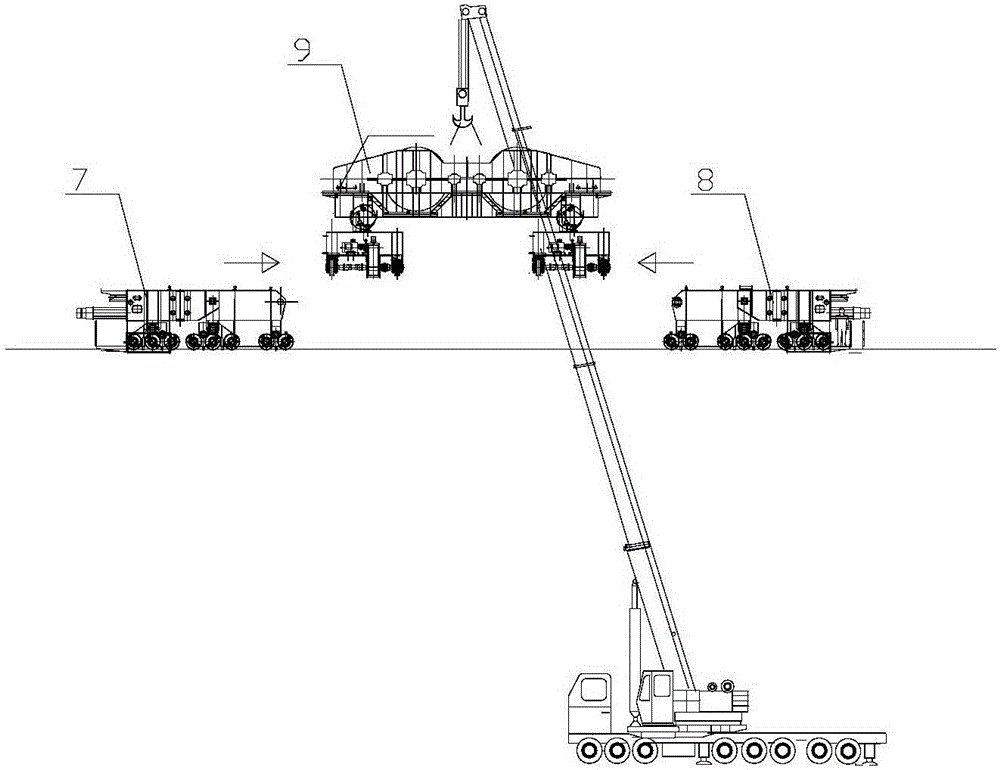

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

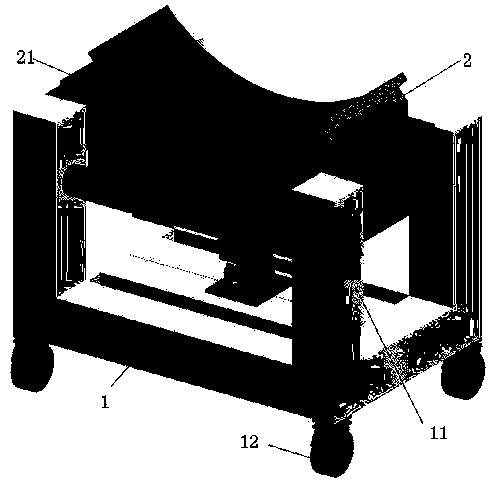

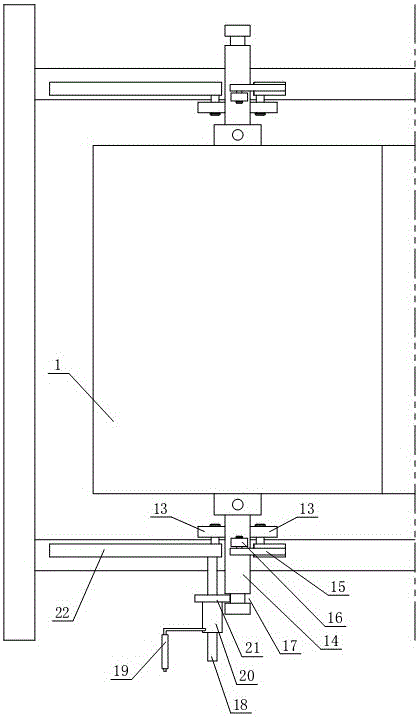

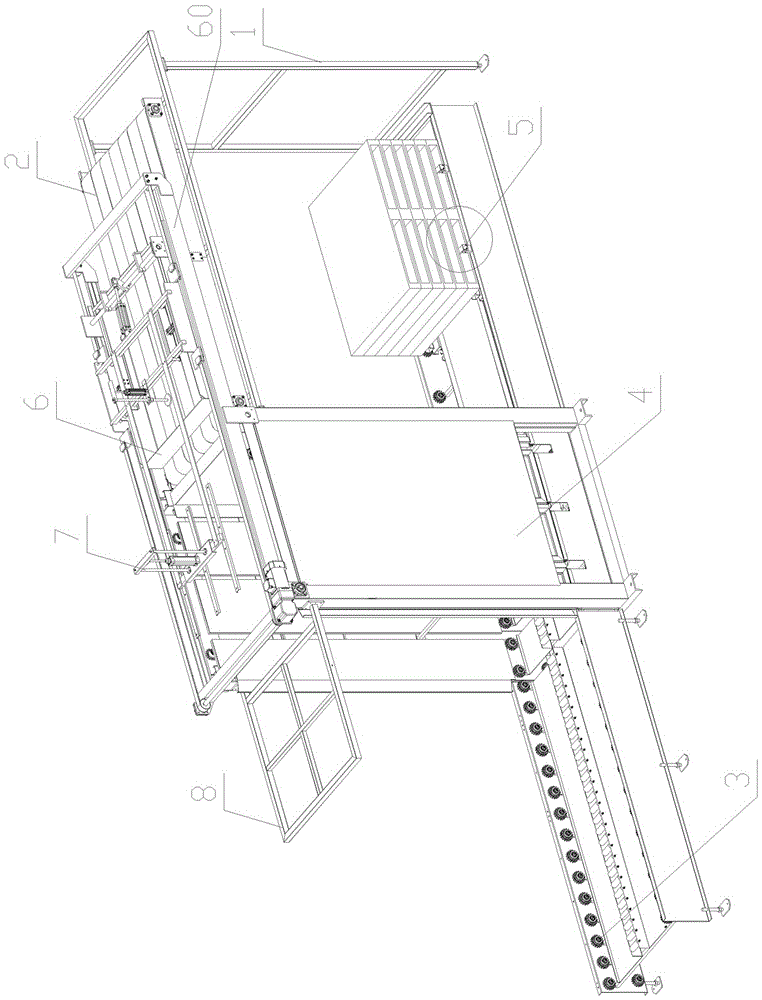

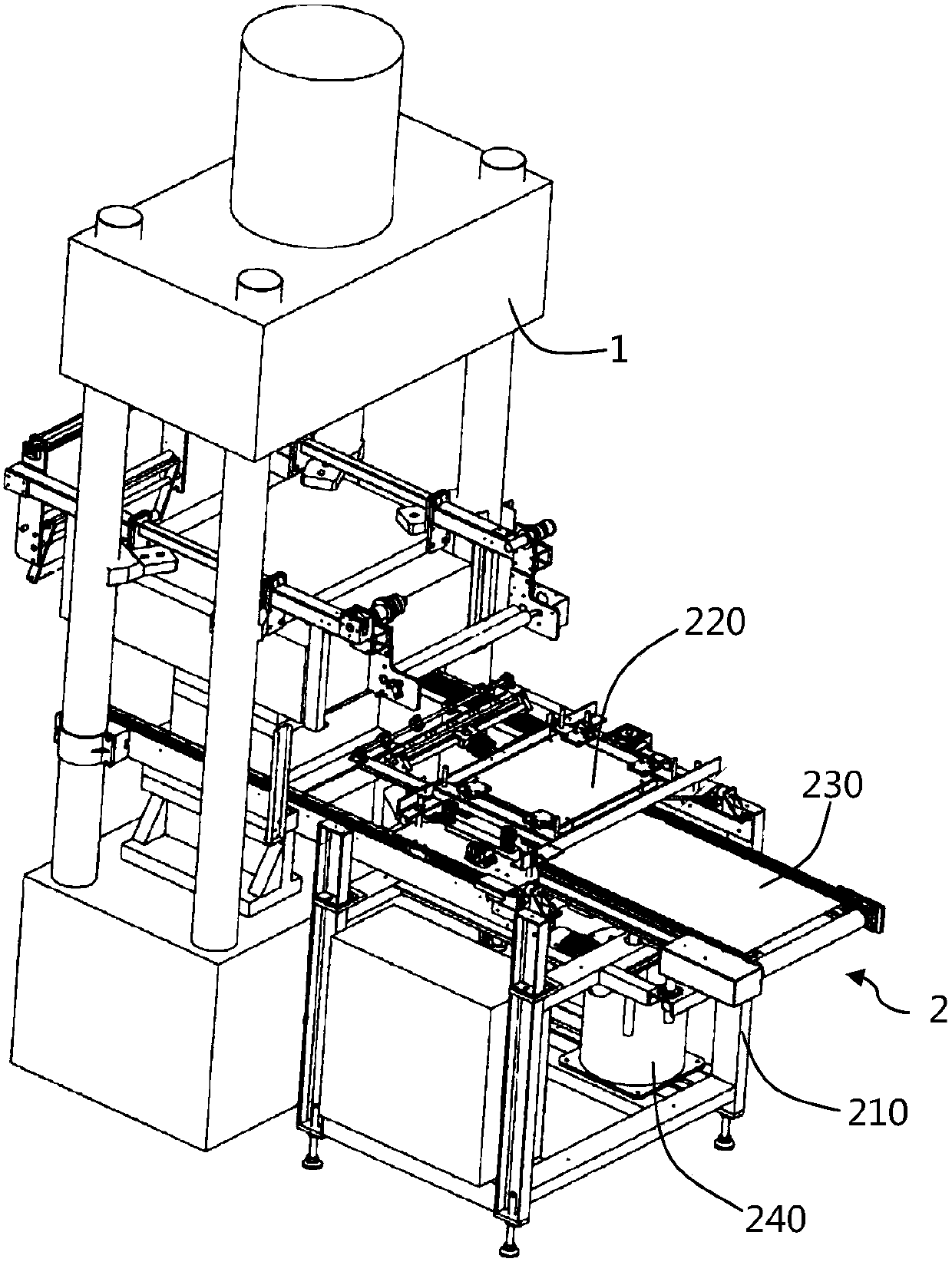

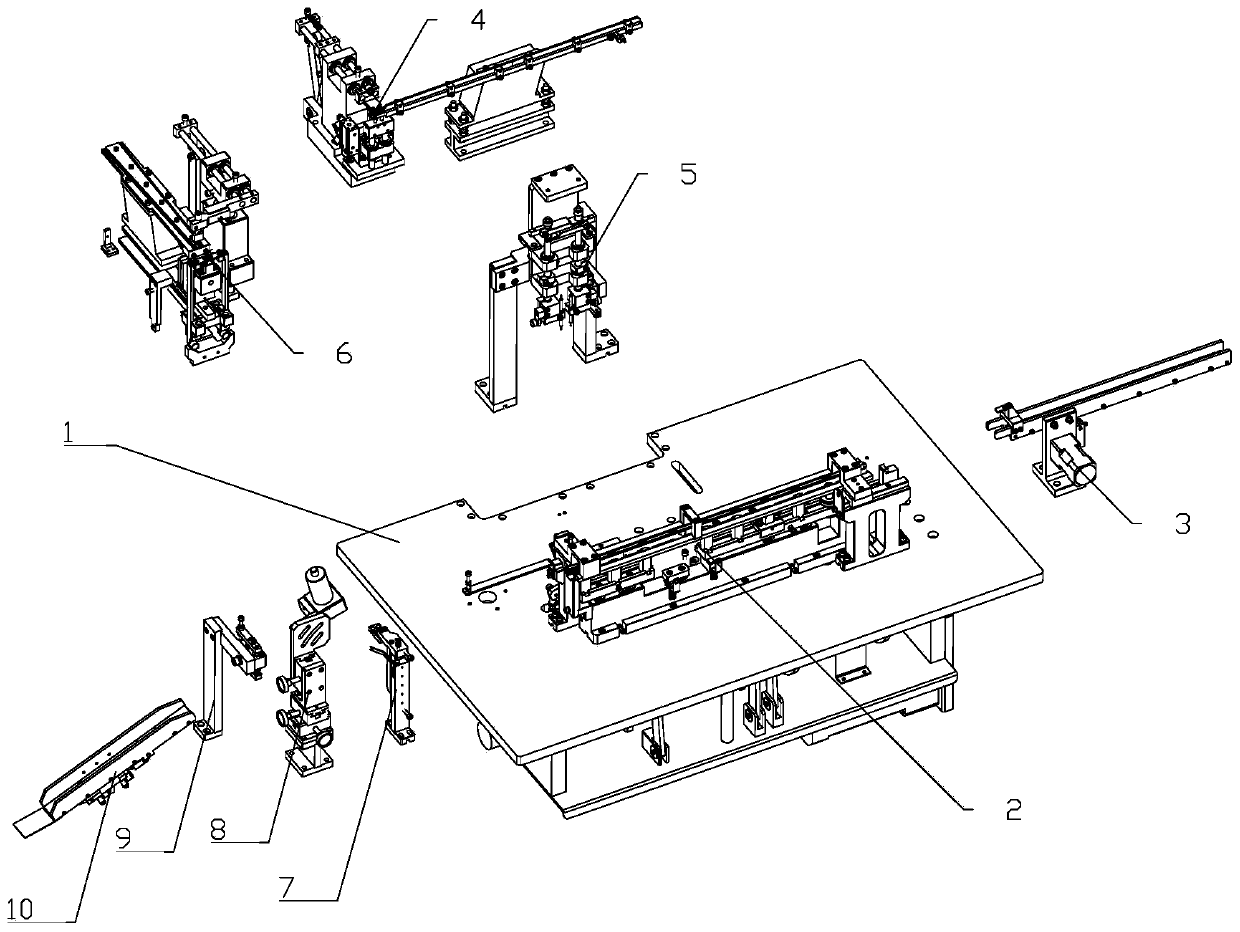

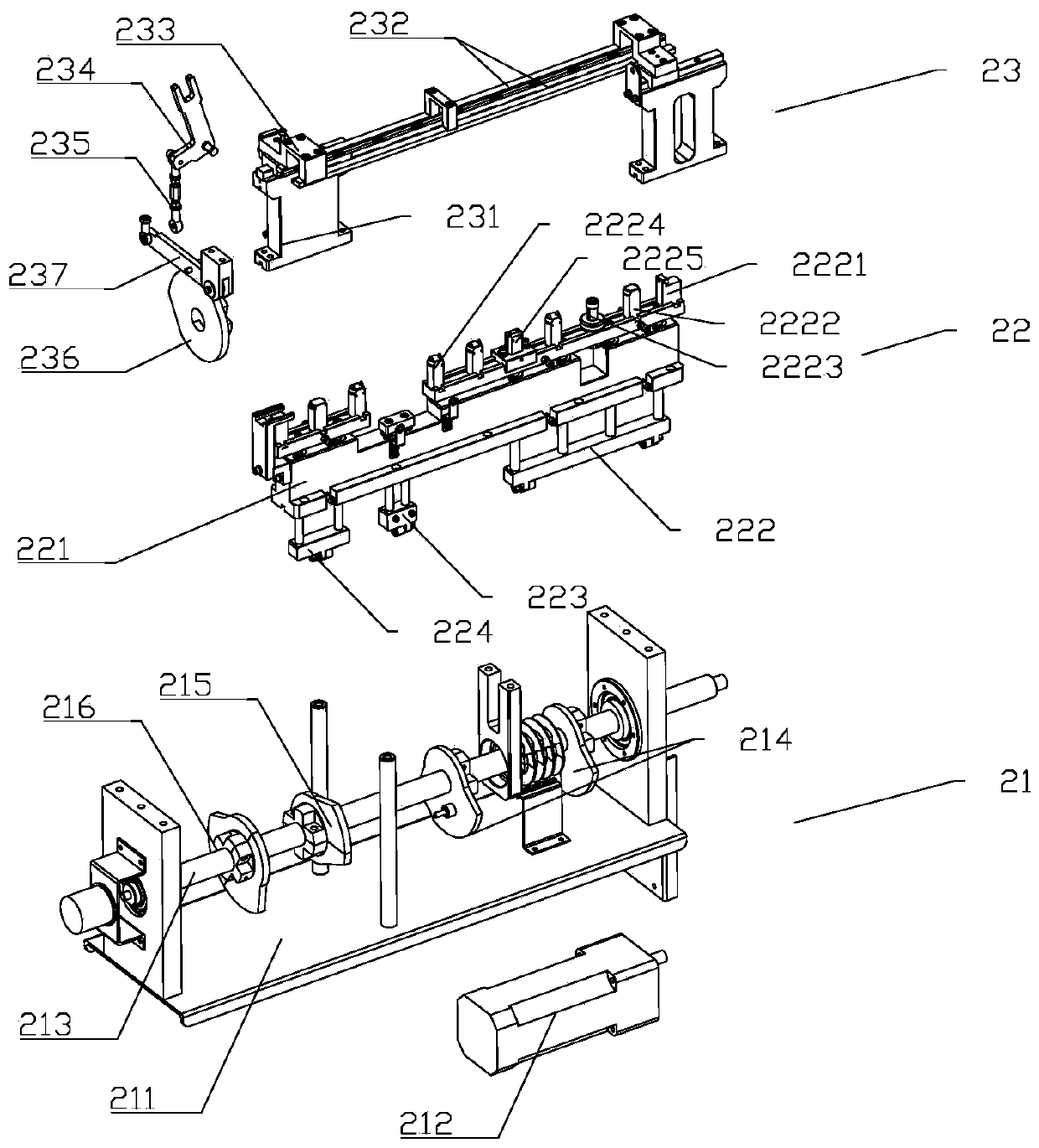

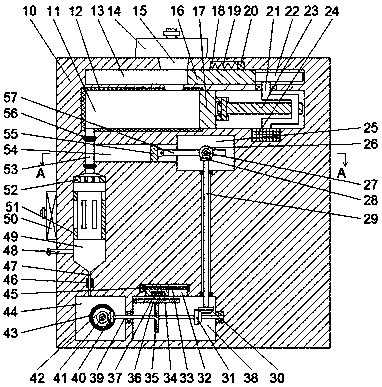

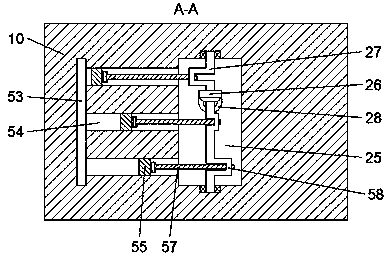

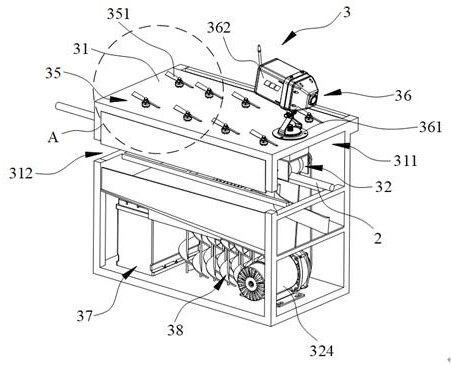

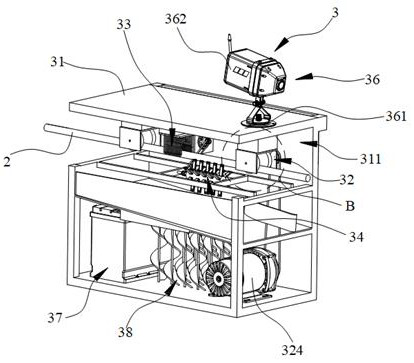

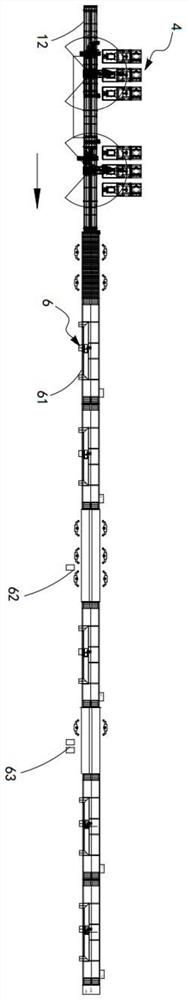

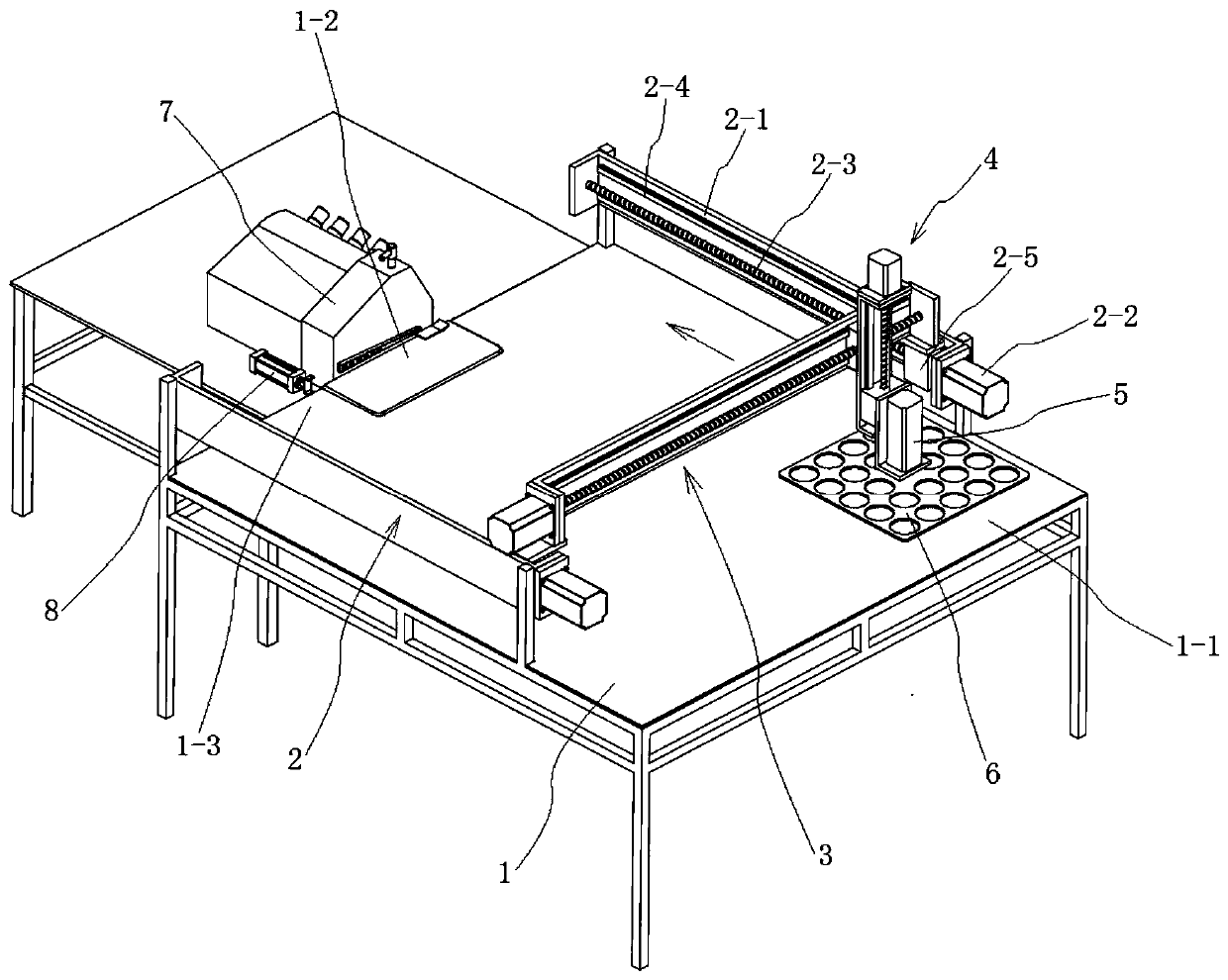

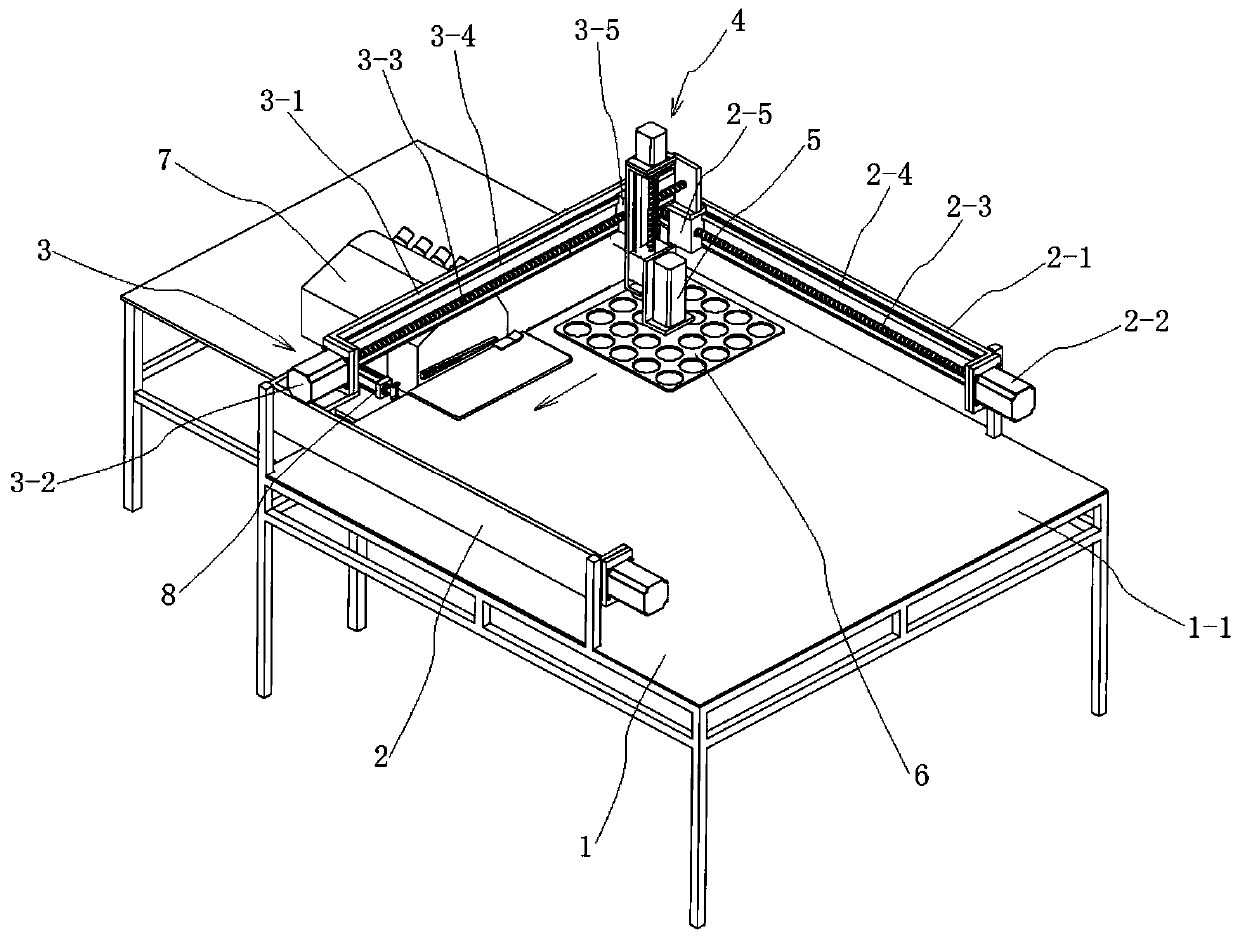

Automatic towel continuous serging device and serging method thereof

ActiveCN110067088AMotor coordination and stabilityHigh movement position accuracyWorkpiece carriersWork-feeding meansTowel clampEngineering

The invention discloses an automatic towel continuous serging device and a serging method thereof, and belongs to the field of towel making equipment. According to the towel continuous serging deviceand the serging method thereof, a pressing plate cooperates with a workbench to press a towel fabric to translate a towel, and the pressing plate is driven to move up and down, rotate, and move horizontally and vertically by a towel clamping and moving mechanism, so that the automatic continuous serging of edge of the towel along the outer contour of the towel on a machine head of a serging machine is realized, and the serging quality and the production efficiency of the towel are improved; in addition, the device is reasonable in structural design, convenient to automatically control, simpleand convenient to operate, and stable and reliable to move. The whole set of towel continuous serging device cooperates with a controller to control the movement process of each part; the serging process is continuous and stable, the connection is in order, and the device can be applied to serging of towels of most sizes, including square towels and towels in other shapes, can replace traditionaltowel serging equipment, and has very high promotion and use values.

Owner:陈建强

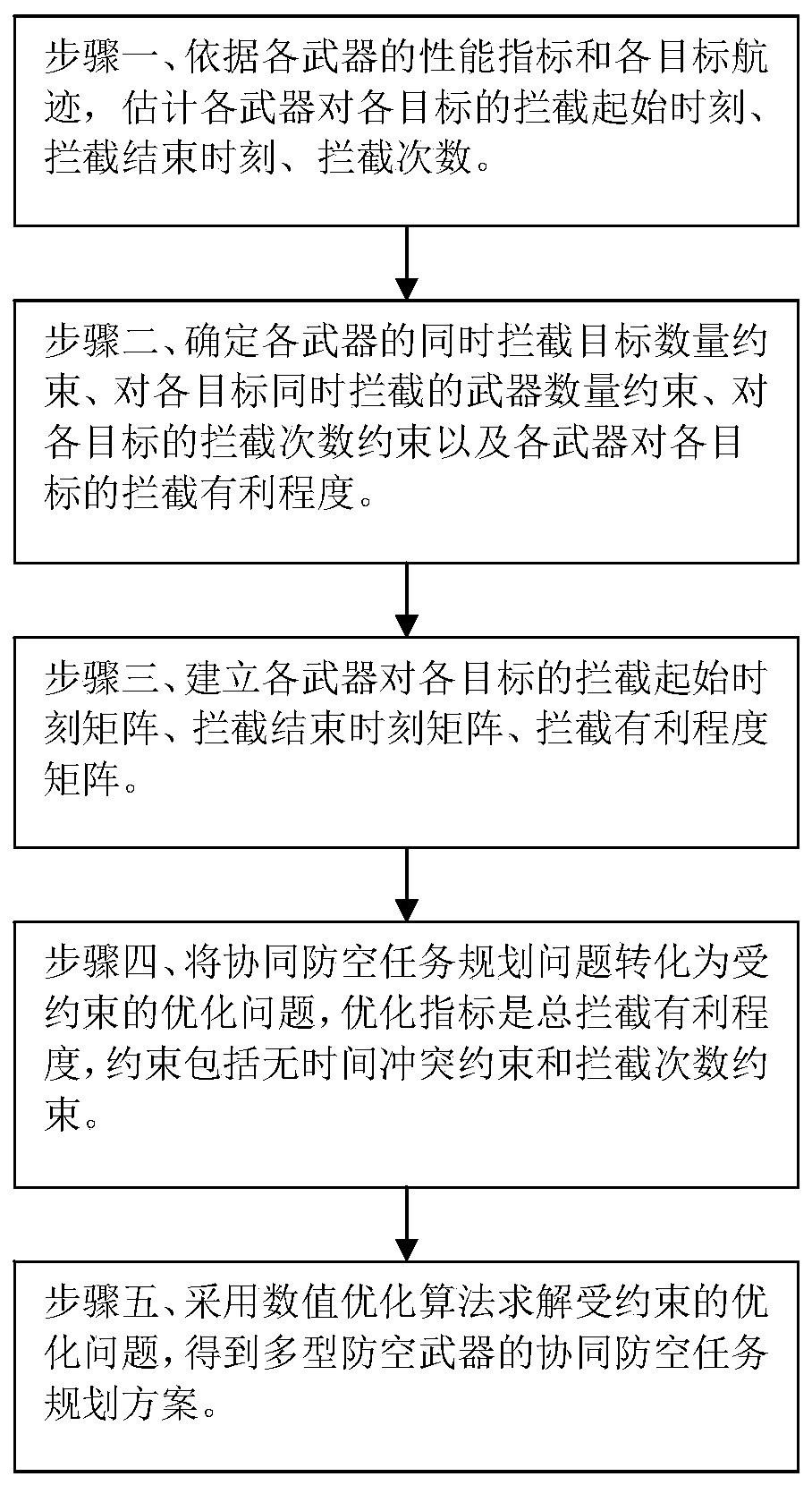

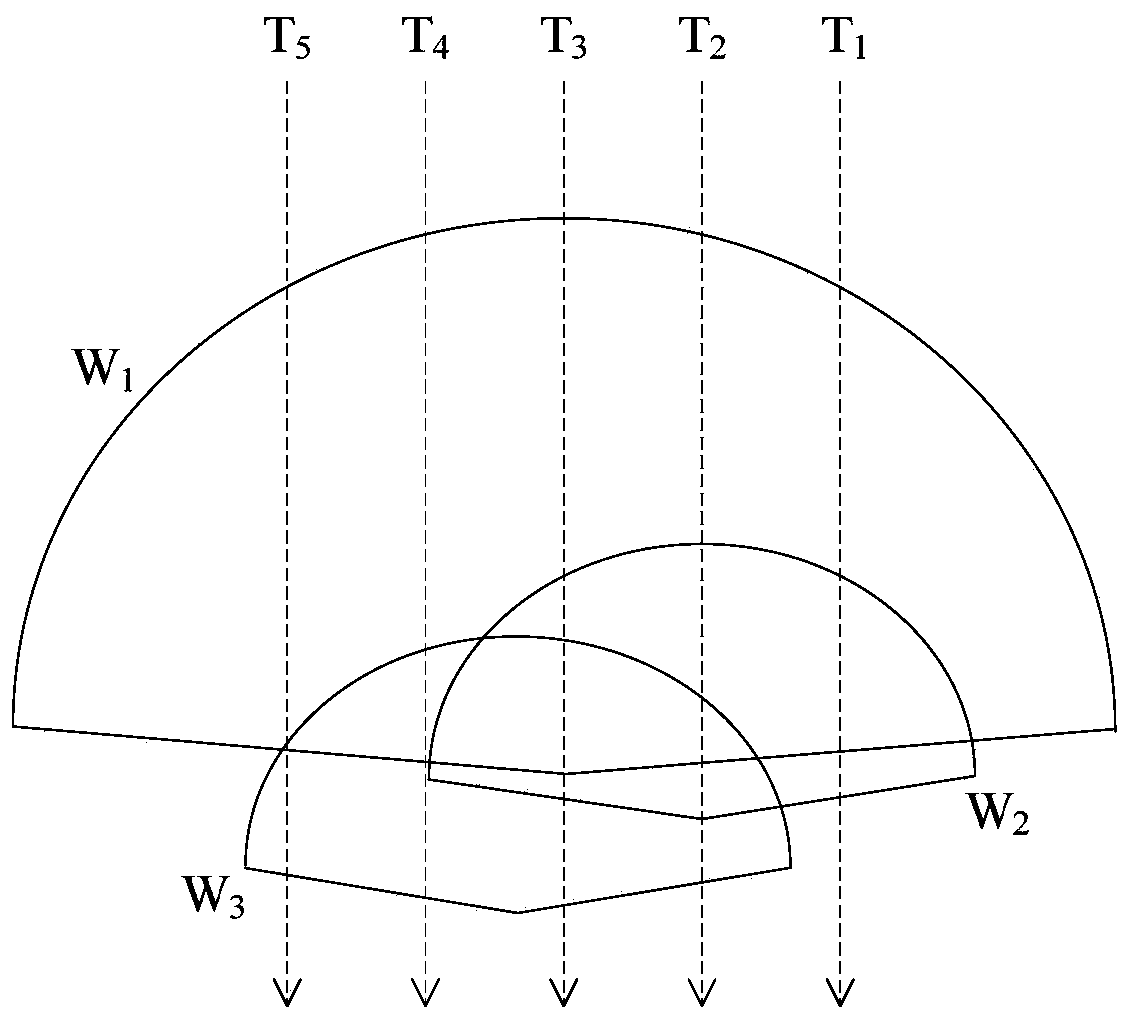

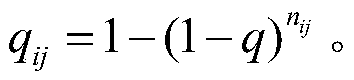

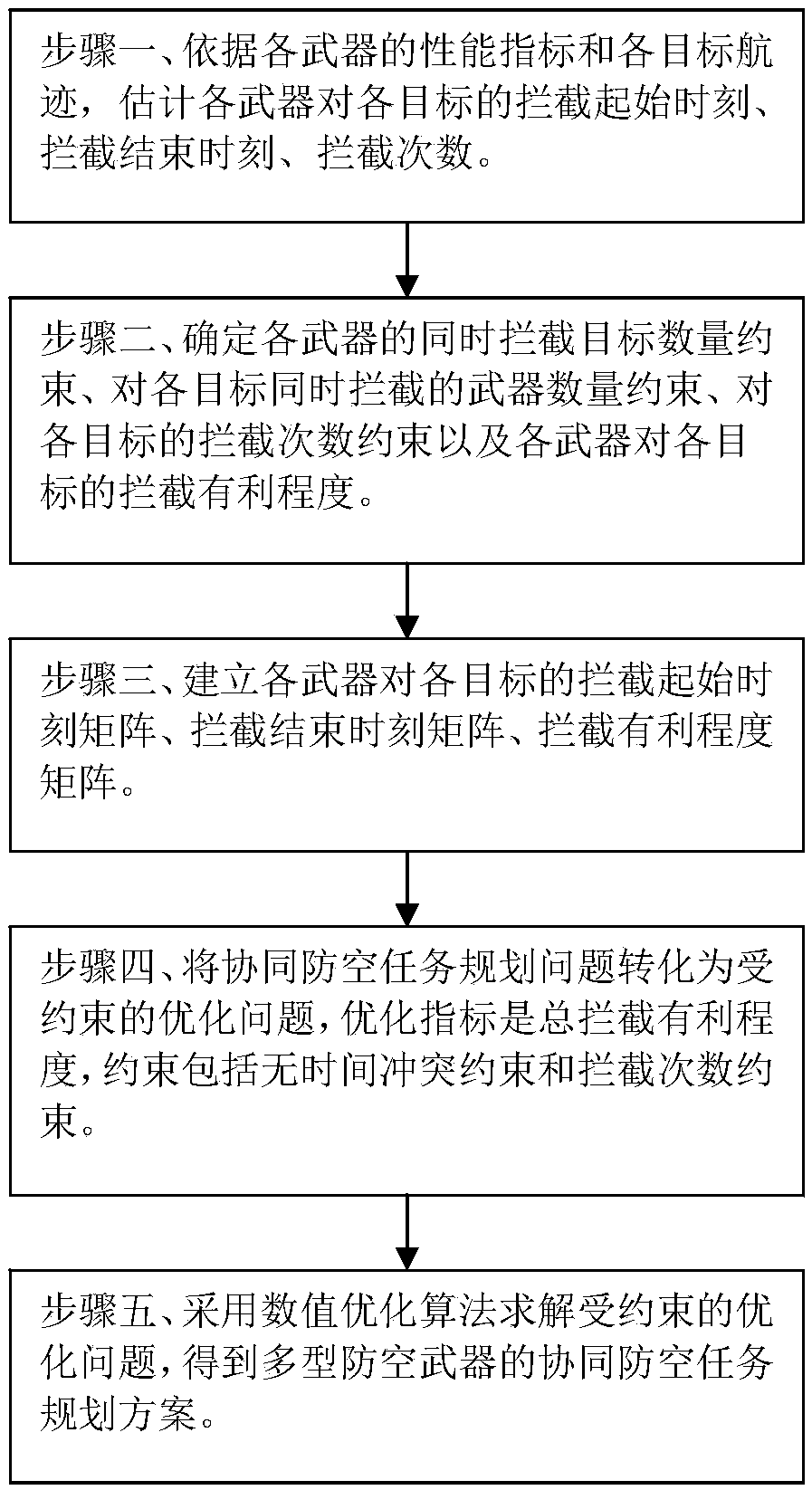

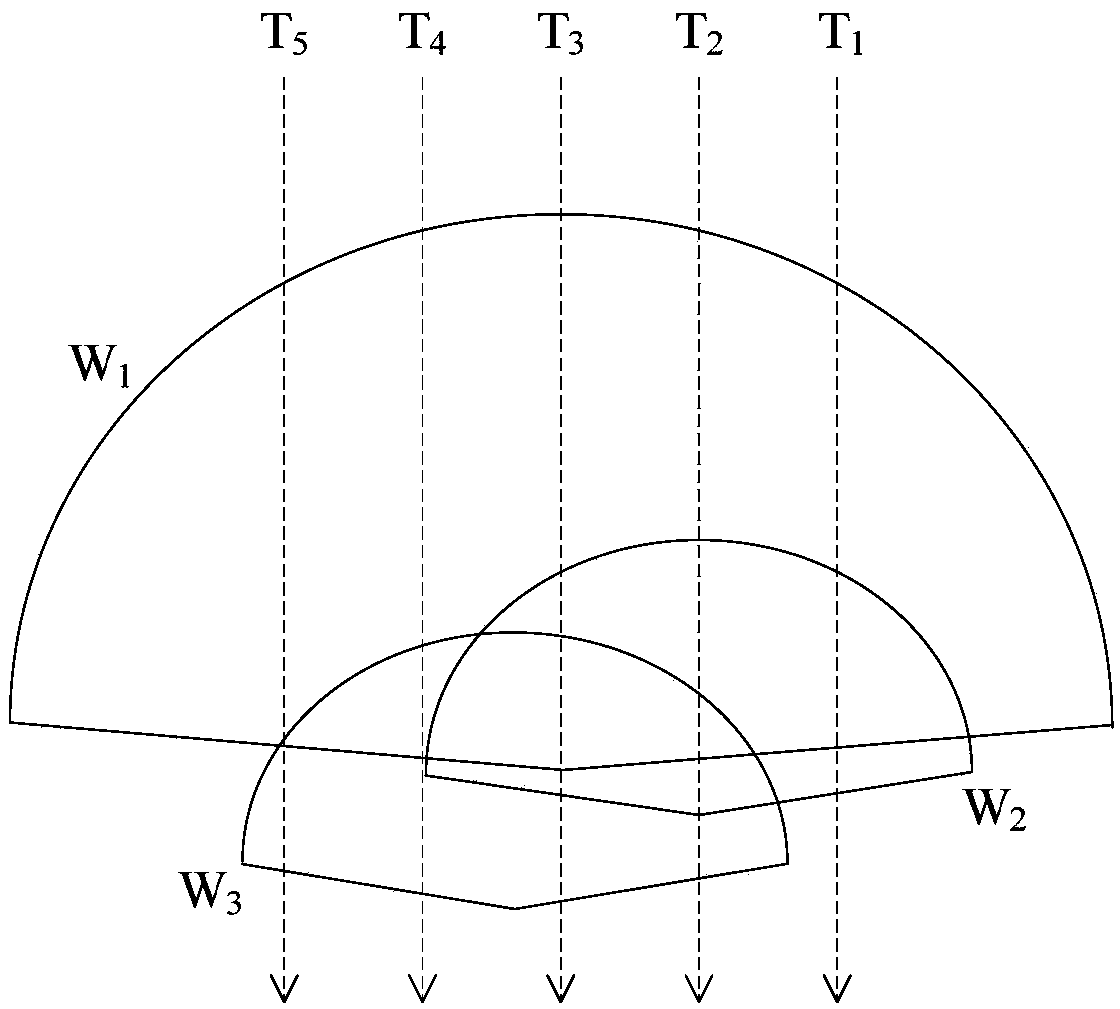

A cooperative air defense mission planning method and system for multi-type air defense weapons

The invention provides a cooperative air defense mission planning method and system for multi-type air defense weapons. According to the performance index of multi-type air defense weapons and the flight path of air targets, the interception start time, interception end time and interception times of each weapon to each target are estimated, and various constraint conditions are determined. Numerical optimization algorithm is used to plan the interception time sequence of multi-type air defense weapons to multi-targets under constraint, and the time period-arm-goal is obtained. The invention is applicable to the combat mission planning, command auxiliary decision-making, combat capability evaluation and the like of multi-type air defense weapons.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

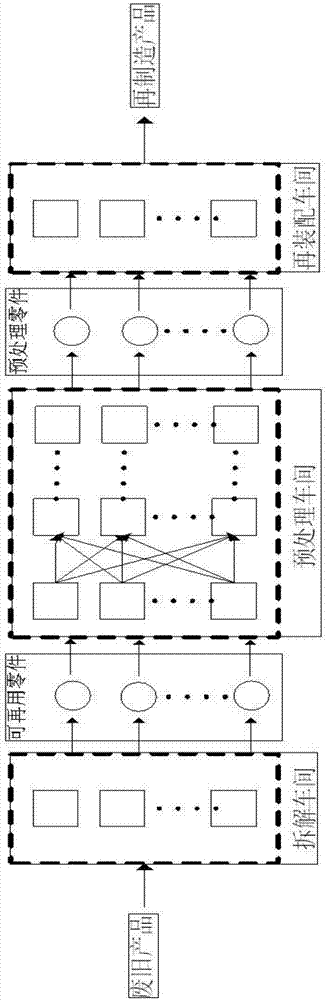

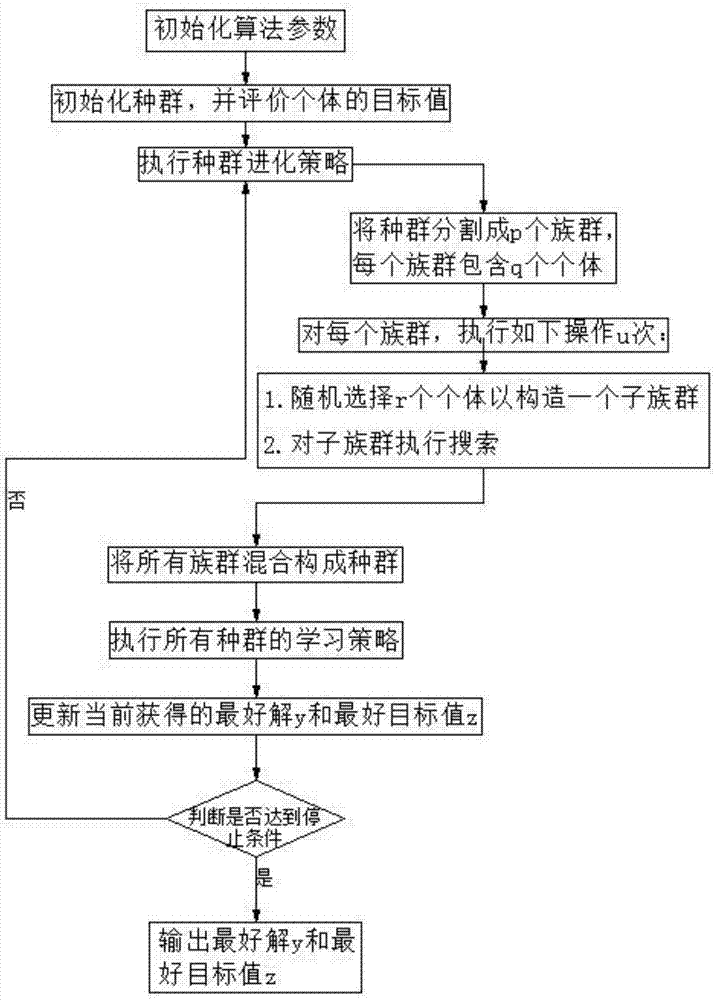

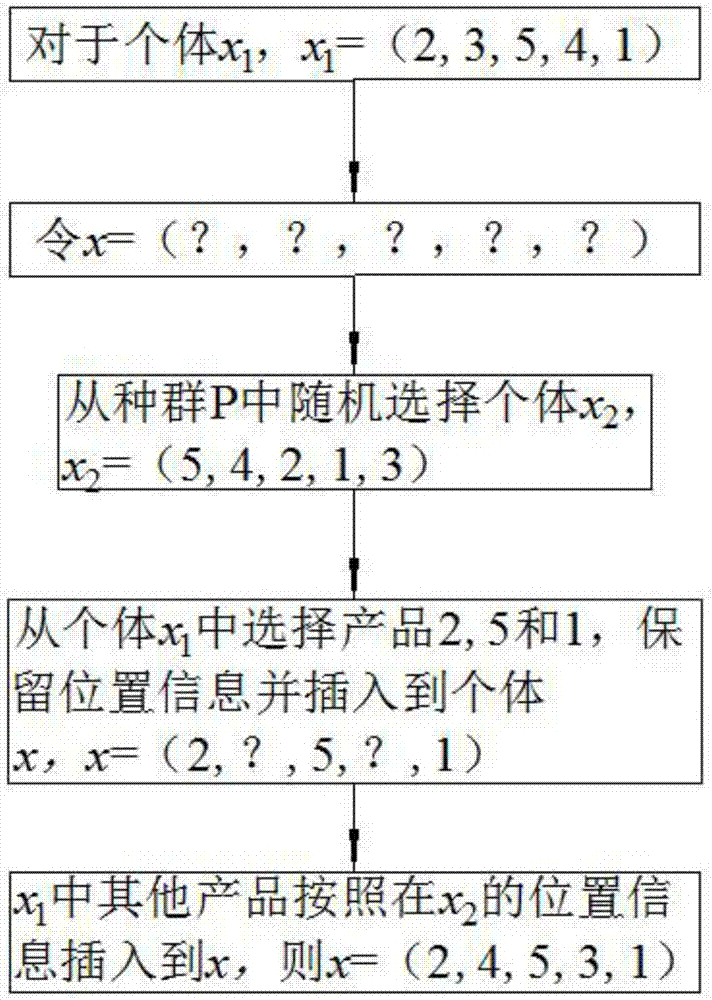

Integrated scheduling method for disassembling, preprocessing and reassembling of remanufacturing system

ActiveCN106980308AReasonable useOrderly cohesionTotal factory controlProgramme total factory controlGlobal optimizationComputer science

The invention belongs to the technical field of information and control, and particularly relates to an integrated scheduling method for disassembling, preprocessing and reassembling of a remanufacturing system. The integrated scheduling method comprises the steps of building an integrated scheduling model of the remanufacturing system according to the production process of disassembling, preprocessing and reassembling of the remanufacturing system, designing a learning mechanism based frog leaping algorithm to perform solving, and finally establishing an integrated scheduling method for disassembling, preprocessing and reassembling of the remanufacturing system. The invention provides a scheduling method capable of realizing global optimization of disassembling, preprocessing and reassembling of the remanufacturing system in allusion to a problem that a disassembling workshop, a preprocessing workshop and a reassembling workshop are uncoordinated and inconsistent in production process because of independent scheduling of the three workshops of the remanufacturing system, thereby achieving orderly connection of the disassembling, preprocessing and reassembling process.

Owner:QINGDAO UNIV

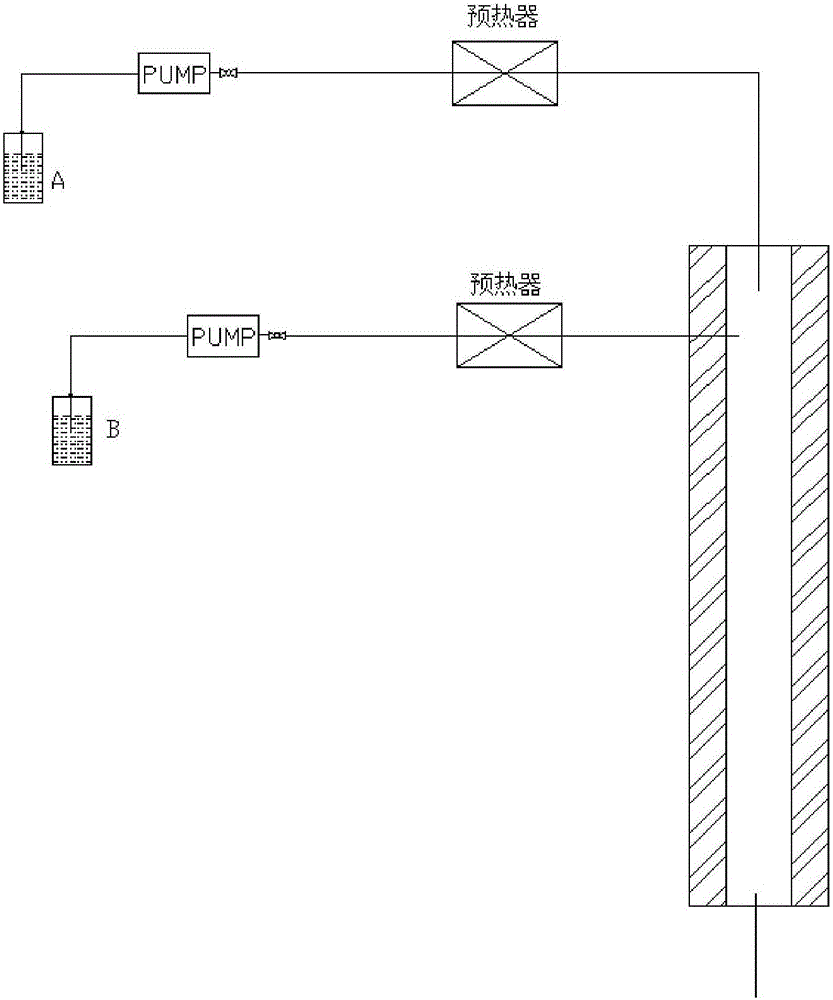

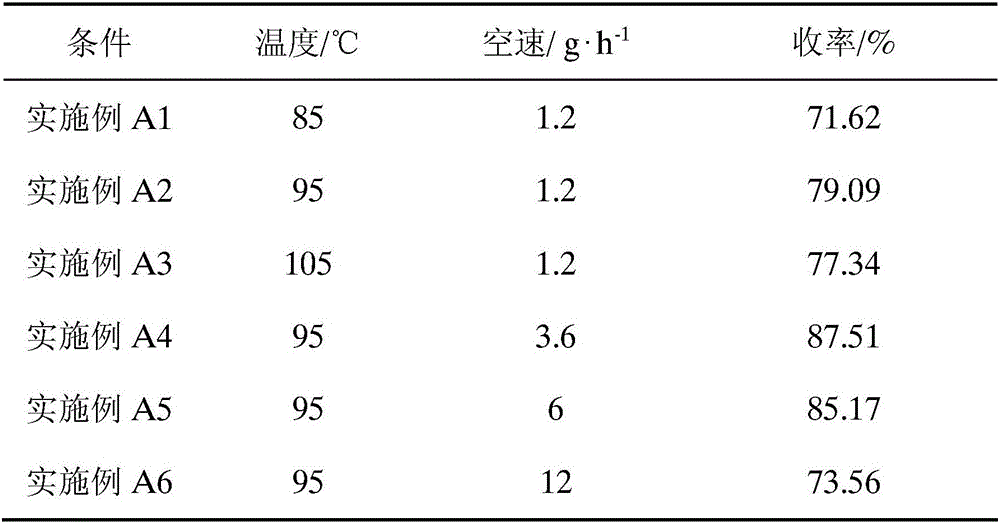

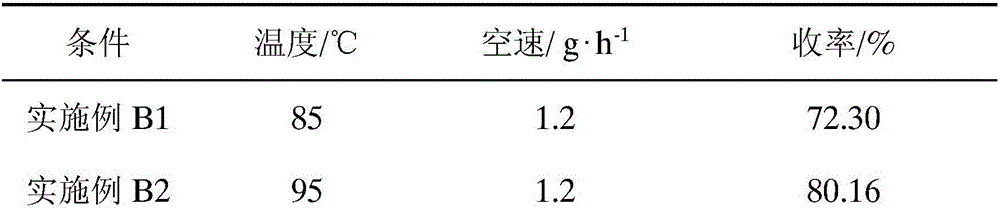

Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate

ActiveCN106008596AOvercoming the problem of instability and easy decompositionHigh feasibilityGroup 5/15 element organic compoundsSolubilityDecomposition

The invention discloses a preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as a glufosinate intermediate. The method comprises the following steps: 1) proper organic solvent, alkaline substance and phase-transfer catalyst are added to cyclic phosphoric anhydride at the temperature of subzero 30 DEG C, stirred, heated to 25-50 DEG C, subjected to a reaction with diethyl oxalate at the room temperature and stirred, and a product is obtained through direct precipitation and filtration from the solvent; 2) water is added to the product, hydrogen chloride is introduced slowly, the pH is controlled, heating is performed, water is removed through rotary evaporation after the reaction is performed for 16 h, and a final product is obtained through vacuum drying. The method has the advantages that the problems of poor solubility and high probability of precipitation of cyclic phosphoric anhydride at a low temperature as well as high probability of ring opening of anhydride and high probability of decomposition of phosphate groups of cyclic phosphoric anhydride under an alkaline condition due to temperature increasing are solved, and the feasibility for preparing 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as the glufosinate intermediate from cyclic phosphoric anhydride is realized successfully.

Owner:ANHUI COSTAR BIOCHEM CO LTD

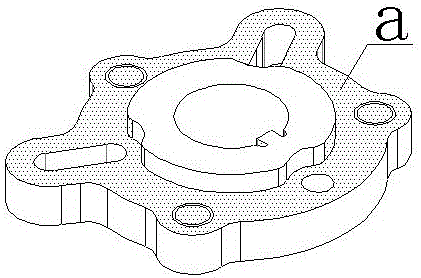

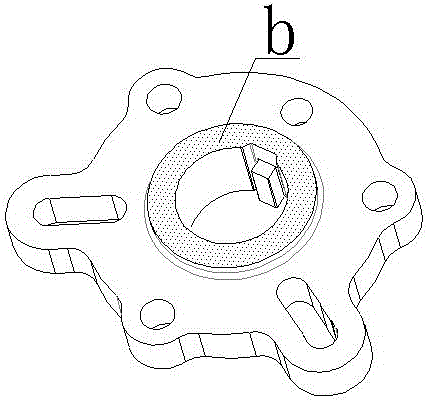

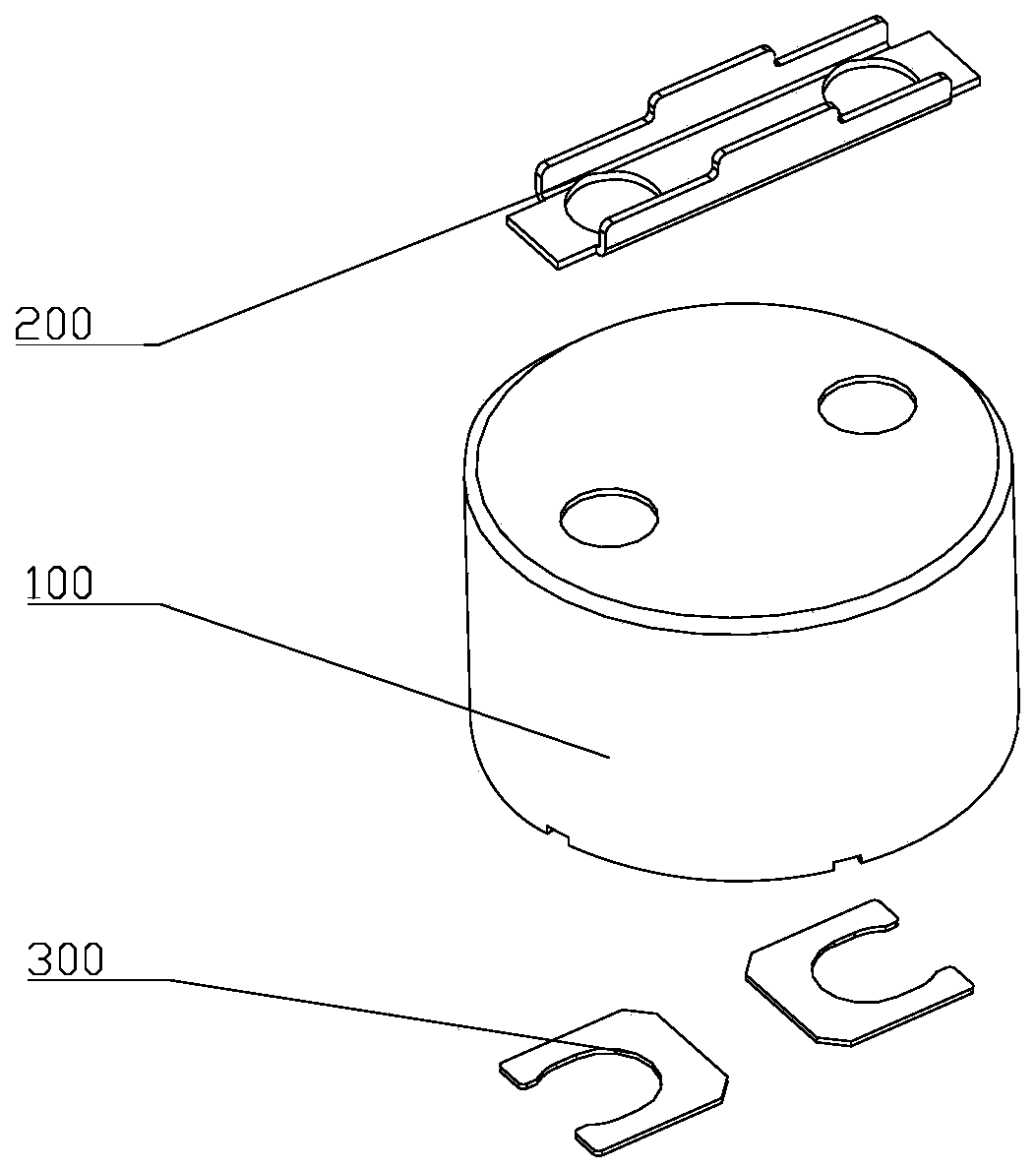

Camshaft toothed wheel hub for automobile engine and powder metallurgical preparation method for camshaft toothed wheel hub

ActiveCN106041094AReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusCamMachining

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgical preparation method for the camshaft toothed wheel hub. The method comprises the following steps: S101, preparing materials; S102, pressing and forming; S103, sintering blank; S104, refining and processing; S105, performing steam treatment; and S106, detecting and packaging. The method is linked up orderly, is fewer in processes, and has a material utilization rate higher than 95%. The camshaft toothed wheel hub obtained by the method is less in machining amount, is high in output per shift and is good in consistency, so that the product manufacturing cost is reduced by 50% when various performance requirements of the camshaft toothed wheel hub are met.

Owner:马鞍山市华东粉末冶金厂

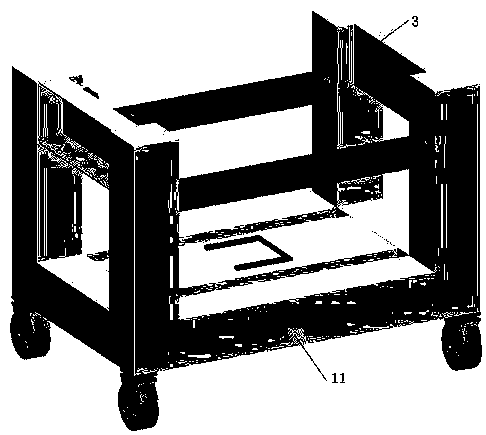

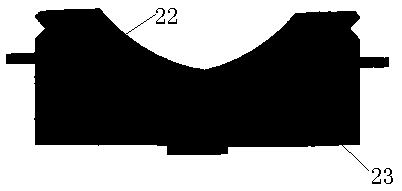

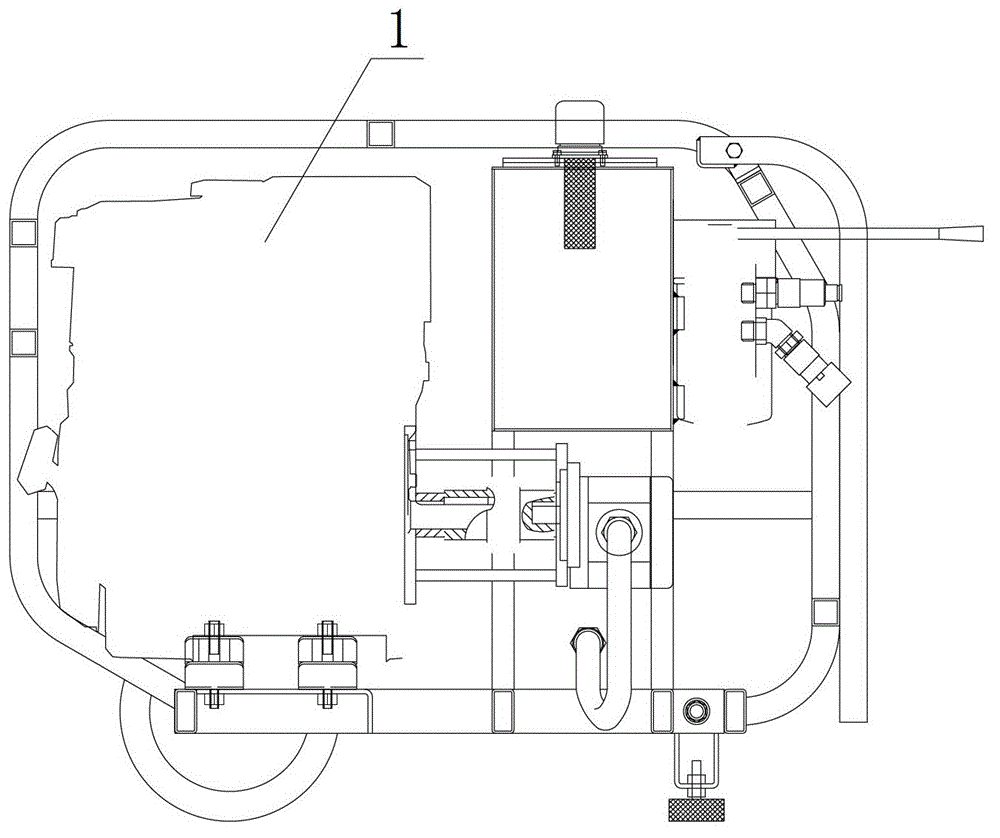

Pipeline lifting vehicle in confined space and using method thereof

The invention relates to a pipeline lifting vehicle in a confined space. The pipeline lifting vehicle in the confined space comprises a jack, and is characterized by further comprising a bottom walking trolley and a pipeline supporting frame; the pipeline supporting frame is arranged in the bottom walking trolley; the bottom walking trolley comprises a framework used for containing the pipeline supporting frame; the two sides of the pipeline supporting frame are provided with limiting baffles; by means of the limiting baffles, the pipeline supporting frame is made to be placed in the framework; the jack is arranged at the bottom of the pipeline supporting frame, and the jack is also arranged in the framework of the bottom walking trolley; a to-be-lifted pipeline is placed on the pipeline supporting frame, the pipeline is conveyed to the assigned position through the bottom walking trolley; and the pipeline supporting frame is jacked through the jack, and therefore the pipeline can reach the assigned operation height. According to the pipeline lifting vehicle, pipeline transporting is performed through universal wheels, and the jack is used for lifting the pipeline; and compared with traditional pipe gallery large caliber pipeline construction, the work procedures of the whole process from that the pipeline enters the gallery to that welding is completed can be linked more compactly and orderly.

Owner:SHANGHAI BAOYE GRP CORP

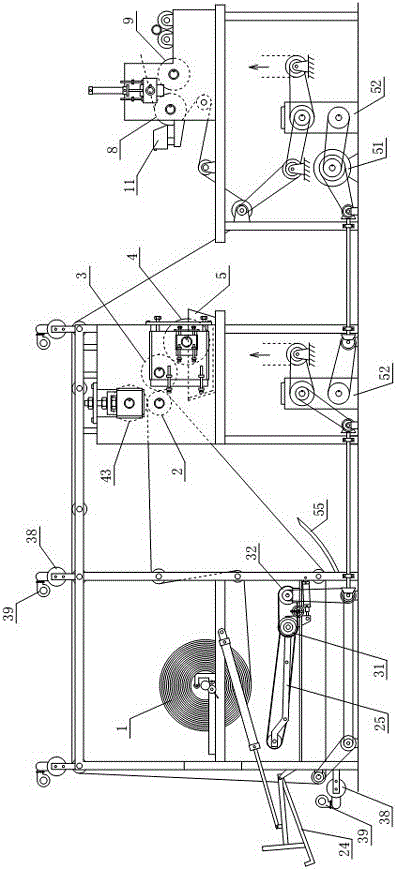

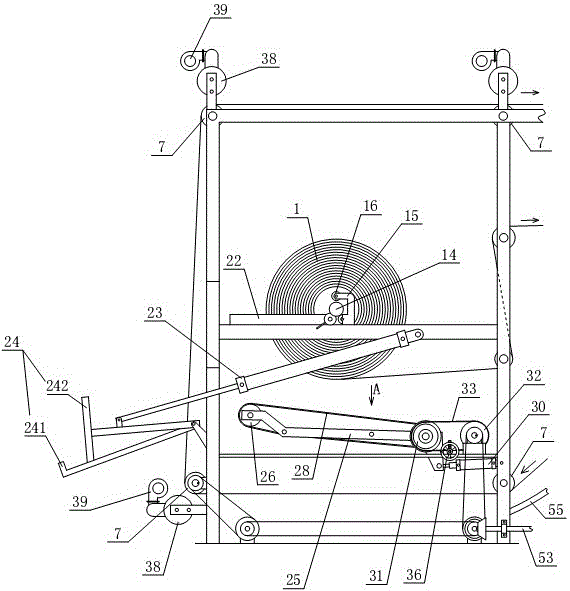

Neck paper machine

ActiveCN106241446AKeep drySimple processPretreated surfacesPackaging toiletriesPaper basedViscose fiber

The invention relates to a neck paper machine which comprises a paper loading conveying system, a viscose system, a rotary drying system and a slitting rolling system; the paper loading conveying system comprises a paper roll supporting mechanism and a paper roll drive mechanism; a raw material paper base is taken down from a paper roll and is conveyed to the viscose system; the viscose system comprises a compression roll, a glue spreading roll and a glue dipping roll; the raw material paper base passes through a gap between the compression roll and the glue spreading roll, is spread with glue, and then is conveyed to the rotary drying system; the rotary drying system comprises a plurality of paper guide rolls; the paper base sequentially gets across each paper guide roll to form a rotary conveying line; a plurality of air-blowing drying mechanisms are arranged on the rotary conveying line in a spaced manner; the tail end of the rotary conveying line is connected with the slitting rolling system; and the slitting rolling system comprises a slitting roll, a material supporting roll and a reel shaft which is mounted in a rotatable and liftable manner. The neck paper machine has the advantages of being simple in process flow, convenient to control, high in working efficiency and good in product quality.

Owner:李红波

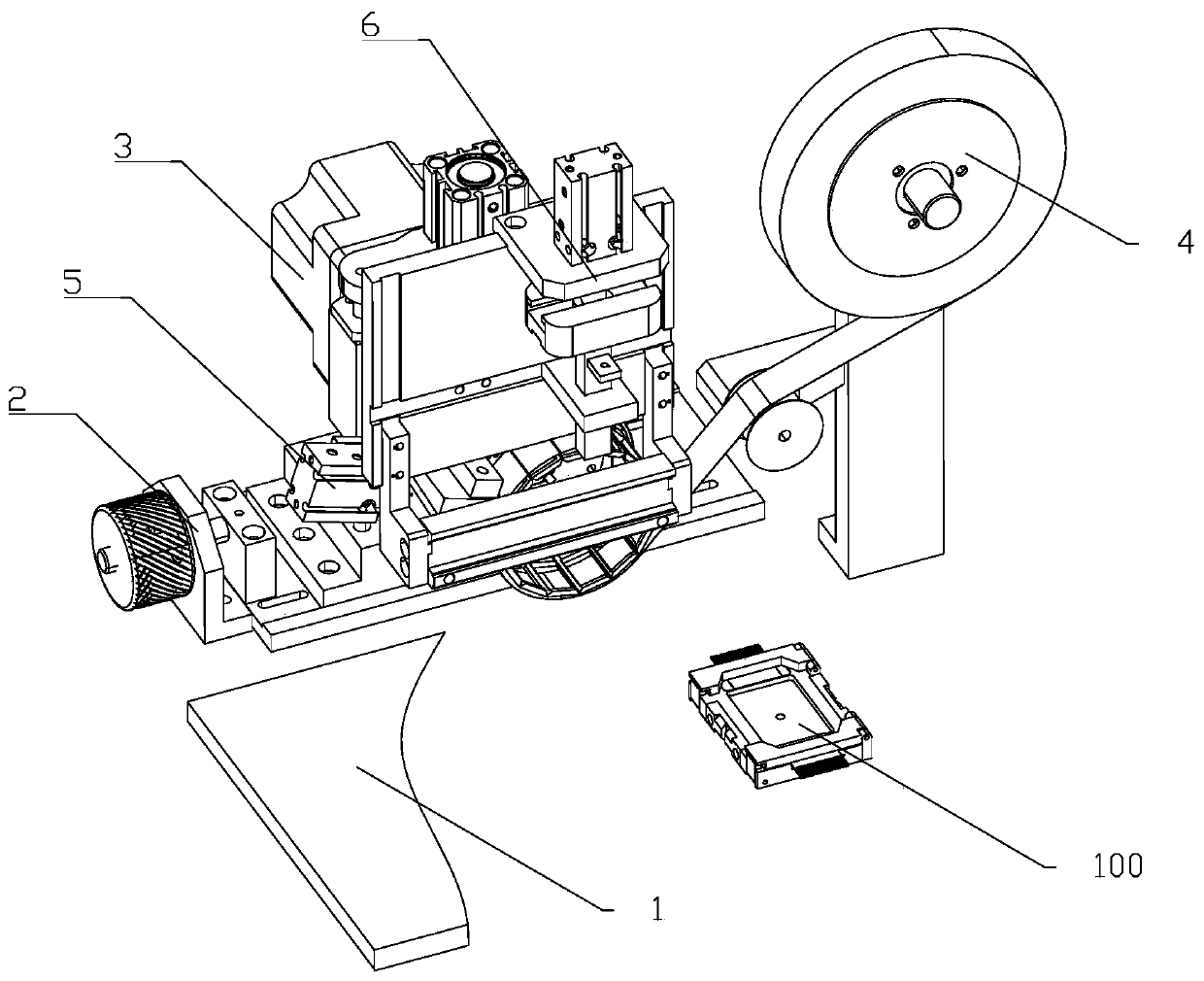

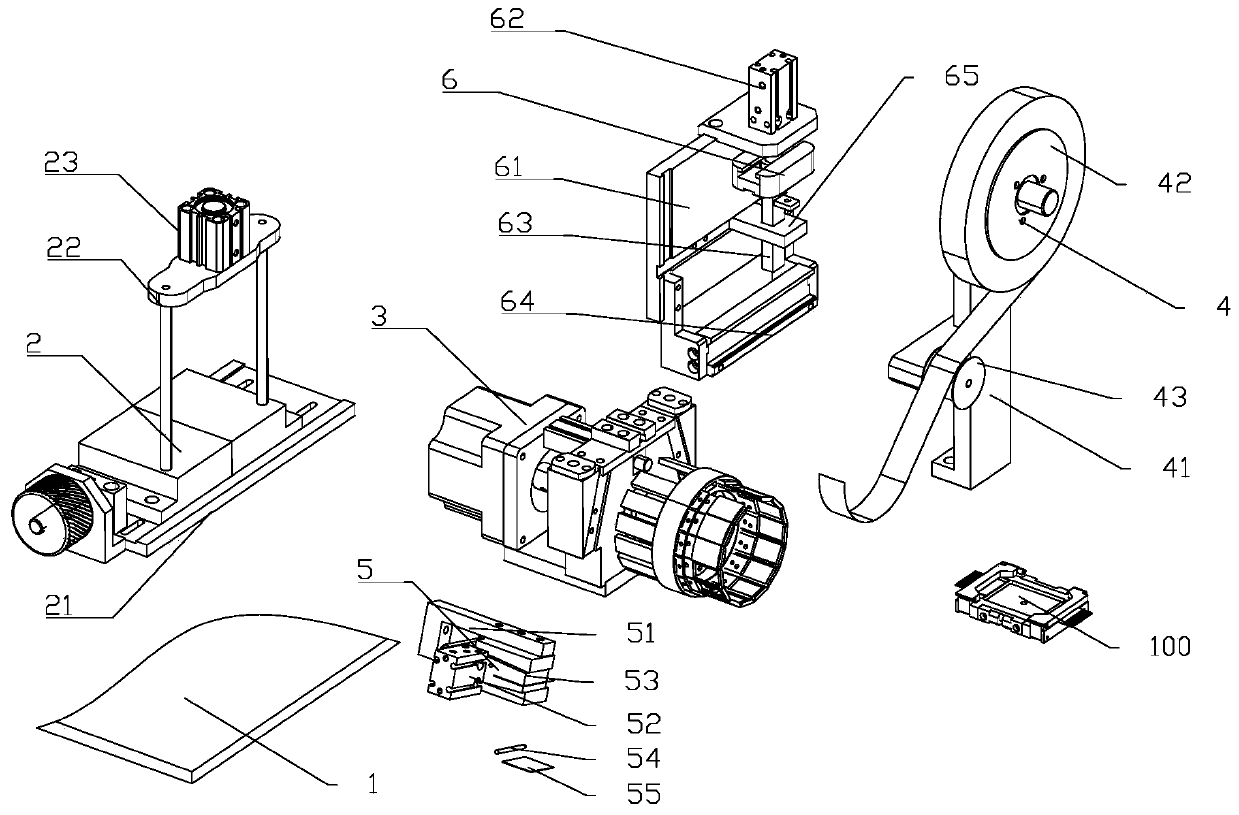

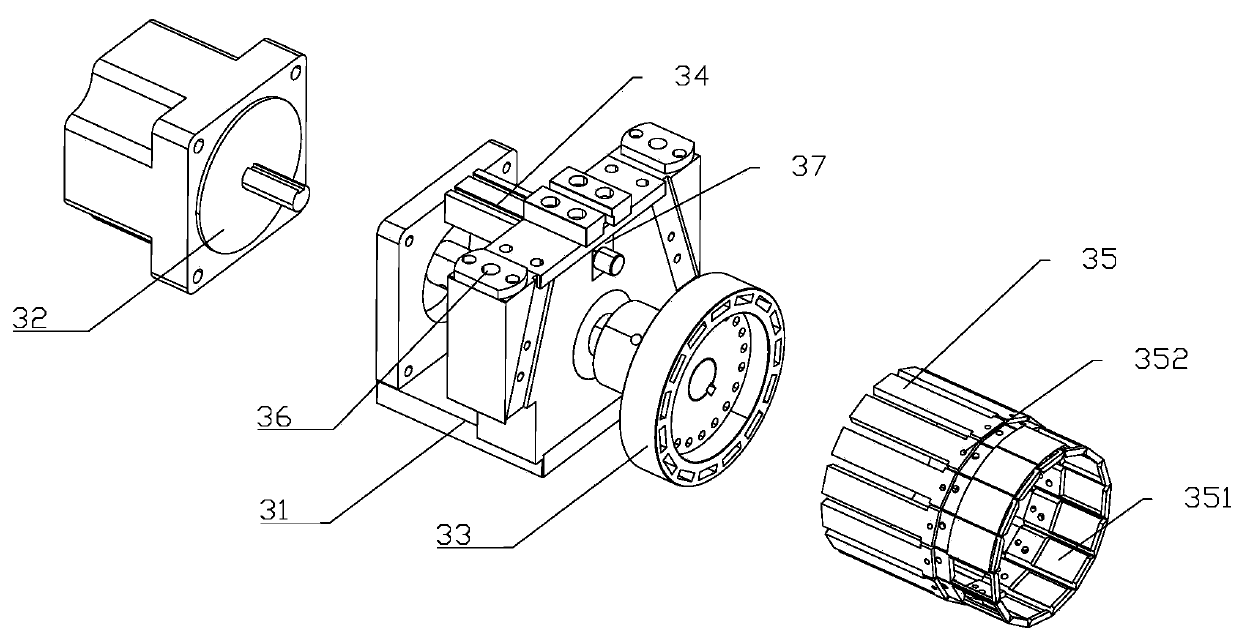

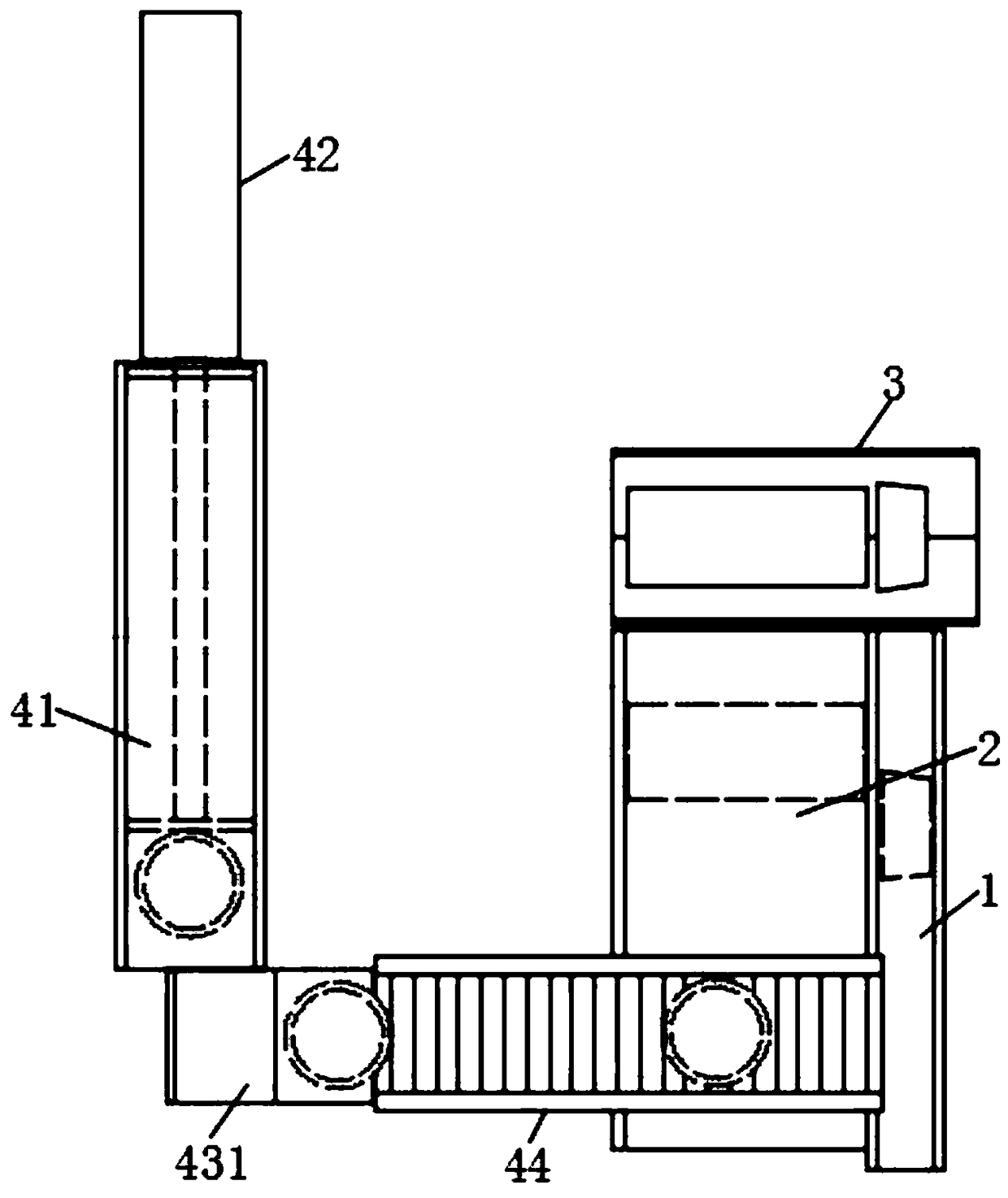

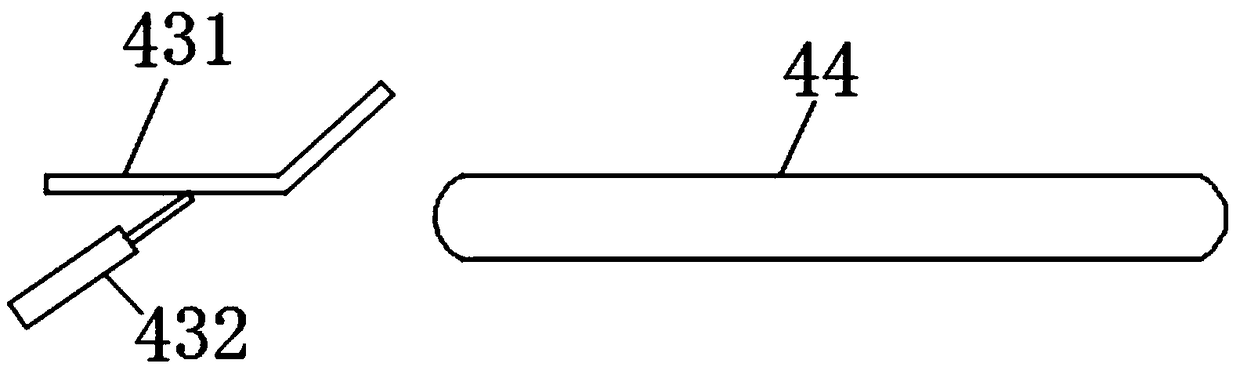

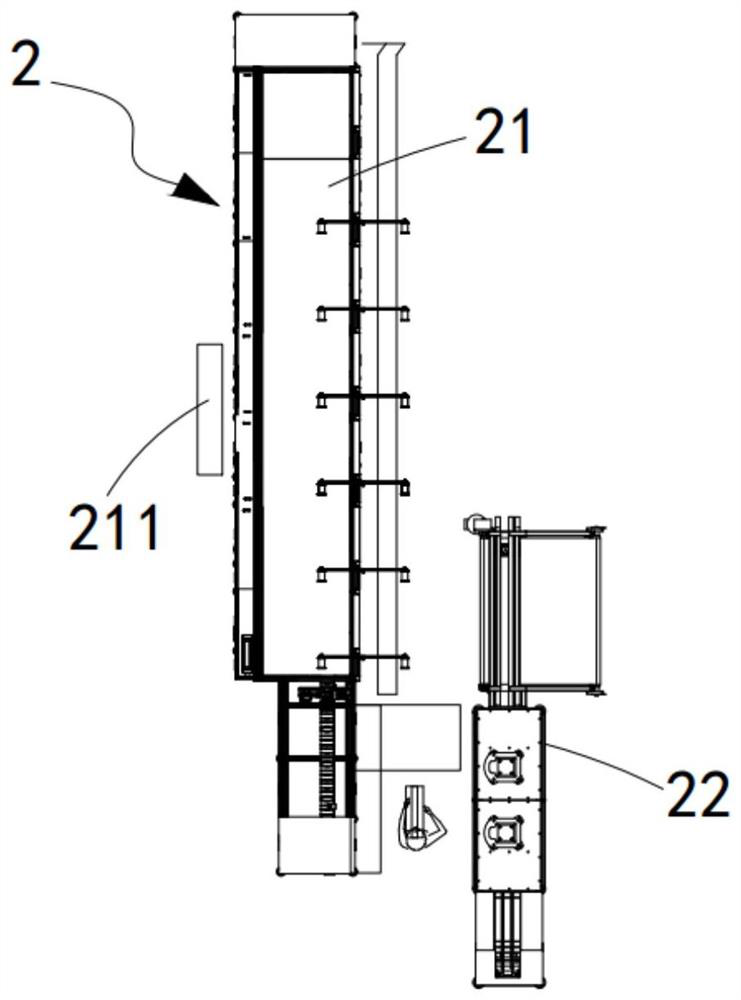

Flat cable end tape attaching device and method

ActiveCN110648805AQuality improvementSame lengthManufacturing wire harnessesStructural engineeringMechanical engineering

The invention relates to the field of flat cable tape attaching and particularly relates to a flat cable end tape attaching device. The device comprises a rack, a base assembly, a winding drum assembly, a film feeding assembly, a cutting assembly and a pressing assembly, wherein the base assembly is installed on the machine frame, the winding drum assembly is connected with the base assembly, thepressing assembly is installed on the machine frame and located over the winding drum assembly, the cutting assembly is obliquely arranged on the winding drum assembly, the film feeding assembly is arranged on the machine frame and located on the side of the winding drum assembly, the winding drum assembly is used for winding a single-sided adhesive tape and sending out the cut single-sided adhesive tape, the cutting assembly is used for carrying out fixed-length cutting of the single-sided adhesive tape on the winding drum assembly, and the pressing assembly is used for attaching the cut single-sided adhesive tape to a surface of a flat cable. The device is advantaged in that a rotary adhesive tape receiving strip is arranged, so working efficiency is improved, the rotary winding drum assembly can achieve feeding, cutting and material moving, no waiting exists between procedures, connection is orderly, and the tape attaching speed is increased.

Owner:昆山展诚电子科技有限公司

Synthesis method of glufosinate intermediate of methyl diethyl phosphite

InactiveCN106046051AEasy to operateOrderly cohesionGroup 5/15 element organic compoundsDiethyl phosphateAlcohol

The invention discloses a synthesis method of glufosinate intermediate of methyl diethyl phosphate. According to the synthesis method, MDP is used as raw materials to take a reaction with an ethyl alcohol gas phase in a tubular reactor to generate methyl diethyl phosphate. The process operation process is simplified; the connection is ordered; the labor cost is greatly reduced; the production cost is reduced. The tubular reactor is used; the reaction equipment using a reaction kettle in the prior art is changed; the tubular reactor can realize the fast separation of a byproduct of hydrogen chloride from the product; the product yield is improved; meanwhile, the continuous operation is also realized; the danger in the industrialization process is avoided; the potential safety hazards are eliminated.

Owner:ANHUI COSTAR BIOCHEM CO LTD

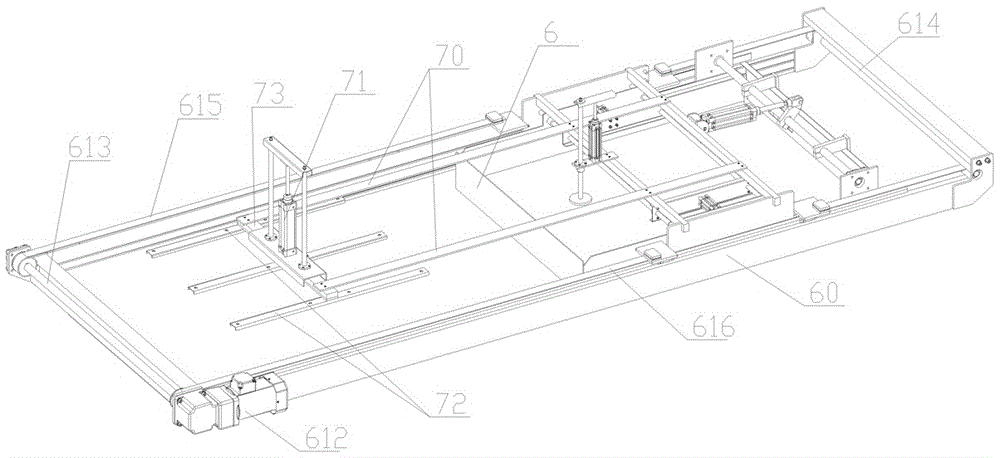

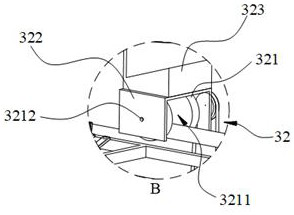

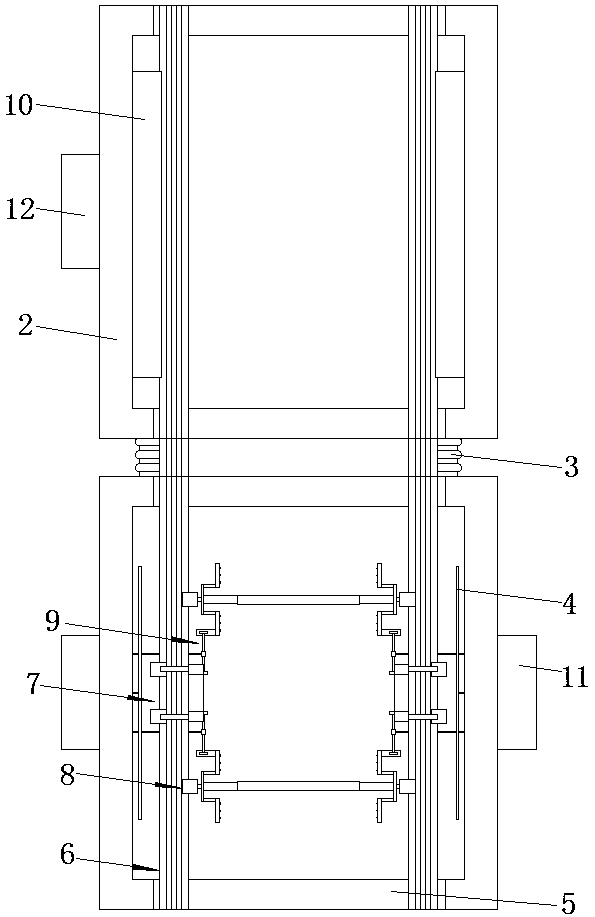

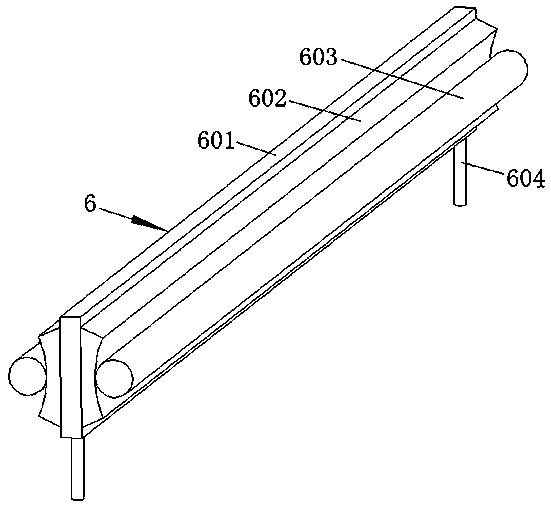

Destacking machine with linkage type can moving and paper taking mechanism and destacking method

ActiveCN105712096ASimple structural designRealize fully automatic controlDe-stacking articlesEngineeringLinear drive

The invention discloses a destacking machine with a linkage type can moving and paper taking mechanism and a destacking method. The technical problem that due to unreasonable station linkage of the destacking machine, the work efficiency of the destacking machine is low is solved. According to the adopted technical scheme, the linkage type can moving and paper taking mechanism is additionally arranged between a can stack lifting mechanism and a can body conveying mechanism, a structure comprises an installing frame fixedly arranged on the top of a rack, a can moving mechanism arranged above the can body conveying mechanism in a crossing manner, a partition paper sucking mechanism located above the can stack lifting mechanism, and a matched horizontal reciprocating type linear drive control mechanism, the partition paper sucking mechanism and the can moving mechanism are fixedly connected through a connecting assembly, the partition paper sucking mechanism is switched between a partition paper storage station and a can stack lifting station through the horizontal reciprocating type linear drive control mechanism, and the can moving mechanism is switched between the can stack lifting station and a can body conveying station through the horizontal reciprocating type linear drive control mechanism. The destacking machine is simple in action, high in frequency and easy to control, the destacking efficiency is improved, and accordingly the beverage filling production efficiency is improved.

Owner:WEIXIAN KECHUANG LIGHT IND EQUIP

Converter smelting parameter monitoring method

InactiveCN107012286AStable controlThe production organization is cohesive and orderlyManufacturing convertersData pointSmelting process

The invention provides a method for monitoring parameters of converter smelting, which respectively determines the DB block addresses of dry dust removal and converter smelting related parameters, and establishes data communication between the computer of the second level of the converter, the first level of dry dust removal and the first level of the converter; during the smelting process, reading Get the real-time data of each parameter and save it; draw and save the query and analysis curve of the real-time data of each parameter in chronological order; draw the change curve, broken line and data point according to the characteristics of the real-time data to clearly reflect the corresponding change of each parameter. In the present invention, the main parameters of dry dust removal and converter smelting are detected in real time during converter production, and curves are drawn as needed, so that each important parameter in the same time period can be analyzed in detail in a timely and effective manner, so as to prevent leakage in the smelting process. The problems such as explosion, abnormal lifting of the gun, and smoke from the water jacket of the oxygen gun are tracked and analyzed, so that the control of the converter smelting process is stable and the production organization is connected in an orderly manner.

Owner:ANGANG STEEL CO LTD

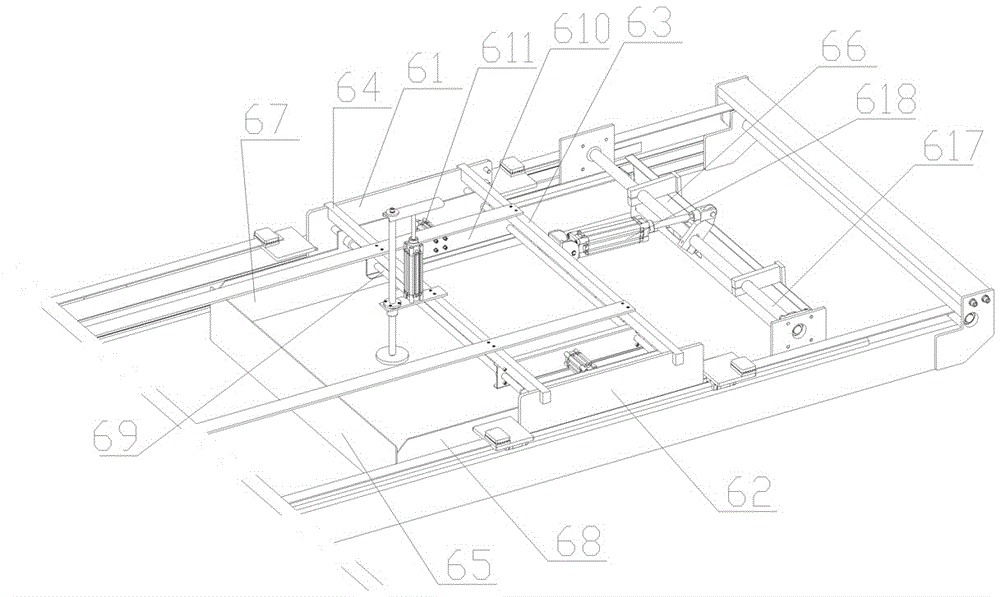

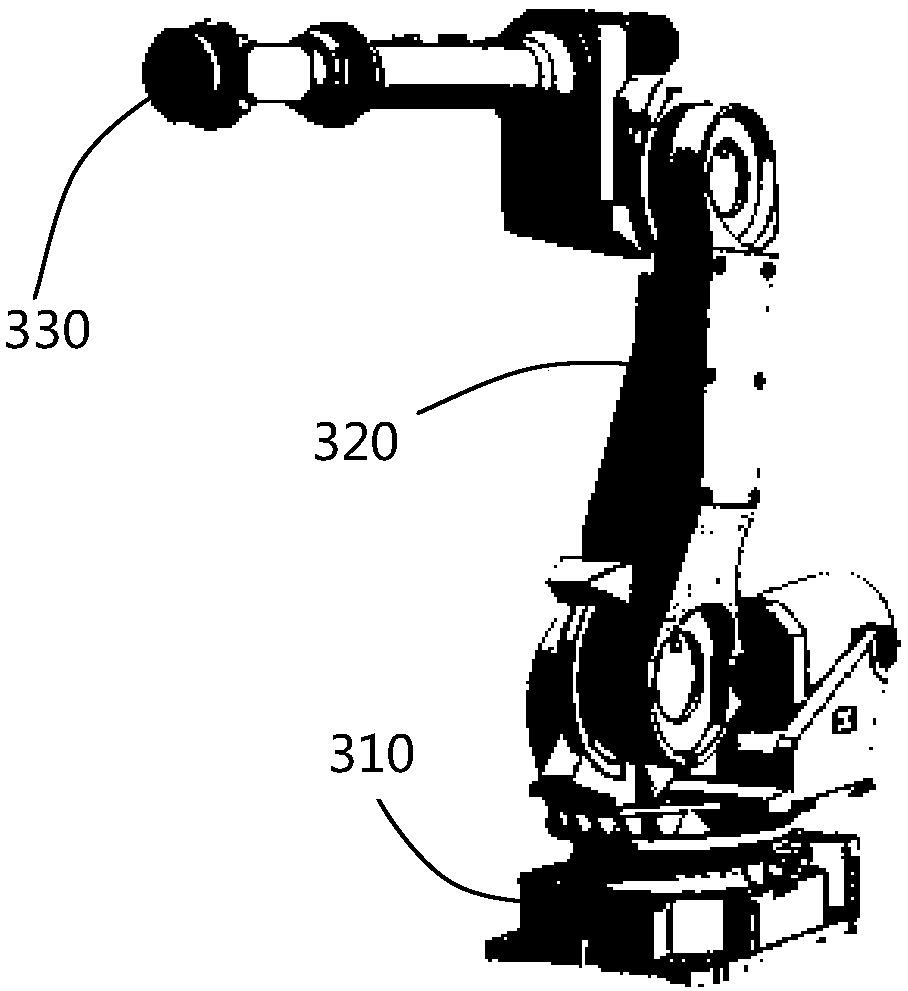

Automatic blank fetching equipment and method for magnetic material oil hydraulic machine

PendingCN107718692AReduce volumeSuitable for large-scale productionPressesEngineeringSmall footprint

The invention discloses automatic blank fetching equipment and method for a magnetic material oil hydraulic machine and belongs to the technical field of magnetic material production equipment, and the automatic blank fetching equipment comprises a controller, a blank fetching machine and a blank fetching robot, wherein the controller is used for controlling the whole equipment, the blank fetchingmachine is arranged on one side of the material output of the oil hydraulic machine, and the blank fetching robot is arranged on any side of the blank fetching machine. The blank fetching robot and the blank fetching machine are in electrical connection with the controller correspondingly, and at least one layer of magnetic molded blank parts which are put in good order on the blank fetching machine are taken away by the blank fetching robot in sequence. According to the automatic blank fetching equipment and method for the magnetic material oil hydraulic machine, the blank fetching robot adopted by the invention is small in volume and land occupied area, for some enterprises with relatively narrow space, the requirements of intelligent production can be better met, and the blank fetchingrobot is suitable for the large-scale production of enterprises; at least one layer of magnetic molded blank parts which are put in good order on the blank fetching machine are taken away by the blank fetching robot in sequence and blank materials are neatly put in good order on a tray, the magnetic molded blank parts are not prone to breakage, the production qualification rate of the blank partsis high, the artificial blank fetching is reduced, and the work efficiency is effectively improved.

Owner:SINOSTEEL TIANYUAN MAANSHAN TONGLI MAGNETIC MATERIAL

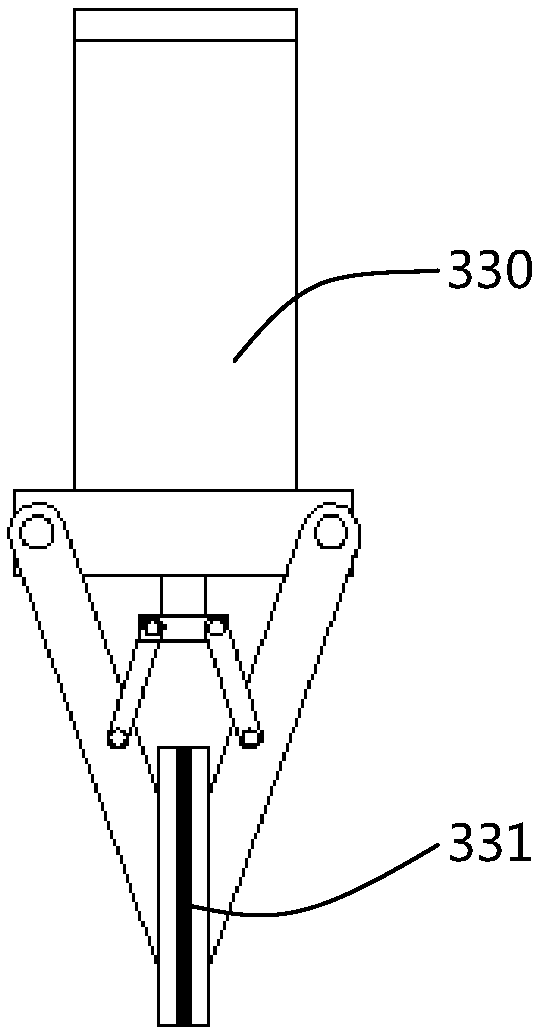

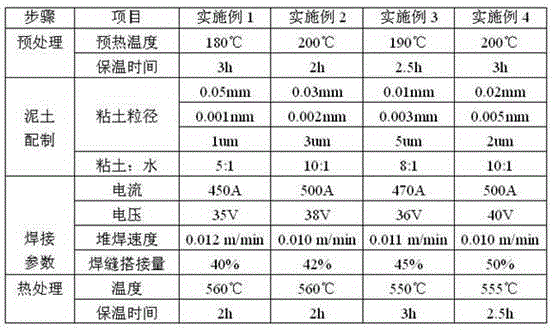

Surface overlaying method of foot roll of continuous casting machine

The invention, which belongs to the technical field of the overlaying, discloses a surface overlaying method of a foot roll of a continuous casting machine. The method comprises the following steps: (1), carrying out pretreatment of a foot roll of a continuous casting machine; (2), carrying out soil preparation; (3), carrying out soil filling; (4), carrying out surface overlaying; (5), removing the filling soil; (6), carrying out heat processing in a heating furnace under the temperature of 550 DEG C to 560 DEG C, carrying out heat preservation for 2 to 3 hours, and then drawing the processed member out of the furnace for cooling; and (7), carrying out rough machine at a tool and flaw detection, and then carrying out fine machine to enable the member to have the required dimension. The method has the following advantages: the steps of the method are linked in order and reasonably; and the operation process is simple and convenient. The surface of the foot roll of the continuous casting machine is flat and smooth; the flexibility and abrasive resistance are high; and the Rockwell hardness HRC can reach over 45. Hot cracks of an overlapping layer and a welding joint are reduced; the service life of the foot roll of the continuous casting machine is prolonged; the maintenance cost is lowered; the using effect of the continuous casting machine during billet production can be improved to the maximum extent; and the product quality can be guaranteed to meet the requirement.

Owner:MAANSHAN BAIYUAN MACHINERY CO LTD

Aluminum tube double-moving extruding machine gasket recycling device and aluminum tube double-moving extruding machine

The invention relates to a gasket recycling device. The gasket recycling device comprises a gasket recycling passage, an aluminum rod conveying passage, an ingot supplying tank and a gasket connectionrecycling mechanism, two ends of the gasket recycling passage and the aluminum rod conveying passage are material inlet ends and material outlet ends, the ingot supplying tank is a tank body with twoends and the upper portion being open and is connected with a mechanical arm, the mechanical arm can drive the ingot supplying tank to move up and down, under an original state, the material outlet ends of the gasket recycling passage and the aluminum rod conveying passage extend to the upper end of one side of the ingot supplying tank correspondingly, the material outlet end of the gasket recycling passage is located on one side of the aluminum rod conveying passage, the end portions of the material outlet ends of the gasket recycling passage and the aluminum rod conveying passage are flushwith each other, the adjacent sides are in fit with each other, the mechanical arm can drive the ingot supplying tank to move upwards or move downwards to return, and the gasket connection recycling mechanism is used for recycling gaskets and putting the gaskets into the gasket recycling passage. The aluminum tube double-moving extruding machine gasket recycling device and an aluminum tube double-moving extruding machine have the advantages that rapid recycling of the gaskets is facilitated, the labor intensity is low, and the production efficiency is high.

Owner:ANLU PHOENIX ALUMINUM LIMITED LIABILITY

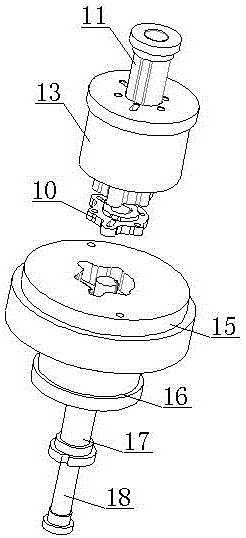

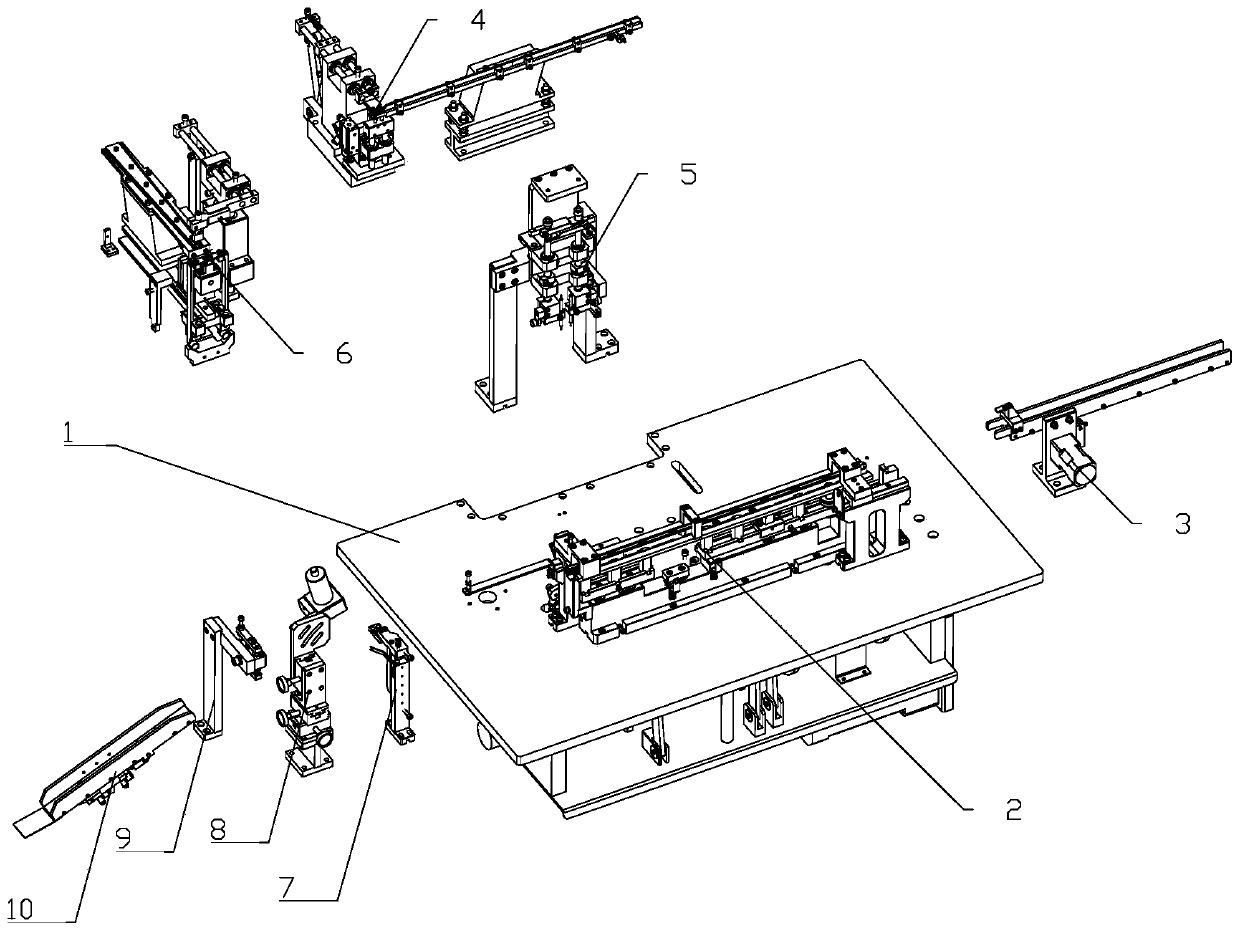

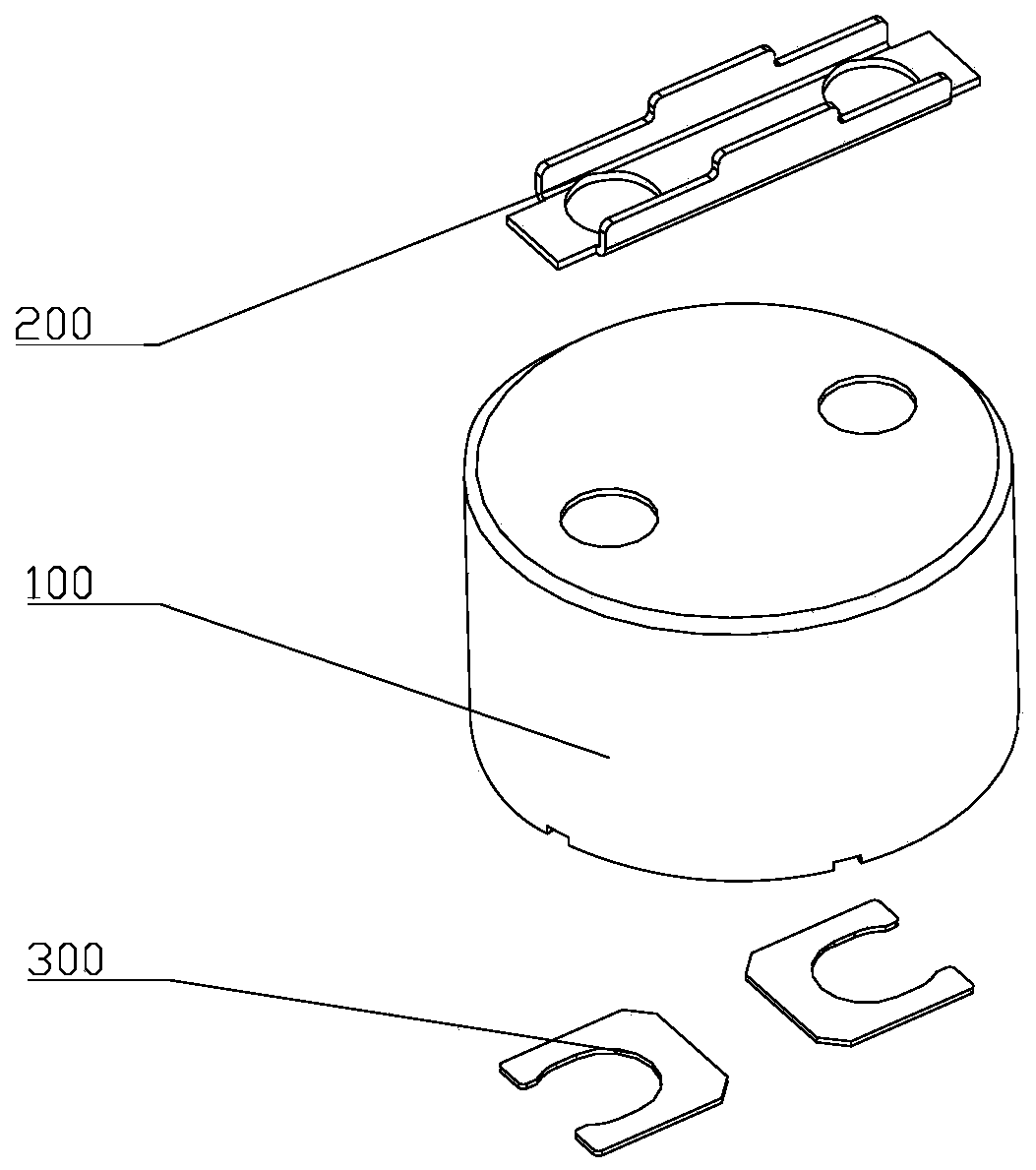

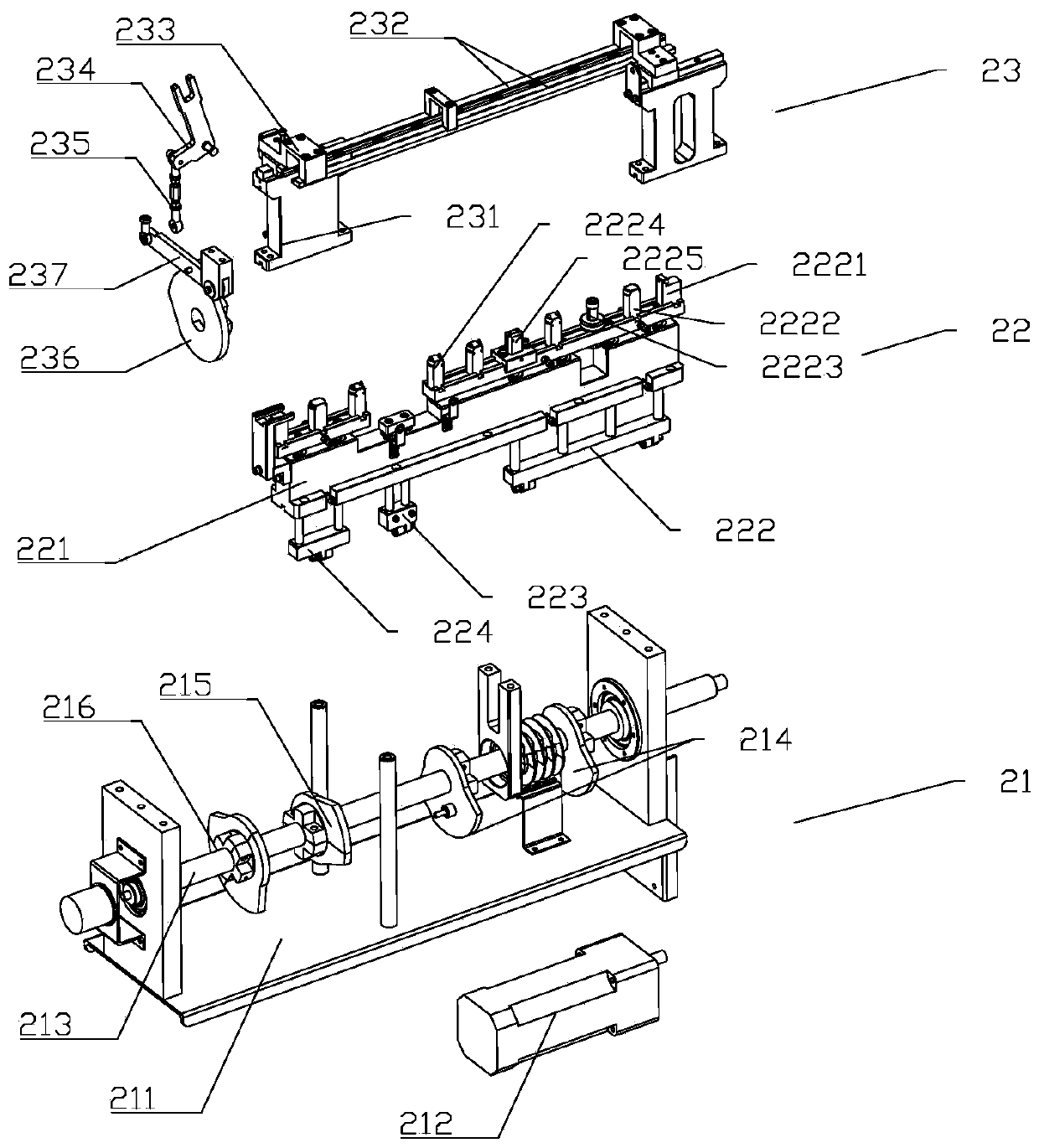

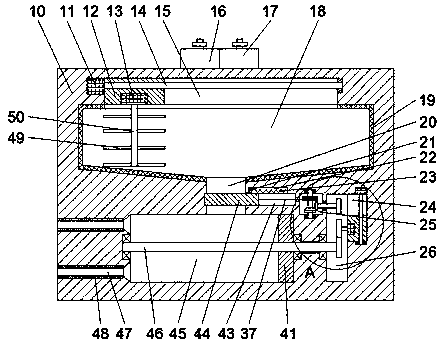

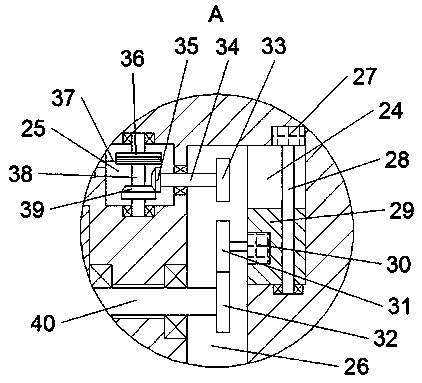

Hydraulic pump and assembly machine thereof

InactiveCN111283422AIncrease success rateMaintain Preload ConsistencyAssembly machinesHydraulic pumpEngineering

The invention relates to the field of hydraulic pumps. An assembly machine of a hydraulic pump comprises a rack, a rotary jig device, a pump cover feeding device, a screw locking device and a sealingdetection device, wherein the rotary jig device, the pump cover feeding device, the screw locking device and the sealing detection device are arranged on the rack, the rotary jig device is arranged atthe center of the rack, the pump cover feeding device, the screw locking device and the sealing detection device respectively correspond to one station of the rotary jig device, four stations are arranged on the jig device, and a loading and unloading conveying device is arranged at the remaining station. The assembly machine of the hydraulic pump has the advantages of high hydraulic pump assembly precision and high jig circulation efficiency, high pump cover assembly precision, accurate separation and transportation of pump covers and accurate sealing detection.

Owner:王加县

Widely-applicable insulating PVC board and production method thereof

The invention discloses a widely-applicable insulating PVC board and a production method thereof. The widely-applicable insulating PVC board comprises the following components in part by weight: 100 parts of PVC powder, 15 to 25 parts of PVC waste powder, 10 to 15 parts of calcium powder, 5 to 10 parts of talcum powder, 0.2 to 0.3 parts of paraffin, 0.3 to 0.5 parts of stearic acid, 1.0 to 1.5 parts of stabilizer, 1.0 to 1.5 parts of CPE, 0.1 to 0.2 parts of magnesium chloride and 1.0 to 1.5 parts of mica powder. The PVC board produced by virtue of the method is good in surface coarseness and brightness; moreover, the surface is continuous, the thickness is uniform, the quality of the board is guaranteed, and the board is durable; the PVC board has good insulating and heat preservation effect, not only can be installed inside a room, but also can be installed outside the room, and is wide in application range.

Owner:ANHUI TIANRUN PLASTIC IND

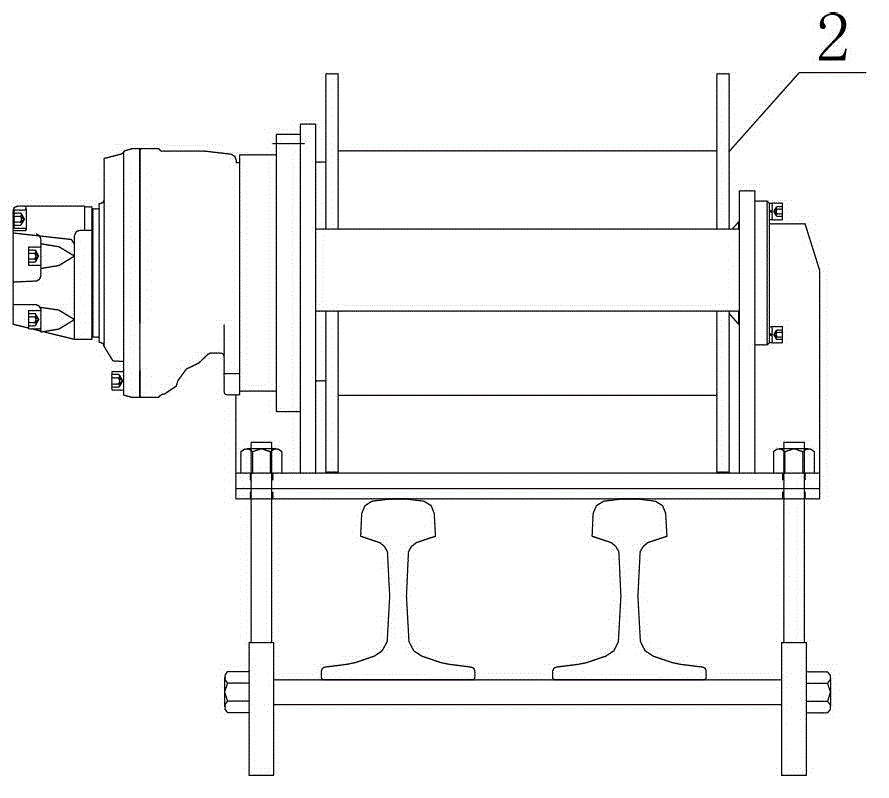

Rail turnout unit

The invention discloses a rail turnout unit comprising concentrated hydraulic power stations for supplying hydraulic power, longitudinal movement power components for supplying longitudinal movement power, transverse movement power components for supplying transverse movement power and lifting power devices for supplying lifting power, wherein the transverse movement power components, the longitudinal movement power components and the lifting power devices are respectively communicated with oil paths at the power output ends of the concentrated hydraulic power stations by virtue of hydraulic hoses and quick couplers. By virtue of concentrated hydraulic power supply, kinetic correlation is formed among the components, and further, the overall deployment of construction is realized, so that the high reliability of the rail turnout unit is achieved. The lifting power devices are clamped on a steel rail in pairs by virtue of symmetrical clamps, thus the rail turnout unit is high in safety. Construction components are separately arranged, and the equipment for completing the lifting and transverse and longitudinal movement actions of sections of the rail is respectively arranged, so that the components can be installed independently, and the installation efficiency of the components is improved.

Owner:BEIJING JINXIN HAIYE TECH

Electrode holder feeding device and method for cylinder capacitance electrode holder welding machine

InactiveCN111203637AReduce in quantityImprove transfer efficiencyConveyor partsLaser beam welding apparatusCapacitanceEngineering

The invention provides an electrode holder feeding device for a cylinder capacitance electrode holder welding machine. The device comprises a vibrating device, a base, a moving frame, a material receiving absorbing block, a material receiving base, a lifting assembly, a drive rod and a cam drive assembly. The base is arranged on the rack. A material receiving base is installed on the base. A material receiving groove is formed in the upper end of the material receiving base. The moving frame is movably fit on the base. The material receiving absorbing block is installed on the end portion of the moving frame. The moving frame is provided with a spring connected with the base. The middle portion of the drive rod is hinged to the base. A ball is arranged at the upper end of the drive rod. The upper end of the drive rod abuts against the end portion of the moving frame. The cam drive assembly is connected to a power part. The cam drive assembly drives the drive rod to move. The lifting assembly is installed on the base. The lifting assembly corresponds to the material receiving base and used for locating and separating an electrode base in the material receiving base. The electrode holder feeding device has the advantages that the electrode holder feeding success rate is high, and moving and taking of an electrode holder are reliable.

Owner:陆小波

A coordinated air defense mission planning method and system for multi-type air defense weapons

ActiveCN109255491BGive full play to combat capabilitiesOrderly cohesionForecastingResourcesReal-time computingAerospace engineering

The invention provides a cooperative air defense mission planning method and system for multi-type air defense weapons. According to the performance index of multi-type air defense weapons and the flight path of air targets, the interception start time, interception end time and interception times of each weapon to each target are estimated, and various constraint conditions are determined. Numerical optimization algorithm is used to plan the interception time sequence of multi-type air defense weapons to multi-targets under constraint, and the time period-arm-goal is obtained. The invention is applicable to the combat mission planning, command auxiliary decision-making, combat capability evaluation and the like of multi-type air defense weapons.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Preparation technical equipment of continuous ceramic fiber and composite material thereof

InactiveCN108563151AEasy to clean and maintainEasy to operateProgramme control in sequence/logic controllersHinge angleFiber

The invention discloses preparation technical equipment of continuous ceramic fiber and a composite material thereof. The equipment comprises a box body, wherein a first cavity, a second cavity, a third cavity, a fourth cavity and a fifth cavity are arranged in the box body from the upper part to the lower part in sequence; a sixth cavity is arranged at the right end of the fifth cavity; a first conveying chute formed in the left end of the third cavity communicates with a position between the second cavity and the fourth cavity; three squeezing channels which are uniformly formed communicatewith a position between the first conveying chute and the third cavity; a second conveying chute communicates with a position between the fourth cavity and the fifth cavity; a first sliding guide block is glidingly matched and connected with the interior of the second cavity; a first connecting rod laterally extending is matched and connected with the right end of the first sliding guide block through a hinge; a first crankshaft extending longitudinally is matched and connected with the extending tail end of the right end of the first connecting rod through a hinge. The equipment is compact instructure, simple to operate, high in degree of automation, and applicable to different ceramic fiber series.

Owner:宁德市益升智能科技有限公司

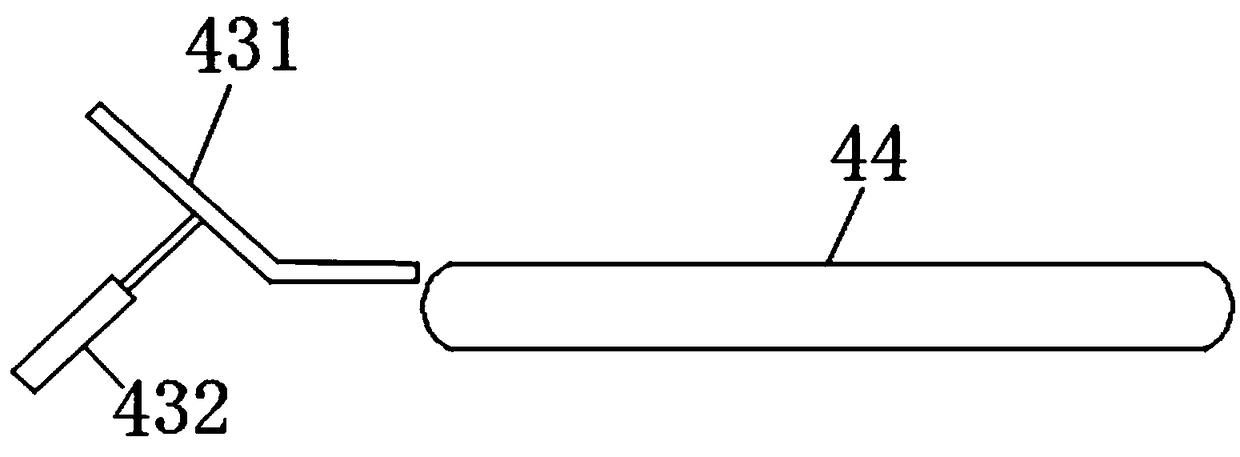

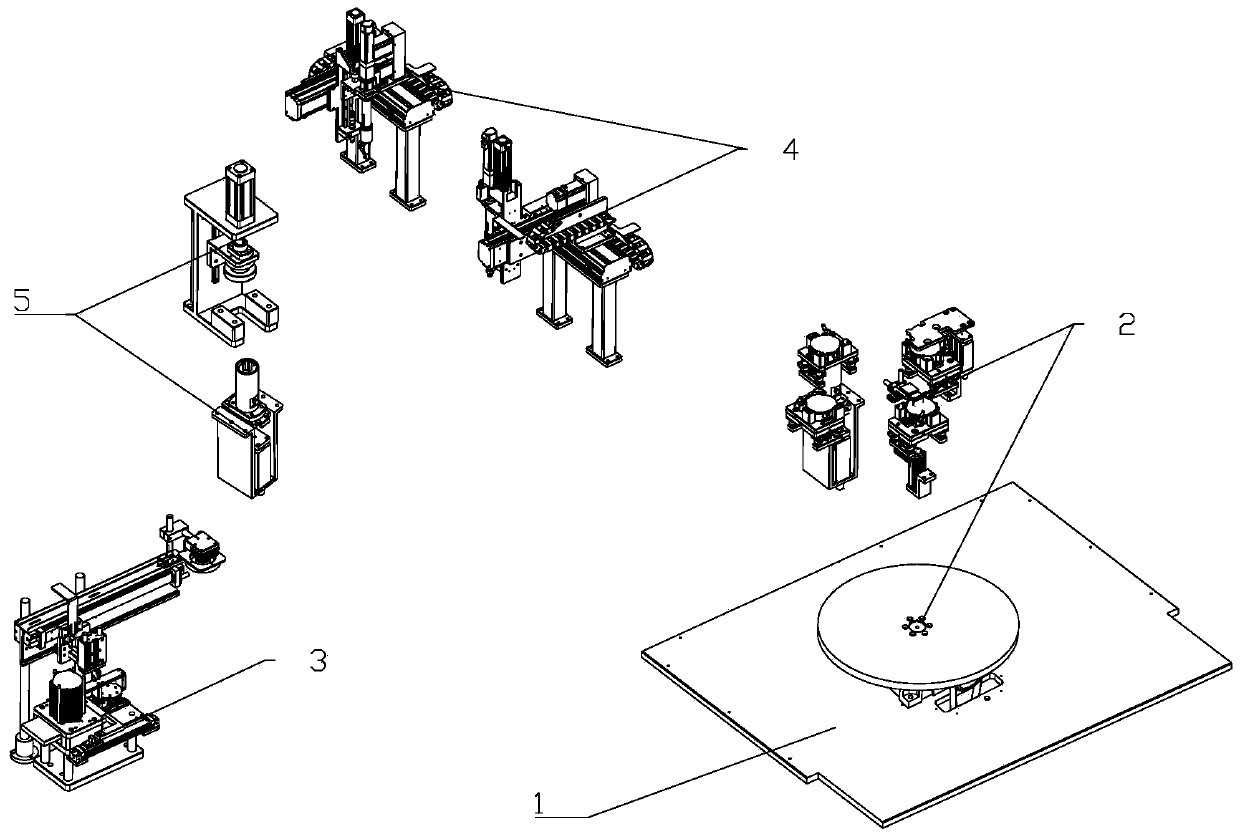

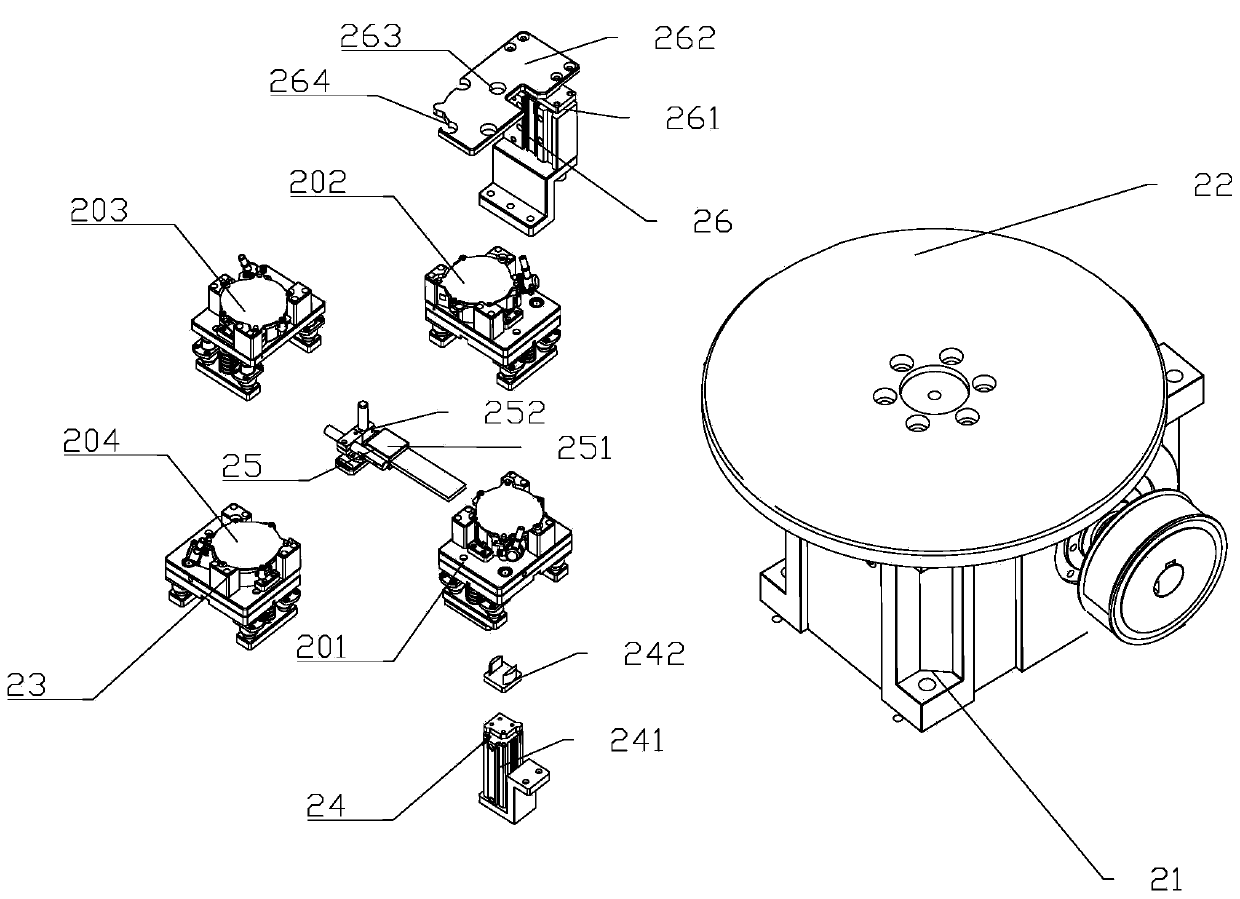

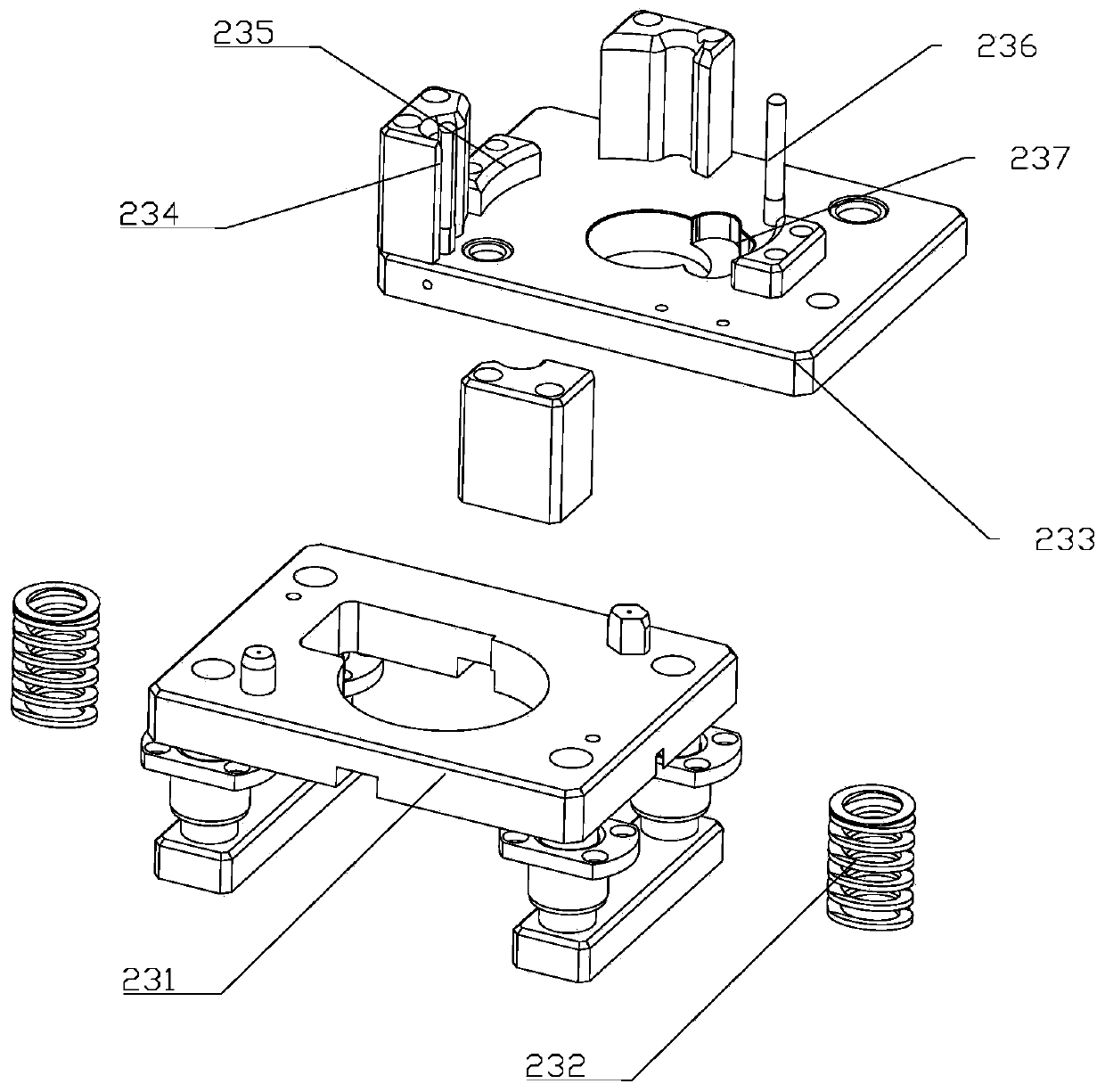

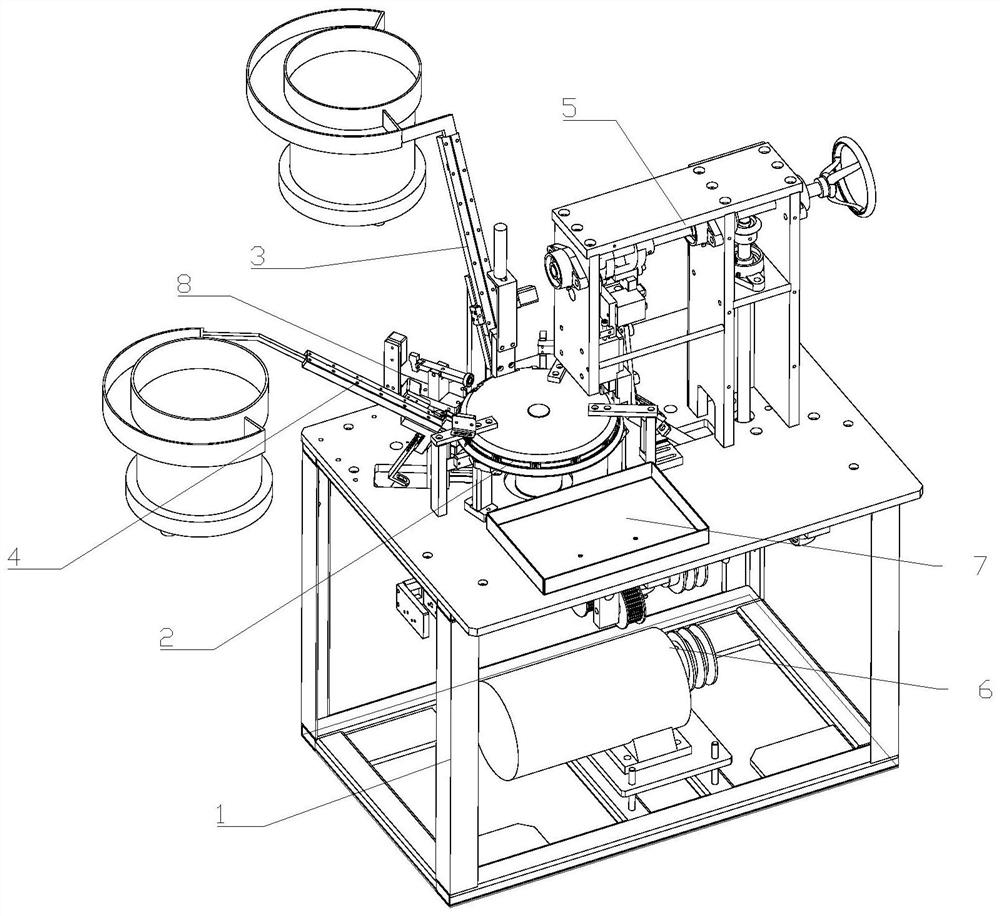

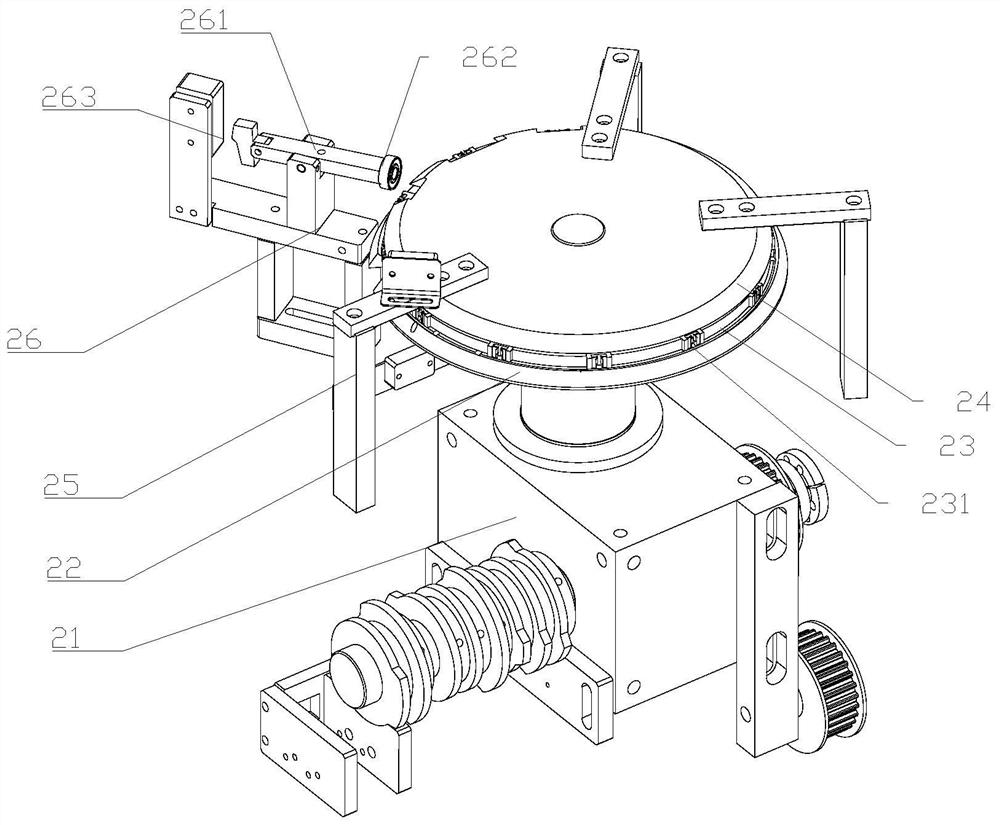

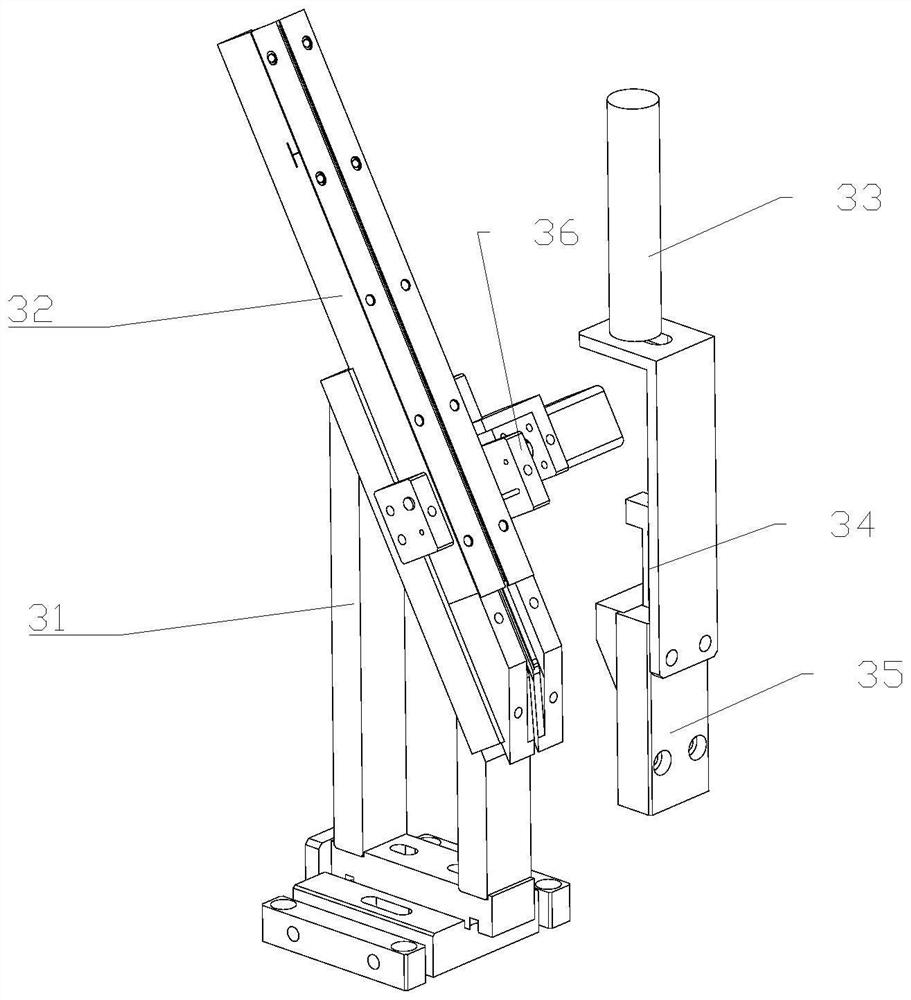

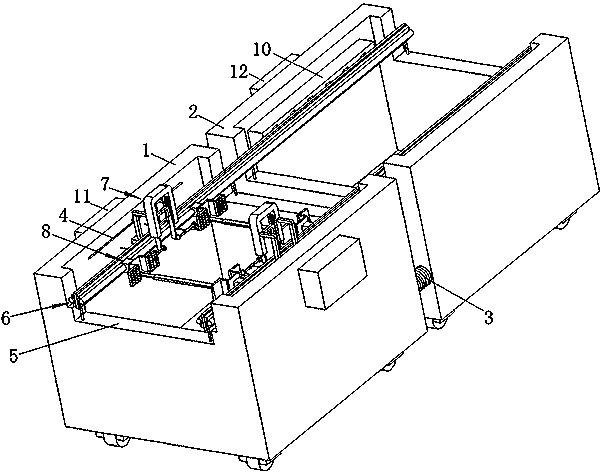

Zipper head automatic assembly equipment and method and industrial control equipment

The invention relates to the technical field of garment production, in particular to zipper head automatic assembling equipment and method and industrial control equipment. Zipper head automatic assembling equipment comprises a rack, a disc carrying device, a zipper base feeding device, a copper buckle feeding device, a copper buckle point riveting device and a power device, the disc carrying device is installed on the rack, the disc carrying device is in a rotating mode, and the zipper base feeding device, the copper buckle feeding device and the copper buckle point riveting device are arranged in the machining direction. The zipper base feeding device, the copper buckle feeding device and the copper buckle riveting device are sequentially arranged on the periphery of the carrying disc device, a material disc is further arranged on the machine frame and located between the copper buckle feeding device and the copper buckle riveting device, the power device is installed on the machine frame, and the power output end of the power device is connected with the carrying disc device and the copper buckle riveting device. The rack is further provided with a zipper base detection device, the zipper base detection device is located behind the zipper base feeding device, and the zipper base detection device corresponds to the carrying disc device. The device has the advantages of high transmission efficiency, orderly action connection and high production efficiency.

Owner:尚飞

Conveying and material passing device of cylindrical capacitor electrode holder welding machine and method

InactiveCN111168229AReduce in quantityImprove transfer efficiencyLaser beam welding apparatusCapacitanceElectric machinery

The invention relates to a conveying and material passing device of a cylindrical capacitor electrode holder welding machine. The device comprises a power assembly, a jig assembly and a transferring assembly; the power assembly is installed on the back surface of a rack, the jig assembly is installed on the front surface of the rack, and the transferring assembly is located above the jig assembly;and the power assembly is used for driving the jig assembly to ascend and descend and driving the transferring assembly to horizontally move, the jig assembly is used for arranging a to-be-machined shell, and the transferring assembly is used for moving a to-be-carried workpiece between stations. According to the conveying and material passing device, the shell ascends and descends by arranging the jig assembly, and different material receiving parts are arranged on the jig assembly, so that the device is better suitable for machining in different procedures; the conveying and material passing device improves the transferring efficiency through the combination of lifting of the jig assembly and the translation of the transferring assembly; and transmission is carried out through cams, themultiple cams are installed on the same main shaft, the number of driving motors is small, and all motions are higher in synchronism and are connected in order.

Owner:陆小波

Power transmission line deicing device

ActiveCN113746050AIncrease the counterweightSuspension stabilityOverhead installationPulleyPower transmission

The invention discloses a power transmission line deicing device. The power transmission line deicing device comprises a frame body, a walking assembly, a heating assembly and a knocking assembly. The frame body is provided with a deicing cavity for accommodating a power transmission line, the power transmission line penetrates through the deicing cavity, a wire inlet opening communicated with the deicing cavity is formed in the side part of the frame body, and the wire inlet opening is used for allowing the power transmission line to enter and exit from the deicing cavity; the walking assembly is located in the deicing cavity and connected with the frame body, the walking assembly comprises a plurality of pulleys, the multiple pulleys are sequentially arranged in the extension direction of the power transmission line, grooves used for clamping the power transmission line are formed in the peripheral sides of the pulleys, and the power transmission line is located in the grooves; the heating assembly is located between any two pulleys and fixed to the frame body, the heating assembly comprises a heating piece, and the heating piece partially surrounds the peripheral side of the power transmission line; the knocking assembly is located in the deicing cavity and connected with the frame body, and the knocking assembly is used for knocking ice on the power transmission line after the power transmission line is heated.

Owner:BINZHOU UNIV

Full-automatic production line of lead-acid battery

InactiveCN112490514ASmall footprintReduce occupancyAssembling battery machinesFinal product manufactureElectrical batteryProcess engineering

The invention relates to the technical field of lead-acid storage battery production and processing, in particular to a full-automatic production line of a lead-acid battery. The full-automatic production line comprises a conveying line, a wrapping plate assembling unit, a cutting and brushing unit, cast-welding units, arranging units and a glue sealing unit, and lead-acid batteries on the conveying line are overlapped through the arranging unit, so that the occupied space of the conveying line is reduced; and on one conveying line, multiple groups of cast-welding units can be arranged by using the arranging units, so that one group of arranging units can arrange the lead-acid batteries satisfying the production and processing of one group of cast-welding units, the condition that the multiple groups of conveying lines are used for respectively supplying the batteries to the cast-welding units is avoided, the occupation of a working space is reduced, and the layout is more reasonable.

Owner:阜阳市广联普惠自动化技术有限公司

Rinsing device for electroplating machining of metal plates

ActiveCN109332257AEasy to rinseEasy clampingDrying gas arrangementsCleaning using liquidsMachiningElectroplating

The invention discloses a rinsing device for electroplating machining of metal plates, and belongs to the technical field of electroplating machining equipment. The rinsing device for electroplating machining of the metal plates comprises a rinsing box and a drying box, the rinsing box and the drying box are fixedly connected through a connecting hose, a cleaning pipe is connected to the inner wall of the rinsing box, mounting grooves are formed in the side walls of the rinsing box and the drying box, the inner walls of the mounting grooves are connected with sliding guide rails, one sides ofthe sliding guide rails are connected with pushing rod pieces, the other sides of the sliding guide rails are connected with clamping assemblies, the pushing rod pieces and the clamping assemblies areconnected through steering mechanisms, and the inner wall of the drying box is connected with symmetrical drying air pipes. According to the rinsing device, the operation is convenient, cleaning reagents washed away from the surface of a plating part can be collected during cleaning, moreover, orderly connection between a rinsing working procedure and a drying working procedure can be achieved sothat the working efficiency can be improved.

Owner:湖州金业表面科技有限公司

A laser welding method for thin metal plates

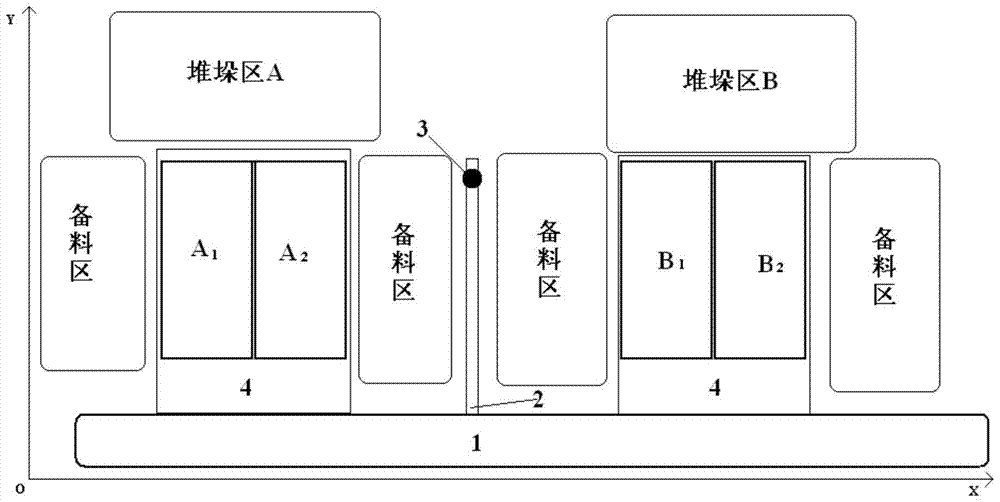

ActiveCN105033458BGuaranteed smooth productionImprove work efficiencyWelding/soldering/cutting articlesMetal working apparatusMetal sheetThin sheet

The invention provides a laser welding method for metal sheets. The laser welding method comprises the following steps that two or more welding worktables are arranged in the direction perpendicular to a welding machine body, and material preparing areas are arranged on the left sides and the right sides of the welding worktables; finished plate stacking areas are arranged in front of the welding worktables; one or more metal sheets in each material preparing area are taken and placed on the corresponding worktable; a laser welding machine is started, a welding head is started for welding operation and moves in the welding seam direction until welding of the two metal sheets on the corresponding worktable is finished; and a welding arm moves towards the second welding worktable, welding is carried out, and meanwhile the welded sheets on the first welding worktable are taken down and placed in the corresponding finished product or semi-finished product stacking area. The steps are repeated, and therefore efficient metal sheet laser welding is achieved. The invention provides a novel laser welding method for the metal sheets. According to the method, the production efficiency can be greatly improved by changing an existing working mode.

Owner:武汉宁致远汽车配件有限公司

A liquid crystal polymer material device

The invention discloses equipment for a liquid crystal polymer material. The equipment comprises a box body as well as a first cavity and a second cavity which are sequentially formed in the box bodyfrom top to bottom, wherein a third cavity is formed in the right end of the second cavity; a fourth cavity located in the bottom end of the first cavity is formed in the left end of the third cavity;a first slide guide groove with a downward opening is formed in the inner wall of the top end of the first cavity in a communication manner; a first slide guide block is connected into the first slide guide groove in a manner of slide fit; a conveying groove is formed between the first cavity and the second cavity in a communication manner; a second slide guide groove located in the bottom end ofthe first cavity is formed in the inner wall of the conveying groove in a communication manner; a second slide guide block is connected into the second slide guide groove in a manner of slide fit; and a third slide guide block is connected into the second cavity in a manner of slide fit. The equipment disclosed by the invention is compact in structure, convenient to operate, and high in automation degree, increases the preparation efficiency for the liquid crystal polymer material, and improves the preparation effect for the liquid crystal polymer material.

Owner:TANGSHAN DONGYA HEAVY IND EQUIP GRP CO LTD

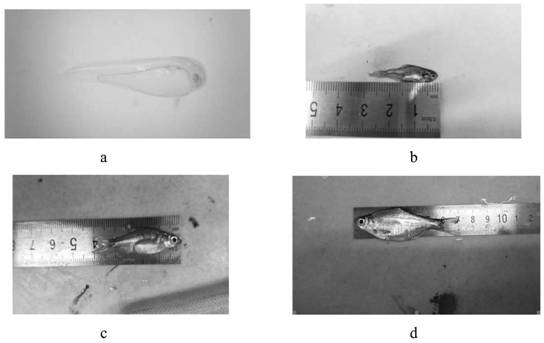

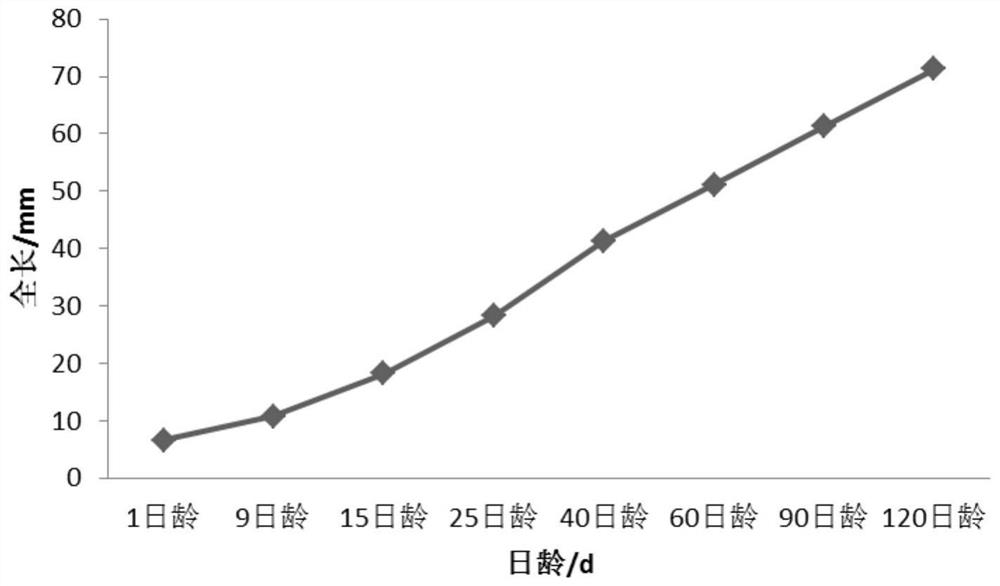

A kind of large-scale cultivation method of Pachymandibacter seedlings

ActiveCN110150185BOrderly cohesionAchieve dynamic balanceClimate change adaptationAnimal feeding stuffGlass fiberJuvenile fish

The invention relates to a method for large-scale cultivation of bream seedlings, belonging to the technical field of rare and unique fish cultivation. According to the characteristics of growth and development of bream larvae, juveniles and juveniles in different stages, breeding ecological learning and nutritional and physiological characteristics, the present invention divides the entire seed cultivation process into three stages: glass fiber tank micro-flow water cultivation, large water surface ecological pond Cultivation and intensive cultivation in running water ponds. The invention constructs a healthy, safe and efficient large-scale seed cultivation mode, which effectively solves a series of problems such as frequent disease occurrence, slow growth speed and low utilization efficiency of facilities in the traditional seed cultivation process, and is a rare species in the upper reaches of the Yangtze River It provides a reference for the large-scale seed breeding of unique fish.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/BDA0000992003570000021.PNG)

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/BDA0000992003570000022.PNG)

![Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate Preparation method of 4-[hydroxy(methyl)phosphoryl]-2-oxobutanoic acid as glufosinate intermediate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/612c6417-1bb1-4030-911a-20a36fce8964/FDA0000992003560000011.PNG)