A laser welding method for thin metal plates

A metal thin plate and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing, etc., can solve problems such as unstable product quality and insufficient industrialization level, and achieve coherent production process, production flexibility, and optimization and improvement of processing efficiency The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

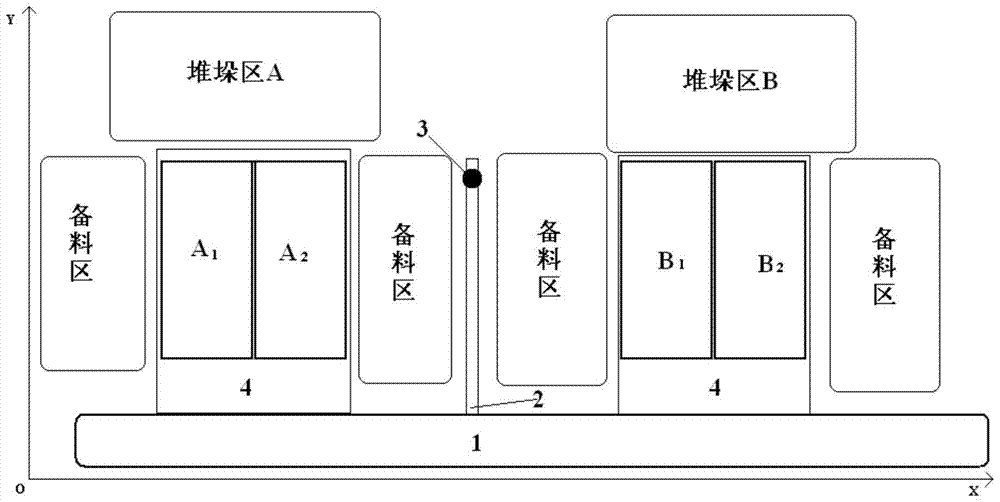

[0022] The laser welding method of the metal thin plate provided by the present embodiment comprises the following steps: (1), two welding workbenches 4 are arranged perpendicular to the direction of the welding machine main body 1, and a material preparation area is set on the left and right sides of the welding workbench 4, Place the metal sheets to be welded in the preparation area, such as figure 1 shown. The metal sheet separating device is installed in the material preparation area, which is convenient for taking the metal sheet.

[0023] (2) The finished board stacking area is set in front of the welding workbench. The surrounding areas of the material preparation area and the finished board stacking area are relatively open, and the raw materials or welding finished products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com