Method for printing and dyeing dacron/chinlon/cotton/spandex multi-component fiber fabric

A multi-component fiber and spandex technology, applied in the field of textile printing and dyeing, can solve the problems of poor commercialization quality, poor high-temperature dispersion stability, and irregular particle shape of ordinary disperse dyes, and achieve the optimization of hydrophilic and easy decontamination finishing process, Ease of care, eliminating potential wrinkling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

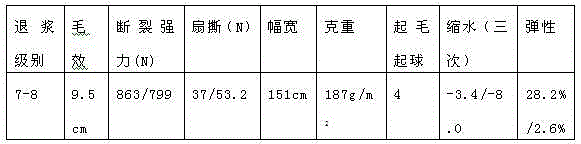

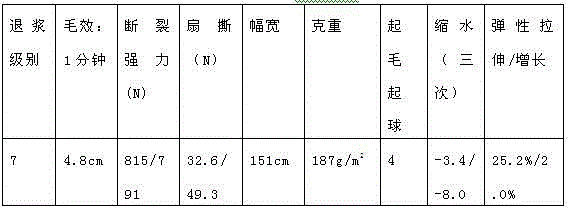

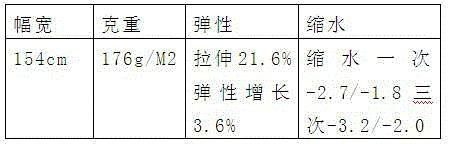

[0055]1. Finished fabric specification: JC55 / T45 32XN140D+40D 174X69 57 / 58" dark blue 82", gray fabric specification: T / C32XN140D+40D 122X69 82"

[0056] 2. Physical index requirements:

[0057] 1). (U.S., Europe) color fastness to washing, discoloration / staining (acetate, cotton, nylon, polyester, acrylic, wool): AATCC61-2A is commonly used in American Standard, the original color is 3-4 white 3;

[0058] 2). Color fastness to dry rubbing / wet rubbing: AATCC8, grade 3 for dry rubbing and grade 2.5 for wet rubbing;

[0059] 3). Appearance after washing Anti-wrinkle (grade): AATCC124 washing is the same as AATCC135 3 times washing, 3.5;

[0060] 4). Breaking strength warp / weft: ASTMD5034

[0061] 5). Fan-shaped tear strength warp / weft: ASTMD1424;

[0062] 6). Slip resistance warp / weft: ASTMD1683;

[0063] 7). Seam strength warp / weft: ASTMD1683;

[0064] 8). Pilling (grade): ASTMD3512 60min, grade 3.5;

[0065] 9). Easy decontamination performance (grade): AATCC130 before w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com