Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451results about How to "Improve product grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based matte touch gloss oil and preparation method thereof

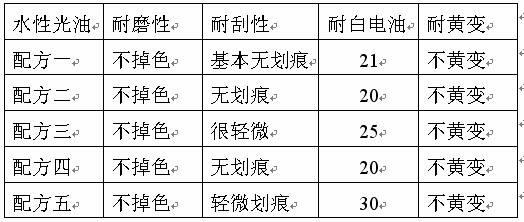

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

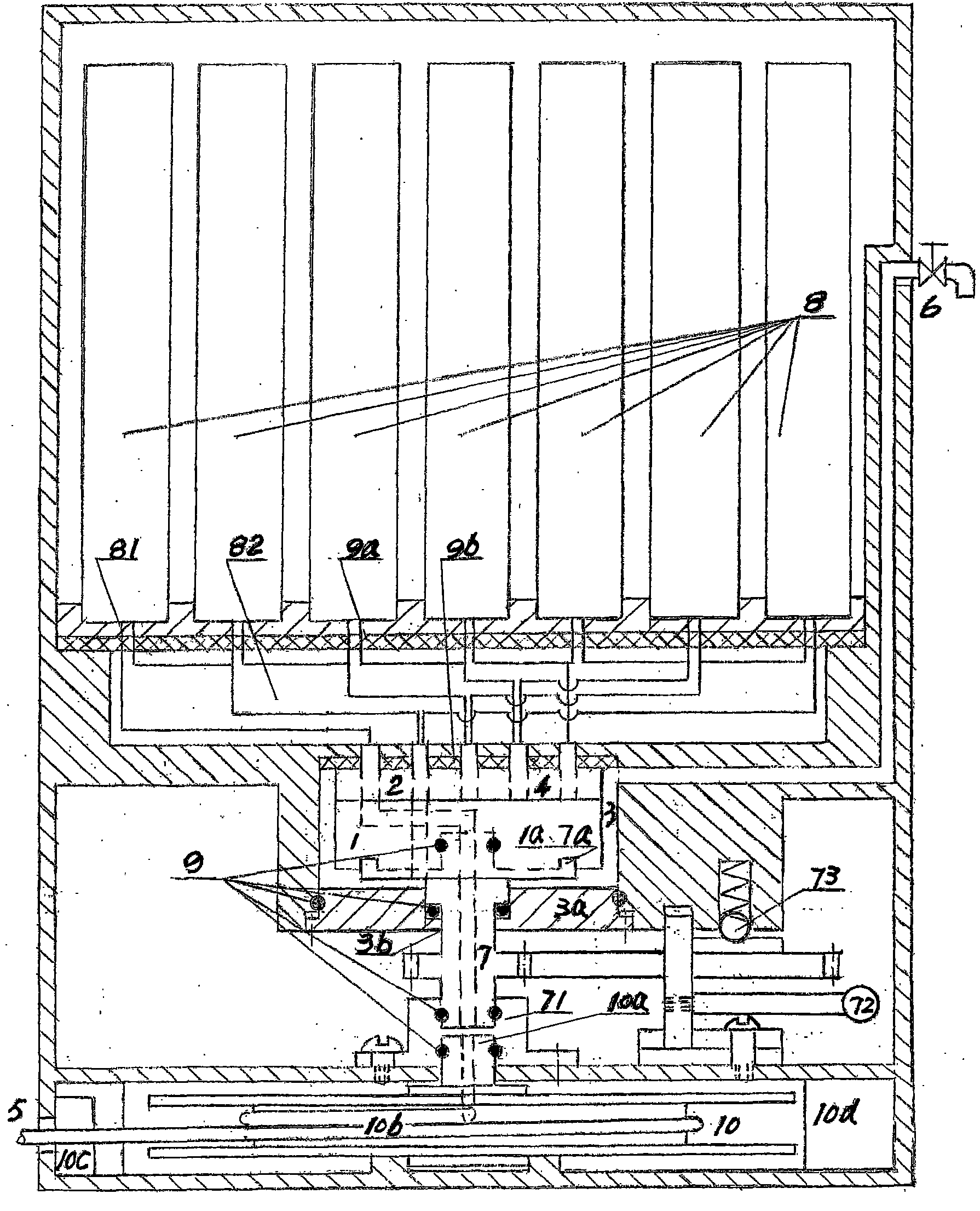

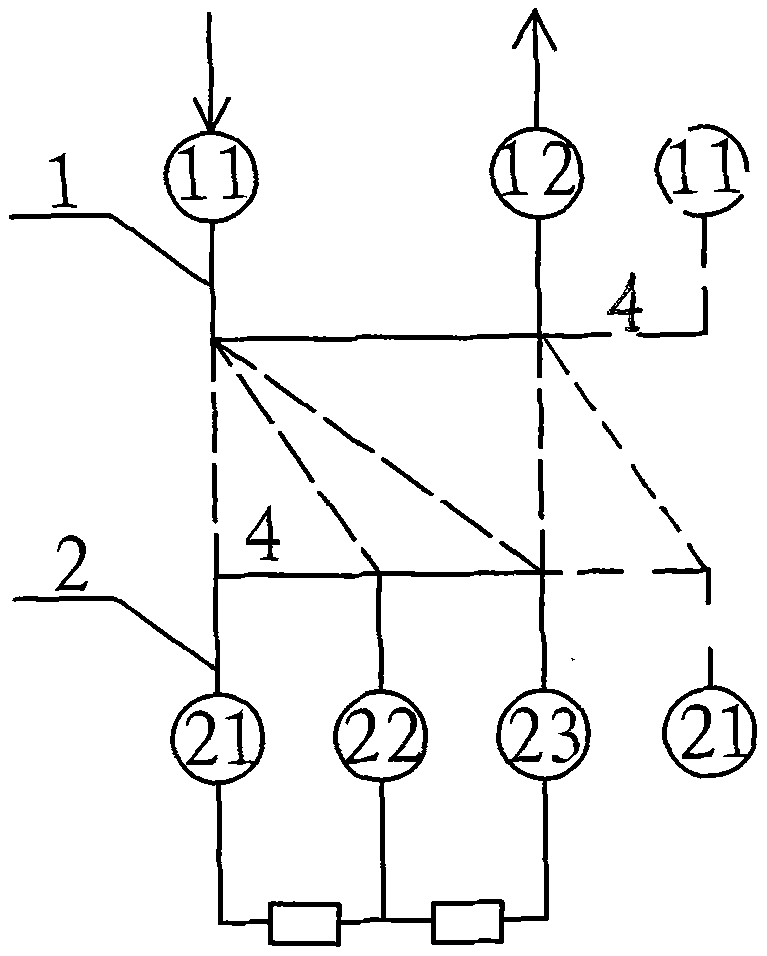

Method for detecting eccentric load of roller washing machine by vibrating sensor

ActiveCN103451891AImprove product gradeEasy to detectOther washing machinesControl devices for washing apparatusPhase relationEngineering

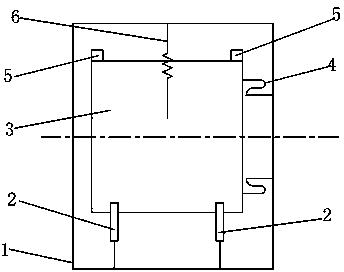

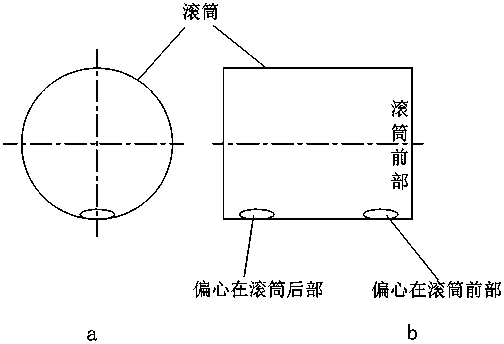

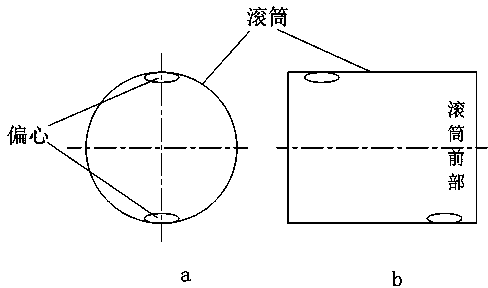

The invention relates to a method for detecting an eccentric load of a roller washing machine by a vibrating sensor. The front-most part or the rearmost part of the outer edge of the outer barrel of the roller washing machine is provided with the vibrating sensor; by utilizing an amplitude and phase relation between vibrations measured in two directions, the vibration state of the outer barrel is judged; a vibration value is tested while rotate speed variation or eccentric weight are tested by adopting an original eccentric load detection method; according to the vibration state of the outer barrel, the distribution of the eccentric load in a roller is judged, and a preset value of the eccentric load is adjusted, and therefore, the weakness that dynamic eccentricity cannot be detected by adopting the original eccentric detection method is overcome. The detection and the protection of the dynamic eccentricity are added, and therefore, the detection precision of the eccentric load is improved, the vibrations and noise when drying is performed are reduced, and the product grade of the rolling washing machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Printing decoration metallic plate capable of panel beating and manufacturing method thereof

ActiveCN101077676AGood decorative effectImprove product gradeSpecial ornamental structuresCoatingsSheet steelSurface tension

The present invention is printed metal plate and its making process. On the surface of coated steel sheet, patterns are first printed with ink fitting the surface coating of steel sheet and through intaglio offset printing, and high temperature cured paint or UV cured paint is then roller coated to the surface of the patterns. The printed metal plate has high decorating effect. Compared with available technology, the present invention has the advantages of environment friendship and low cost.

Owner:青岛河钢复合新材料科技有限公司 +1

Two-die three-punch upsetter and working method

The invention relates to a two-die three-punch upsetter. A third punch die is a trimming die or a forging and pressing die and is arranged on a large slide block, and a first punch die and a second punch die are arranged on a lifting plate; a first concave die corresponds to the first punch die and the second punch die, and a second concave die corresponds to the third punch die; and axis of the second concave die and the third punch die are oppositely kept on the same straight line all the time. A working method comprises the following steps of: forming a workpiece by rotating a crank shaft twice; when the large slide block is upset for the first time, upsetting a blank into a primary upsetting semi-finished workpiece by the first punch die and preserving the semi-finished workpiece in the first concave die; upsetting a secondary upsetting semi-finished workpiece into a finished workpiece by the third die and ejecting the finished workpiece out; when the large slide block upsets for the second time, upsetting the primary upsetting semi-finished workpiece into the secondary upsetting semi-finished workpiece by the second punch die and ejecting the secondary upsetting semi-finished workpiece out; and air beating by the third punch die. The invention can achieve the functions of various upsetters, such as a one-die two-punch upsetter, an outer hexangular trimming machine, a three-die three-punch upsetter, and the like.

Owner:杨东佐

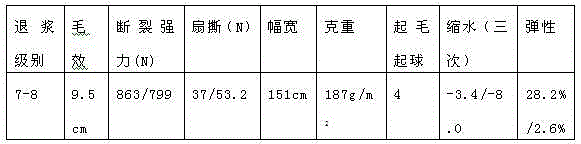

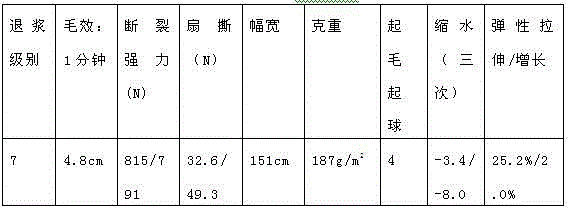

Dyeing and finishing technology of blended fabric of tenel and cotton

InactiveCN101363158APromote migrationQuality improvementBiochemical fibre treatmentSingeingPulp and paper industrySurface-active agents

The invention discloses a dyeing and finishing technique of a tencel and cotton blended fabric. Firstly, textiles are treated by two positive and one reverse singeing, desizing and scouring and bleaching treatment, clipless mercerizing by a clipless mercerizing machine, and continuous open width pad dyeing, then loose color of the textiles and surface active agent are removed by washing to carry out easy care treatment, finally softening is carried out by adopting mechanical force. The invention has simple process. The invention greatly increases the strike immigration performance of the textiles and is easily dyed uniformly, thus improving the quality of tencel and cotton fabric and the product levels. The dyed surface fabric has good textural quality which is similar to tencel, soft hand feeling, soft light color, comfortable and breathable wear, easy care, and can be widely applied to shirt fabrics with top quality and home surface fabrics.

Owner:浙江誉华集团湖州印染有限公司

Ultra fine soft wool yern and its production method

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

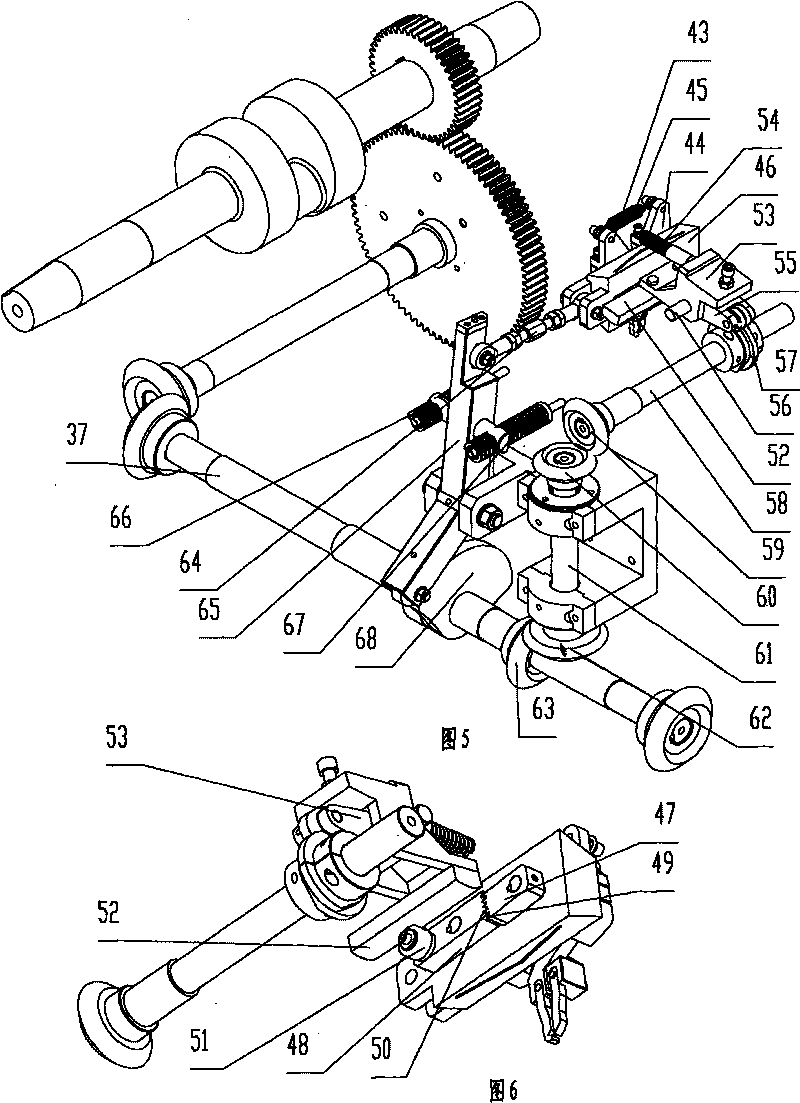

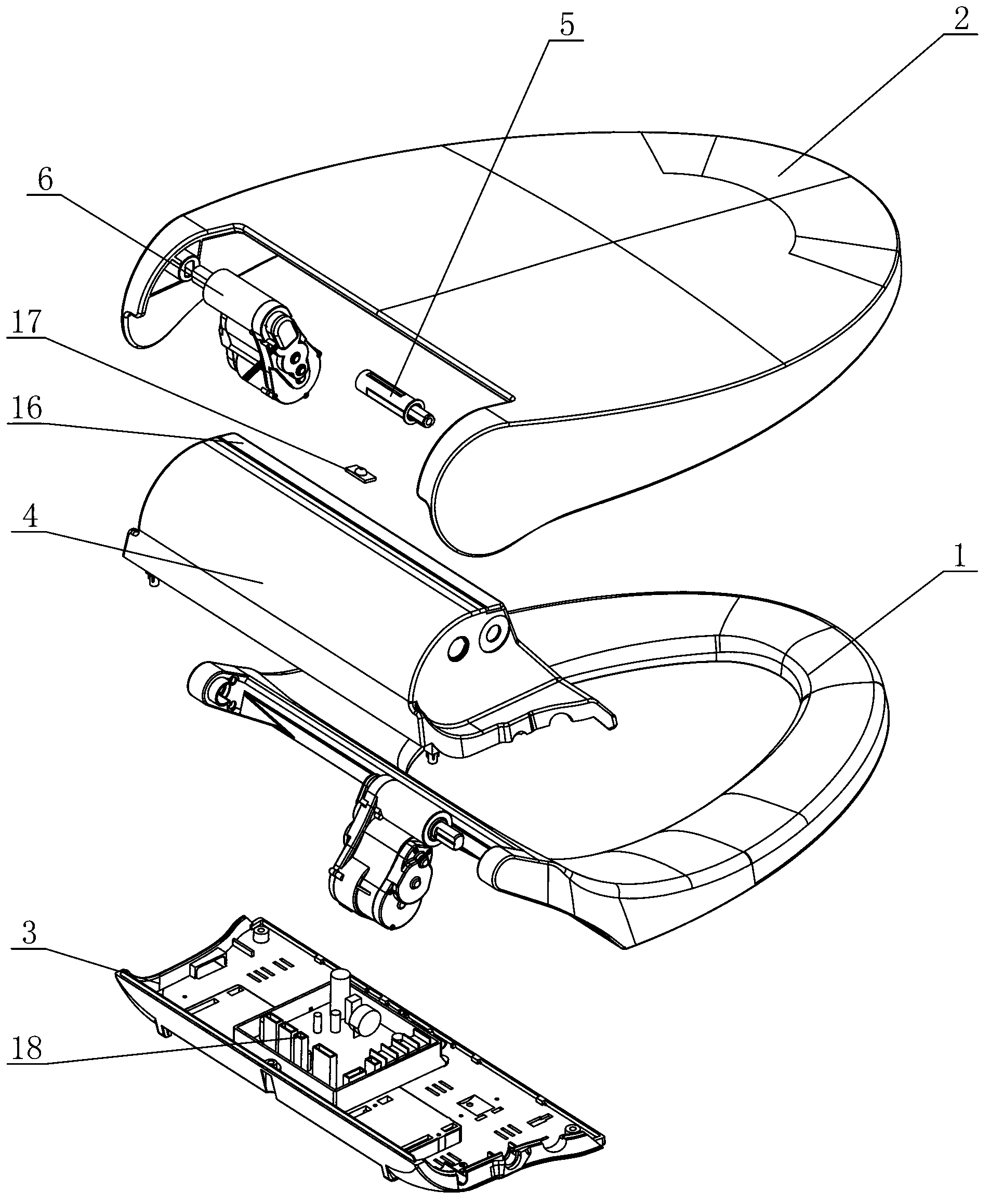

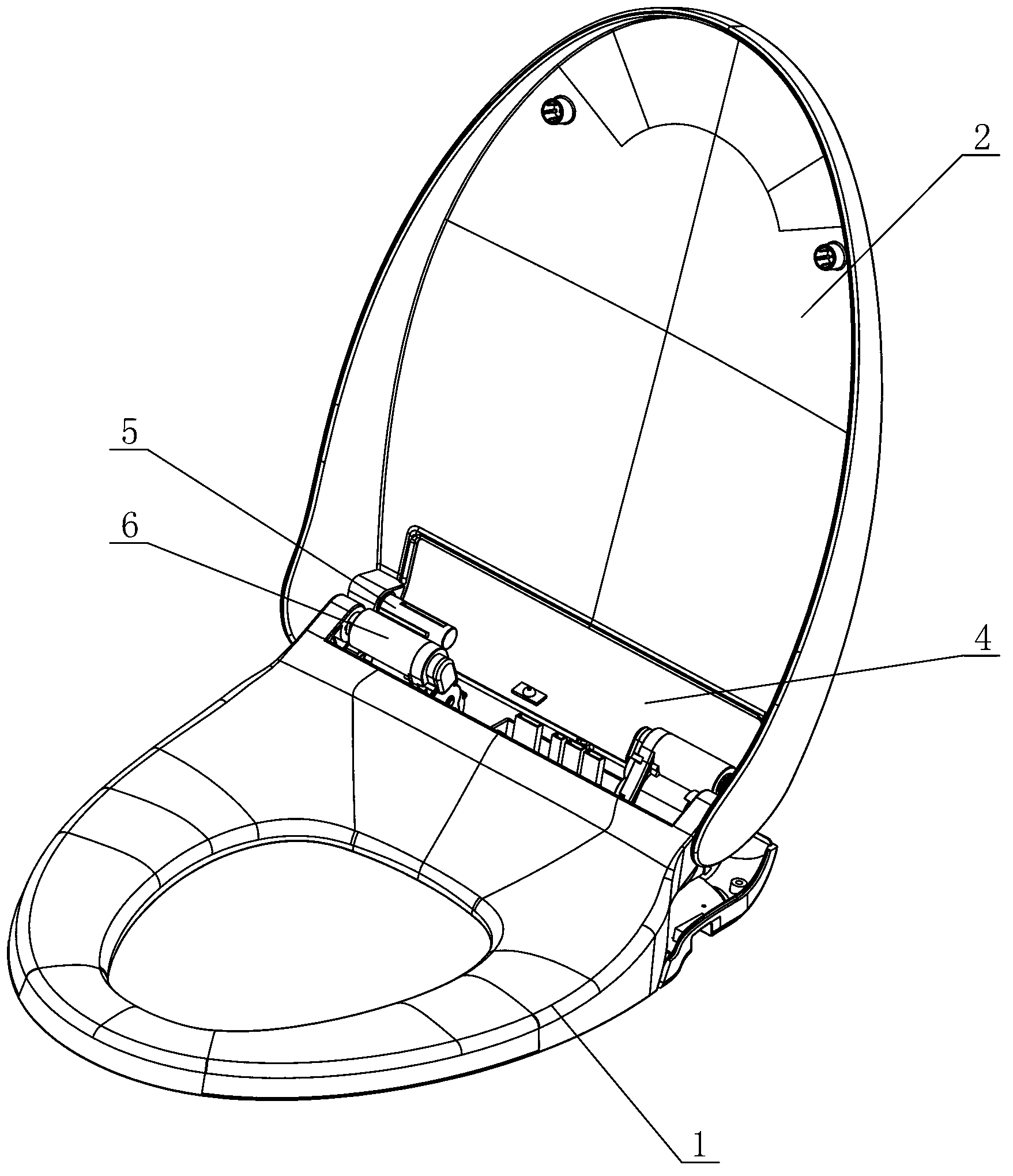

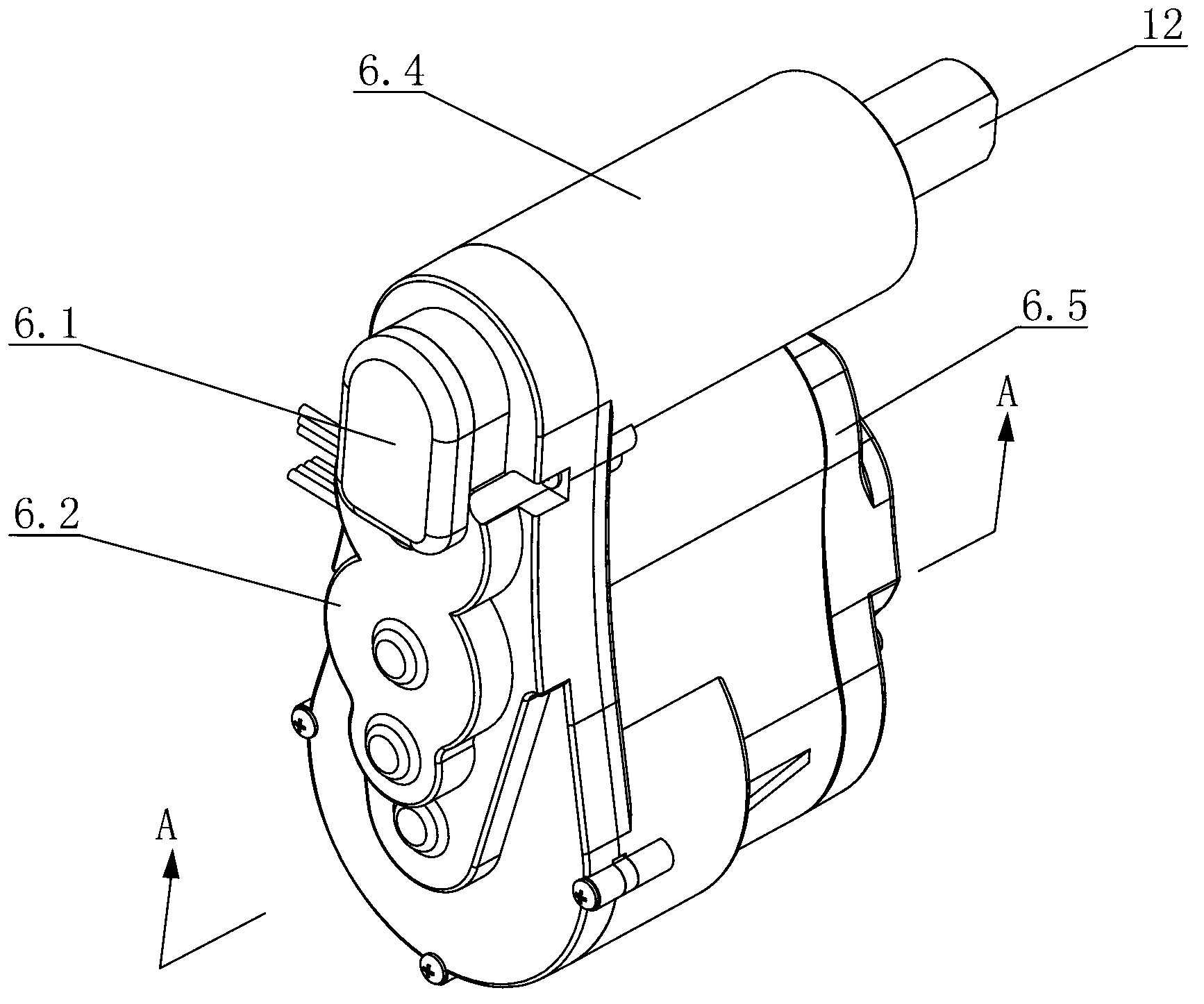

Automatic cover-flipping device for toilet cover plate and control method thereof

The invention discloses an automatic cover-flipping device for a toilet cover plate, which comprises a casing and the cover plate hinged to the casing, wherein the cover plate is composed of a seat ring and a panel; and the casing is formed by the assembling of an upper casing and a lower casing, and is characterized in that a connection rod / an automatic cover-flipping mechanism connected with one side of the seat ring / the panel is arranged on one side of the casing, and an automatic cover-flipping mechanism / a connection rod connected with the other side of the seat / the panel is arranged on the other side of the casing; and automatic cover-flipping mechanisms comprises gear sets, and motors, electromagnetic clutches, and torque balance elements connected in sequence through the gear sets. The control method comprises two control manners of manual triggering and auto-induction triggering to control the up / down of the cover plate, wherein the two control manners all run in the power-up state. The device is convenient to operate, comfortable and practical, mute, high in intelligence and product quality, and suitable for various intelligent toilets and intelligent toilet covers.

Owner:ZHONGSHAN AIMAS SANITARY WARE

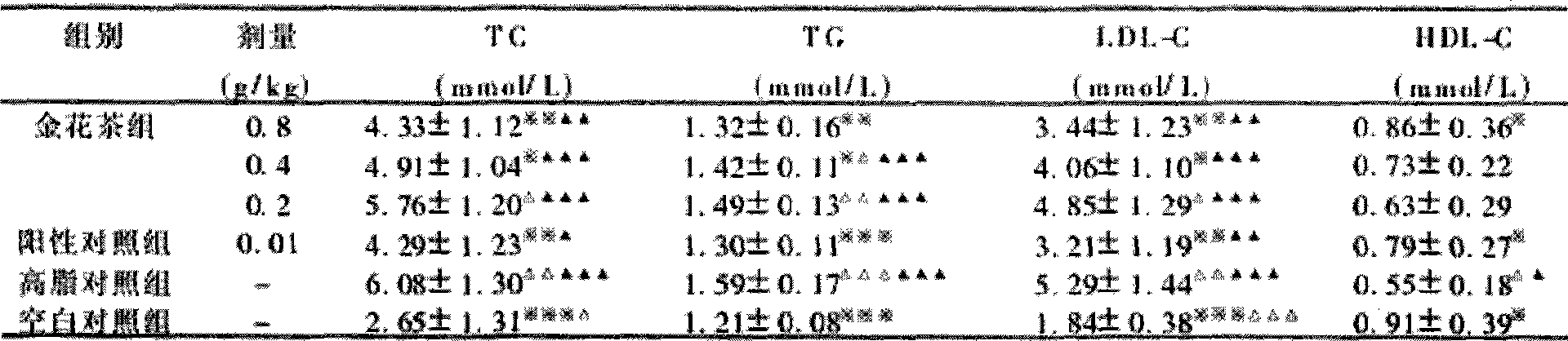

Camellia chrysantha polysaccharide lozenge and method for producing the same

InactiveCN101485789AHigh recovery rateHigh activityMetabolism disorderAntinoxious agentsCholesterolFiltration

The invention relates to a polysaccharide buccal tablet prepared from Camellia nitidissima, which mainly comprises the following raw materials: polysaccharide substances extracted from the Camellia nitidissima, a sweetening agent, trehalose, citric acid and the like. The preparation method comprises the following steps: adopting supersonic waves to leach the Camellia nitidissima first, adopting a nano-filtration method to perform concentration production of a concentrated Camellia nitidissima solution, performing spray drying, tabletting and package, and obtaining the product. The product has the functions of reducing blood sugar, blood pressure, blood fat and cholesterol in serum, inhibiting tumor growth, preventing atherosclerosis, activating various enzymes in human body, improving the immunological competence of the body, prolonging senescence, improving digestion of intestinal canals, and the like, has complete health-care functions, is suitable to be eaten by common people, and has obvious health-care effect.

Owner:GUANGXI FUXIN SCI & TECH

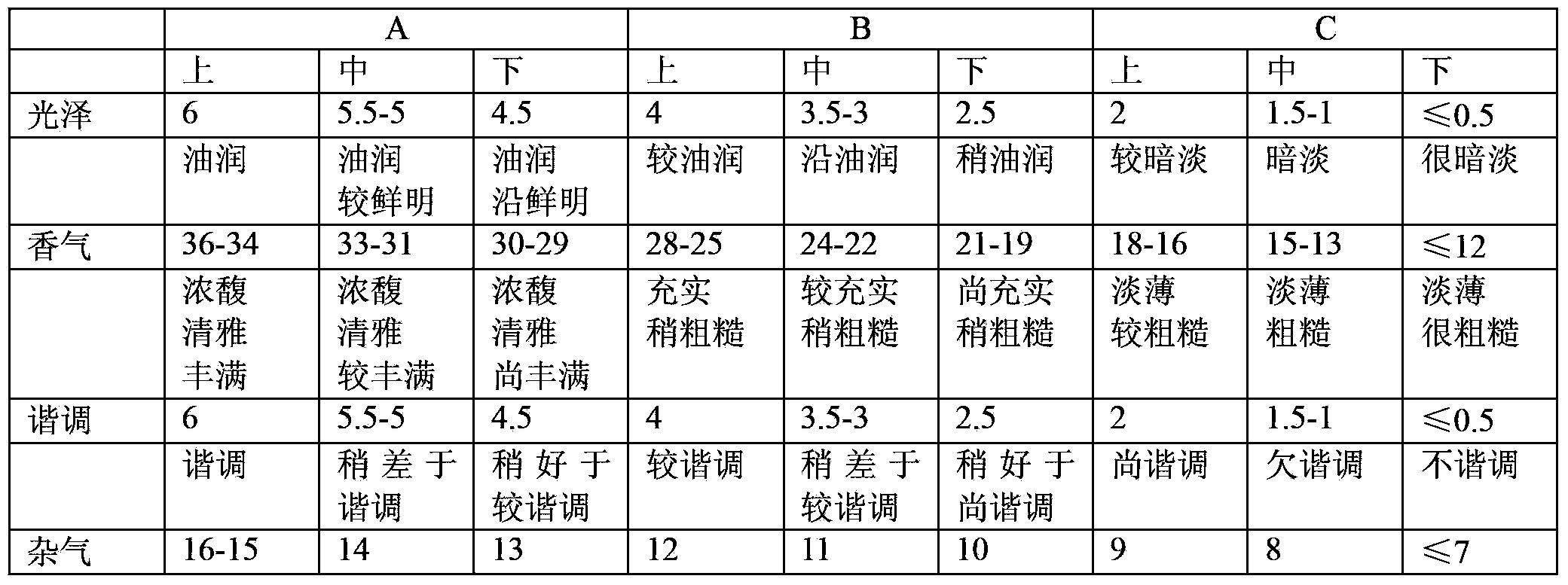

Method for reconstituting tobacco leaves by paper making method based on membrane separation technique

ActiveCN103349351AImprove efficiencyReduce energy consumptionTobacco preparationUltrafiltrationEvaporation

The invention relates to application of a membrane separation technique in a tobacco sheet producing process. The method comprises the following steps of carrying out preprocessing, digestion and screening on tobacco stems, tobacco powder and low-grade tobacco leaves, carrying out separation and purification on screened coarse liquid through a ceramic membrane separating device, protein, saccharides, pectin and other macromolecule substances in the coarse liquid are eliminated, carrying out further purification through an organic ultrafiltration membrane to obtain finer purified liquid, and carrying out the organic membrane and double-effect evaporation, concentration, coating and drying, wherein trapped liquid processed by a membrane technique is reused in the digestion process. The method is simple in separation process, low in energy consumption, free of pollution and capable of eliminating macromolecule protein and pectin and maintaining effective substances in tobacco, improves tobacco quality, reduces energy consumption and can create certain economic benefit.

Owner:JIANGSU JIUWU HITECH

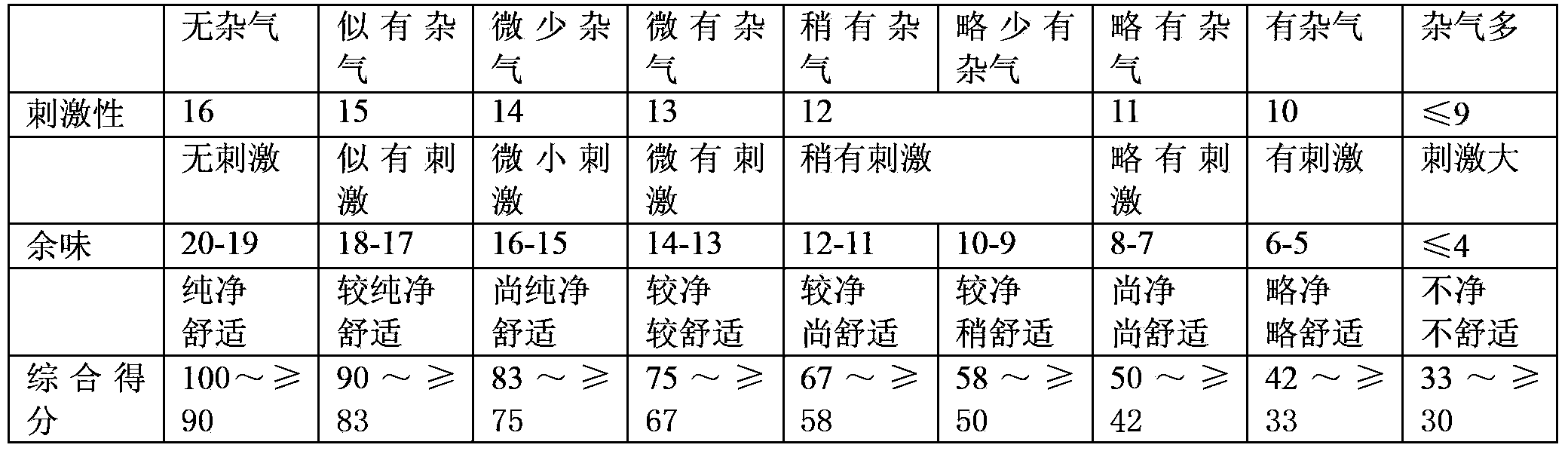

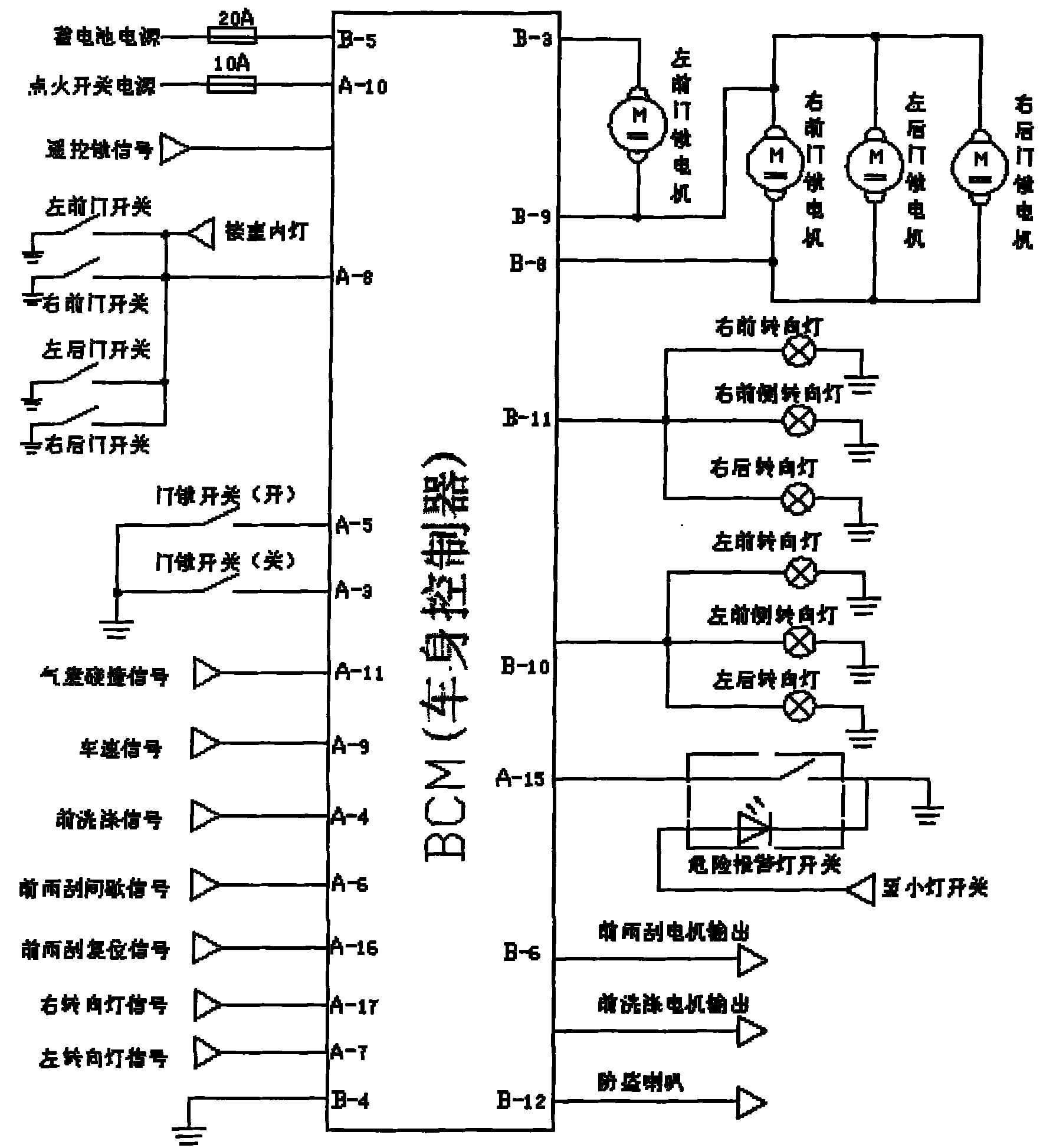

Vehicle body controller and control method thereof

InactiveCN101863253AReduce in quantityEasy to upgradeElectric/fluid circuitSignal processing circuitsLight driven

The invention relates to a vehicle body controller and a control method thereof. The vehicle body controller integrates a windscreen wiper intermittent controller, a remote-control door lock controller and a turn light controller which are originally independently controlled into a whole for uniform control by adopting an integral control mode so as to not only save the installation structure of the controller, but also decrease chips of an internal control circuit. The vehicle body controller realizes windscreen wiper intermittent control, remote-control door lock and central-control door lock control and turn light control and increases the functions of collision unlocking, traveling vehicle automatic locking, claxon anti-theft alarm, and the like on the basis. The vehicle body controller internally comprises a main controller module, a power supply processing circuit, a signal processing circuit, a central-control lock driving module, a turn light driving module, a windscreen wiper intermittent driving module and a claxon driving module. The control method can overcome the defect of high fault rate of an independent control unit and also reduces the integral vehicle cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

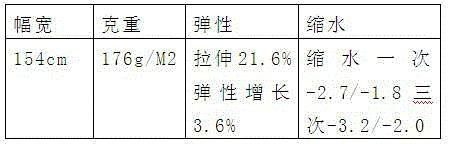

Method for printing and dyeing dacron/chinlon/cotton/spandex multi-component fiber fabric

ActiveCN104532611AEliminate potential wrinklesGuaranteed smooth productionBleaching apparatusDyeing processFiberPolymer science

The invention belongs to the technical field of printing and dyeing of textiles and in particular relates to a method for printing and dyeing a dacron / chinlon / cotton / spandex multi-component fiber fabric. The method comprises the following sequential steps: preparing gray fabric, turning seams, rolling enzyme and carrying out cold stacking, bleaching and washing at low temperature, sizing, mercerizing, dyeing and after-finishing. After dyeing, finishing and functional after-finishing, the fabric has fluffy style, and is stiff and smooth and elastic, is capable of absorbing moisture and releasing sweat, and is comfortable and has a close fitting effect; the fabric is integrated with the advantages of a plurality of advantages; the effect of adopting advantages while overcoming disadvantages is exerted; the requirements of superior-quality fabric can be met; meanwhile, the fabric is hydrophilic, and is easy to decontaminate and due to after-finish, the fabric has the characteristic of easiness in cleaning; the quality of the fabric is improved; the enterprise competitiveness is improved.

Owner:HUAFANG

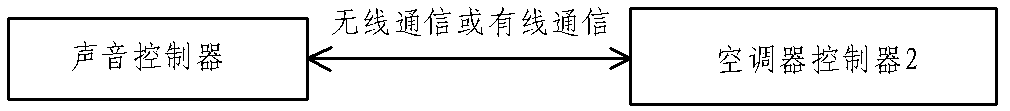

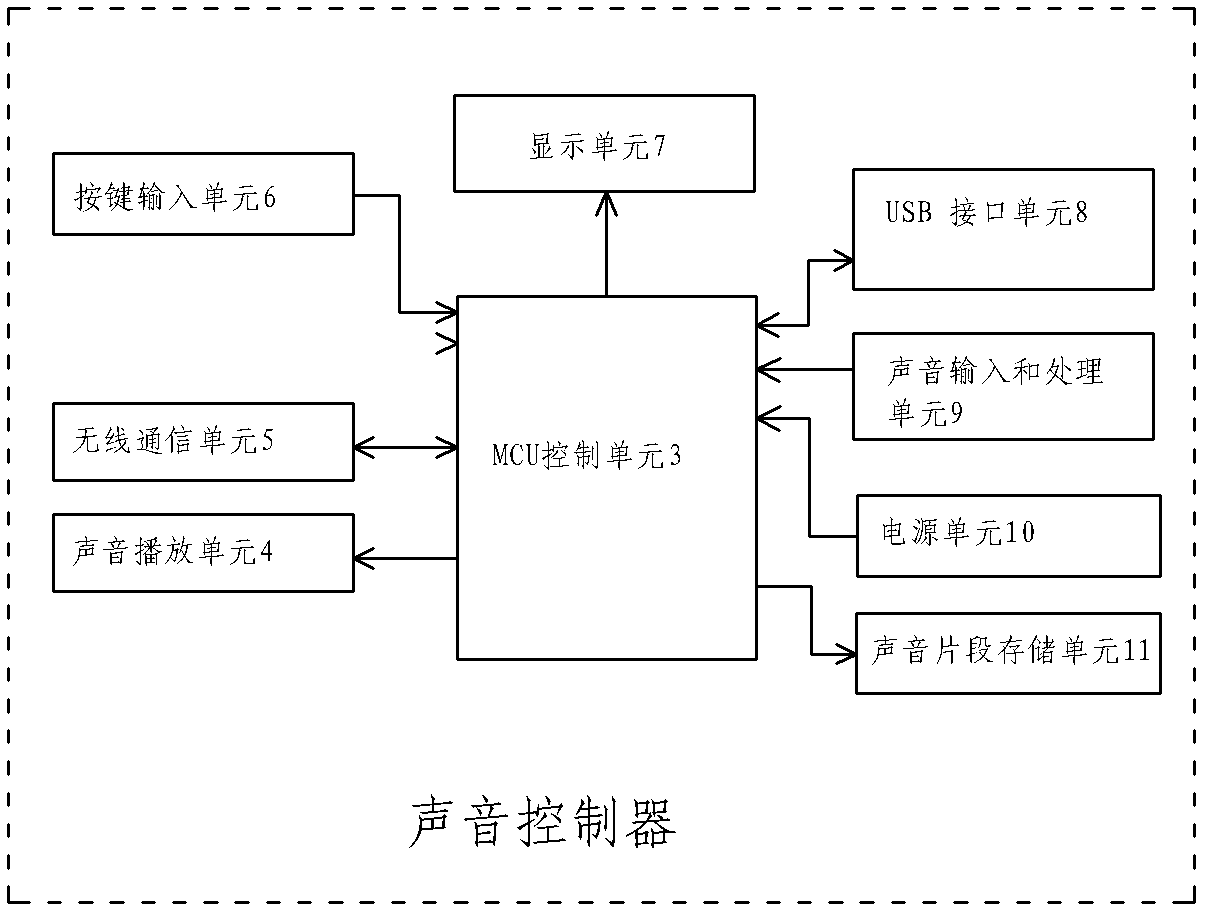

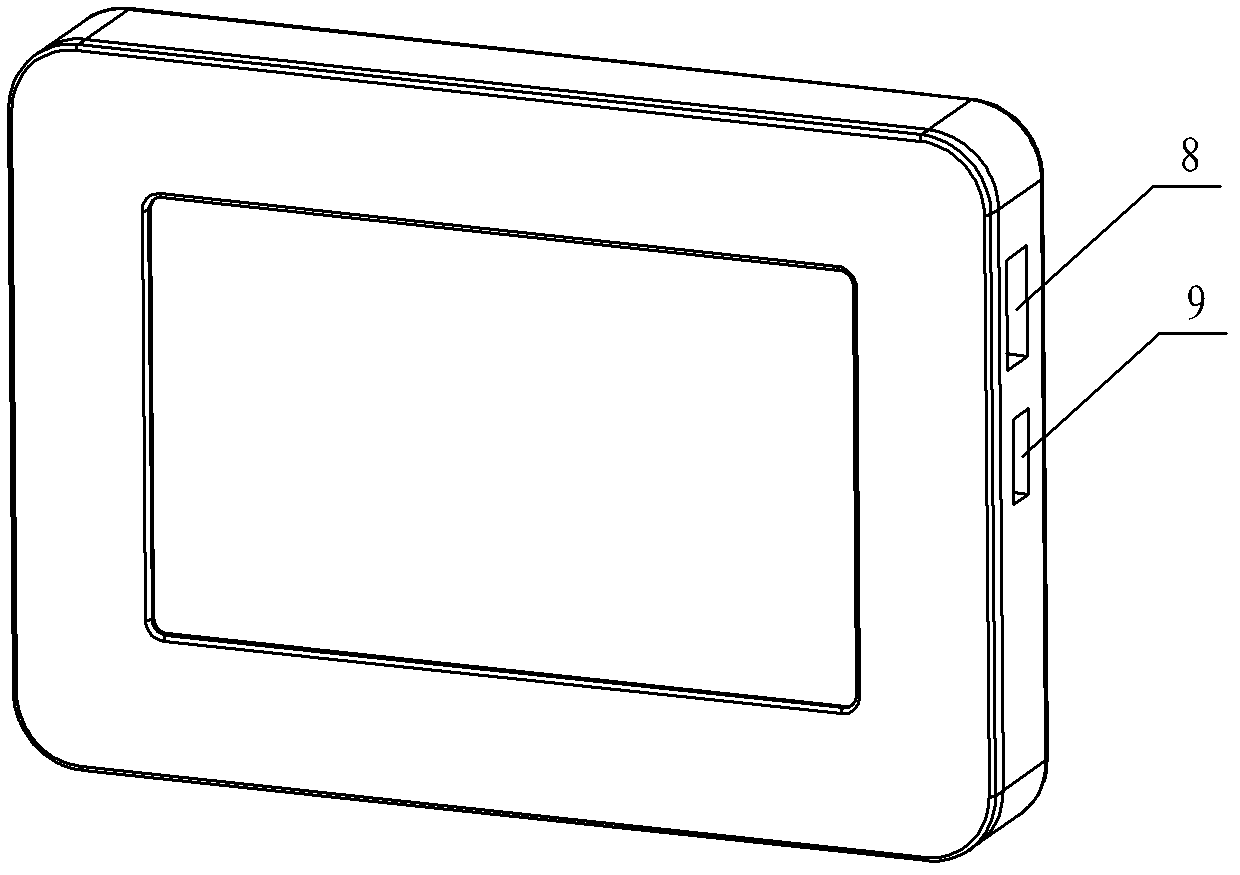

Sound controller of air conditioner having custom acoustic control function

InactiveCN102183075AEasy to useRealize voice control functionSpace heating and ventilation safety systemsLighting and heating apparatusUser needsCommunication unit

The invention discloses a sound controller of an air conditioner having a custom acoustic control function. By the sound controller, a user records and stores voice segments according to corresponding functions or states of the air conditioner, and then the user needs to repeat the recorded and stored voice segments to adjust to the corresponding functions or the states by controlling the air conditioner by the sound controller. After the sound controller detects outside voice segments, the outside voice segments can be compared with the voice segments of all acoustic control commands in a storage unit in the sound controller; when the outside voice segments are accordant with some of the voice segments in the storage unit, an instruction for operating the corresponding functions or the states of the air conditioner is sent and sent to the air conditioner by a communication unit in the sound controller; and corresponding voices are played by a sound playing unit in the sound controller to remind the user. The sound controller is characterized by flexible operation, good generality and wide application range.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

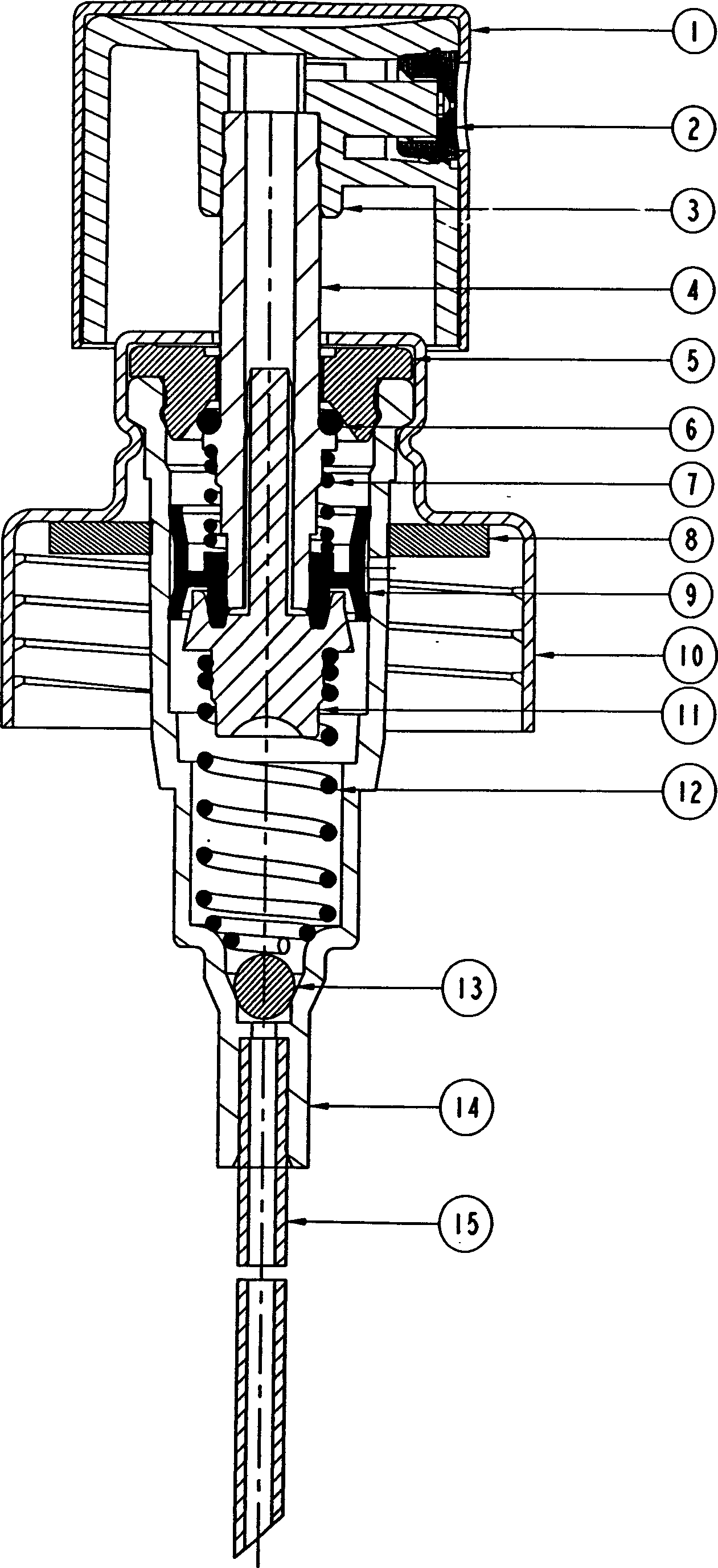

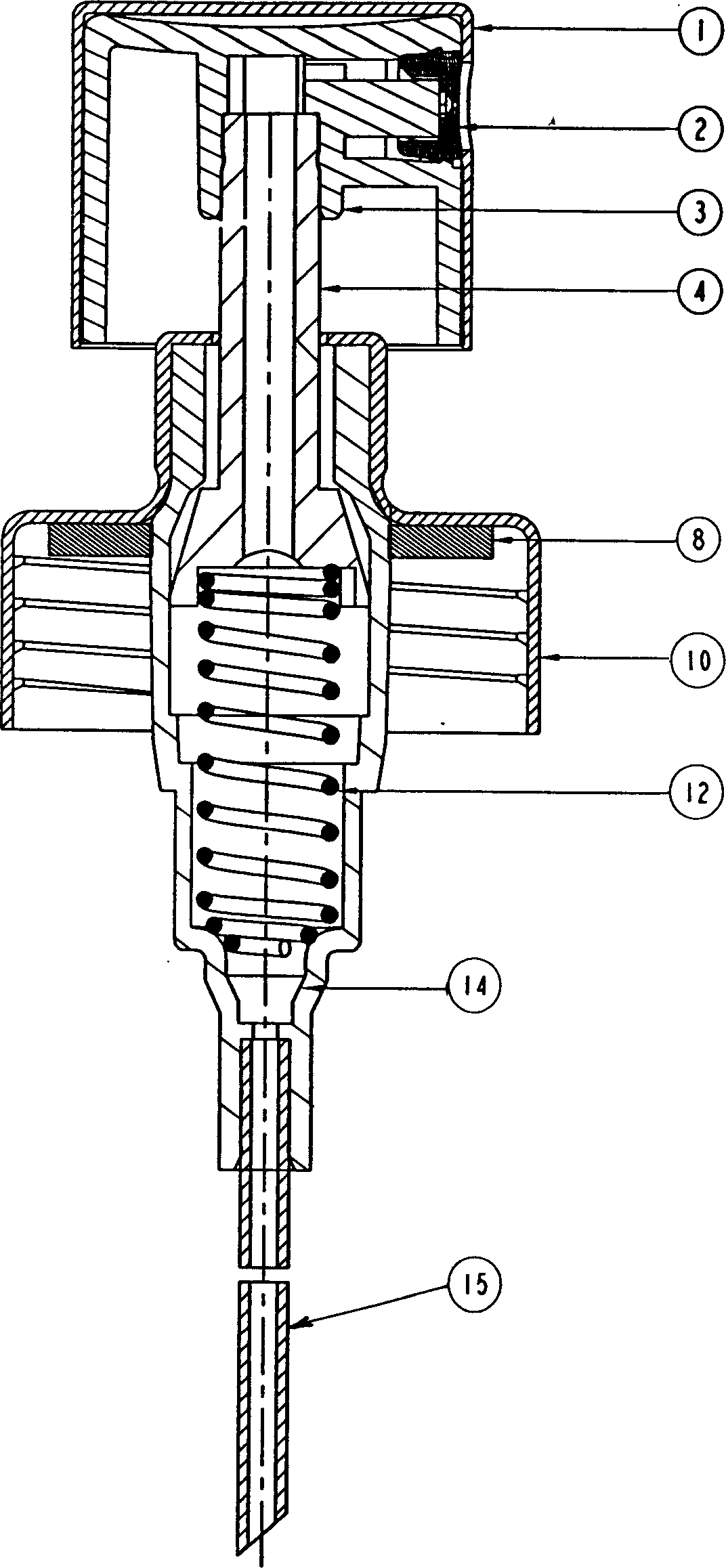

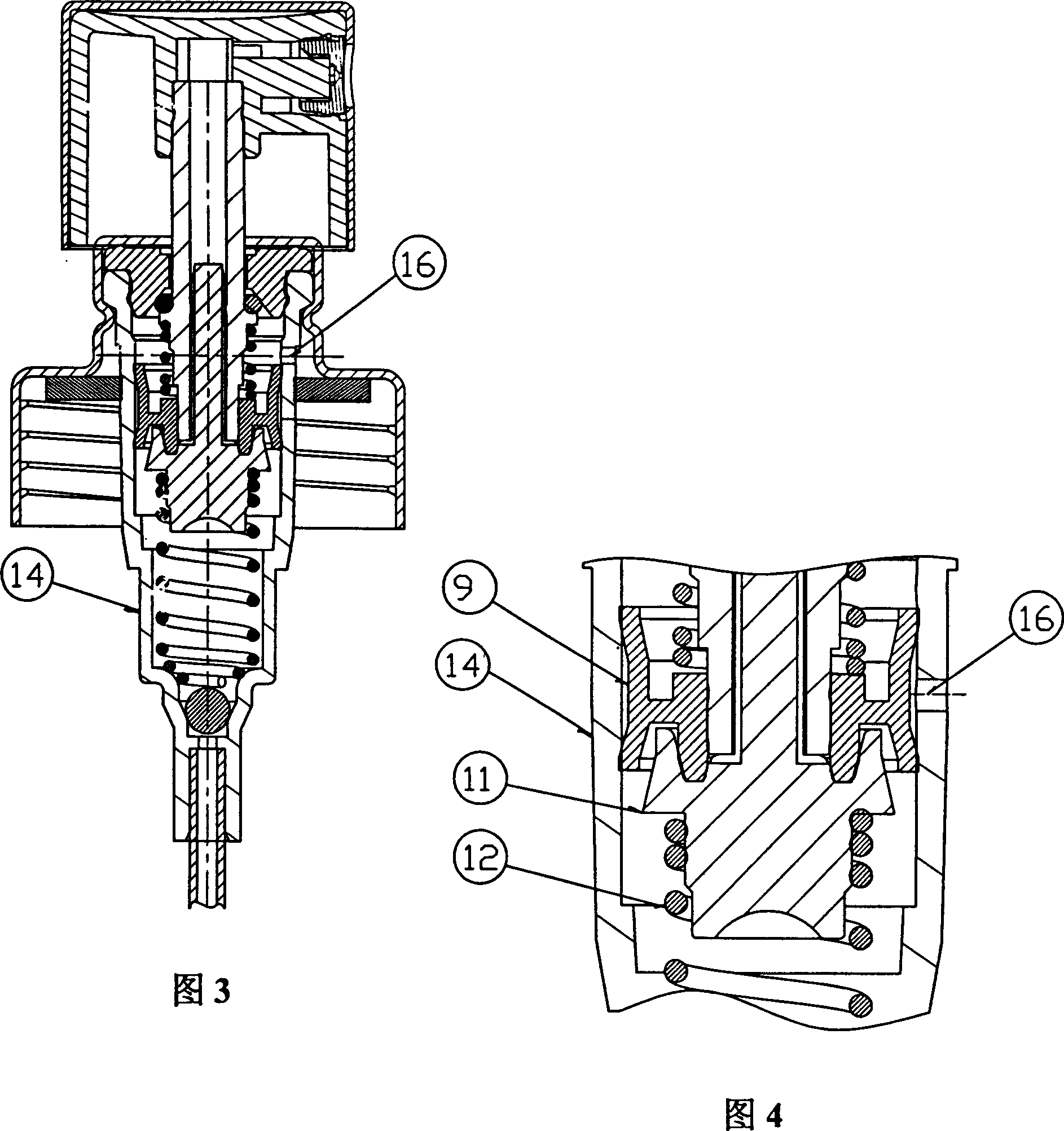

Miniature sprayer sealing device

InactiveCN1775375APrevent leakageImprove product gradeLiquid spraying apparatusLiquid dispensingSprayerEngineering

The present invention relates to a miniature sprayer sealing device designed for preventing leakage. Said device includes the following several components: push-cap, spraying piece, head cap, valve rod, sealing ring, fastener, long spring, pump body and suction tube. Said invention also provides the concrete structure of every above-mentioned component, connection mode of all the components and working principle of said miniature sprayer sealing device.

Owner:黄建壮

Colour changing printed fabric

InactiveCN1590637AImprove product gradeEase of industrial implementationDyeing processEngineeringSlurry

Owner:ZIBO HUANFENG TEXTILE

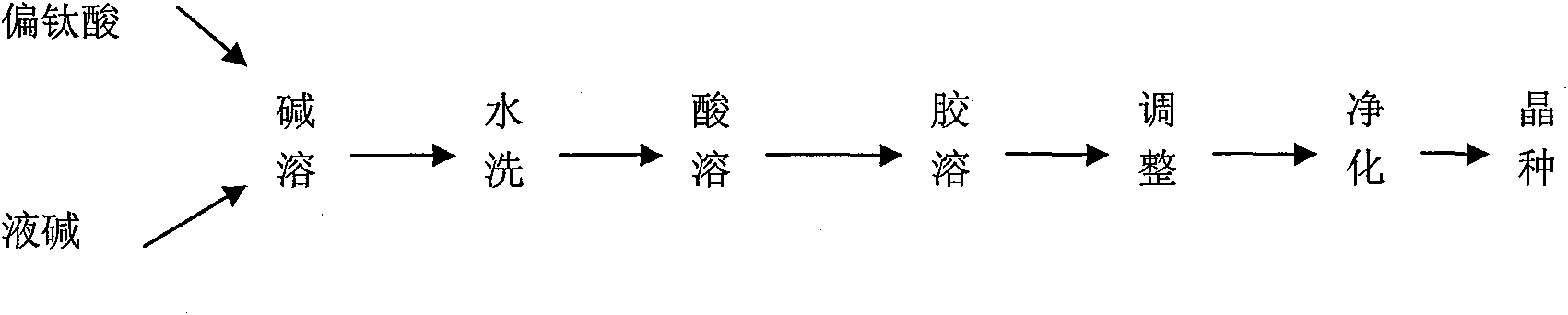

Preparation of white titanium pigment double action crystal seed from metatitanic acid

ActiveCN101565201AFast phase changeSimplify operating proceduresPigmenting treatmentTitanium dioxideX-raySodium sulfate

The invention relates to a preparation of white titanium pigment double action crystal seed from metatitanic acid, which is characterized in the process of (1) alkali dissolving, boiling the metatitanic acid purified by water washing with thermokalite; (2) water washing, removing residue sodium hydroxide and generated sodium sulfate thereby; (3) neutralizing and acid dissolving, neutralizing by hydrochloric acid and acid solution; (4) peptizing to generate a seed suspension, evaporating the suspension at a temperature from 105 to 300 DEG C., grinding, measuring the rutile microcrystalline with weight percentage over 90-98% by a X-ray diffractometer. The preparation uses metatitanic acid produced during sulphuric acid production process as raw material, adopts sol-gel process, with the produced rutile microcrystalline is safe and non-toxic, simple and easy to get raw material, low in cost, thus capable of evidently improving quality of product, enhancing stability of product quality and market competitiveness.

Owner:江西添光钛业有限公司

Polyester type ultra-low density polyurethane resin for shoes

The present invention is the recipe of three component polyurethane resin for insole. The polyurethane resin includes one component A of active hydrogen-containing mixture comprising long chain polyol polymer, chain expanding agent, cross-linking agent, surfactant, foaming agent and other assistants; one component B comprising polyester or polyether modified MDI pre-polymer; and one component C or catalyst component of glycol solution of triethylidene diamine. The polyurethane resin has density as low as 0.25-0.30 g / cu cm, capacity of making the product firm and good in appearance, and other advantages.

Owner:无锡双象新材料有限公司

Jacquard reversible lint

InactiveCN1851085AImprove water absorptionImprove product gradeCarpet cleanersFloor cleanersFiberEngineering

The invention discloses a two-faced plush cleaning cloth. It can satisfy the need of using repeatedly, the slapping-up and the good ability of absorbing water. The invention adopts super thin fiber serving as raw material. It can be used widely in the top grade concourse such as the top grade eating serving trade, the cabaret and the hotel. It is used for the Turkish towel, the tablecloth and the dishware matting cloth of the top grade hotel.

Owner:仲柏俭

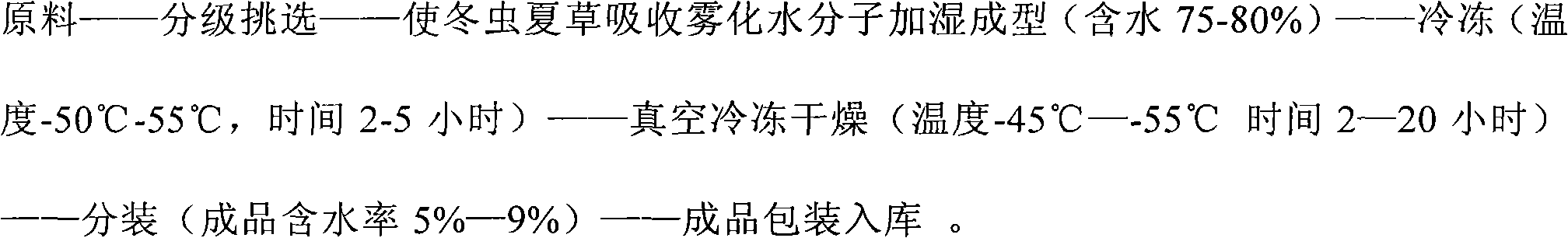

Biological vacuum freezing and drying method for aweto

InactiveCN101317562AFresh colorStrong fragranceDead plant preservationPlant ingredientsPreservation methodsOphiocordyceps sinensis

The invention relates to aweto biological vacuum freezing and drying method, belonging to the field of preservation method of animals and plants. The aweto biological vacuum freezing and drying method comprises the steps as follows: (1) the aweto absorbs low-temperature atomized water molecular, the water absorption is 75-80%; (2) quick freezing is carried out for 2-5 hours at the temperature of -50-55 DEG C; (3) the vacuum freezing and drying are carried out for 2-20 hours at the temperature of -45-55 DEG C, so as to lead the moisture content of the finished product to achieve 5-9%. The product obtained by the invention can achieve sanitary requirement of edible fungi which can be directly eaten; the product has good water absorption, really achieves the original shape, colour, tastes and nutritive effect of purely wild aweto, improves the real additive values of the aweto and is suitable for long-term storage.

Owner:吕坤秋

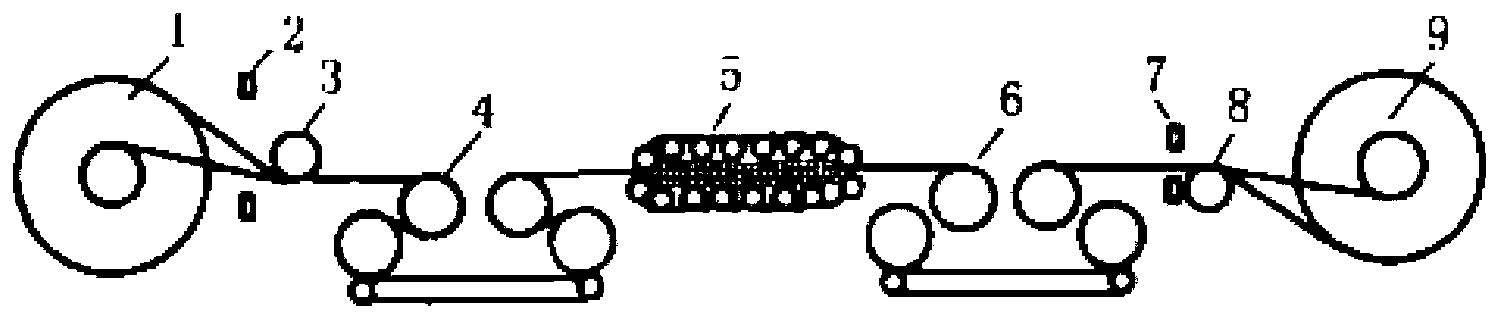

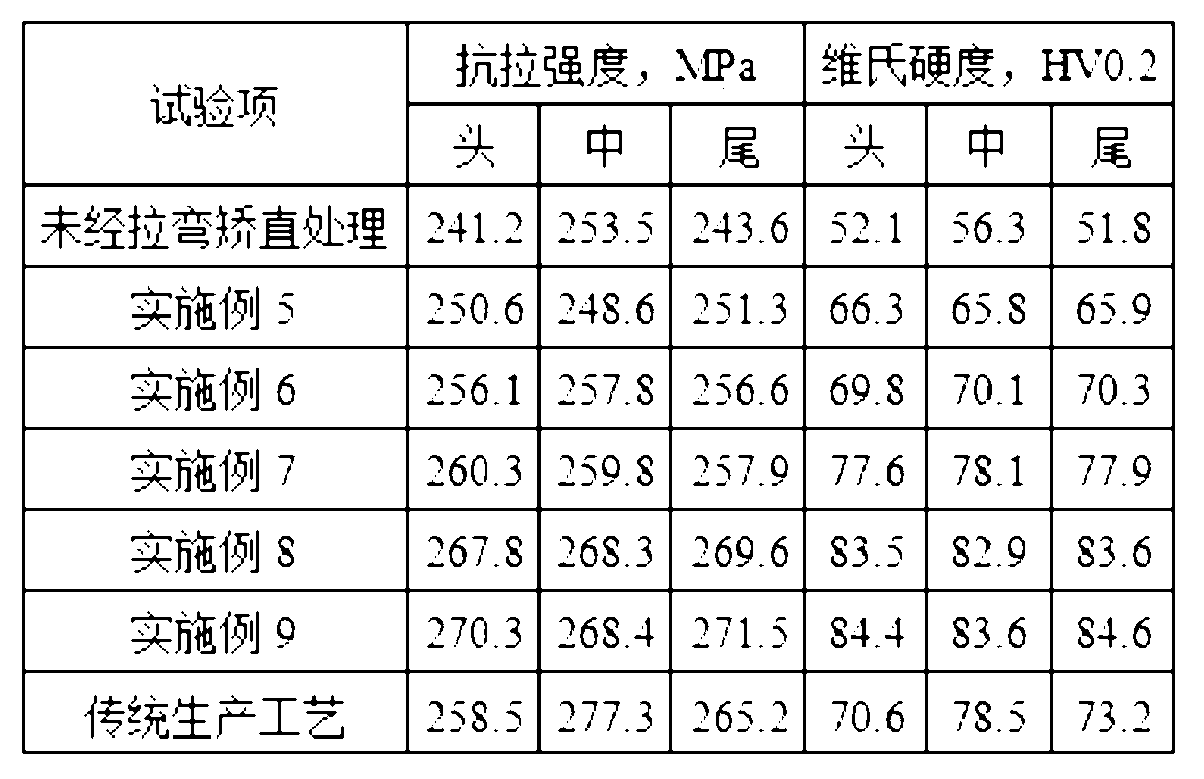

Production process of semi-hard soft copper belts

ActiveCN102699024ATune performanceUniform performanceMetal rolling arrangementsCopperMaterials science

The invention discloses a production process of semi-hard soft copper belts. The process comprises a coarse rolling work procedure, an annealing work procedure, a middle rolling work procedure, an annealing work procedure, a fine rolling work procedure, a normal annealing work procedure, a cleaning work procedure, a bending pulling straightening work procedure, a cutting work procedure and a packing work procedure. Compared with the prior art, the production process has the advantages that the normal annealing is adopted. Compared with the low-temperature annealing process, the production process has the advantages that soft copper belt products can be obtained, in addition, the bending pulling straightening work procedure is added, the bending pulling straightening is mainly used for improving the belt form quality of hard belt materials, the process is equivalent to once rolling at an ultralow processing rate, and the belt materials can generate certain plastic deformation after the bending pulling straightening, so the products are processed into the semi-hard soft state from the soft-state processing, the product performance regulation is reached through controlling the elongation rate and the tension, the obtained copper belt products have uniform performance, in addition, the belt form quality of products is greatly improved, the product grade is improved, and the use requirements of customers are met.

Owner:ANHUI ZHONGYUAN NEW MATERIALS CO LTD

High-transparency physical antibacterial polyolefin fruit and vegetable storage and transportation preservative film

The invention provides a high-transparency physical antibacterial polyolefin fruit and vegetable storage and transportation preservative film, comprising polar PVC resin, primary plasticizer, auxiliary plasticizer, a liquid heat stabilizer, a physical bactericide, antibacterial agent, a solid heat stabilizer, lubricant, anti-blocking agent and dye. On the basis of maintaining or improving the MAPfunction, the high-transparency physical antibacterial polyolefin fruit and vegetable storage and transportation preservative film can improve the physical antibacterial effect, reduces usage of chemical preservative, reduces secondary pollution of chemicals on environment and products, has the effects of beautifying package, highlighting appearance quality of fruits and vegetables and enhance product grade, is in accordance with the higher requirements proposed in fruit and vegetable storage and transportation preservation industry, especially in the use of MAP material in logistic preservation, so as to achieve the aims of improving logistic preservation effect, improving dynamic preservation benefit, and meeting consumer requirements.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

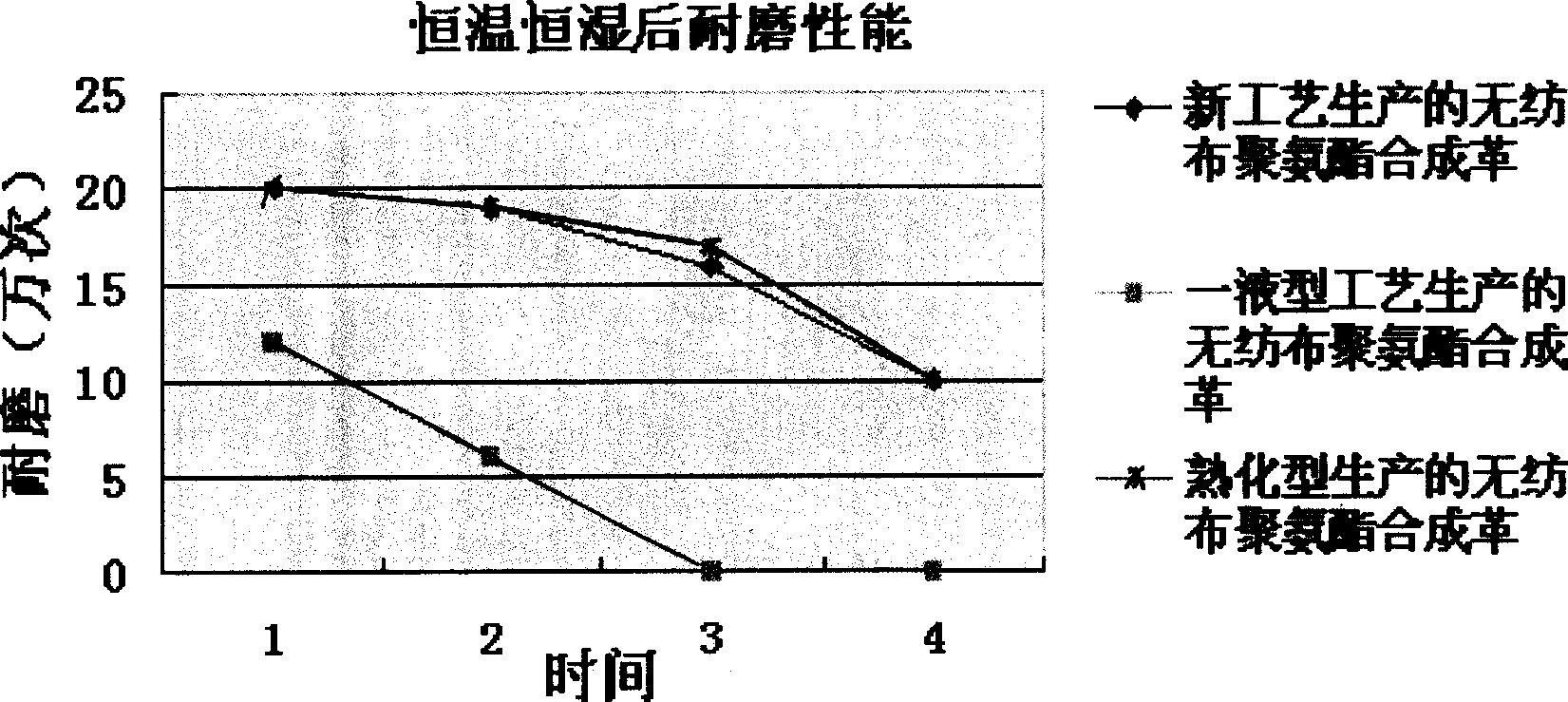

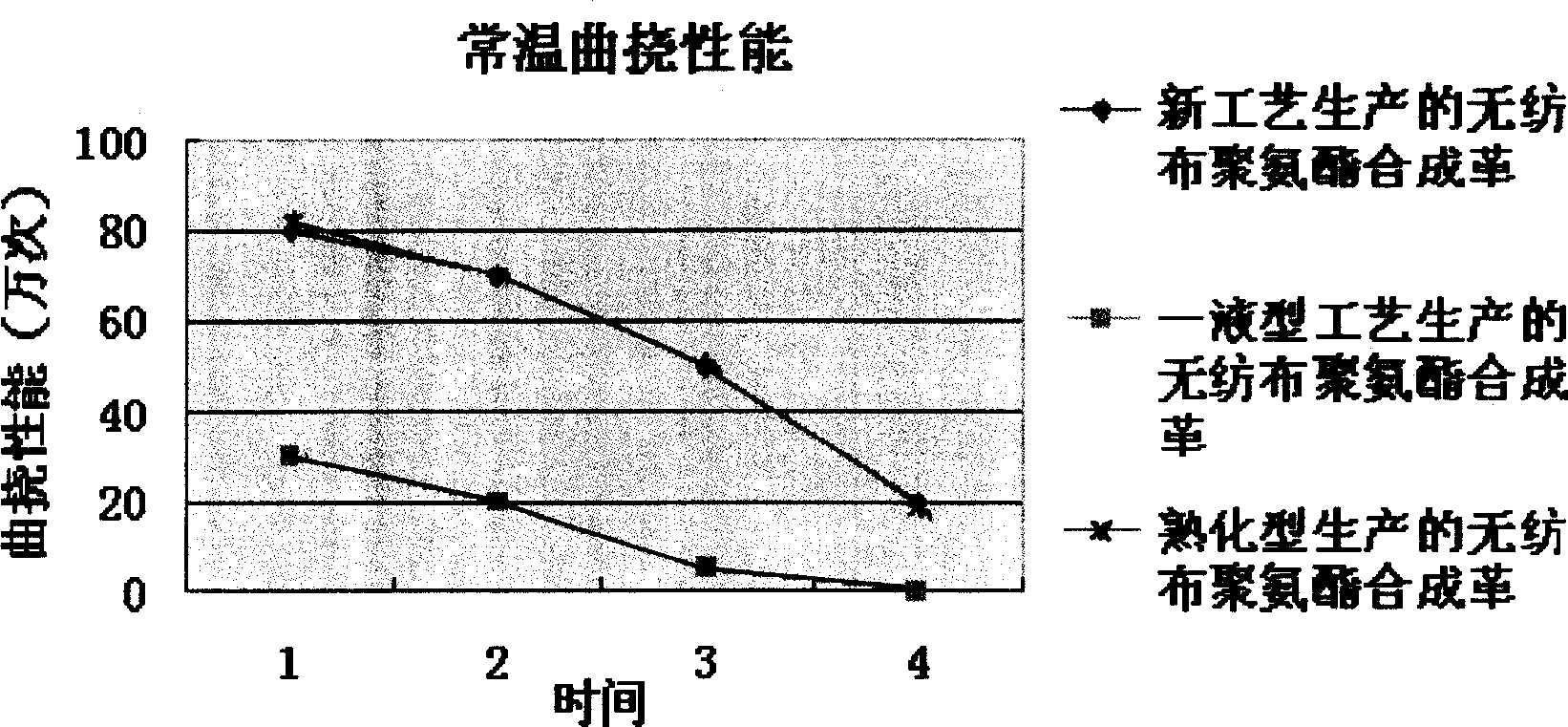

Two-liquid type rapid stripping synthetic leather composite overlay

ActiveCN101503861AHigh peel strengthHigh tear strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsBursting strengthTemperature resistance

The invention provides a two-liquid type quick forming instant peeling synthetic leather composite veneer, which is mainly characterized in that bonding layer resin is added with a quick crosslinker and a crosslinking catalyst, so that the two-component bonding layer resin achieves quick crosslinking, and can achieve proper degree of crosslinking through normal veneering process so as to achieve the aim of instant peeling. The high peeling hydrolysis resistant non-woven fabric polyurethane synthetic leather produced by the process has good physical and mechanical properties such as high peeling strength, tearing strength and bursting strength, bending resistance, low temperature resistance, hydrolysis resistance, acid and alkali resistance and the like.

Owner:ANHUI ANLI MATERIAL TECH

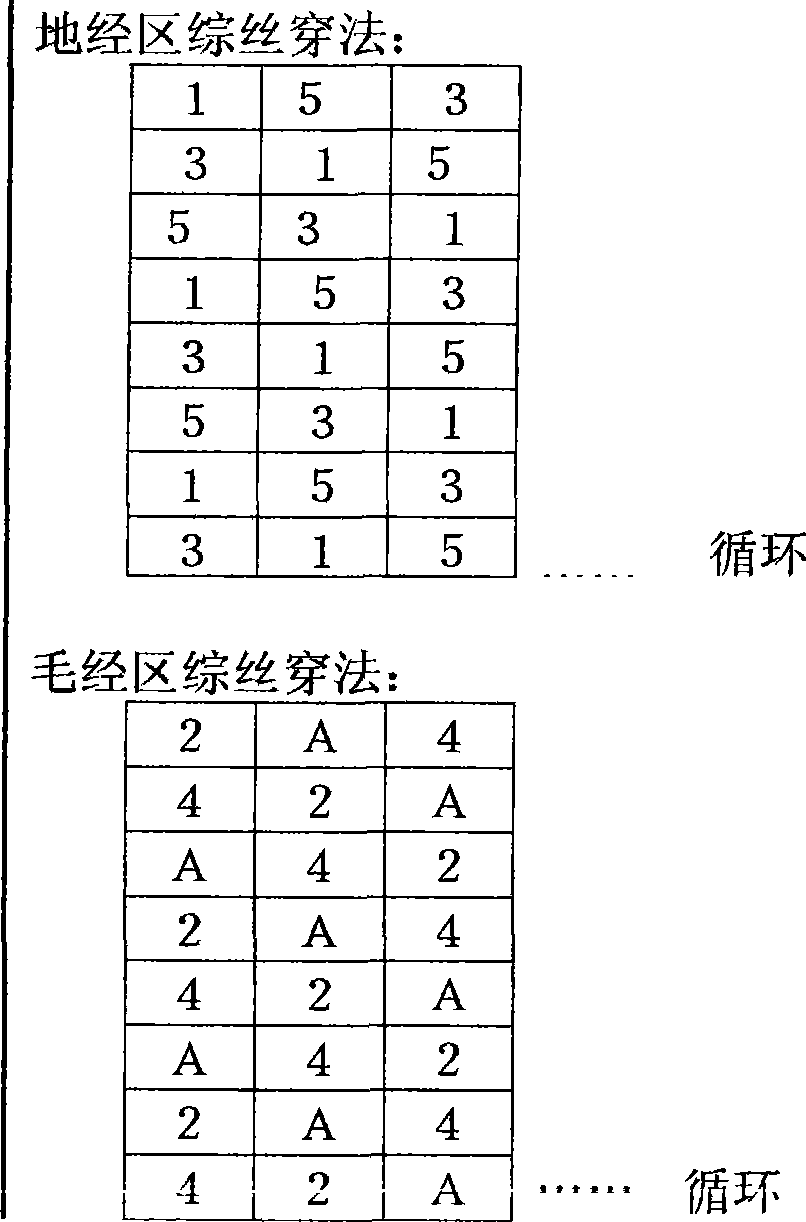

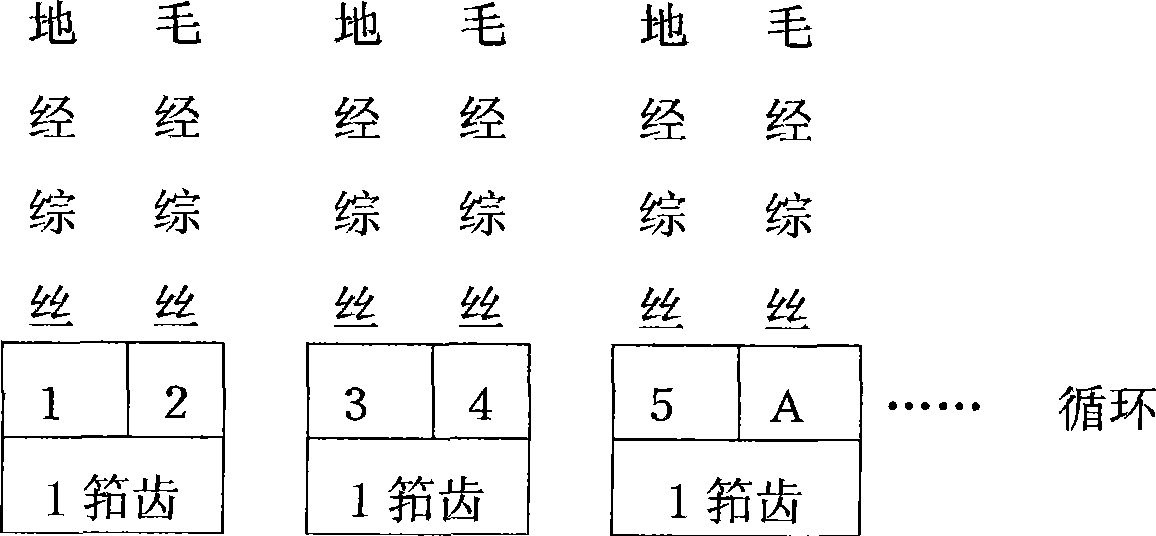

Three-layered jacquard towel weaving technique thereof

The invention discloses a three-layer jacquard towel and a weave process thereof. The weave process comprises the following steps that: towel ground warp is divided into three layers, and the towel ground warp and napping warp are arranged in turn in the proportion of 5:1 by number; during weaving, the napping warp and one layer of the three layers of ground warp is woven with weft yarn to form terry, while the other two layers of ground warp is respectively woven with weft yarn to form towel foundation fabric, thereby weaving into the three-layer jacquard towel. Moreover, the weave process adopts a napping warp tensile force ranging between 35 and 40kg and a ground warp tensile force ranging from 395 to 405kg; post treatment adopts overflow machine treatment, oscillation drying and stentering shaping; and the towel manufactured by the weave process has soft handfeel, diversified color and strong pattern stereovision.

Owner:SUNVIM GROUP

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

Vacuum plating film coating

A paint for the vacuum deposition on plastics is proportionally prepared from plant oil, polyol, acid anhydride, rosin, acrylic copolymer, polyhydroxy polymer, modified polyolefin, isocyanate and solvent mixture through alcoholysis, esterifying, addition reaction and aminoesterifying.

Owner:汕头市长崎制漆有限公司

Fresh water treatment machine

InactiveCN102008845AExtend your lifeEasy to installWater/sewage treatmentMultistage water/sewage treatmentPurification aspectsEngineering

The invention relates to the water treatment industry, in particular to the deep filtration and purification aspects of drinking water. The invention discloses a fresh water treatment machine comprising a backflushing filter element, an engine base with a water inlet and a water outlet, a water path switcher and a sealing cover which contacts and is matched with the engine base to form a sealed inner cavity, the built-in water path switcher is provided with a hollow rotating shaft, one end of the hollow rotating shaft is hermetically communicated with a switching water nozzle of a rotary disc of the hollow rotating shaft, the other end of the hollow rotating shaft penetrates through a shaft via hole to form a rotatable water nozzle pipeline, another switching water nozzle of the rotary disc is communicated with another water nozzle pipeline of the engine base through the inner cavity, a fixed disc of the water path switcher is provided with 2-15 water nozzles which correspond to the water nozzles of the rotary disc, are arranged at isotonic included angles as units, correspondingly connected with 1-7 filter elements and form a filter channel, the fixed disc contacts and is matched with the rotary disc, only the water inlet and the water outlet are communicated, and the hollow rotating shaft drives the rotary disc to rotate a switching position by using each isotonic included angle as a unit and form a backflushing channel of the backflushing filter element.

Owner:杜也兵

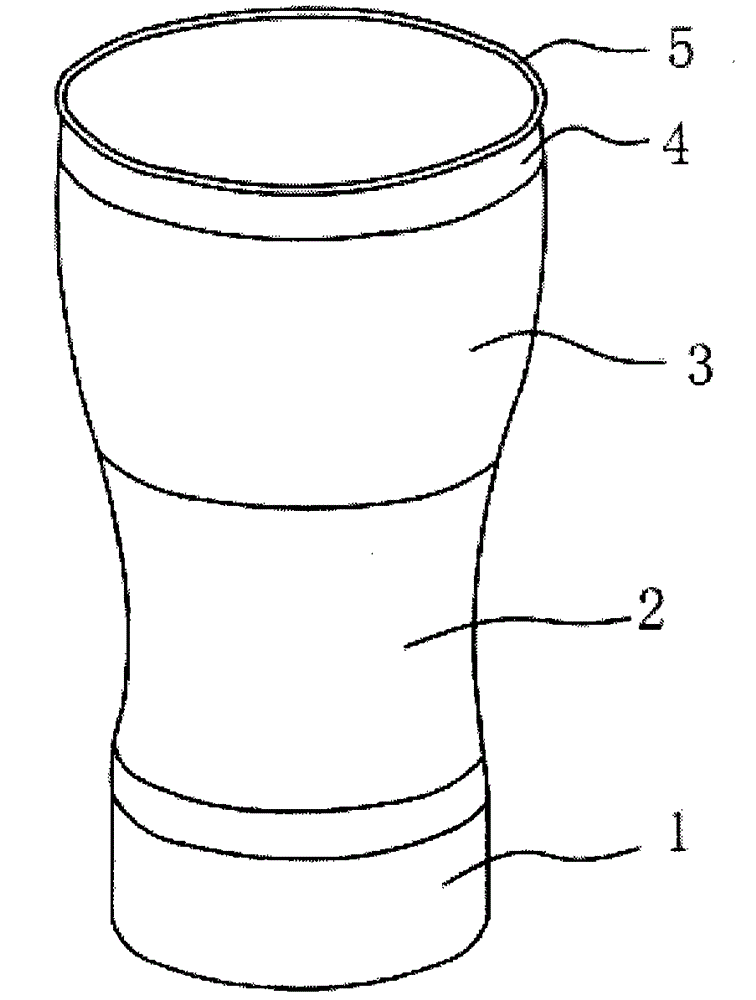

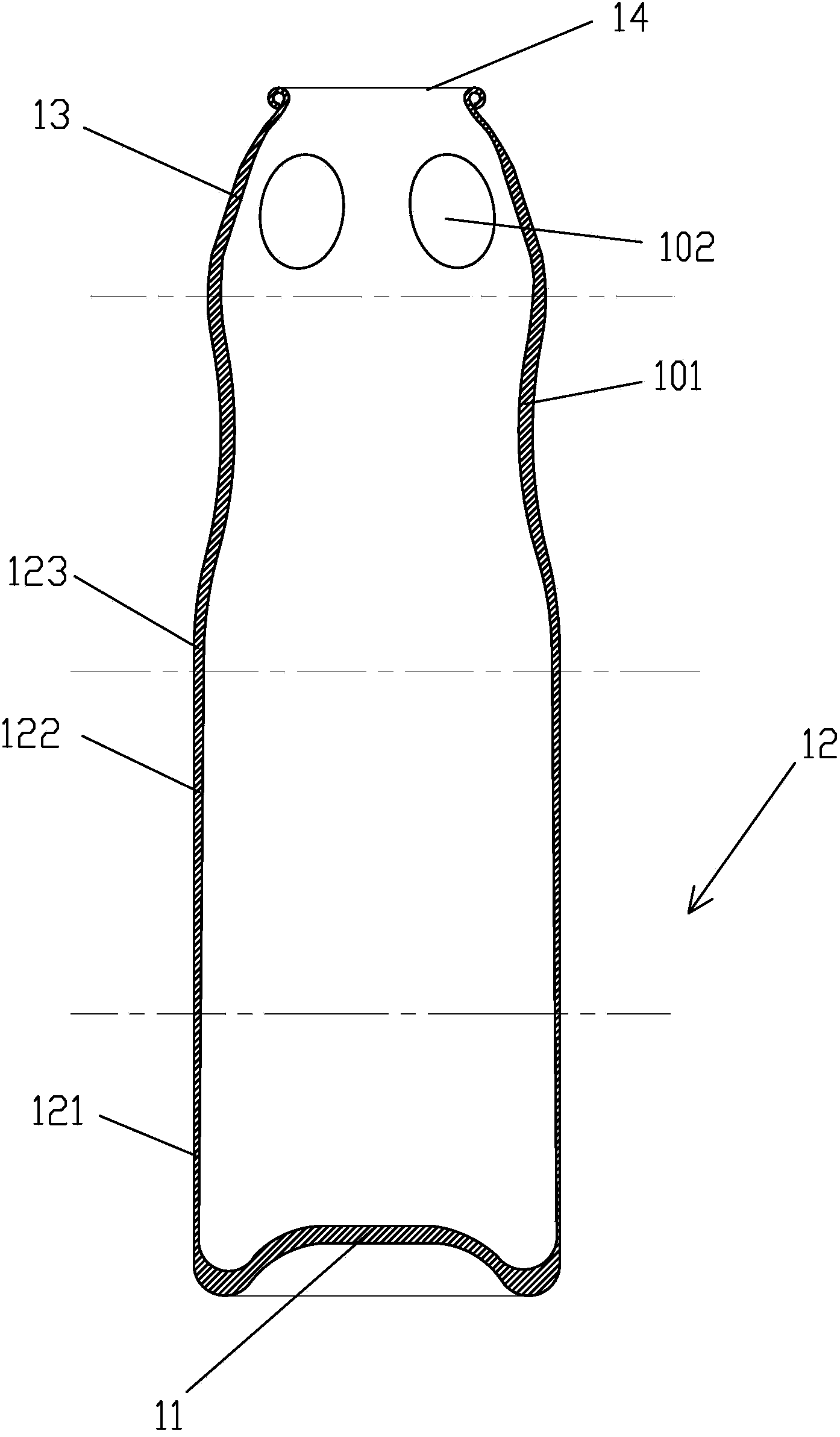

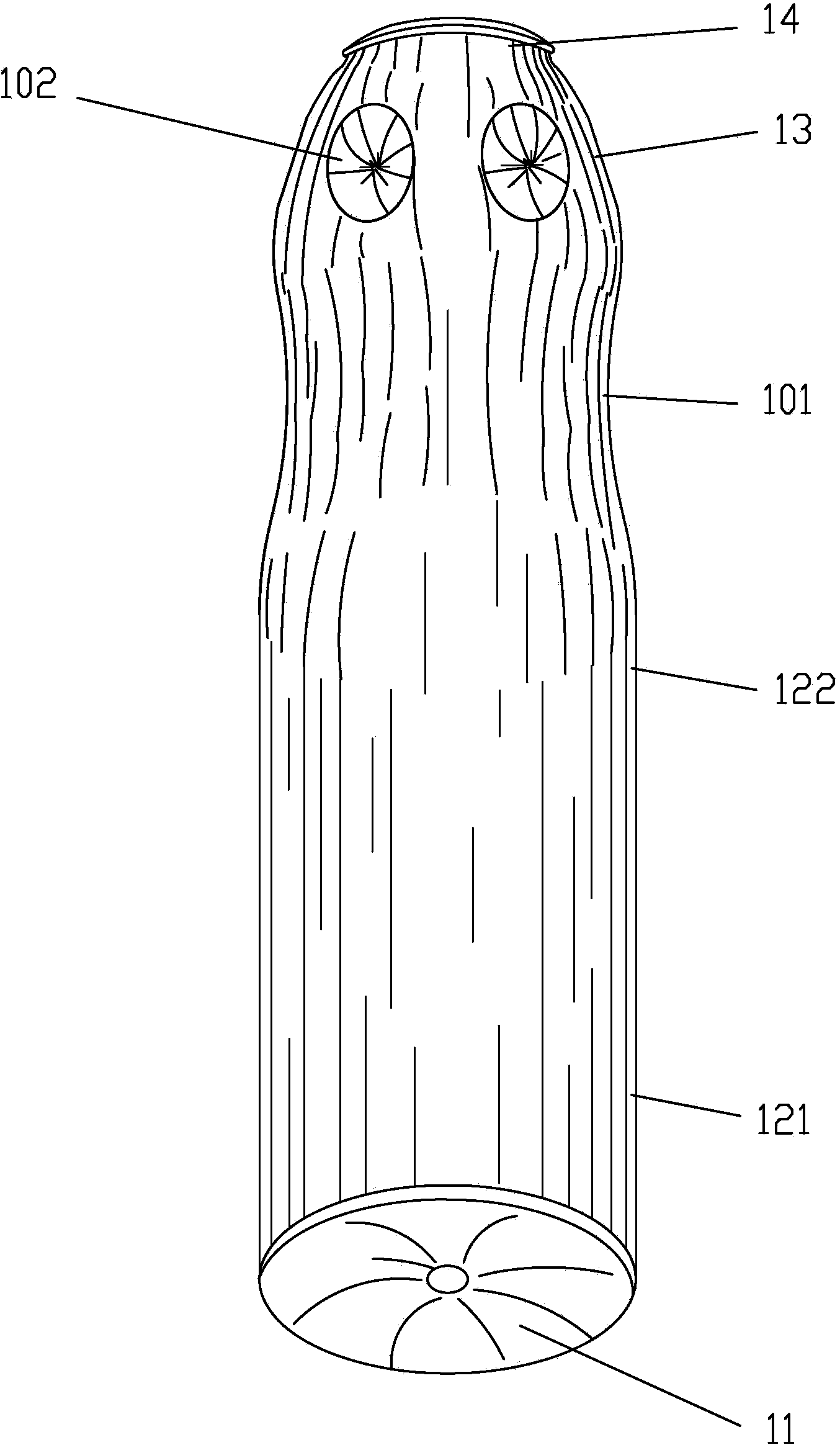

Special-shaped aluminum cup and production method thereof

ActiveCN104907451ABeautiful surface printingImprove product gradeDrinking vesselsRigid containersProduct modelingMethods of production

Owner:宁波新同翔包装科技有限公司 +1

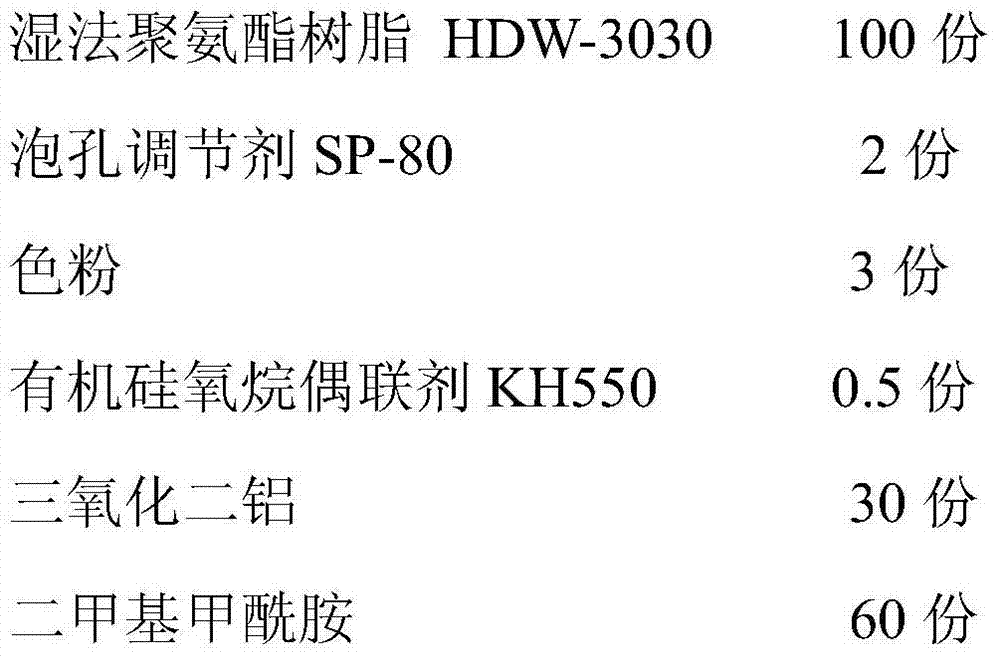

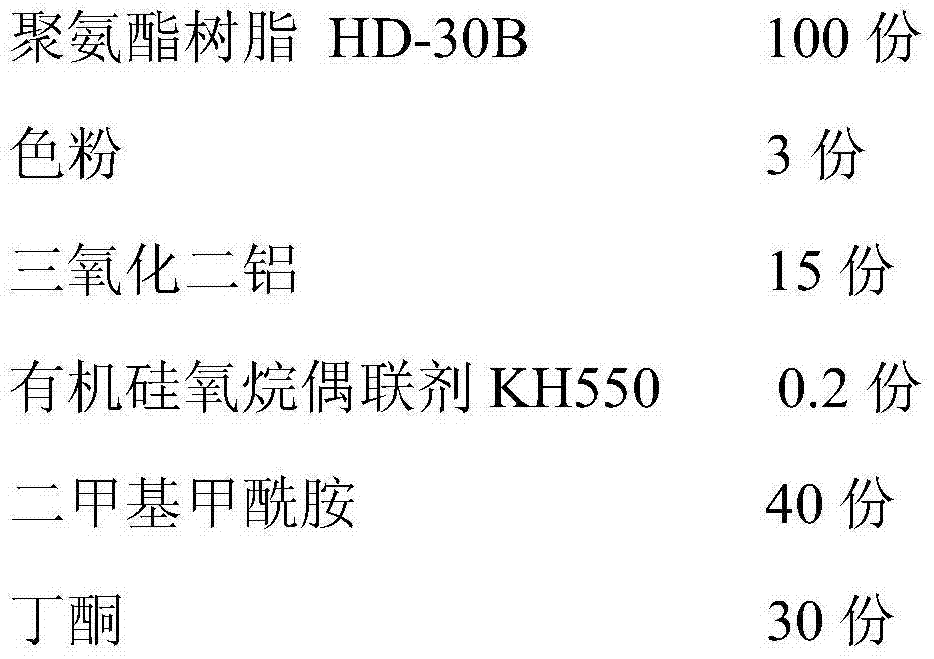

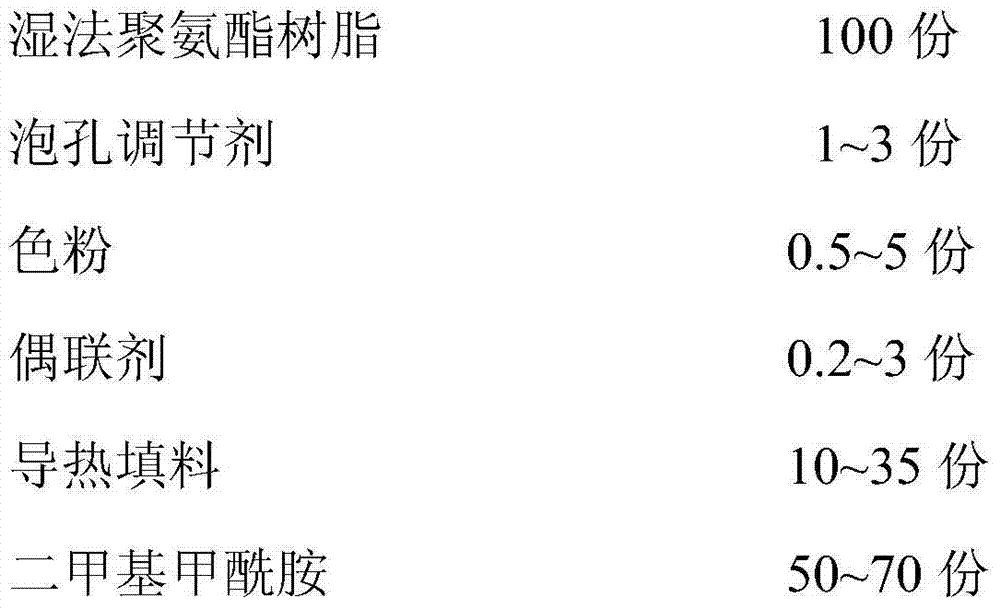

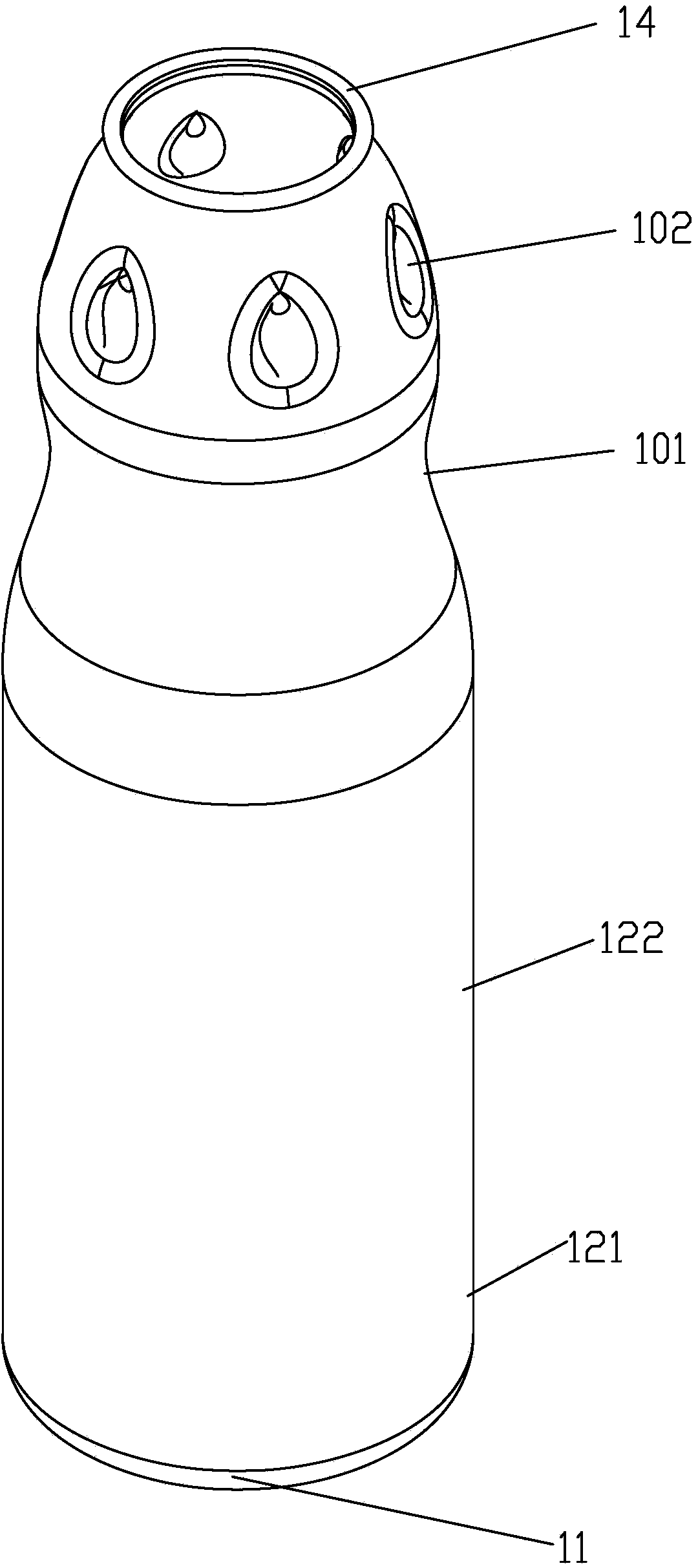

Thermal conductive polyurethane synthetic leather production method

InactiveCN104328690AImprove thermal conductivityImprove wear resistanceSynthetic resin layered productsTextiles and paperMoisture permeabilitySlurry

The invention discloses a thermal conductive polyurethane synthetic leather production method which comprises the following process: selecting base cloth, coating with wet process polyurethane slurry, solidifying, washing with water, expanding and drying, veneering by dry method, and finishing the surface; first of all, the base cloth is coated with the wet process polyurethane slurry with conductive filler; then, the coated substrate is solidified by wet method for adjusting of bubble hole structure and expanding and drying for production of thermal conductive and breathable Base; finally thermal conductive breathable polyurethane synthetic leather is produced by veneering by dry method and finishing the surface of the thermal conductive and breathable Base. The thermal conductive polyurethane synthetic leather prepared by the method is relatively high in thermal conductivity coefficient, the thermal conductivity coefficient reaches 0.06-0.09W .M <-1> .K <-1>, compared with traditional synthetic leather, the thermal conductivity is increased by more than 30%, and the bubble hole is even, delicate, soft in hand feeling, good in drapability, air and moisture permeability, similar to natural leather in apparent and hand feeling, and simple in manufacturing process.

Owner:SHAANXI UNIV OF SCI & TECH

Aluminum variable wall special-shaped packaging tin and manufacturing method thereof

The invention discloses an aluminum variable wall special-shaped packaging tin and a manufacturing method thereof. The aluminum variable wall special-shaped packaging tin comprises a tin bottom, a tin barrel, a tin shoulder and a tin opening. The tin barrel is divided into a barrel body lower section, a barrel body middle section and a barrel body upper section, and the wall thickness of the barrel body lower section, the wall thickness of the barrel body middle section and the wall thickness of the barrel body upper section are sequentially increased. An annular groove capable of enabling a user to grab the tin conveniently is formed in the barrel body upper section, and accordingly the hand feeling is more comfortable and firmer. The tin shoulder is conical, a plurality of pits which are recessed inwards are formed in the outer wall of the tin, so that the aluminum variable wall special-shaped packaging tin is overall more attractive, and the visual stereoscopic impression is enhanced. Anti-counterfeiting can also be effectively achieved, and enterprise brands are made to be highlight. The aluminum variable wall special-shaped packaging tin which is simple in manufacturing method, simple in structure, attractive in appearance, convenient to grab, capable of effectively achieving the anti-counterfeiting function and low in production cost and the method for manufacturing the packaging tin are provided.

Owner:GUANGDONG EURO ASIA PACKAGING

Method for simulating velvet burnt-out by polyamide ammonia

InactiveCN104452164AWith imitation silk effectLow costPile loops cuttingPattern makingFiberPolymer science

The invention discloses a method for simulating velvet burnt-out by polyamide ammonia. The method comprises the following steps: preparing a gray fabric; pre-moulding; shearing in a circle manner; performing burnt discharge; dyeing; rolling to be soft; drying and sizing; ironing and shearing; and moulding a finished product. By adopting three different kinds of fibers in the raw materials, chinlon in chinlon-covered ammonia in a base fabric is alkaline-resistant but not acidproof, wool dacron is not alkaline-resistant, and all wool with patterns are fully burnt out by using caustic soda during burnt discharge to expose the chinlon-covered ammonia base fabric, so that the third dimension is strong and the burnt discharge effect of true velvets is achieved. As the base fabric contains spandex, a product is good in elasticity and strong in serviceability and not only can be used for making jackets, but also can be used for making underwear, so that the using field of a shell fabric is expanded, and the product can be used for making various spinning products such as home textiles, decorative products, costumes, and toys. The product is high in grade, low in price and high in quality. As the base fabric is too large in elasticity and cannot be galled, the structure of the gray fabric is changed to a pile loop structure, and wool is generated by shearing in the circle manner.

Owner:IANGSU COLLEGE OF ENG & TECH

High color fastness cotton fabric dyeing method capable of effectively saving water and reducing pollution

InactiveCN102677489ASufficient raw materialsLow pricePeptide preparation methodsDyeing processColour fastnessSalt free

The invention discloses a high color fastness cotton fabric dyeing method capable of effectively saving water and reducing pollution. The method includes the following steps that 1, a chicken feather protein powder is prepared and dissolved with a sodium hydroxide solution; 2, a cationic biological protein derivative additive is prepared; 3, a cotton fabric is modified with the cationic biological protein derivative additive; 4, the modified cotton fabric is subjected to a reactive dye salt-free dyeing; and 5, a color fixation post-processing is performed to the dyed fabric. According to the high color fastness cotton fabric dyeing method capable of effectively saving water and reducing pollution, during the color fixation processing, the surplus cationic biological protein derivative additive raffinate after the cotton fabric is subjected to the modification process is used for subjecting the dyed cotton fabric to a secondary color fixation processing, so that water is remarkably saved, the product color fastness is improved, and the pollution is reduced. The salt-free dyeing is utilized during the dyeing process, so that the cotton fabric dyeing method is capable of effectively saving water, reducing pollution and enabling products to achieve a high color fastness.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com