Two-liquid type rapid stripping synthetic leather composite overlay

A two-component, synthetic leather technology, applied in the field of synthetic leather, can solve the problems of cold resistance, low hydrolysis resistance, large floor area, scratch resistance and poor wear resistance of synthetic leather surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Microfiber veneer for sports shoes.

[0086] The formulation of the dry slurry is by weight:

[0087] Top coat:

[0088] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0089] Solvent 30~80 parts

[0090] Colorant 20-30 parts

[0091] Leveling agent 0.5~1 part

[0092] 0.5~1 parts of peeling aid

[0093] Functional additives 1 to 5 parts

[0094] Adhesive layer:

[0095] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0096] Solvent 10~50 parts

[0097] Colorant 20-30 parts

[0098] Leveling agent 0.5~1 part

[0099] Functional additives 0.5~3 parts

[0100] 8-10 parts of cross-linking agent

[0101] Catalyst 1-3 parts

[0102] Superfine lignin (800-1000 mesh) 5-10 parts

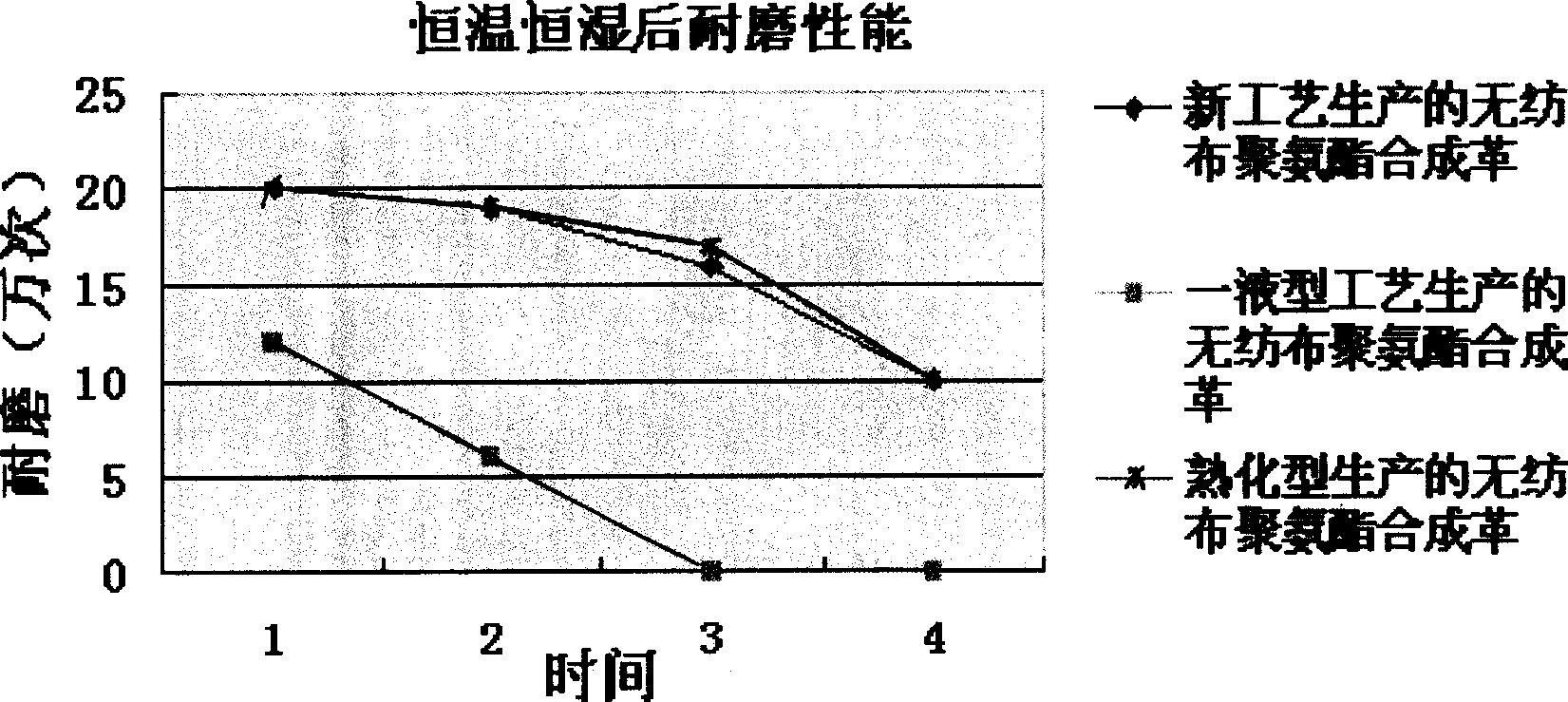

[0103] The physical properties of the made microfiber leather are: wear-resistant H-22*1000 times, peeling>100N / 3cm, cold resistance:>-20℃*80,000,

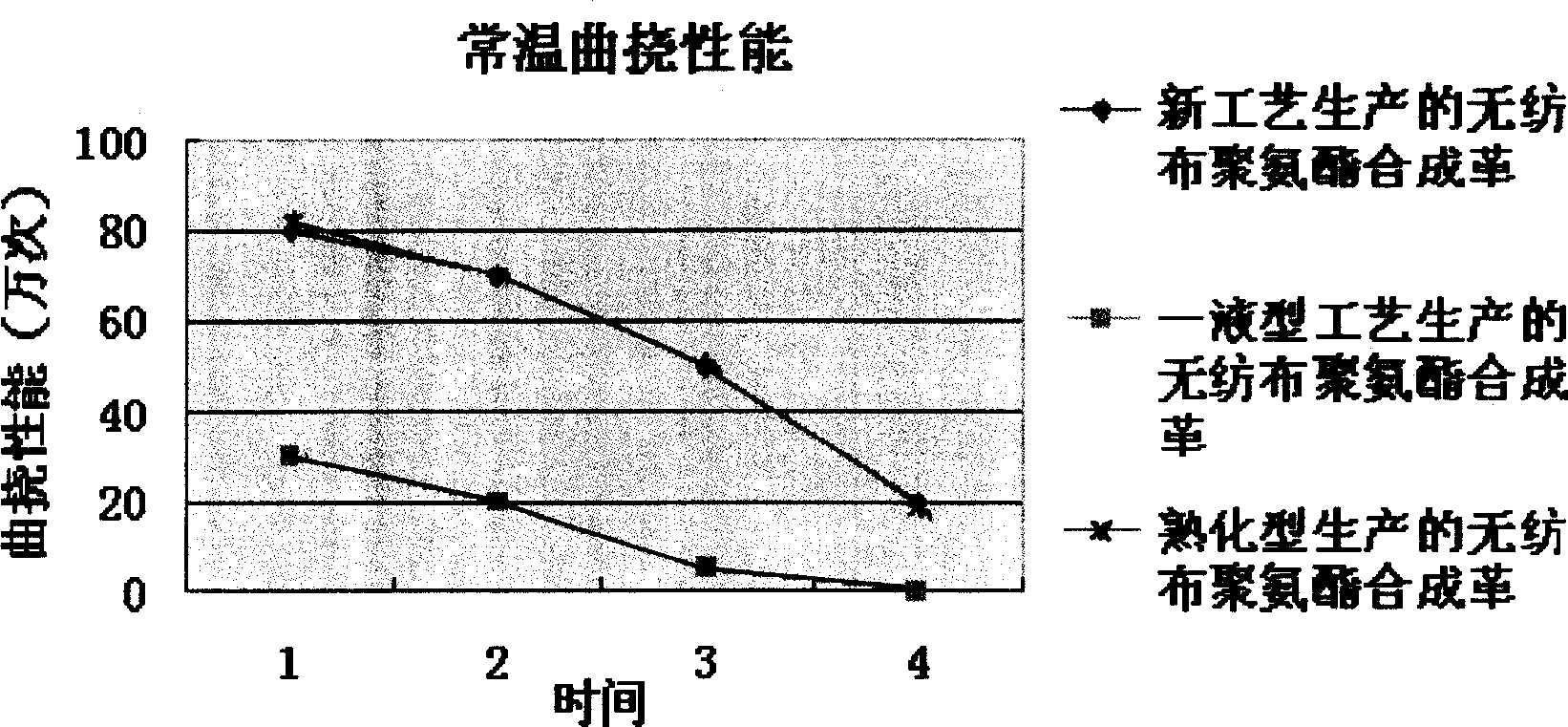

[0104] Bending at room temperature: >2 million times. If one-component phys...

Embodiment 2

[0106] High-performance space leather veneer.

[0107] The formulation of the dry slurry is by weight

[0108] Top coat:

[0109]Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0110] Solvent 30~80 parts

[0111] Colorant 20-30 parts

[0112] Leveling agent 0.5~2 parts

[0113] 0.5~1 parts of peeling aid

[0114] Functional additives 1 to 5 parts

[0115] middle layer:

[0116] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0117] Solvent 30~50 parts

[0118] Color 0.5~15 parts

[0119] Leveling agent 0.5~1 part

[0120] Functional additives 1 to 5 parts

[0121] Adhesive layer:

[0122] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0123] Solvent 10~50 parts

[0124] Colorant 20-30 parts

[0125] Leveling agent 0.5~1 part

[0126] Functional additives 0.5~3 parts

[0127] Crosslinker 12-16

[0128] Catalyst 1-3

[0129] The physical properties of the leather prod...

Embodiment 3

[0132] High performance sofa leather veneer

[0133] The formulation of the dry slurry is by weight

[0134] Top coat:

[0135] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0136] Solvent 30~80 parts

[0137] Colorant 20-30 parts

[0138] Leveling agent 0.5~2 parts

[0139] 0.5~1 parts of peeling aid

[0140] Functional additives 1 to 5 parts

[0141] middle layer:

[0142] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0143] Solvent 30~50 parts

[0144] Color 0.5~15 parts

[0145] Leveling agent 0.5~1 part

[0146] Functional additives 1 to 5 parts

[0147] Adhesive layer:

[0148] Polyether, polyester polycarbon copolymer polycarbonate type resin 100 parts

[0149] Solvent 10~50 parts

[0150] Colorant 20-30 parts

[0151] Leveling agent 0.5~1 part

[0152] Functional additives 0.5~3 parts

[0153] Crosslinker 14-16

[0154] Catalyst 1-3

[0155] The physical properties of the leather produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com