Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

A solar cell and conductive paste technology, applied in the field of solar cells, can solve the problems that the electrodes easily affect the photoelectric conversion efficiency of the cell, and achieve the effects of outstanding conductivity, low density, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

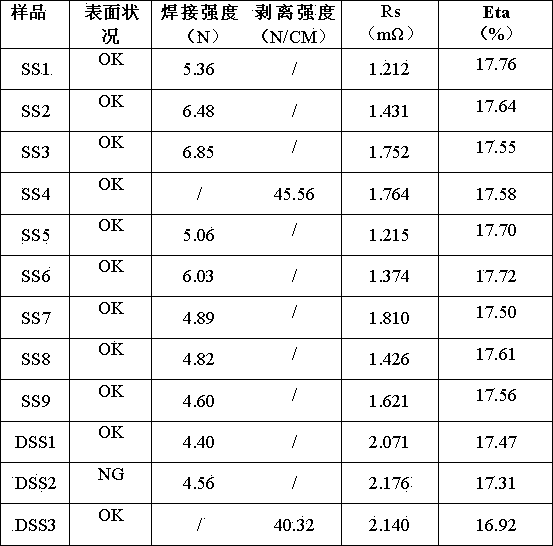

Examples

preparation example Construction

[0023] The invention also provides a method for preparing conductive paste for crystalline silicon solar cells, the steps of which include: dispersing conductive metal powder, inorganic binder and conductive carbon in an organic carrier, and grinding to obtain the conductive paste. The dispersion of the present invention is not limited, for example, it may be under stirring conditions.

[0024] Preferably, the conductive carbon is dispersed in the organic carrier to obtain the conductive carbon paste, and then the conductive metal powder and the inorganic binder are mixed with the conductive carbon paste.

[0025] Preferably, the step of dispersing the conductive carbon in the organic vehicle includes mixing the conductive carbon dispersion and the organic binder dispersion. Wherein, the conductive carbon dispersion includes conductive carbon, a dispersant and a first organic solvent. The organic binder dispersion includes an organic binder, additives and a second organic sol...

Embodiment 1

[0036] This example is used to explain the silver paste to the glossy seed layer.

[0037] (1) Preparation of glass powder:

[0038] Get 81 parts by weight of PbO, 9.0 parts by weight of SiO 2 ,, 6.0 parts by weight ZnO, 4.0 parts by weight TiO 2 . Mix the oxide powders uniformly with a V-shaped mixer, transfer them into a corundum crucible, and place them in a silicon carbide rod furnace. Raise the temperature in the silicon carbide rod furnace to 550°C, keep it warm for 0.5h, then raise the temperature to 1250°C, keep it warm for 2h, quench and filter with water to obtain glass slag. Put the glass slag into a ball mill jar for wet milling for 8.5 hours, filter and dry, and then dry mill for 0.5 hours to obtain the medium particle size D 50 It is a glass frit of 0.65μm and a glass frit with a softening point of 480°C.

[0039] (2) Preparation of conductive carbon paste:

[0040] According to the mass ratio of terpineol: butyl carbitol = 70:30, the organic solvents are e...

Embodiment 2

[0047] This example is used to explain the silver paste to the light surface electrode.

[0048] (1) Using the same steps as in Example 1 to prepare glass powder.

[0049] (2) Preparation of conductive carbon paste:

[0050] Mix the organic solvents evenly according to the mass ratio of terpineol: butyl carbitol: tributyl citrate = 60:20:20 to form a mixed solvent.

[0051] Take 4.0 parts by mass of carbon nanotubes (FloTube9000 produced by Beijing Tiannai Technology Co., Ltd., with a diameter of about 11 nm, an average length of 10 μm, and a specific surface area of 180-250 m 2 / g), 1.2 parts by mass of the dispersant PVP and 94.8 parts by mass of the mixed solvent were stirred evenly, and then sanded several times with a sand mill to obtain a carbon nanotube dispersion.

[0052] Get the mixed solvent of 93.5 mass parts, add the organic binder STD-4 of 5.0 mass parts (Dow's product, viscosity is 4), the modified hydrogenated castor oil of 0.5 mass parts, the stearyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com