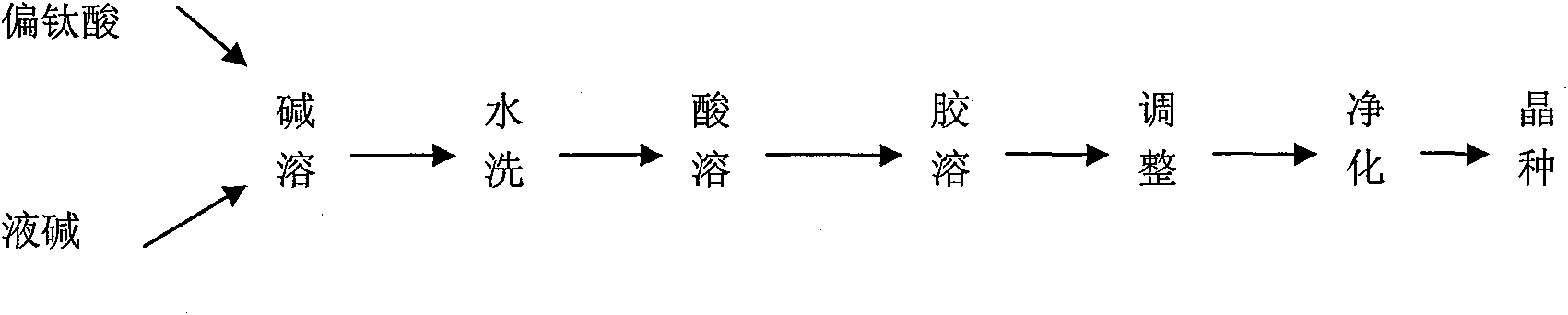

Preparation of white titanium pigment double action crystal seed from metatitanic acid

A technology of double-effect crystal seed and metatitanic acid, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, fibrous filler, etc., can solve the problems of increased production cost, complicated preparation process, and product quality fluctuation, so as to save investment, Uniform particle size distribution, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: described percentage is weight percentage; Said every part is weight part;

[0078] (1) Alkali soluble

[0079] Take [Fe 2 o 3 ]2 o 3 ]<0.01%, 128g of liquid caustic soda with a concentration of 30%, and the weight ratio of alkali to titanium is 1.2; the preheating temperature of metatitanic acid during alkali dissolution: 60°C, the preheating temperature of NaOH: 110°C; Adding speed: add dropwise for 5 minutes; then boil together, alkali cooking time: 120 minutes, add water after ripening: 180ml, temperature of sodium titanate after cooling: 55°C.

[0080] (2) washing

[0081] Pour the reactant into a Buchner funnel for water washing, and use desalted water with a resistivity greater than 100,000 ohm cm to wash away Na 2 SO 4 and excess NaOH, and at the same time, part of the alkali metal titanate is hydrolyzed to form orthotitanic acid during the water washing process. After adding 100ml of water to the reaction bottle, add the filter cake, start s...

Embodiment 2

[0086] Embodiment 2: described percentage is weight percentage; Said every part is weight part;

[0087] (1) Alkali soluble

[0088] Take [Fe 2 o 3 ]2 o 3 ]<0.01%, 176g of liquid caustic soda with a concentration of 30%, and the weight ratio of alkali to titanium is 1.65; the preheating temperature of metatitanic acid during alkali dissolution: 60°C, the preheating temperature of NaOH: 100°C; Adding speed: add dropwise for 5 minutes; then boil together, alkali cooking time: 120 minutes, add water after ripening: 160ml, temperature of sodium titanate after cooling: 60°C.

[0089] (2) washing

[0090] Pour the reactant into a Buchner funnel for water washing, and use desalted water with a resistivity greater than 100,000 ohm cm to wash away Na 2 SO 4 and excess NaOH, and at the same time, part of the alkali metal titanate is hydrolyzed to form orthotitanic acid during the water washing process. After adding 100ml of water to the reaction bottle, add the filter cake, start ...

Embodiment 3

[0095] Embodiment 3: described percentage is weight percentage; Said every part is weight part;

[0096] (1) Alkali soluble

[0097] Take [Fe 2 o 3 ]2 o 3 ]<0.01%, 160g of liquid caustic soda with a concentration of 30%, and the weight ratio of alkali to titanium is 1.5; the preheating temperature of metatitanic acid during alkali dissolution: 60°C, the preheating temperature of NaOH: 120°C; Adding speed: add dropwise for 5 minutes; then boil together, alkali cooking time: 120 minutes, add water after ripening: 180ml, temperature of sodium titanate after cooling: 60°C.

[0098] (2) washing

[0099] Pour the reactant into a Buchner funnel for water washing, and use desalted water with a resistivity greater than 100,000 ohm cm to wash away Na 2 SO 4 and excess NaOH, and at the same time, part of the alkali metal titanate is hydrolyzed to form orthotitanic acid during the water washing process. After adding 100ml of water to the reaction bottle, add the filter cake, start s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com