Conveying and material passing device of cylindrical capacitor electrode holder welding machine and method

A capacitive electrode and feeding device technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of error-prone connection between positioning and conveying, and low shell conveying efficiency, so as to improve the stability of retrieving materials, Actions are easier to control accurately and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

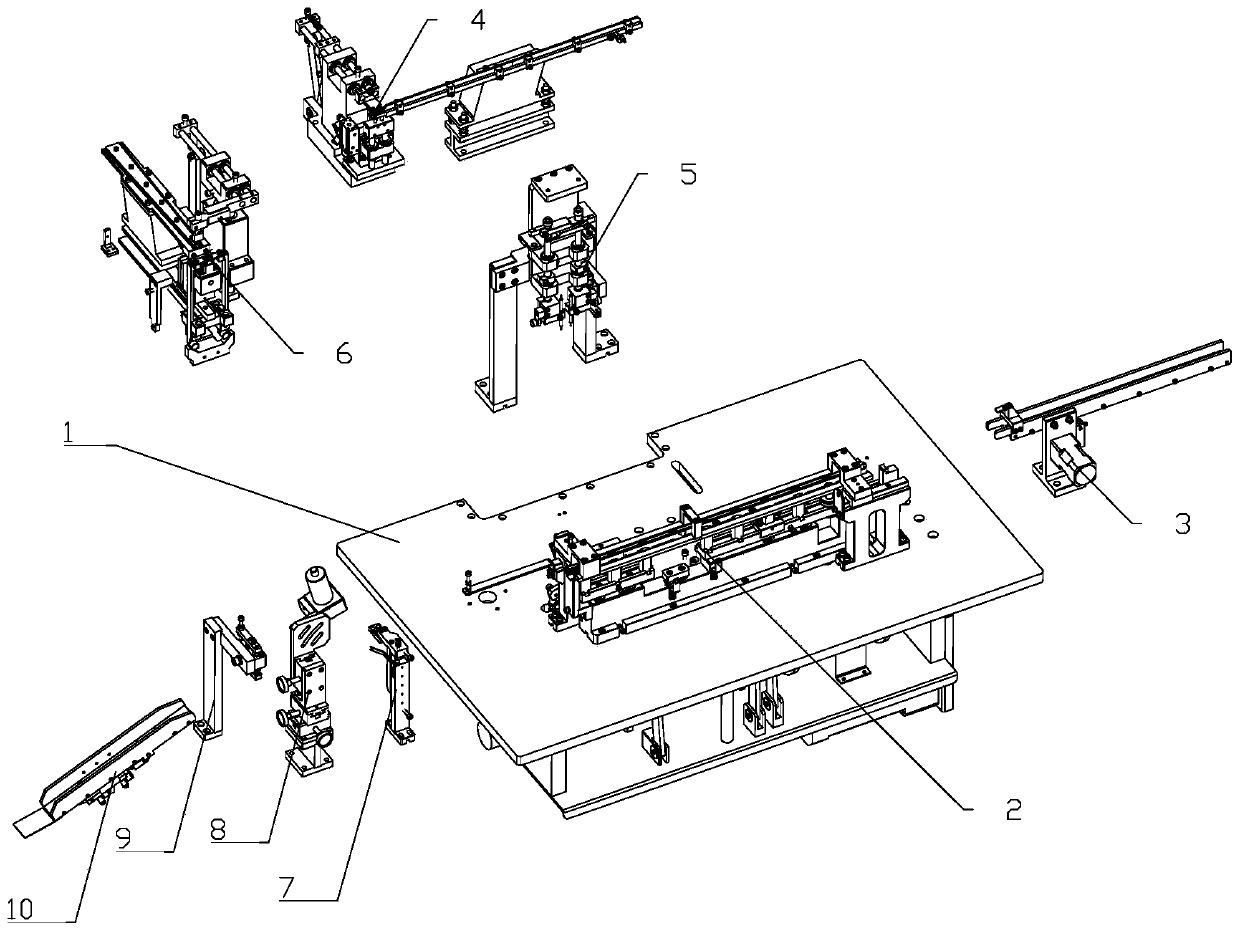

[0027] Such as figure 1 As shown, a cylindrical capacitor electrode seat welding machine includes a frame 1 and a conveying device 2 installed on the frame 1, a shell feeding device 3, an electrode seat feeding device 4, an electrode seat welding device 5, an iron Sheet feeding device 6, pressing device 7, laser welding device 8, detection device 9 and unloading device 10; the shell feeding device 3 is located at the feeding end of the conveying device 2, and the unloading device 10 is located at the conveying The discharge end of the material passing device 2; the electrode holder feeding device 4 and the iron sheet feeding device 6 are located at the side of the conveying material passing device 2, the electrode holder welding device 5 is located above the conveying material passing device 2, and the electrode holder welding device 5 Corresponding to the electrode seat feeding device 4; the pressing device 7, the iron sheet feeding device 6 and the laser welding device 8 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com