Neck paper machine

A paper machine and scarf technology, which is applied in the field of production and processing equipment for disposable scarf paper, can solve the problems that toilet paper machines cannot be used for scarf paper and cannot produce scarf paper, and achieve a high degree of automation, good drying effect, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

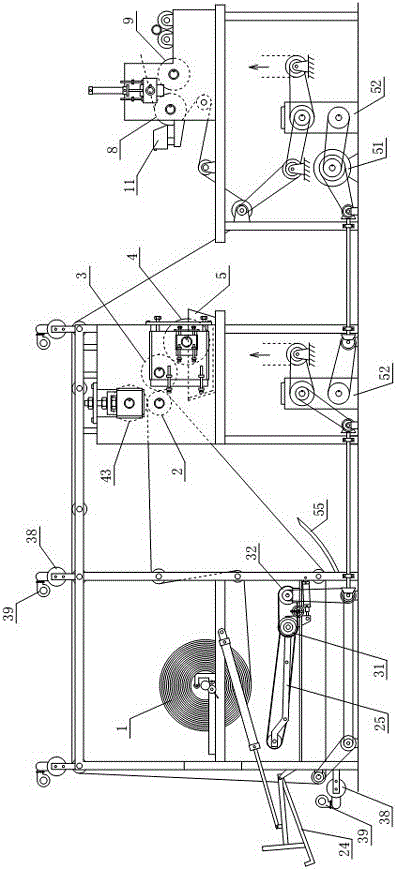

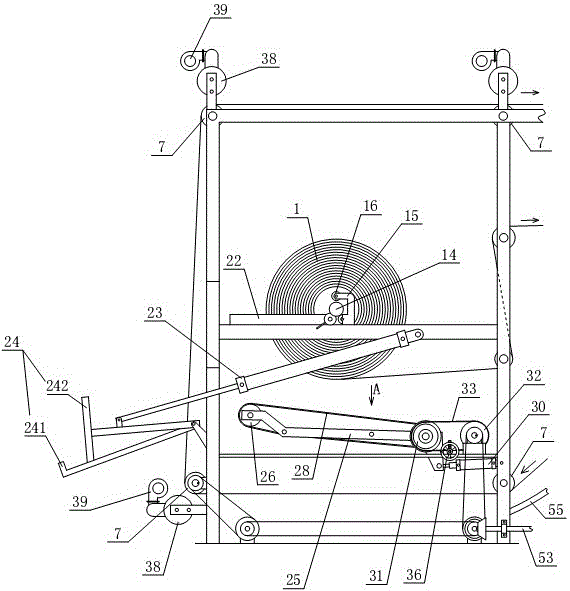

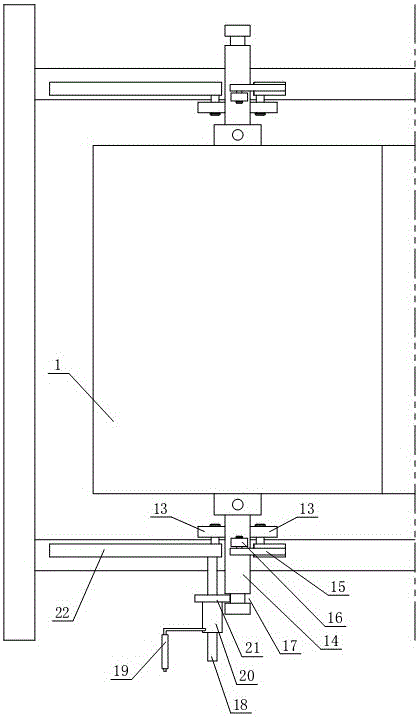

[0040] With reference to the accompanying drawings, the neck paper machine of the present invention includes a paper feeding system, a glue system, a rotary drying system and a slitting and winding system arranged on the frame, wherein: the paper feeding system includes a paper roll for rotating installation 1 paper roll supporting mechanism and the paper roll driving mechanism used to drive the paper roll to rotate, the raw paper base is removed from the paper roll and sent to the glue system; With the dipping roller 4 and the rubber material tank 5 arranged under the dipping roller 4, the pressing roller 2 is arranged correspondingly to the rubberizing roller 3, and at least one group of axially arranged rubber pressing rollers is arranged on the circumference of the cylindrical surface of the pressing roller 2. Block 6, each group of rubber pressing blocks 6 is a plurality of intervals, the raw paper base passes through the gap between the pressing roller 2 and the glue roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com