Rail turnout unit

A rail and turnout technology, which is applied in the field of railway turnout laying units, can solve the problems of heavy operating machinery, inability to decelerate, heavy machine weight, etc., and achieve the effect of realizing construction and loading operations, ensuring reliable performance, and reducing the weight of a single piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The core of the present invention is to provide a railway track turnout laying unit. When the railway track turnout laying unit is carrying out railway construction, the installation and operation of each construction component is light and simple, and the construction is safe and reliable.

[0051] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

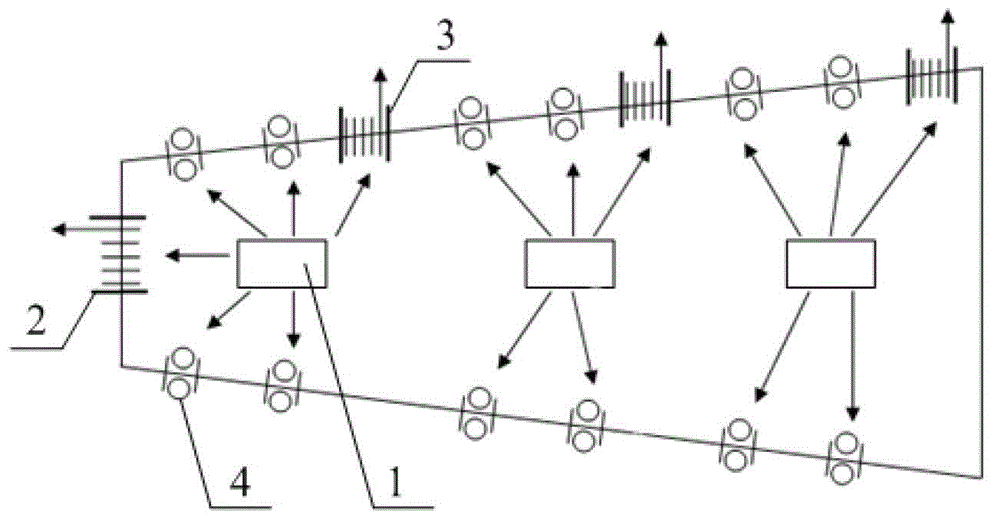

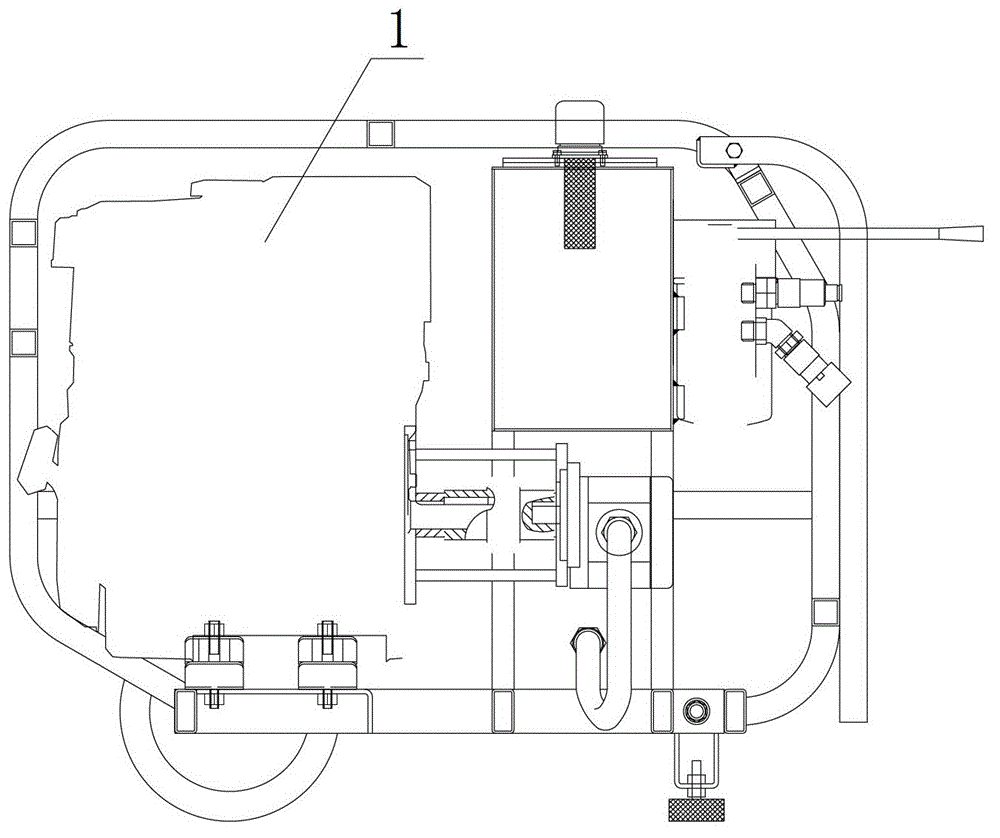

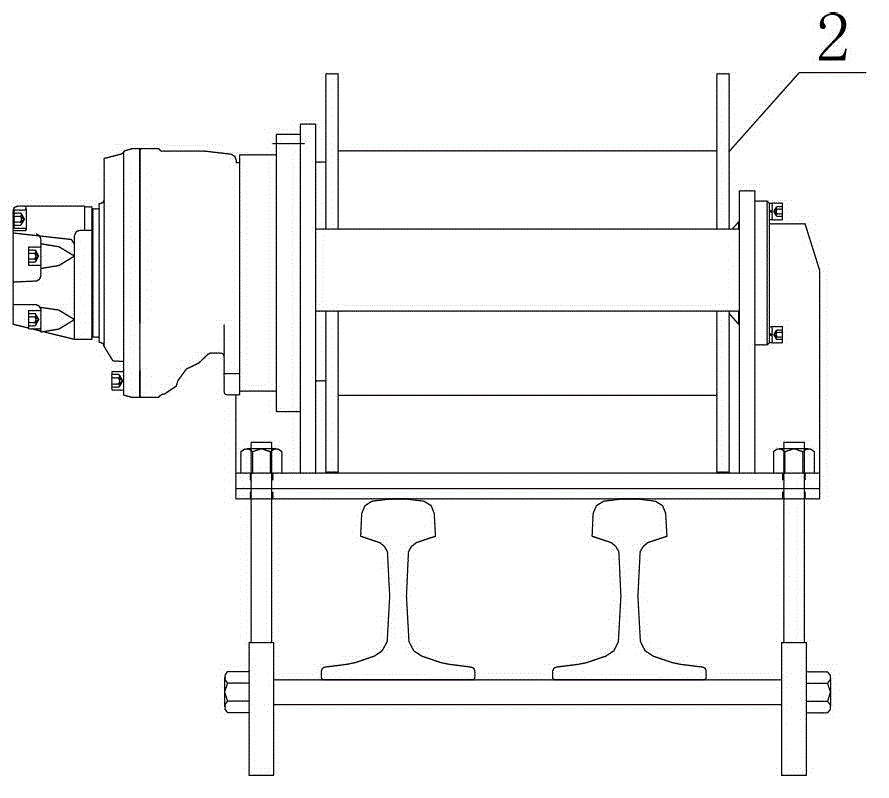

[0052] Please refer to Figure 1 to Figure 7 ,in, figure 1 It is a schematic diagram of the whole structure of the railway turnout laying unit in an embodiment of the present invention; figure 2 It is a structural schematic diagram of a centralized hydraulic power station in an embodiment of the present invention; image 3 It is a structural schematic diagram of a longitudinally moving power assembly in an embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com