Integrated scheduling method for disassembling, preprocessing and reassembling of remanufacturing system

A scheduling method and preprocessing technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of inability to achieve orderly connection and overall optimization of the three workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings.

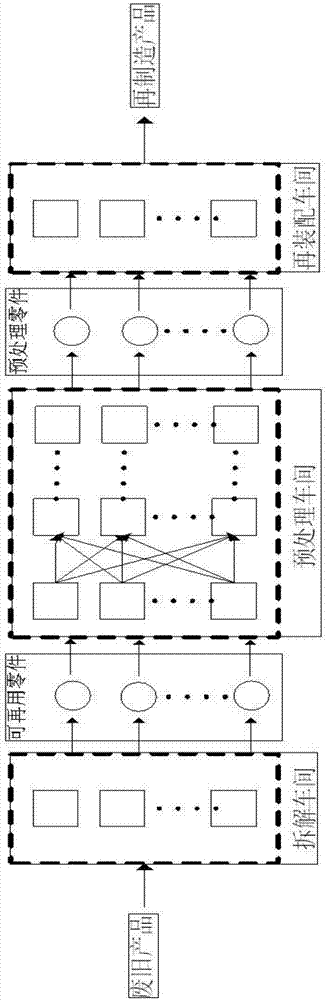

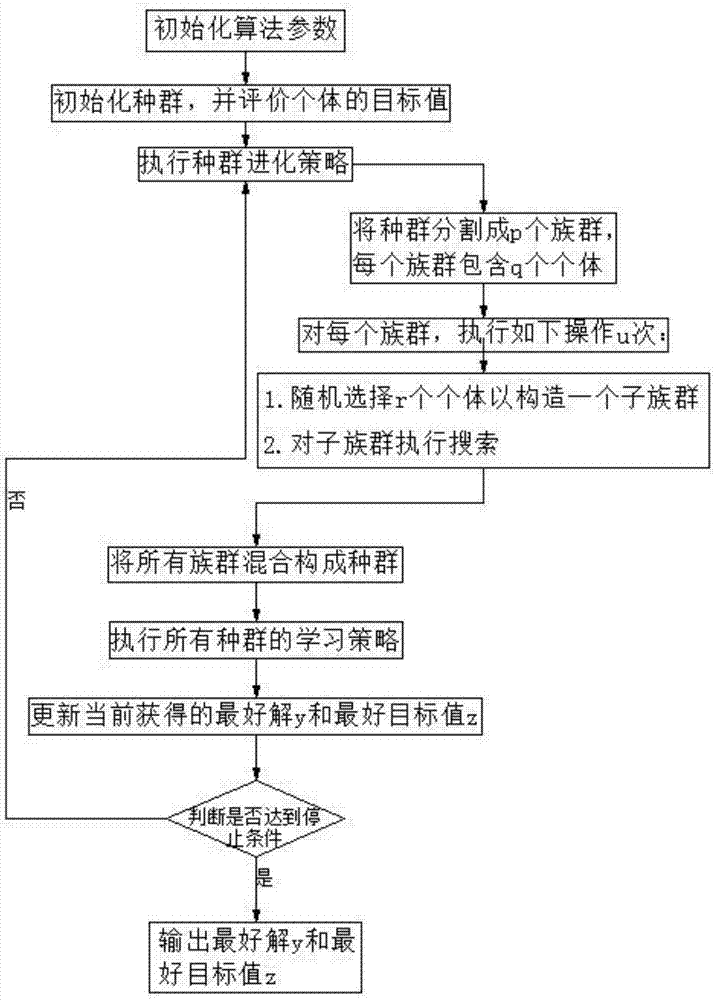

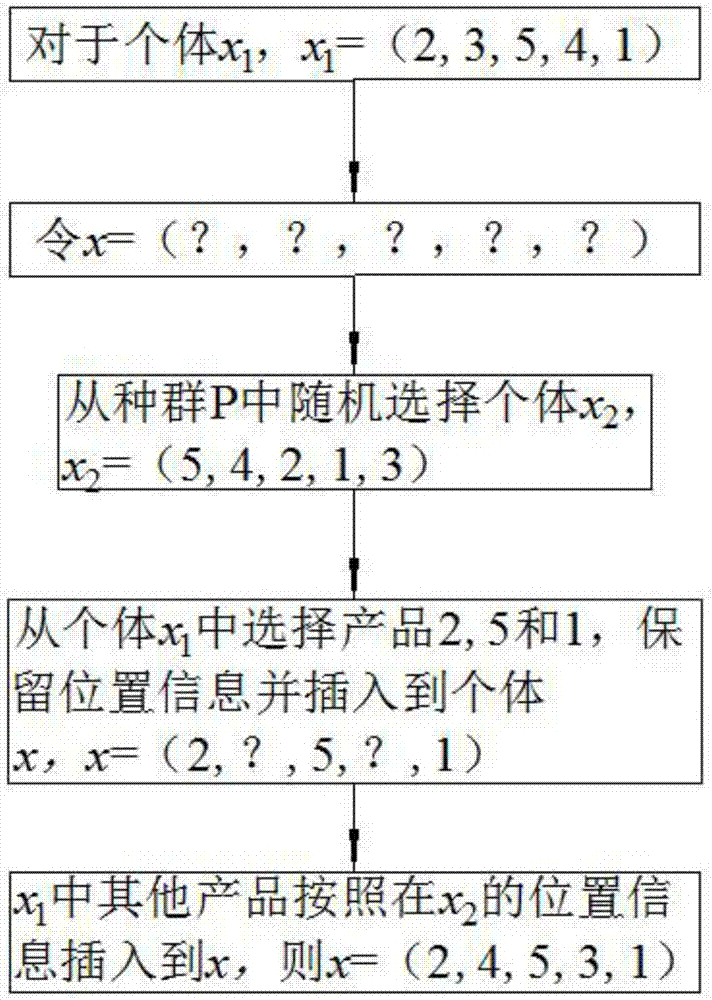

[0074] Such as figure 1 and figure 2 , an integrated scheduling optimization method for dismantling, preprocessing and reassembly of a remanufacturing system, said method comprising the following steps:

[0075] Step 1: Construct an integrated scheduling model according to the remanufacturing production process. According to attached figure 1 The structure of the integrated scheduling flow chart is shown to build an integrated scheduling model, where the symbols involved are defined as follows:

[0076] i product index, i=1,2,...,n;

[0077] j part index, j=1,2,...,m;

[0078] l Pretreatment workshop stage index, l=1,2,...,s;

[0079] k workstation index, for the dismantling workshop, k=1,2,...,r D ;For the pretreatment workshop, k=1,2,..., For reassembly shop, k=1,2,...,r RP ;

[0080] The dismantling time of product i;

[0081] The pretreatment time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com