Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Does not affect production rhythm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

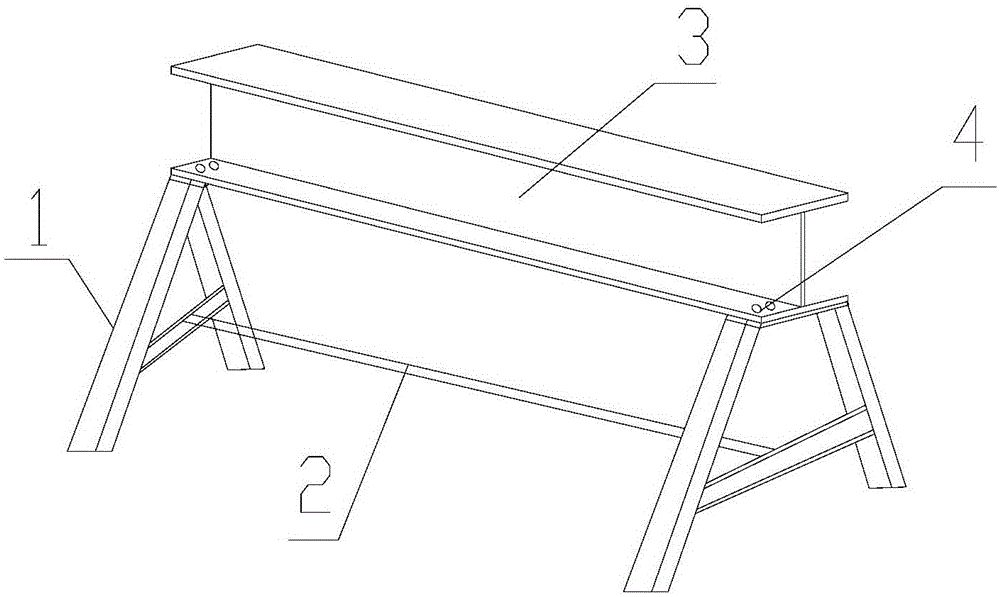

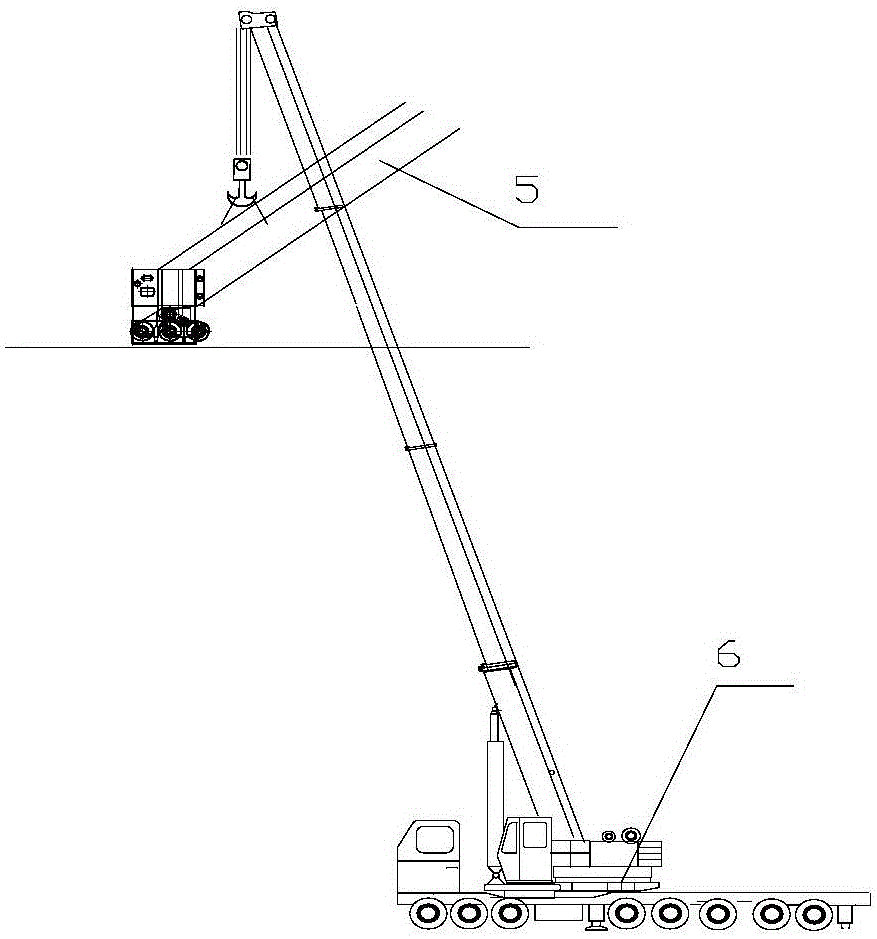

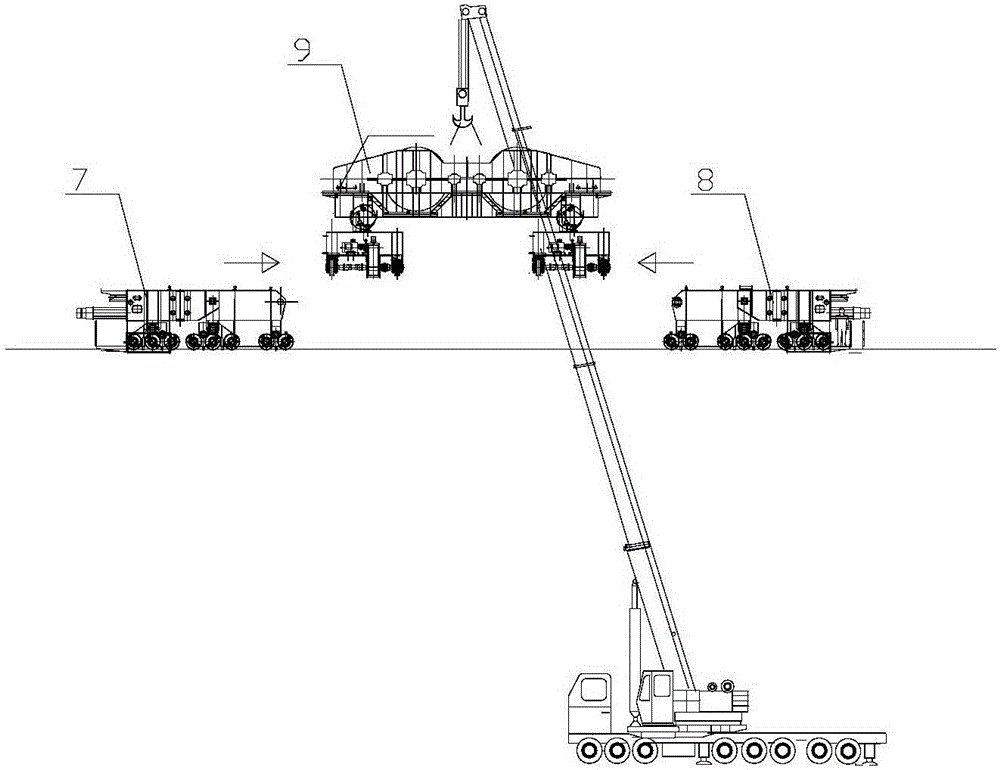

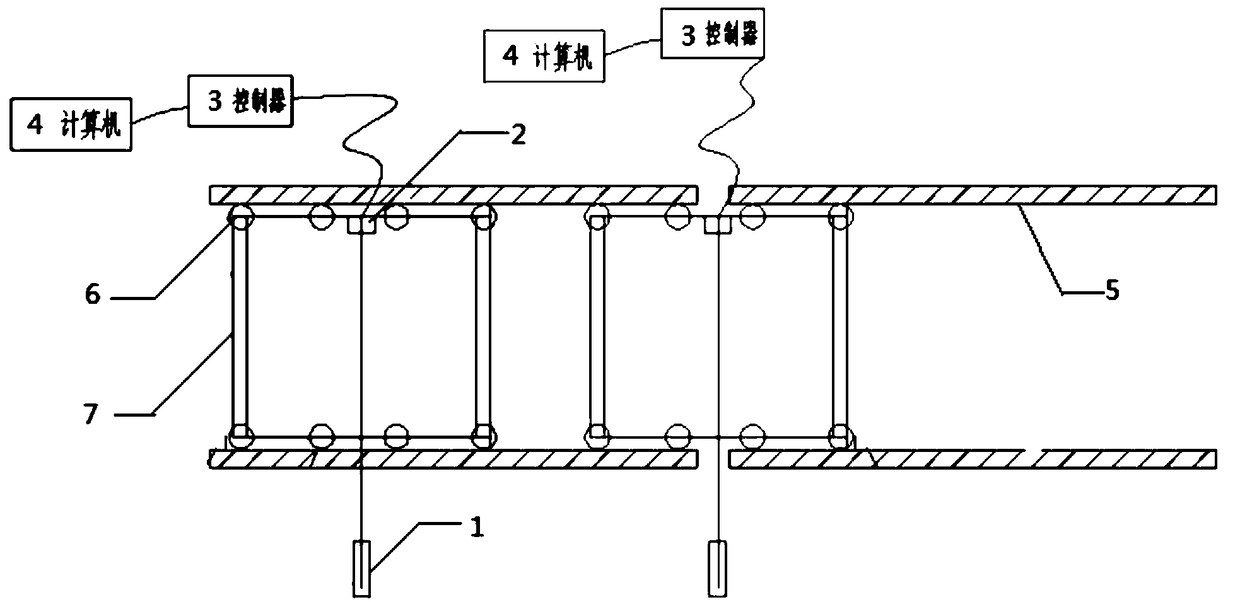

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

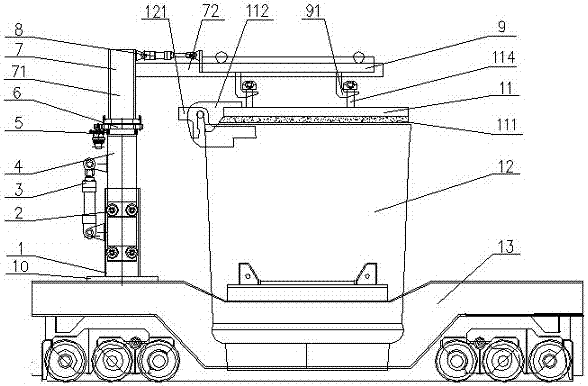

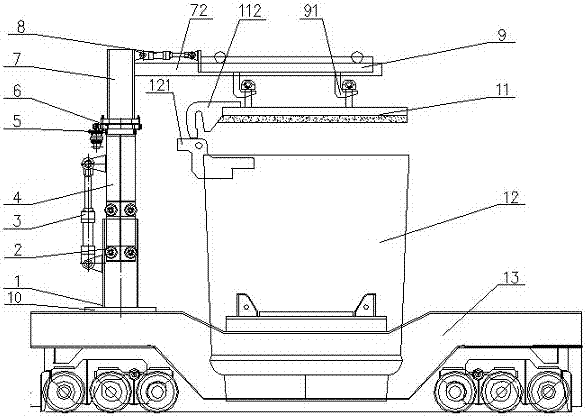

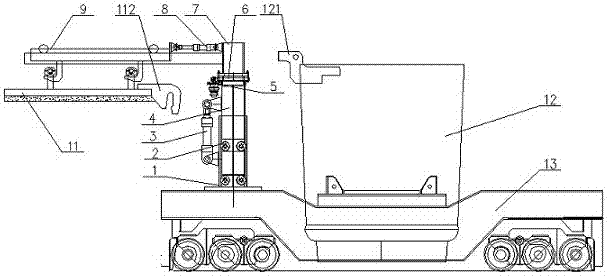

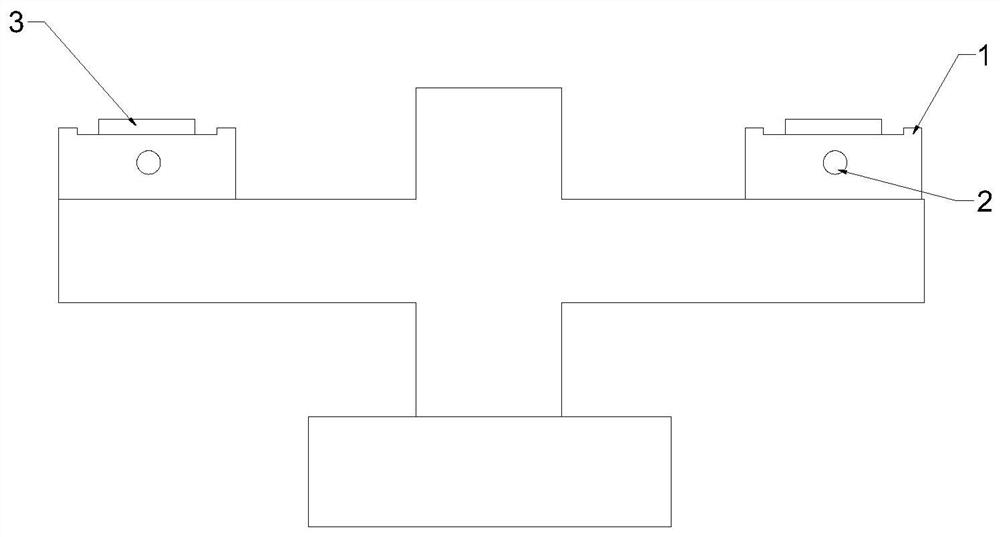

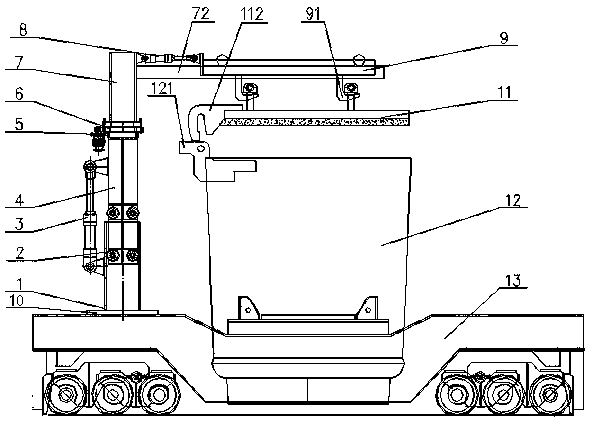

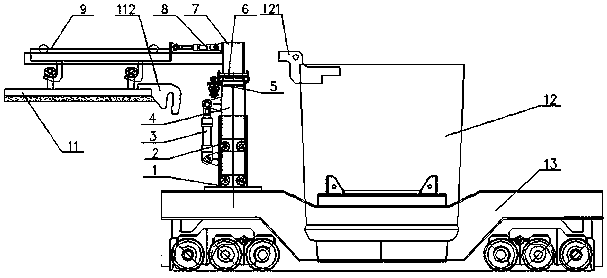

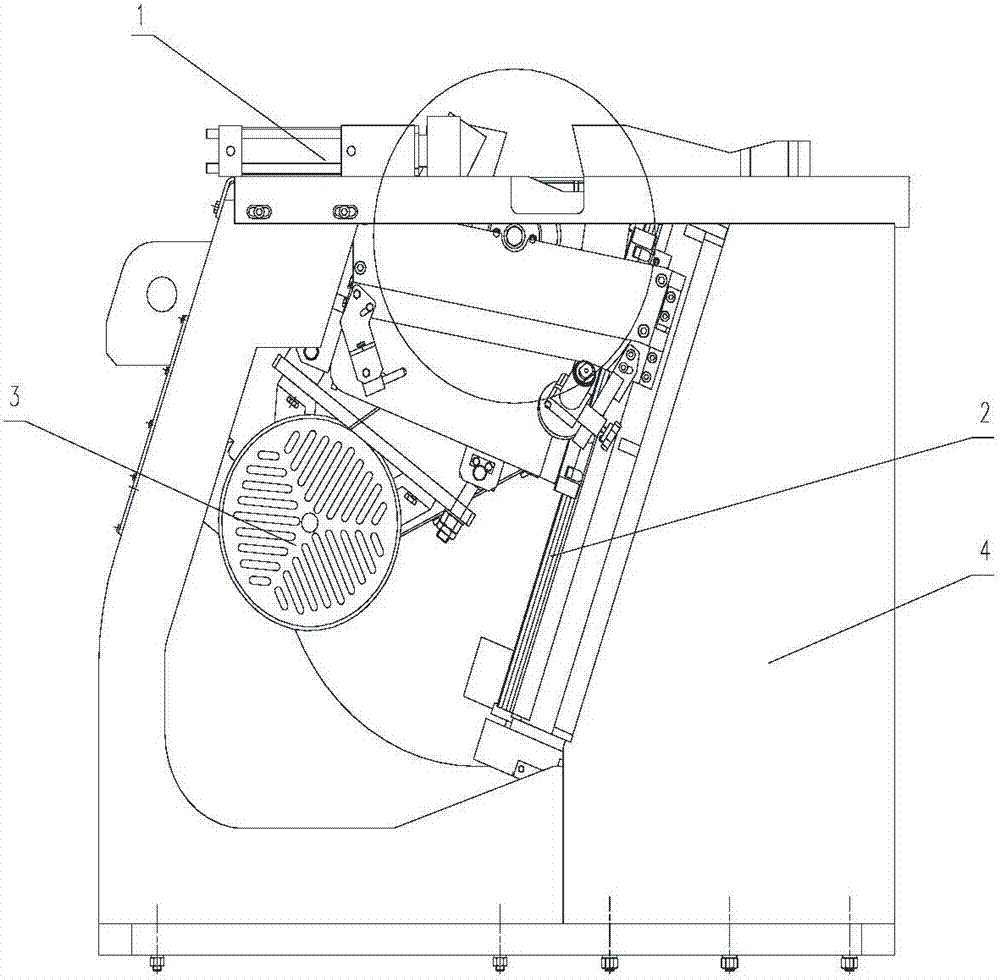

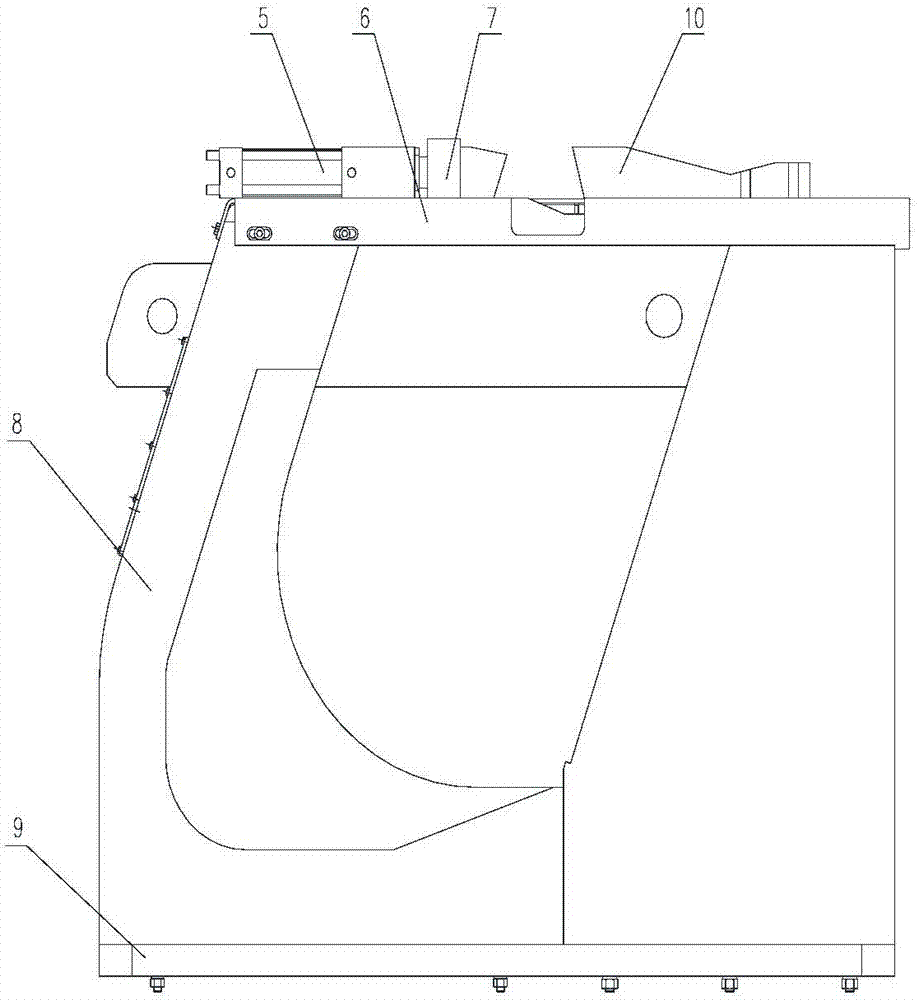

Steel ladle full-course covering and uncovering device and molten steel carrying device

ActiveCN107096914ALow headroom requirementsNo additional construction costs requiredMelt-holding vesselsHydraulic cylinderEngineering

The invention provides a steel ladle full-course covering and uncovering device and a molten steel carrying device. The steel ladle full-course covering and uncovering device comprises a fixed stand column, a lifting hydraulic cylinder, a lifting stand column, a rotation driving motor, a slewing bearing, a rotary frame, a transverse moving hydraulic cylinder and a transverse moving trolley. The fixed stand column is fixed on a platform; the lifting stand column is connected onto the fixed stand column in a sleeving manner; the lifting hydraulic cylinder drives the lifting stand column to go up and down along the fixed stand column; the rotary frame comprises a vertical rod and a horizontal rod connected with the vertical rod; the bottom of the vertical rod and the top of the lifting stand column are connected through the slewing bearing; the rotation driving motor is fixed on the lifting stand column and drives the slewing bearing to rotate so as to drive the rotary frame to rotate; the transverse moving trolley is positioned on the horizontal rod; and the transverse moving hydraulic cylinder drives the transverse moving trolley to move along the horizontal rod. The steel ladle full-course covering and uncovering device has low requirements for clearance above a steel ladle, is free of impact during covering and uncovering, and is low in equipment failure rate, small in maintenance quantity and smooth in production.

Owner:WISDRI ENG & RES INC LTD

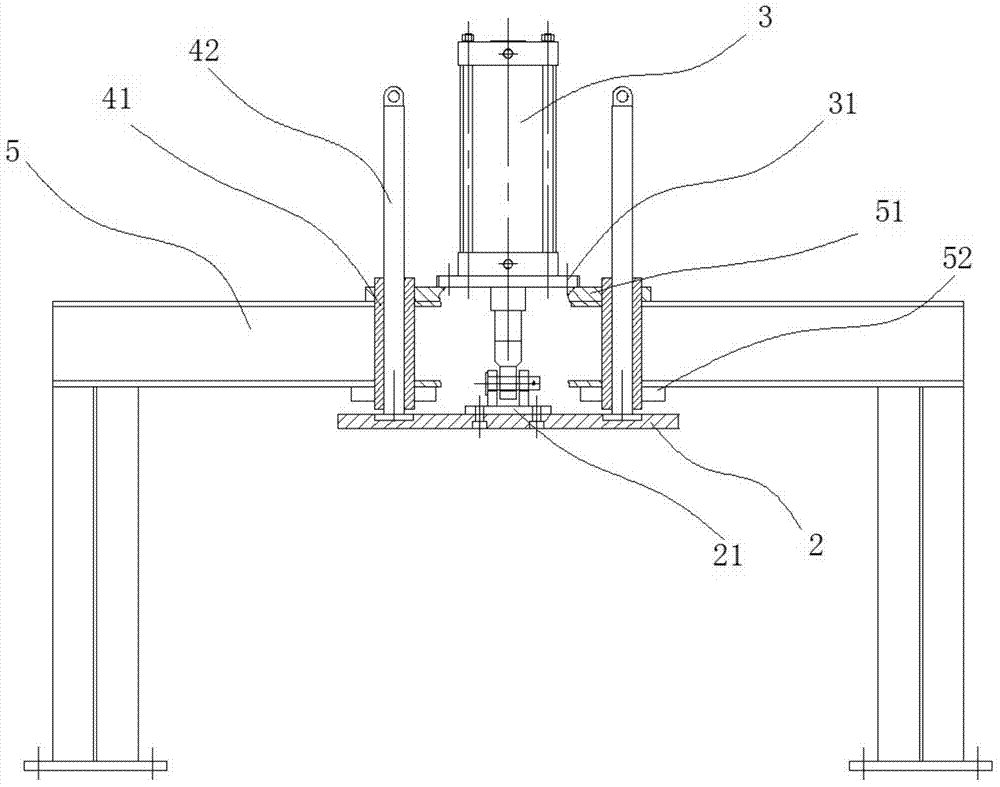

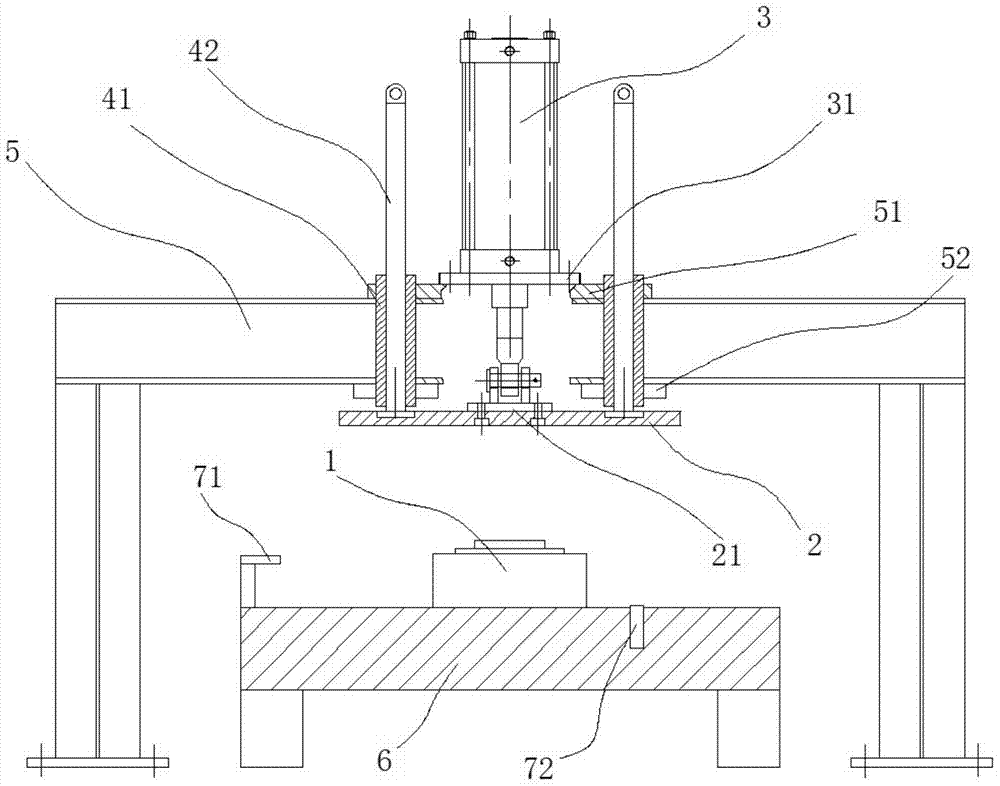

Device and method for eliminating turriform of band steel roll

The invention discloses a device and a method for eliminating the turriform of a band steel roll. The device comprises a chuck, a driving cylinder and a bracket, wherein the chuck is driven by the driving cylinder and is connected with the driving cylinder, and the bracket is arranged on a cylinder body of the driving cylinder. The device is characterized in that at least two guide mechanisms which are symmetrically arranged relative to a piston rod of the driving cylinder are arranged, each guide mechanism consists of a guide sleeve and a guide rod, the guide sleeves are fixedly connected to the bracket, and the guide rods are fixedly connected to the chuck and are in sliding connection with the guide sleeves. Through the arrangement of the guide mechanisms, the chuck cannot be deviated under the influence of stress in the downwards pressing process, the balance of downwards pressing force is ensured, and the service life of the mechanisms is prolonged. The quality of the band steel roll can be accurately controlled by a sensor for detecting the band steel roll and the chuck, and the turriform of the band steel roll is fully automatically eliminated.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Molten iron desiliconization agent with high-ferric red mud as matrix and application method thereof

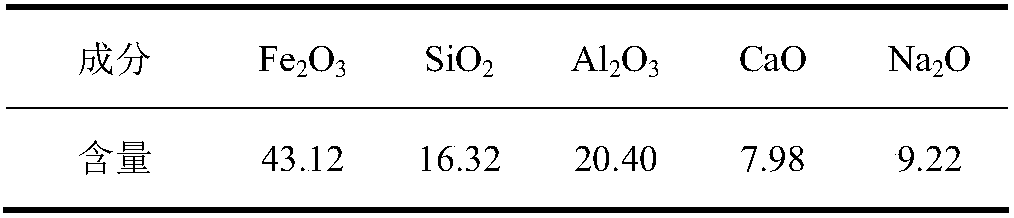

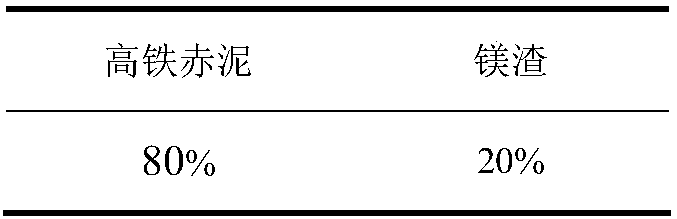

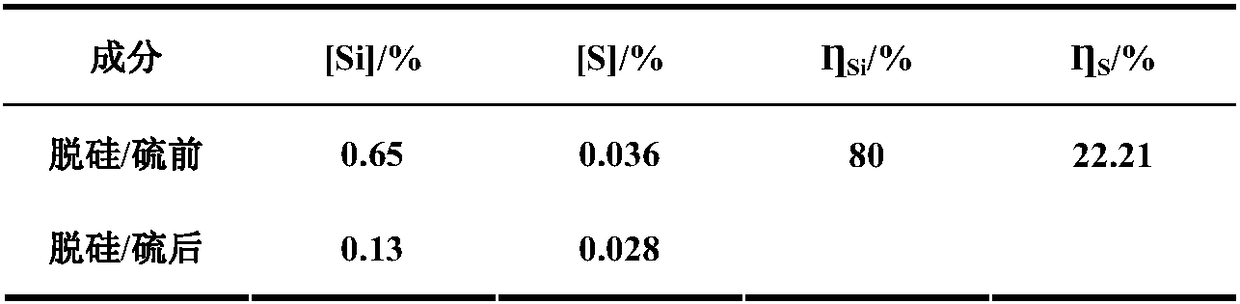

InactiveCN108220521ADesilication reaction time is sufficientImprove desiliconization efficiencySlagRed mud

The invention discloses a molten iron desiliconization agent with high-ferric red mud as a matrix and an application method thereof. The molten iron desiliconization agent comprises, by mass percent,70%-90% of high-ferric red mud and 10%-25% of magnesium slag. The binary basicity of the desiliconization agent is controlled within 0.6-1.2. The high-ferric red mud comprises 35-55% of Fe2O3, 10-20%of Al2O3, 5-15% of Na2O, and the balance SiO2, TiO2, CaO and impurities. The magnesium slag contains calcium oxide greater than or equal to 55%, magnesium oxide greater than or equal to 6% and silicondioxide less than or equal to 35%. Before or when blast-furnace tapping, the dry molten iron desiliconization agent is added into a hot metal ladle at 20-40 kg per ton of molten iron.

Owner:ANGANG STEEL CO LTD

Online hot blank corner crack clearing device and method

The invention relates to an online hot blank corner crack clearing device and method. An online hot blank corner crack clearing device is additionally arranged between the sector section of a continuous casting machine and a torch cutter. Through the process of preheating preparation, preheating locating, preheating, clearing, smoke collection and slag treatment, clearing can be conducted on the corner portions on the four corners of a cast blank at the same time, the corner portions can be in smooth transition, and the defects that a corner re-clearing area is excessively large, and the lossof a steel material is high are effectively overcome; through automatic locating, the requirement for clearing cast blanks of different section dimensions is met, through adjustment of a burner, the requirement for different clearing depths is met, and through adjustment of energy medium parameters, the online hot blank corner crack clearing device is adapted to the change of a drawing speed; theautomatic clearing procedure can be started through one-button type operation, and online clearing does not influence the continuous casting production rhythm.

Owner:ANGANG STEEL CO LTD

UV code spraying device of steel tube

The invention discloses a UV code spraying device of a steel tube. The UV code spraying device of the steel tube comprises a UV bar code spray printing assembly, a number spray printing assembly and a UV solidifying assembly, wherein the number spray printing assembly, the UV bar code spray printing assembly and the UV solidifying assembly are sequentially installed in the advancing direction of the steel tube sprayed with a code from right to left. Numbers and bar code information are marked on the surface of the steel tube, and a unique identify label is given to the steel tube; the UV bar code has the advantages of being good in adhesive force and not prone to abrasion, and can be well applied to track steel tubes one by one in an online mode; the UV solidification is adopted, so that the bar code is dried instantly, the production rhythm is not affected, and an original production process can be continued in a seamless mode; the tracking of identifications of the steel tubes one by one is improved, and the code spraying is the basic link of the identification tracking in the production process of the steel tubes; the UV code spraying device of the steel tube is not restricted to being used in a production line of the steel tubes, and can also be applied to a production line of steel boards or other production lines with bad conditions.

Owner:HANGZHOU ZHEJIANG UNIV JINGYI ELECTROMECHANICAL TECH ENG

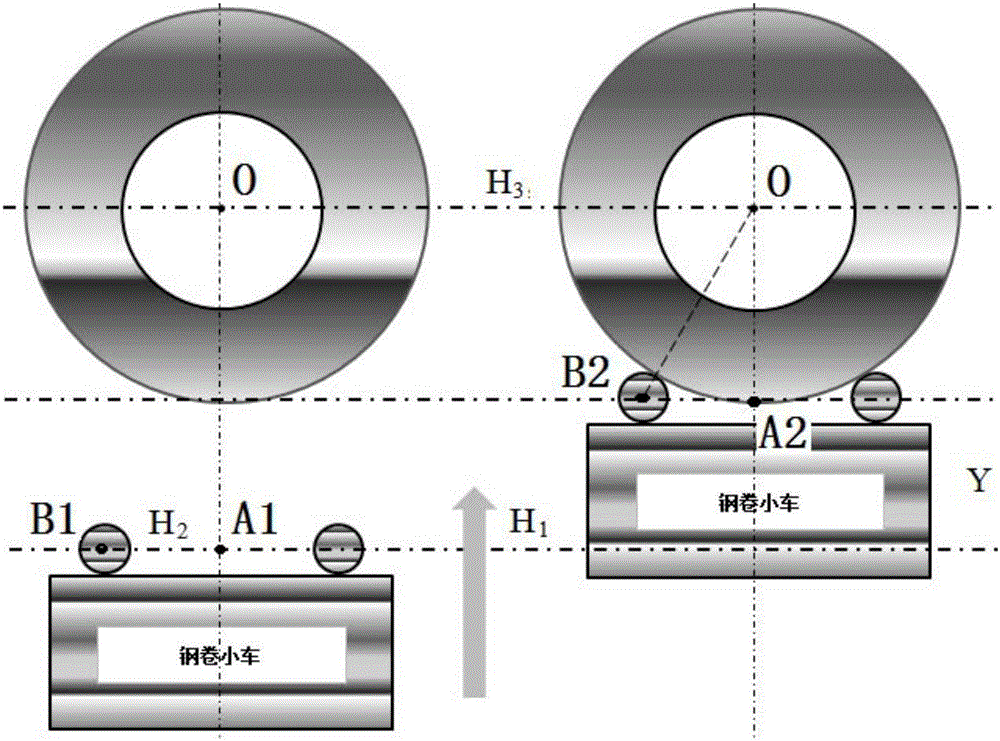

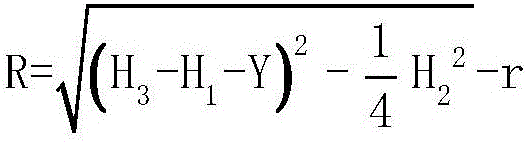

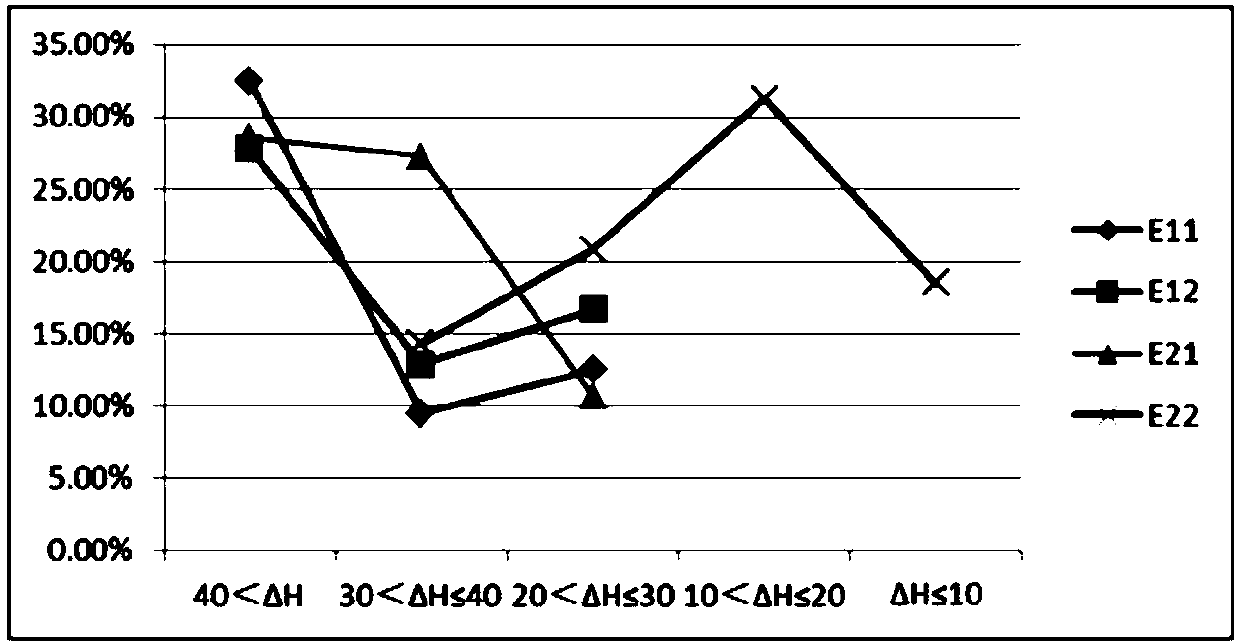

Inserting coil steel reel diameter measuring method and system

InactiveCN106570329AAvoid collisionDoes not affect production rhythmSpecial data processing applicationsInformaticsEngineering

The invention belongs to the technical field of steel reel measurement and discloses an inserting coil steel reel diameter measuring method. The method comprises steps of acquiring a vertical height (H3) of an axle wire of a recoiling machine dabber, a vertical height (H1) of an axle wire of each steel reel trolley cradle roller, a radius (r) of the steel reel trolley cradle roller, and a distance (H2) between the centers of two cradle rollers on the steel reel trolley, acquiring a displacement (Y) of the steel reel trolley when the steel reel trolley vertically moves upward until the steel reel trolley cradle rollers are abutted against the outer wall of the steel reel, building a mathematic calculation module based on the vertical height (H3) of the axle wire of the recoiling machine dabber, the vertical height (H1) of the axle wire of each steel reel trolley cradle roller, the radius (r) of the steel reel trolley cradle roller, and the distance (H2) between the centers of the two cradle rollers on the steel reel trolley as well as the acquired displacement (Y) of the steel reel trolley, and acquiring a calculating formula between a steel reel radius (R) and the displacement (Y) of the steel reel trolley according to the mathematic module. The invention provides a high-efficient inserting coil steel reel measuring method.

Owner:BEIJING SHOUGANG CO LTD

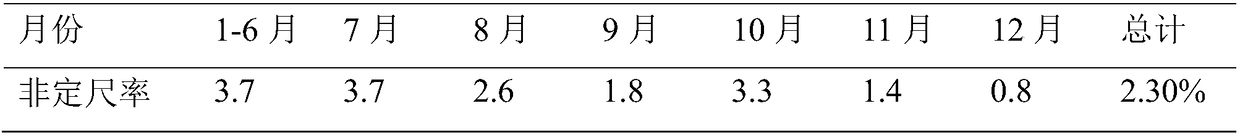

Method for increasing cutting fixed length yield of casting machine

InactiveCN108246996AImprove the qualified rate of cutting to lengthImprove reliabilitySteelmakingControl system

The invention discloses a method for increasing the cutting fixed length yield of a casting machine. The method for increasing the cutting fixed length yield of the casting machine comprises the stepsthat the count of a drive roller of a sector-shaped segment serves as a basis, the data is sent to a casting flow control system and a casting machine cutter control system through communication to be subjected to data and logic processing, blank length measuring calculation is carried out, and the method serves as a cutting fixed length measuring manner. By means of the method for increasing thecutting fixed length yield of the casting machine, the cutting fixed length yield of the casting machine is increased, the steelmaking production cost is reduced, the normal production rhythm is notaffected while the cost is reduced, meanwhile, no extra requirement is mentioned for equipment precision, and good popularization value is achieved.

Owner:BAOTOU IRON & STEEL GRP

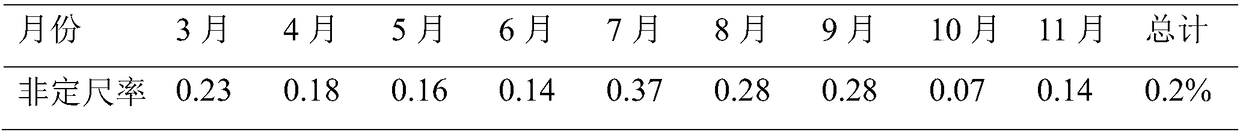

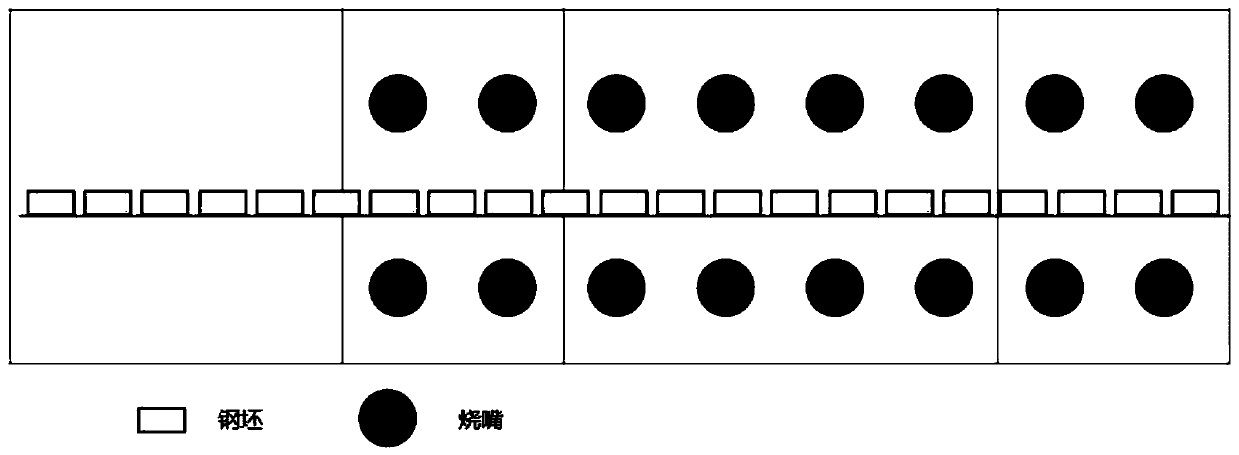

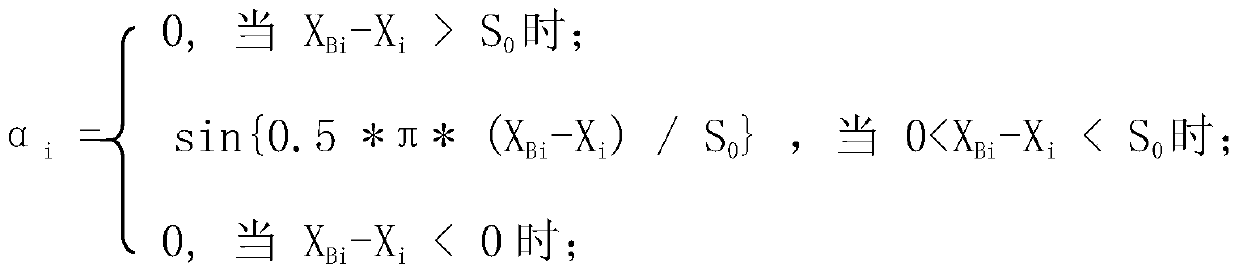

Automatic distinguishing control method for maximum heating temperature of steel rolling heating furnace

ActiveCN110656234ARealize fine controlImprove product qualityFurnace typesHeat treatment process controlProcess engineeringPID controller

The invention discloses an automatic distinguishing control method for the maximum heating temperature of a steel rolling heating furnace. The method is characterized in that a second-stage combustioncontrol system of the heating furnace utilizes a thermodynamic model, and a temperature setting initial set value T0 is calculated according to a steel type component, a size specification, a charging temperature, a target tapping temperature and a predicted residence time parameter of a steel billet; and a maximum heating temperature limiting step is set, particularly, a burner i control area S0is defined, a maximum heating temperature weight coefficient alpha i of the steel billet I is defined, the maximum heating temperature Tlimit at the burner I is calculated, T0 is compared with Tlimit, the smaller value is taken as as Tfinal, and Tfinal is used as the final set value of a PID controller corresponding to the burner to carry out temperature control. The method has the beneficial effects that the limitation of the maximum heating temperature of steel grades can be automatically realized under the conditions that the furnace is not empty, the production rhythm is not influenced and manual intervention by operators is not needed, fine control of the production process is realized, and the product quality is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Test method of oxidation burning loss rate of billet steel processed by steel rolling heating furnace

InactiveCN110542622ASimple test methodEasy to operateWeighing by removing componentLoss rateHeating furnace

The invention discloses a test method of oxidation burning loss rate of a billet steel processed by a steel rolling heating furnace. The method comprises the following steps: 1) weighing a steel sample, and recording mass of the steel sample; 2) placing the steel sample in a test module, integrally placing the test module and the steel sample on an upper surface of the billet steel which is goingto be placed in the furnace for being heated; 3) placing the test module and the steel sample into the furnace with the billet steel, after being heated step by step in the heating furnace, taking outthe test module and the steel sample with the billet steel, placing the steel sample in water for cooling, cooling to normal temperature and then taking out the steel sample, wiping up iron scales onthe surface; 4) drying the iron scales wiped up, weighing the dried steel sample, and recording the mass of the steel sample; 5) calculating the oxidation burning loss rate of the steel sample according to change of mass of the steel sample before and after being placed in the heating furnace. The test method of oxidation burning loss rate of the billet steel, provided by the invention, is simpleand easy to carry out and can test the oxidation burning loss rate of steels of different types; the module can be used repeatedly for many times; and a simple and effective method for actual measurement of data of oxidation burning loss of the billet steel is provided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for producing low sulphur steel through carrying out CAS-OB refining on premelting calcium aluminate

InactiveCN102876848AReduce pollutionImprove desulfurization performanceProcess efficiency improvementAluminateCalcium in biology

The invention provides a method for producing low sulphur steel through carrying out CAS-OB (Composition Adjustment by Sealed Argon Bubbling-Oxygen Bubbling) molten steel ladle refining on premelting calcium aluminate. The method mainly comprises the following steps: converter tapping, deep desulfurization in a CAS-OB refining furnace (argon stirring is carried out on molten steel during the whole process of refining desulfurization), drossing, refining, alloying treatment and continuous casting. Deep desulfurization is carried out by the method, so that the desulfurization rate can reach more than 85%, the sulfur content in the molten steel can be controlled below 0.002% stably, and the desulfurization efficiency is high and stable. Compared with the prior art, the method is simple to operate and stable in desulfurization effect, and does not influence the production rhythm. A used desulfurizer is aluminum-calcium premelting refining slag, is subjected to high-temperature melting treatment during the manufacturing process, has the characteristics of uniform compositions, low sulphur and low melting point, can achieve slugging quickly to desulfurize quickly, and reduces the environmental pollution.

Owner:辽宁中汇环保科技有限公司

Iron adding process-based medium-high silicon molten iron desilication method

InactiveCN103667579AStrong process flexibilityDesilication reaction time is sufficientProcess efficiency improvementSlagPre treatment

The invention discloses an iron adding process-based medium-high silicon molten iron desilication method, and belongs to the technical field of molten iron pretreatment. The process of adding molten iron into a molten iron ladle by utilizing an iron mixing furnace / vehicle serves as molten iron desilication reaction time in a melting furnace; the potential energy of iron molten serves as stirring power of the melting furnace. A solid oxidizer and a slag-regulating agent in the same proportion as that of the iron flow of the iron mixing furnace / vehicle are added continuously to realize high-efficiency desilication. The method has the advantages that the burden of high-silicon molten iron in converter smelting is lightened; the cost of steel smelting is reduced; moreover, the process is simple; the operability is high; the equipment investment is low; the operating cost is low.

Owner:德龙钢铁有限公司

Method for lowering high-vanadium-titanium molten iron blowing desulfurization drossing iron loss

The invention provides a method for lowering high-vanadium-titanium molten iron blowing desulfurization drossing iron loss. Before desulfurization, the contents of C, Mn, V, Si, S, P, Ti in molten iron and the temperature of the molten iron are controlled; argon or nitrogen-argon mixed gas is adopted as a carrier, and Ca and Mg powder is adopted as a desulfurizer for blowing desulfurization; and a slag-modifier is added into the molten iron according to a ratio of 0.3-0.8 kg per ton of iron for desulfurization. After desulfurization, the argon or nitrogen-argon mixed gas is introduced into the molten iron; drossing is performed until 1 / 4-1 / 3 of slags remain; and then the slag-modifier is added into the molten iron according to a ratio of 0.2-0.5 kg per ton of iron, and then drossing is performed until the slags are totally removed. After the slags are totally removed, the molten iron comprises the contents of 3.9-4.5% of C, 0.10-0.33% of Mn, 0.24-0.49% of V, 0.10-0.4% of Si, 0.001-0.004% of S, 0.05-0.16% of P and 0.10-0.30% of Ti, and the temperature of the molten iron is 1240-1320 DEG C. By adopting the method, the slag status of the desulfurization slags of the molten iron can be greatly improved; the high-vanadium-titanium molten iron blowing desulfurization drossing iron loss and steel and iron consumption are effectively reduced; and the smelting cost of enterprises is lowered.

Owner:ANGANG STEEL CO LTD

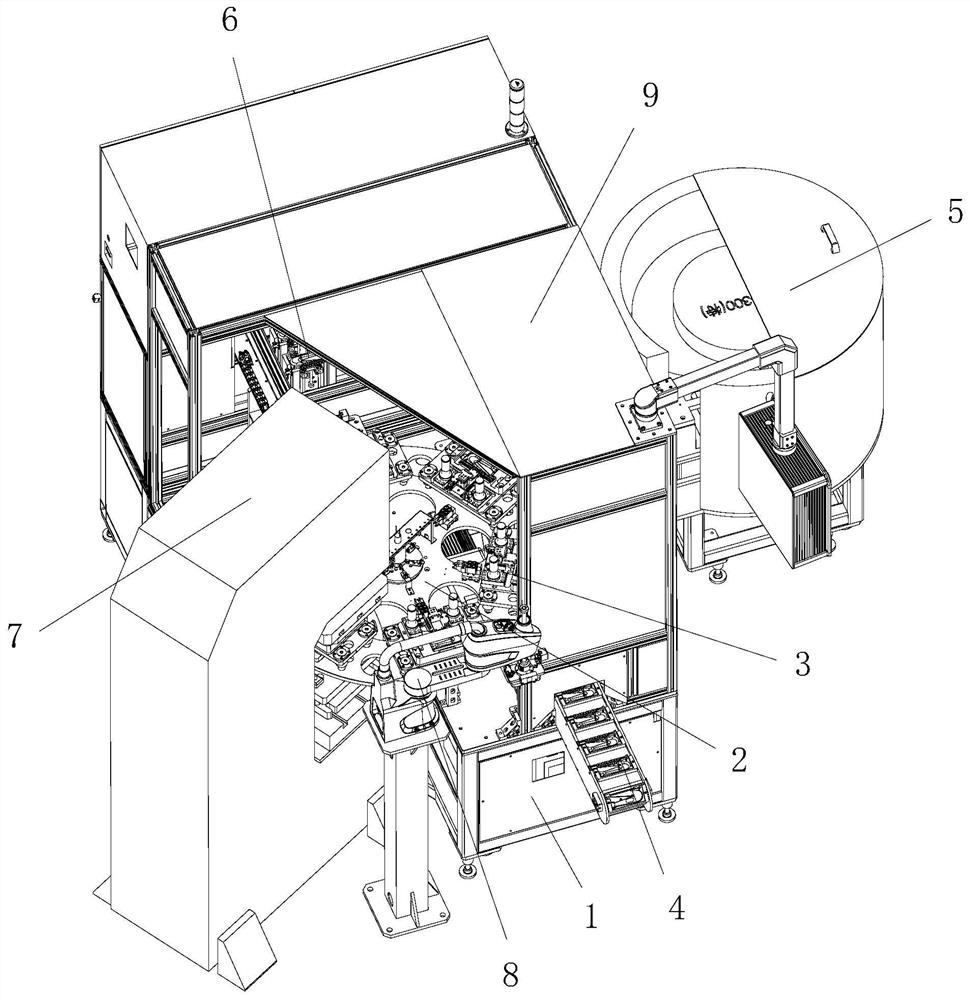

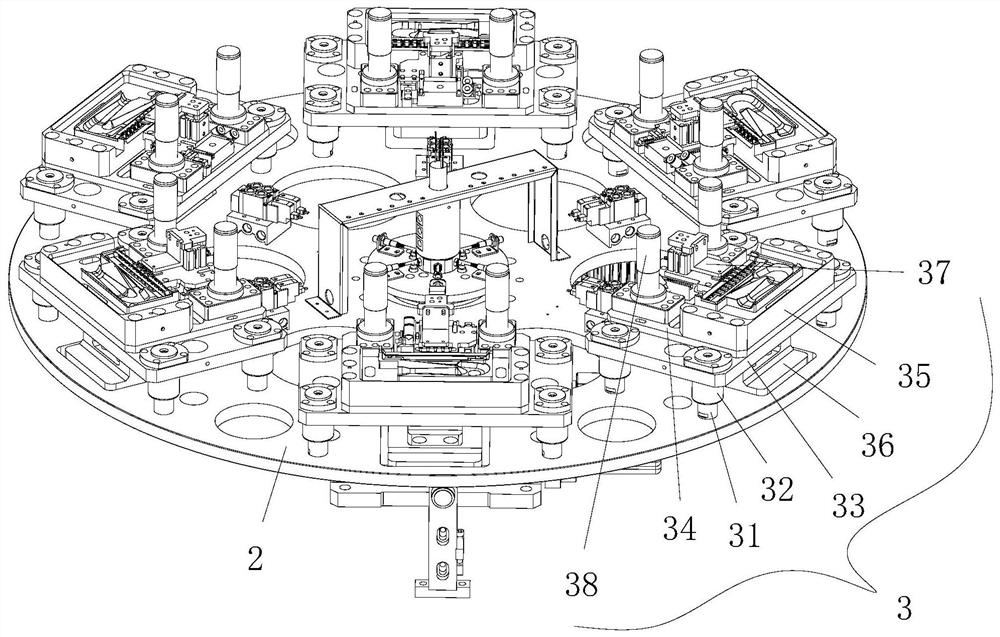

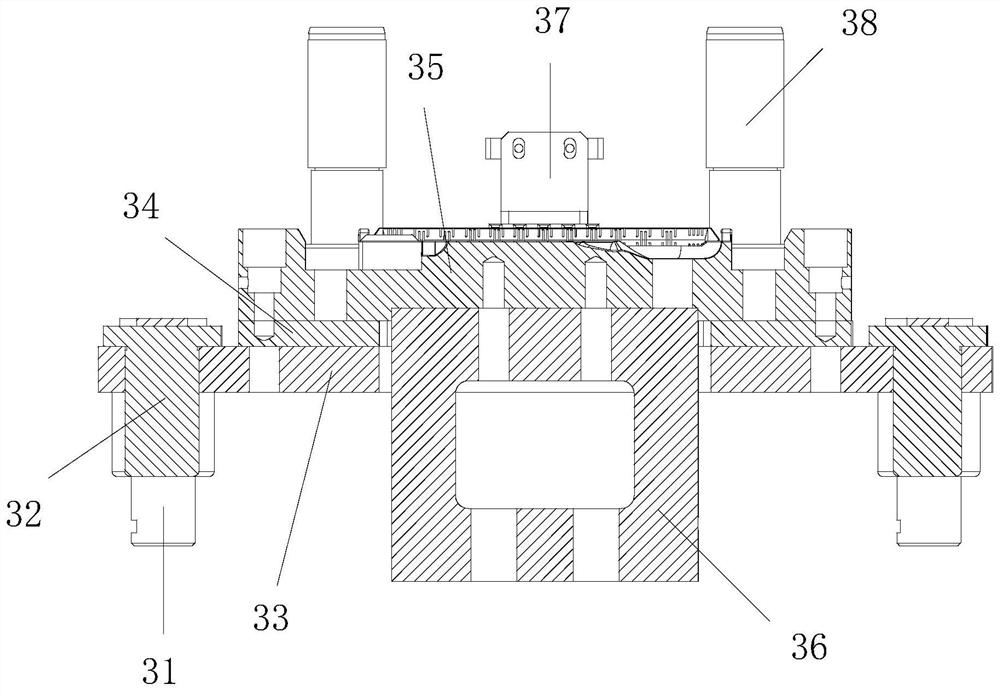

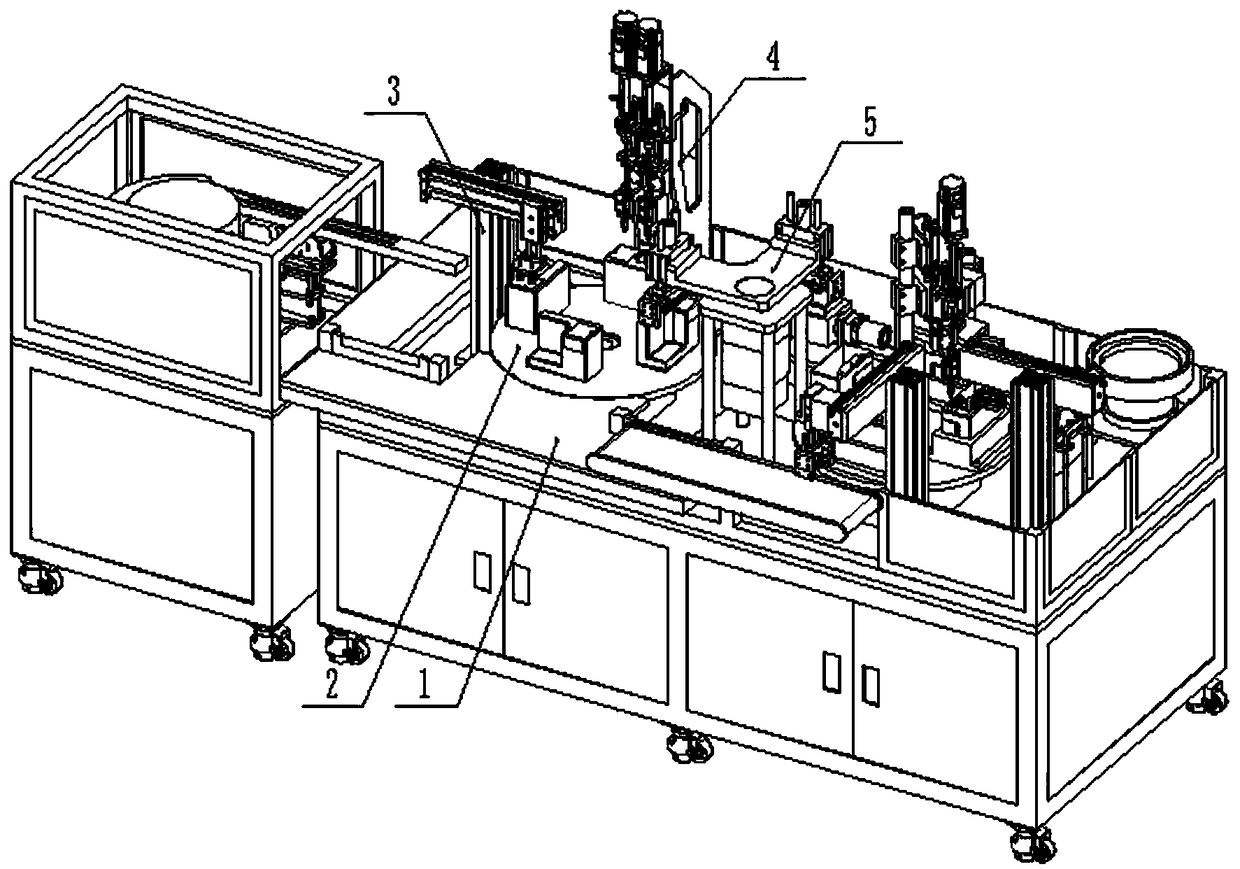

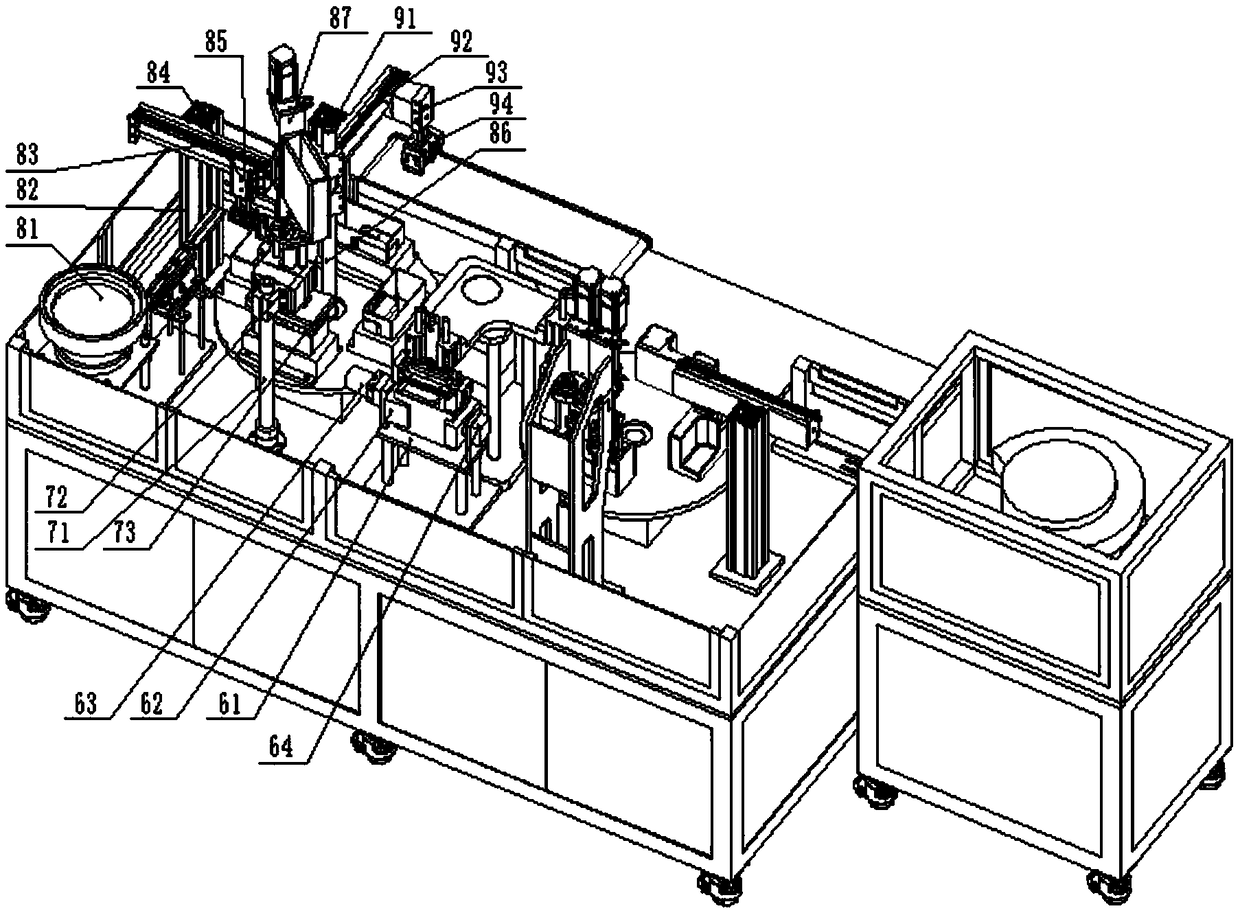

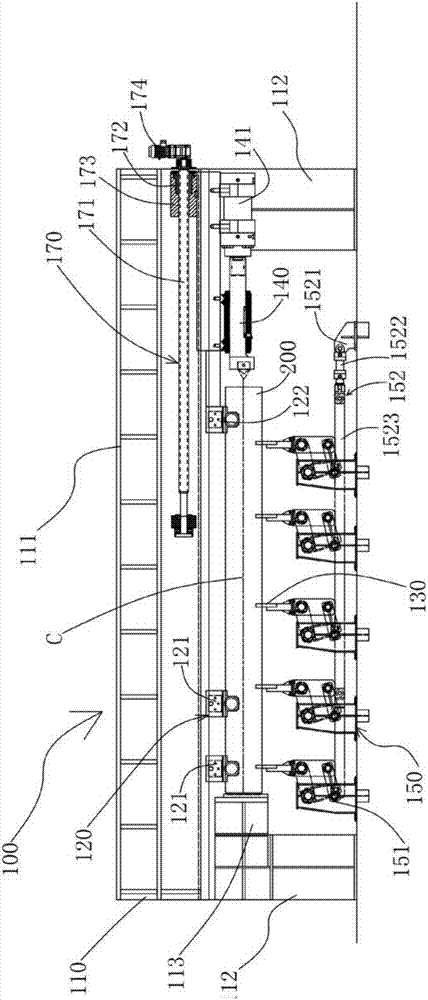

Fire grate automatic assembly line

The invention discloses an automatic fire grate assembly line, which comprises a rack, a rotary disc mechanism mounted on the rack, carrier stamping toolings mounted in an array and annularly distributed on a rotary disc of the rotary disc mechanism, an A-piece conveying and feeding mechanism, a U-piece feeding mechanism, a B-piece supplying and feeding mechanism, a riveting press and a discharging mechanical arm sequentially distributed around the rotating disc mechanism; and a protective cover is further installed on the rack, the rotating disc mechanism is located in the protective cover, and a man-machine operation interface and an alarm indicator lamp are installed on the protective cover. In this way, the fire grate automatic assembly line provided by the invention is compact in structure, stable in operation and capable of replacing manual work to automatically assemble fire grates, the efficiency is improved while the product quality is guaranteed, and a large amount of labor can be saved.

Owner:KUNSHAN LITE AUTOMATION EQUIP

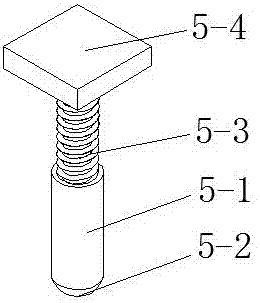

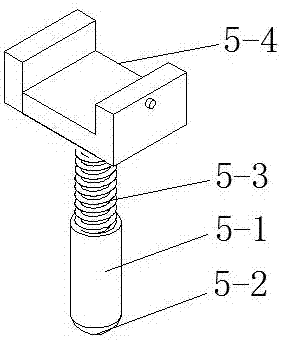

Spraying supporting frame and a spraying device

The invention discloses a spraying supporting frame and a spraying device and belongs to the technical field of coating spraying. The supporting frame comprises a supporting rod; a height adjusting device is arranged on the supporting rod; and a universal ball is arranged at the bottom of the supporting rod. According to the supporting frame, by arranging the universal ball, the requirement of axial constant speed walking of the supporting frame on the inner wall of a mould cavity which rotates with the constant speed is met; by arranging the height adjusting device, the requirement that a supporting pushing rod reaches the level is met; and meanwhile the supporting frame is simple in structure, can be quickly mounted at the front end of the pushing rod and prone to disassembling, and does not affect the production rhythm.

Owner:XINXING DUCTILE IRON PIPES CO LTD

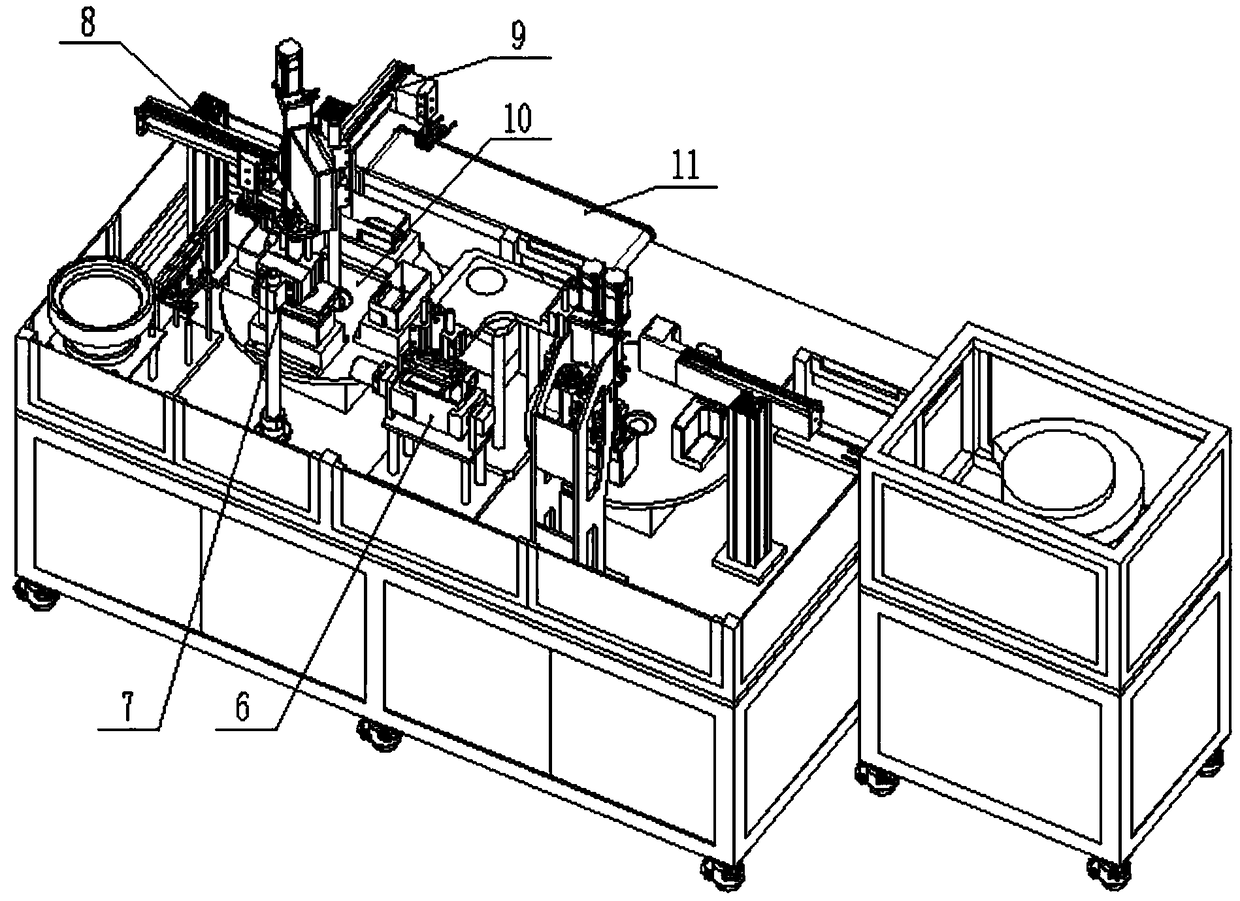

Electric box assembly line

PendingCN109014908ARealize automated assemblyIncrease productivityAssembly machinesProduction lineAssembly line

The invention discloses an electric box assembly line, and belongs to the field of automatic assembly. The electric box assembly line comprises a workbench. The workbench is provided with a first multi-station rotary table and a second multi-station rotary table. The first multi-station rotary table is provided with four work fixtures. The second multi-station rotary table is provided with four work fixtures as well. According to the electric box assembly line, a transposition mechanical arm and an overturn device are arranged between the first multi-station rotary table and the second multi-station rotary table, the transposition mechanical arm can transfer workpieces in the work fixtures on the first multi-station rotary table to the overturn device, and after the overturn device overturns the workpieces, the workpieces are transferred into the work fixtures of the second multi-station rotary table by the transposition mechanical arm, an electric box cover and an earth tag can be conveniently assembled, and normal production of an automatic production line is guaranteed.

Owner:山东红宝自动化有限公司

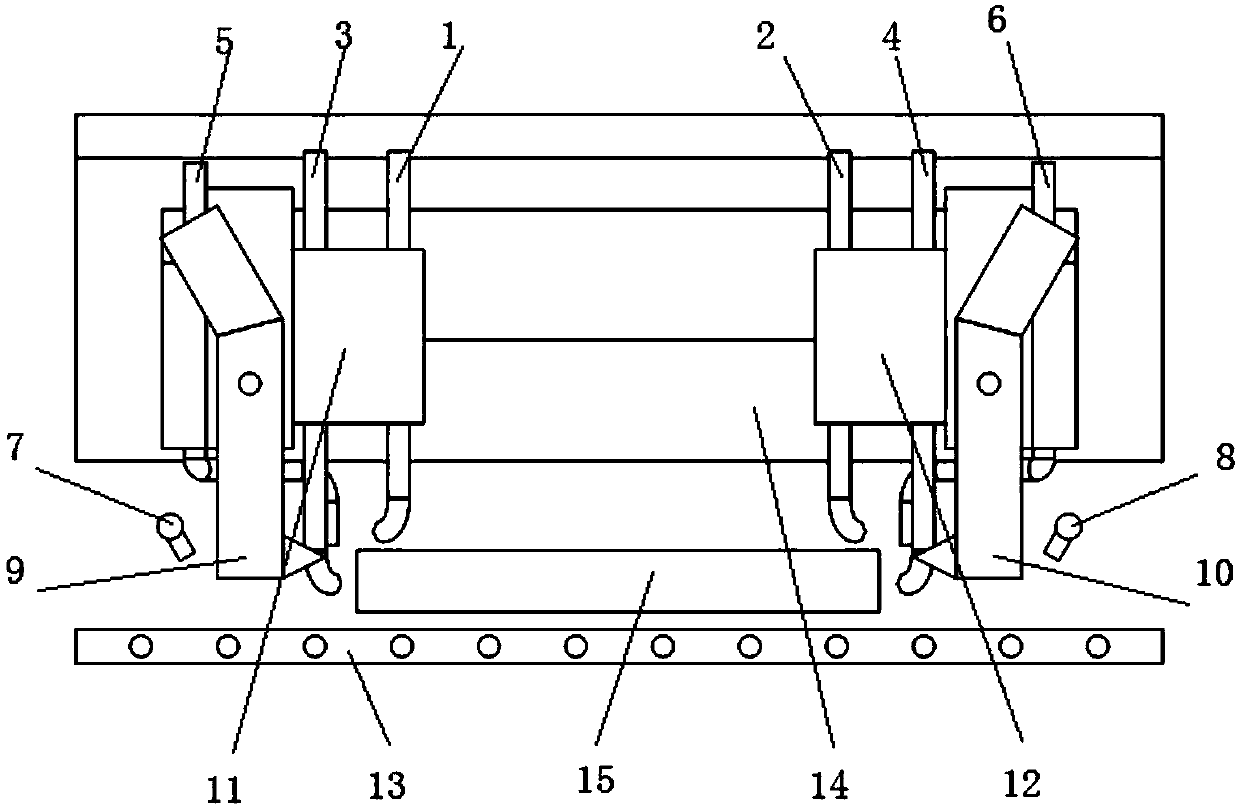

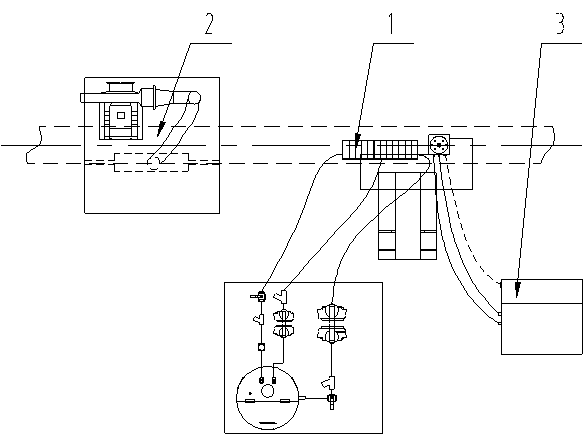

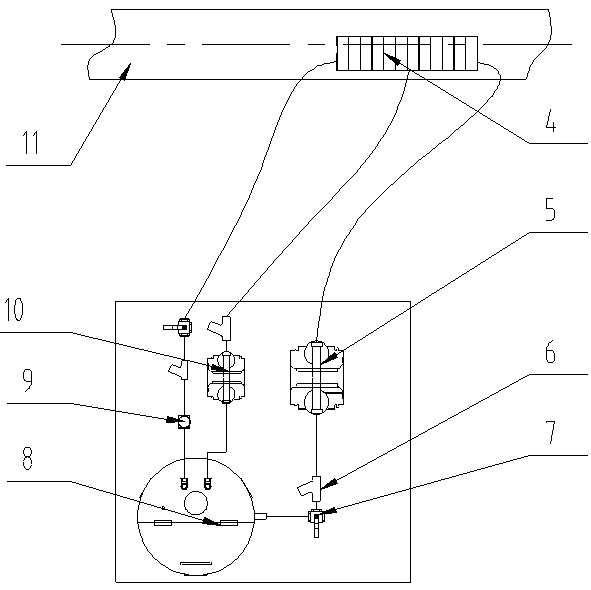

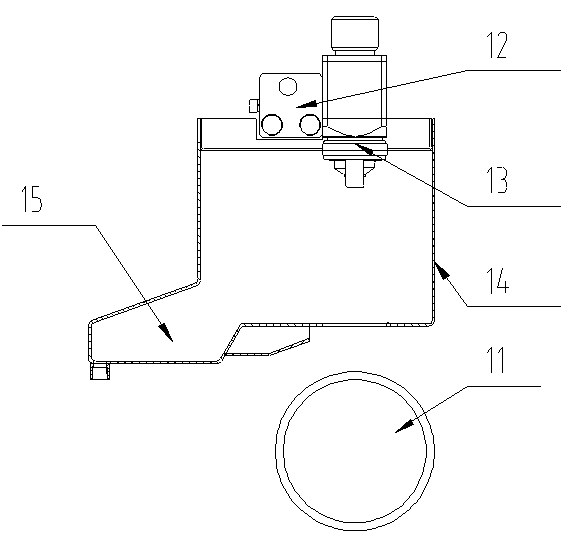

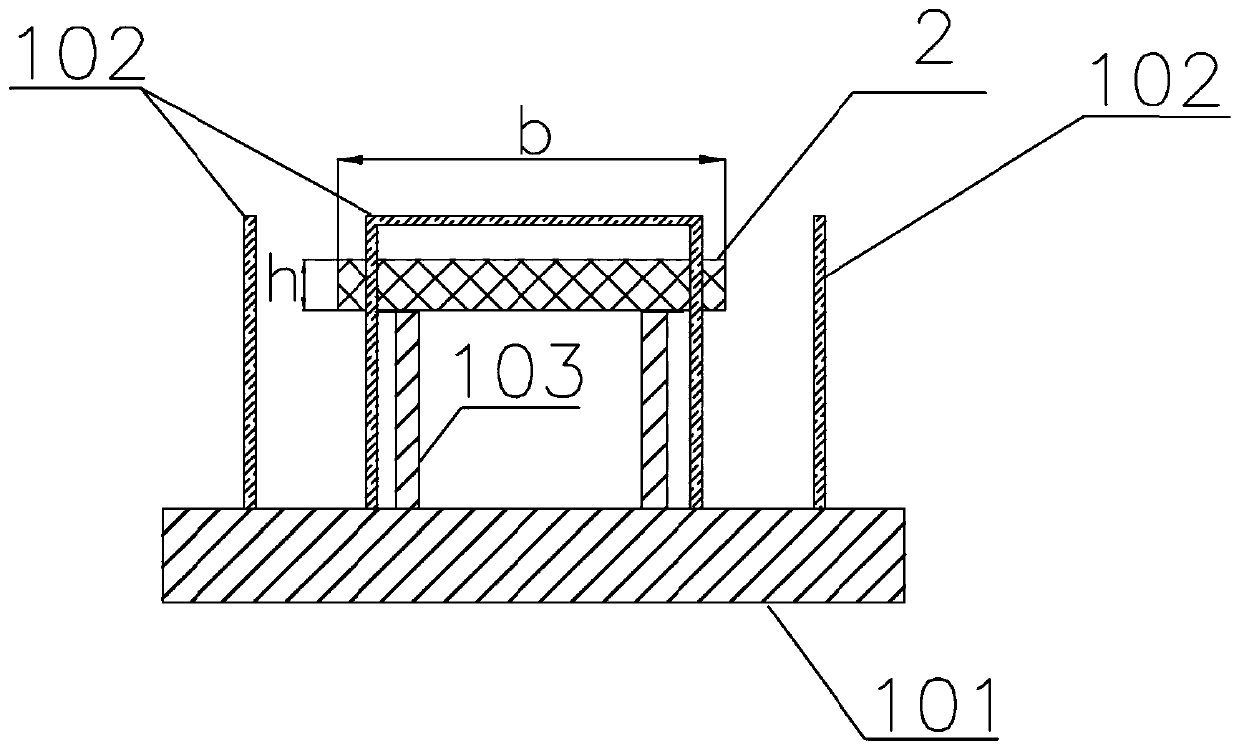

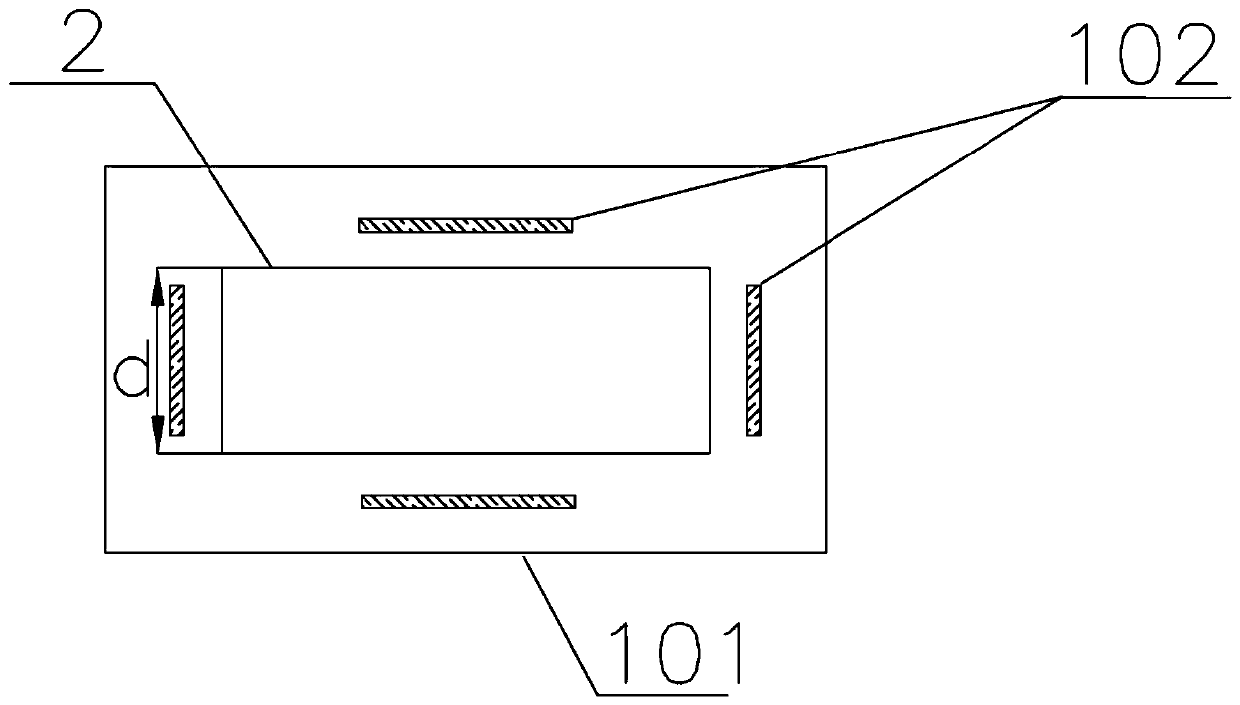

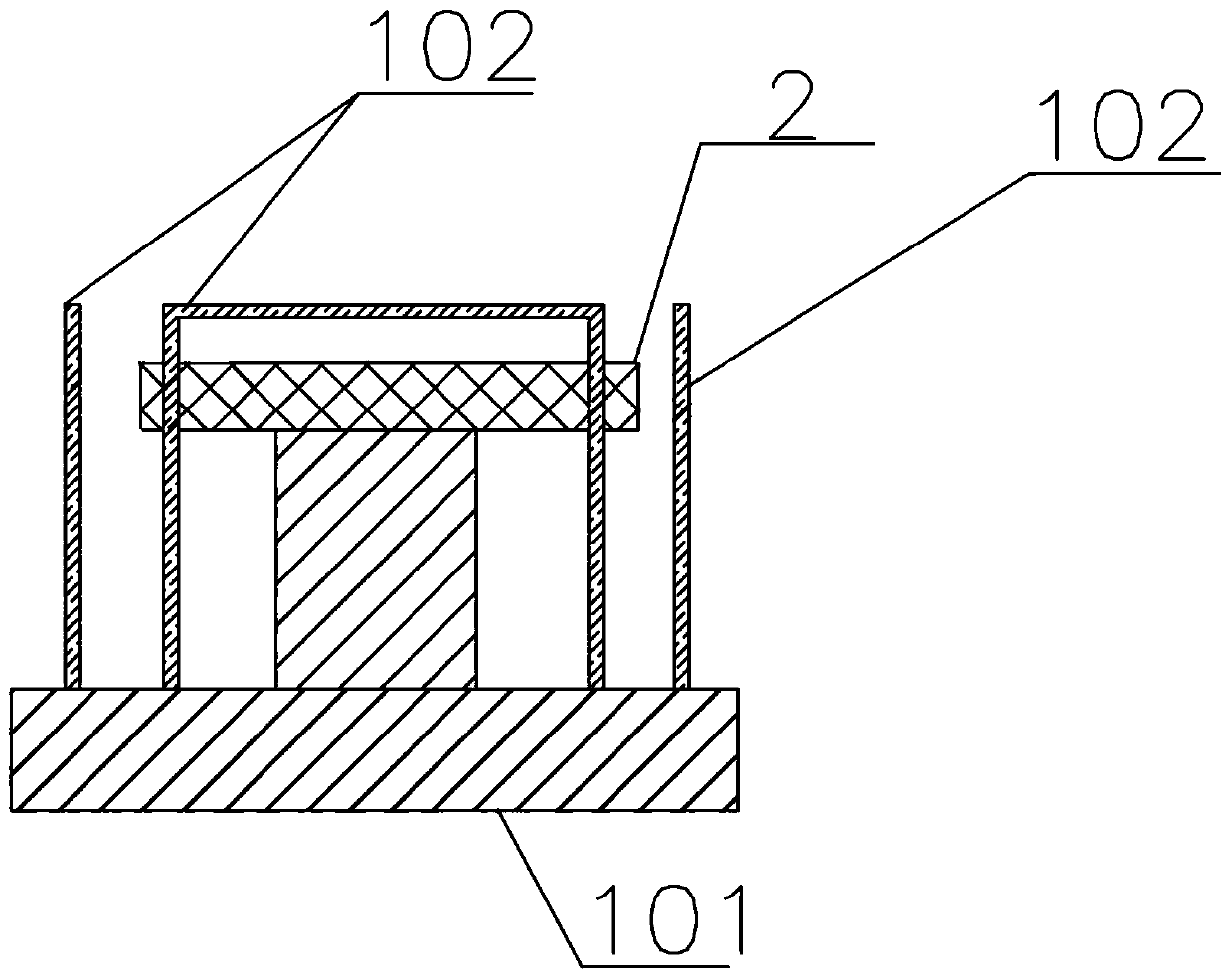

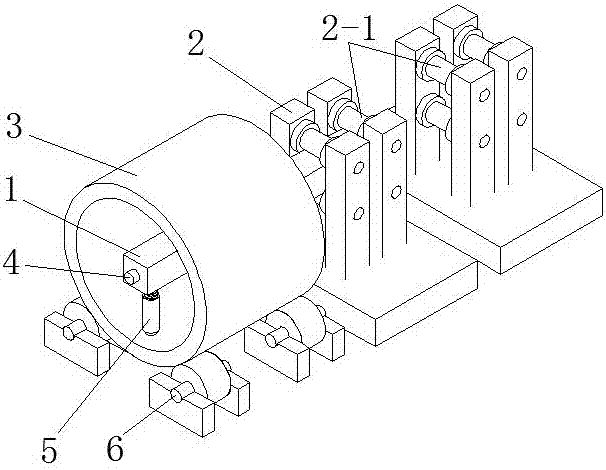

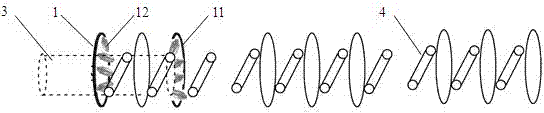

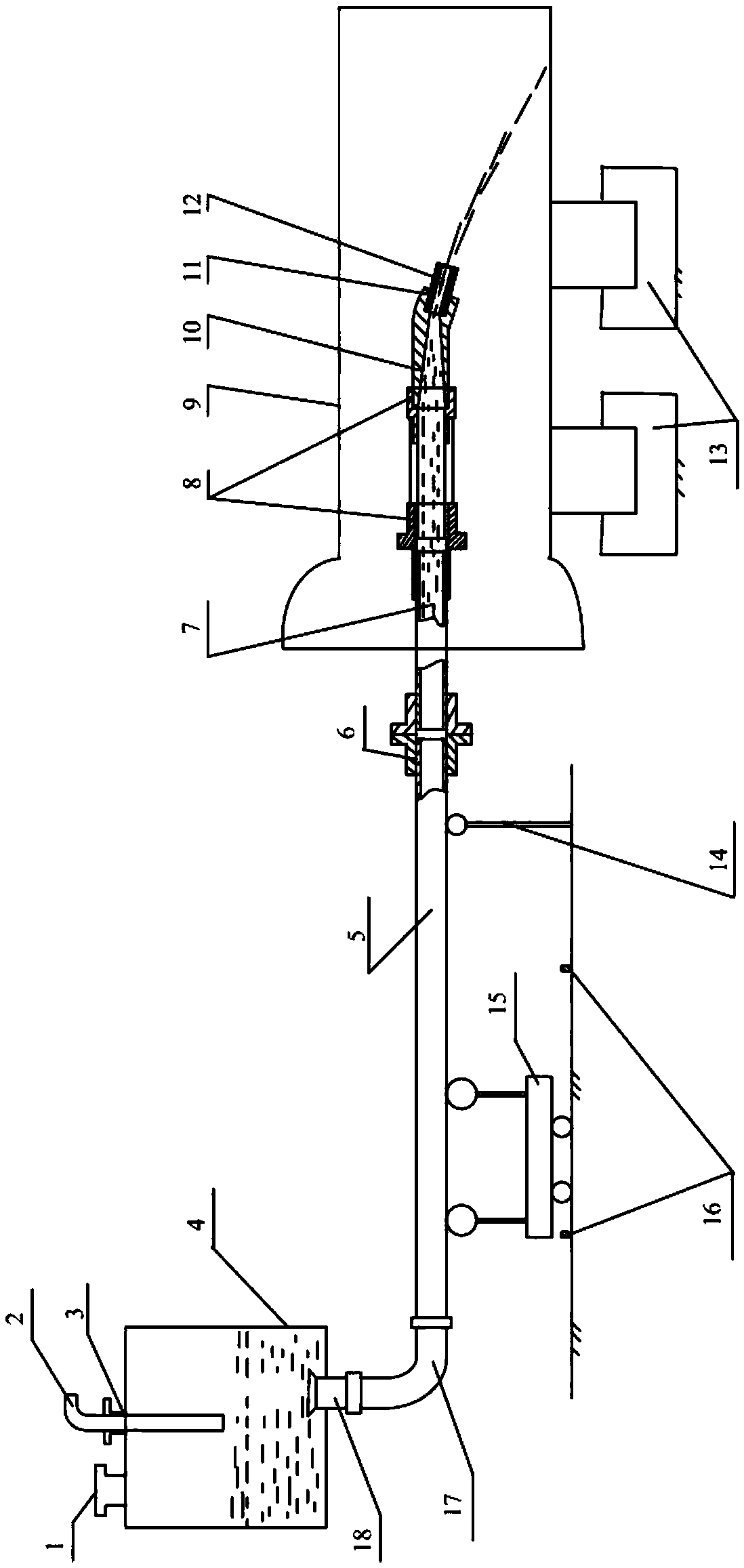

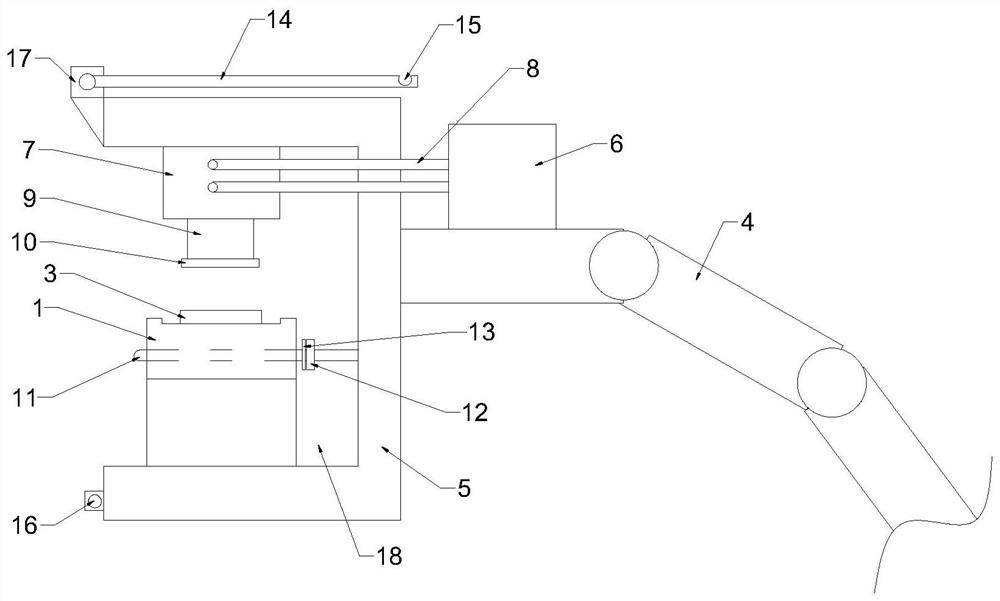

Internal cooling device and method of steel pipe on-line cooling

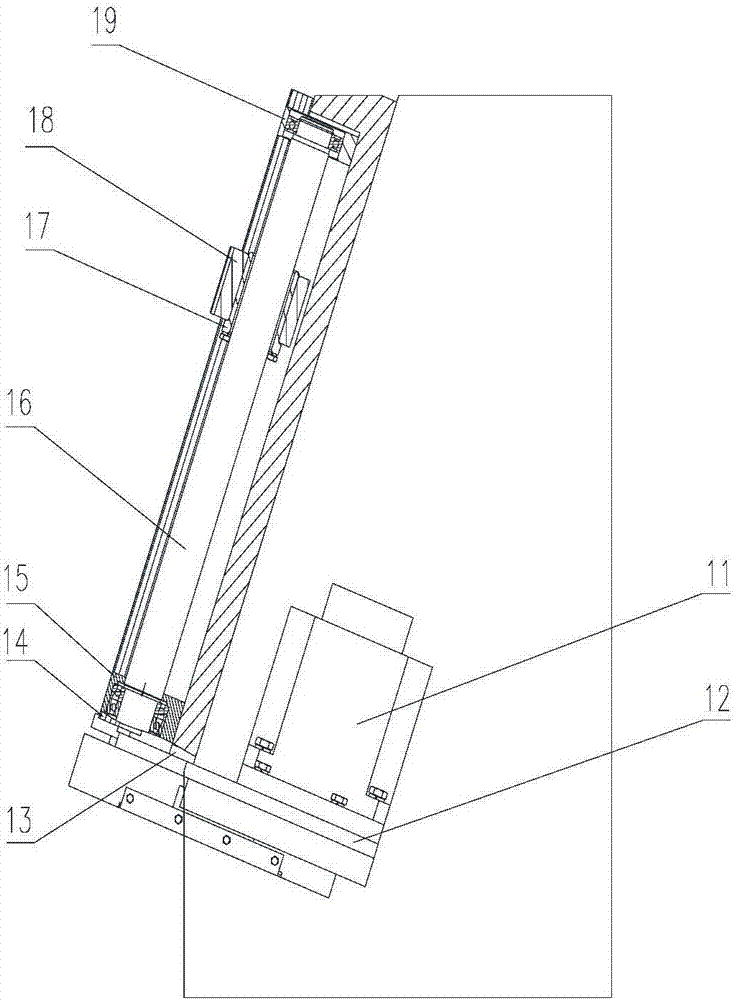

ActiveCN107971352AImprove mechanical propertiesDoes not affect production rhythmTemperature control deviceWork cooling devicesTemperature differenceMechanical property

The invention relates to an on-line heat treatment technology of steel pipe production, in particular to an internal cooling device and method for steel pipe on-line cooling. According to the internalcooling device and method for steel pipe on-line cooling, the internal cooling device for spraying water from the head part or the tail part into a steel pipe is arranged at the front part, the backpart or the middle part of a steel pipe on-line spraying ring cooling device, and a movable inner spraying axial flow cooling device is arranged at the gap position in the steel pipe on-line sprayingring cooling device, wherein the movable inner spraying axial flow cooling device (2) comprises an up-and-down lifting driving device (24), a front-and-back movement driving device (23), a support (22) and a movable inner spraying axial flow spray pipe (21), so that the temperature difference between the inner wall of the steel pipe and the outer wall of the steel pipe is reduced, the on-line cooling uniformity is improved, the comprehensive mechanical property of the steel pipe is effectively improved, the specification of steel pipes capable of being cooled can be expanded, and the uniformity of the temperature of the inner wall and temperature of the outer wall and the consistency of the radial structure of steel pipe on-line cooling are realized, the production rhythm of on-line hot rolling of the steel pipe is not influenced, and the production efficiency is improved; the production of double-length steel pipes or triple-length steel pipes can also be met; and the length of the steel pipe capable of being cooled is close to 40m or even longer.

Owner:BAOSHAN IRON & STEEL CO LTD

Converter furnace lining thickness radar intelligent detection system

InactiveCN108534656AFast measurementShort measurement timeElectrical/magnetic thickness measurementsRadio wave reradiation/reflectionEngineeringErosion

The invention discloses a converter furnace lining thickness radar intelligent detection system. The system comprises a lifting mechanism, a radar device and a controller. The lifting mechanism and the radar device are connected with the controller. The lifting mechanism is connected with the radar device. The lifting mechanism lifts or lowers the radar device under the control of the controller.The radar device upwardly and downwardly moves in the detected converter furnace under driving of the lifting mechanism and transmits electromagnetic waves to the surface of the detected converter furnace lining. The controller processes the data acquired by the radar device. According to the converter furnace lining thickness radar intelligent detection system, converter furnace lining thicknessdetection is performed by using the radar device so that the system has the characteristics of high automation level and short measurement time and can realize converter furnace lining thickness measurement and provide the more accurate lining erosion information.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

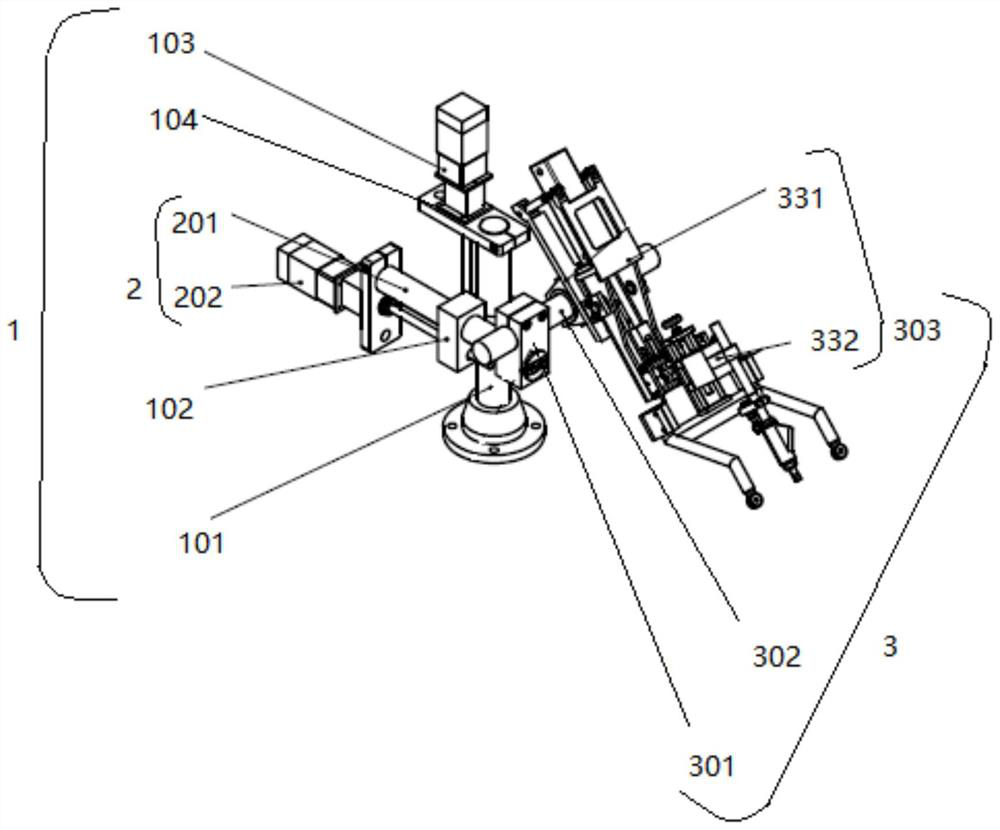

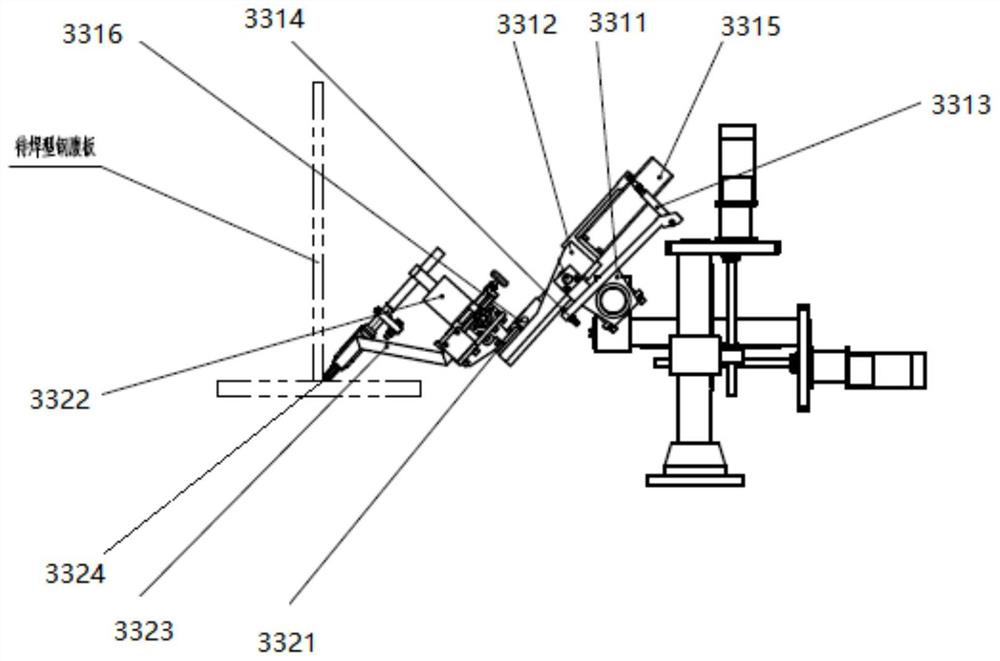

Adjusting device for welding gun

ActiveCN113770615AReal-time adjustmentReduce production and procurement costsWelding/cutting auxillary devicesAuxillary welding devicesStable statusEngineering

The invention relates to an adjusting device for a welding gun. The adjusting device comprises a lifting mechanism which is used for adjusting the height of the welding gun, a translation mechanism arranged on the lifting mechanism and used for adjusting the horizontal position of the welding gun, and a turning mechanism arranged on the translation mechanism and used for adjusting the inclination angle of the welding gun in real time. The height and the horizontal position of the welding gun are adjusted by controlling the actions of the lifting mechanism and the translation mechanism, so that the position of the welding gun roughly meets the welding requirement; and the turning mechanism can adjust the welding angle of the welding gun in real time in the welding process, and the welding gun can be aligned with a welding seam for small motion uncertainty deviation, so that the welding process of the welding gun is always in a stable state, and the welding quality is guaranteed. The adjusting device can meet welding of profile steel products with different section specifications, does not interfere with or influence the production rhythm, is easy to overhaul and maintain, can realize automatic operation, and has a wide application prospect.

Owner:BERIS ENG & RES CORP +1

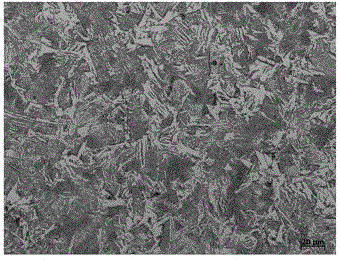

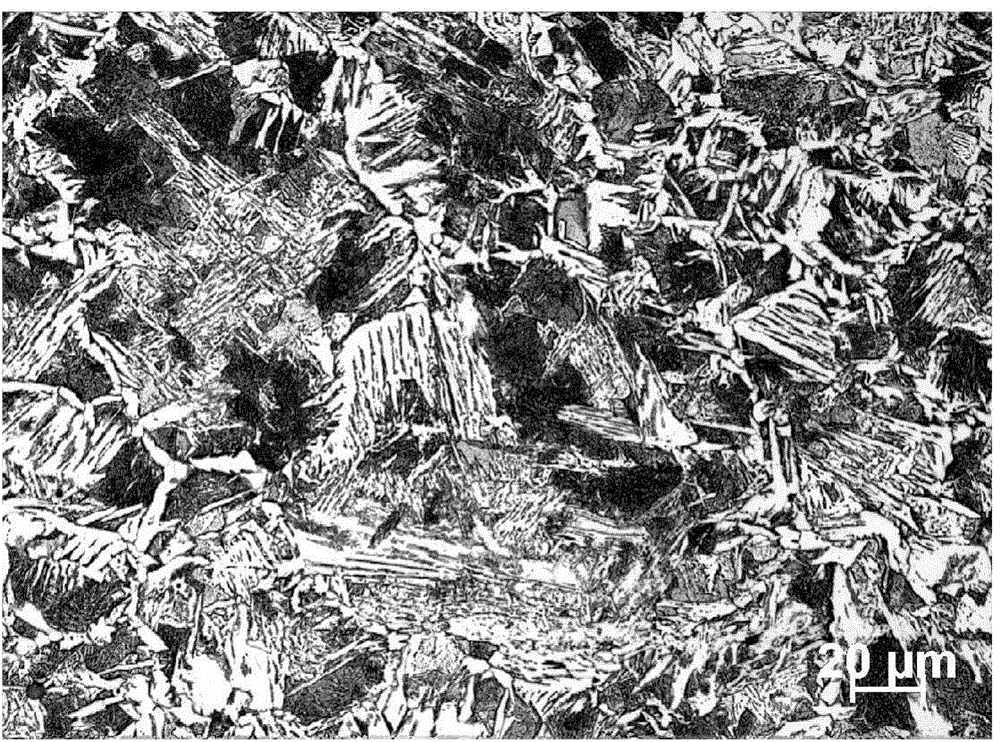

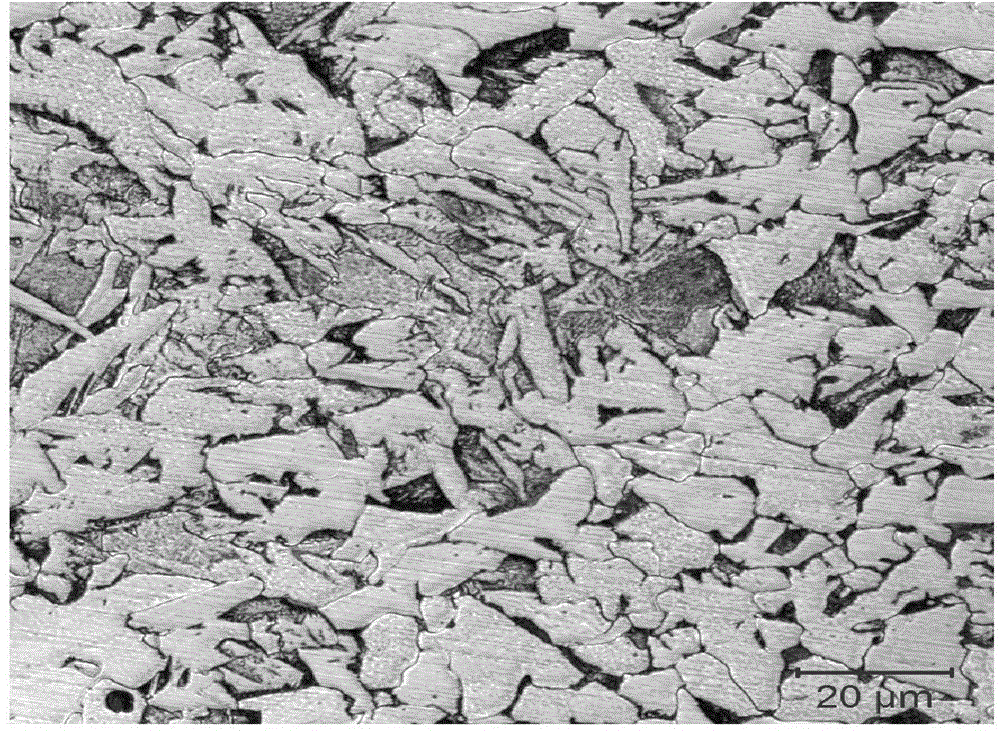

Method for controlling widmannstatten structure in upgrade of C-Mn steel

ActiveCN103572021BSignificant impactEnhanced inhibitory effectReduction rateUltimate tensile strength

The invention relates to a method for controlling widmannstatten structure in upgrade of C-Mn steel. The heating temperature is 1170-1180 DEG C, the soaking temperature is 1150-1160 DEG C, the tapping temperature is controlled at 1130-1140 DEG C, the finish rolling and initial rolling temperature is 810-930 DEG C, the finish rolling temperature is guaranteed to be 780-800 DEG C, accumulated reduction rate in finishing rolling is 50-70%, the cooling temperature is 760-780 DEG C, cooling speed is 10-15 DEG C / s, former 4 groups of collectors are used for forced cooling, the cooling intensity of the former 4 groups of collectors is 2000-3500m<3> / h, the last 6 groups of collectors are used for weak cooling, the cooling intensity of the last 6 groups of collectors is 1500-2500 m<3> / h, and the red temperature is 610 DEG C-640 DEG C. According to the method, the defect of widmannstatten structure in upgrade production of C-Mn steel is better overcome, widmannstatten structure is improved obviously, and the toughness and plasticity of the rolled steel plate are improved obviously.

Owner:NANJING IRON & STEEL CO LTD

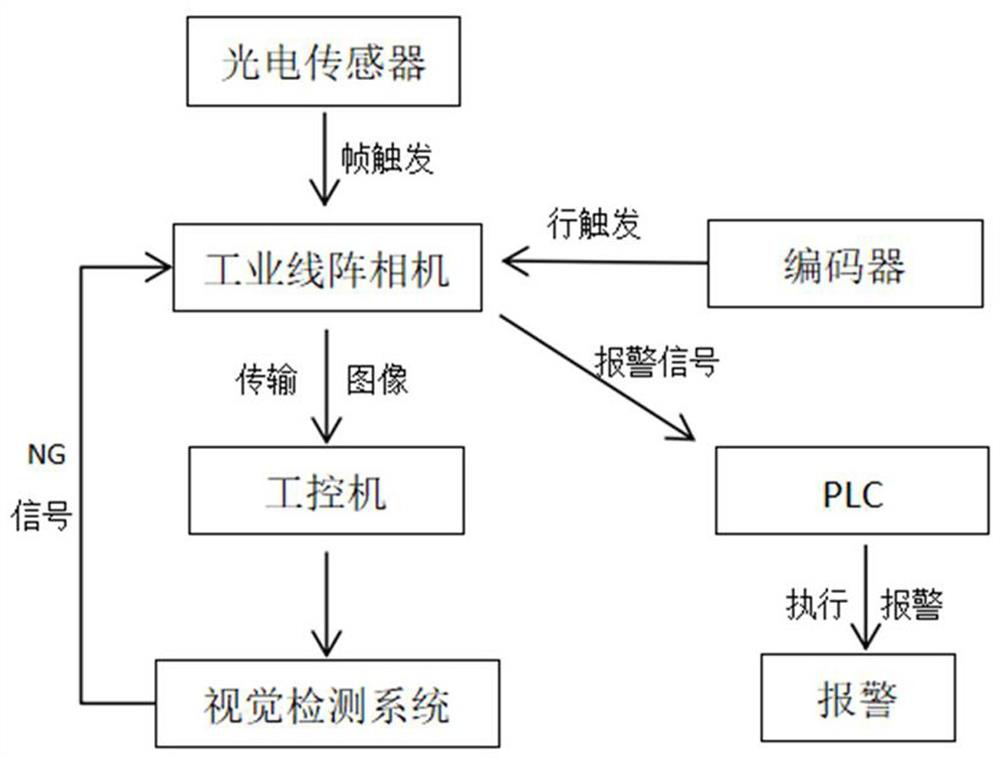

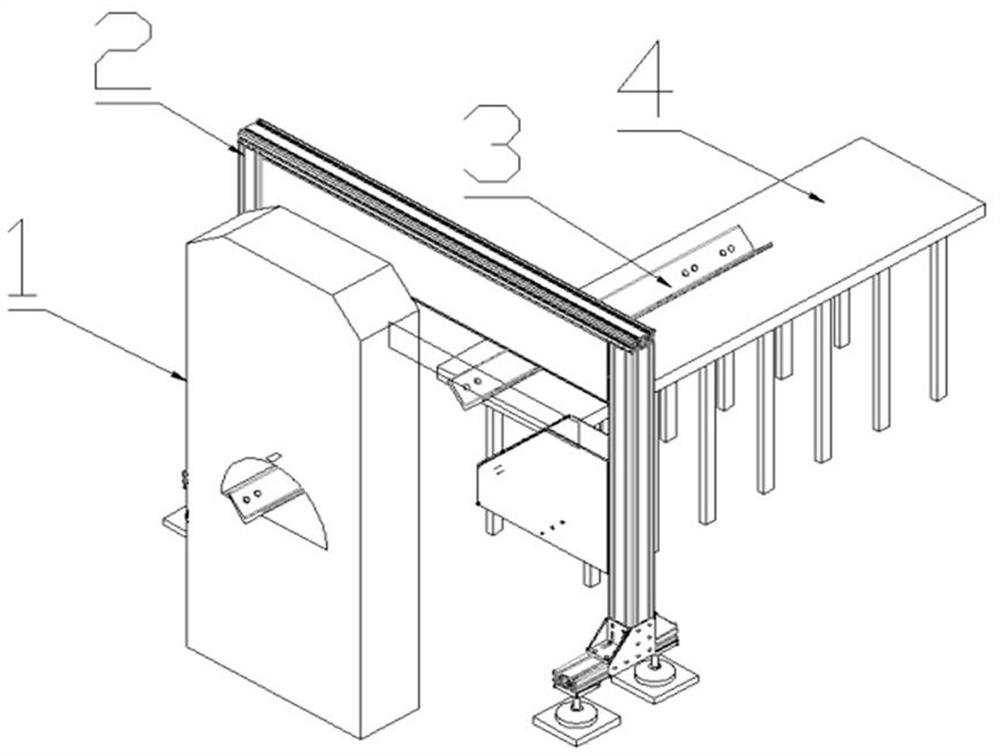

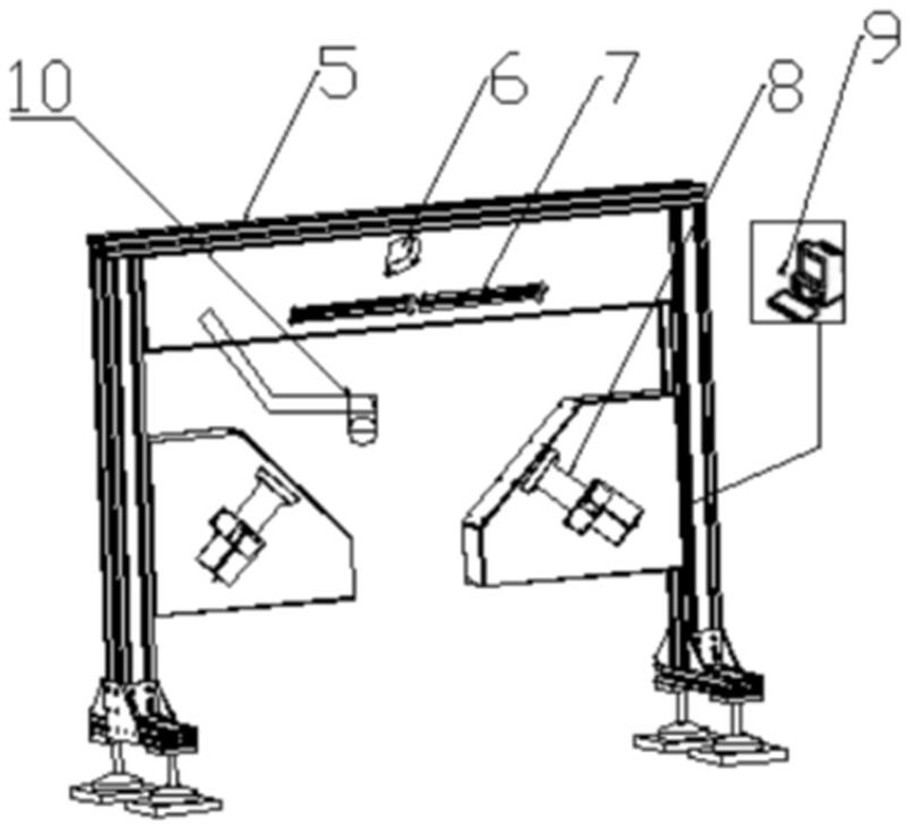

Electric power angle steel intelligent detection system and method based on image recognition

The invention discloses an electric power angle steel intelligent detection system and method based on image recognition. The detection system is arranged at an angle steel finished product end on the premise of not changing an angle steel processing line, and the detection system comprises a main body support, an image sampling device, an angle steel sensing device and a detection control system; the main body support is a doorframe-shaped support; the image sampling device and the angle steel sensing device are installed on the main body support, the angle steel conveying device penetrates through the main body support, and the image sampling device includes two sets of industrial linear array cameras and is used for sampling two right-angle faces of angle steel; the angle steel sensing device comprises a photoelectric sensor and an encoder, the photoelectric sensor is used for detecting the conveying position of angle steel, and the encoder senses the angle steel conveying speed and controls the camera shooting frequency; and the detection control system judges and displays angle steel processing results. The device is independent of an original angle steel processing equipment production line, and the original angle steel production line is not transformed while intelligent angle steel detection is achieved.

Owner:SHANDONG ELECTRICAL ENG & EQUIP GRP

Cast tube inner wall cleaning device

The invention provides a cast tube inner wall cleaning device and relates to cast tube inner wall cleaning equipment, in particular to a spherulitic graphite cast tube inner wall gas type cleaning device. The cast tube inner wall cleaning device comprises a sealing tank, a steel tube, a coupler, a spray gun head, a supporting roller set, a supporting rack and a movable trolley. A sand inlet and a nitrogen inlet are processed in the upper portion of the sealing tank. A nitrogen outlet is formed in the lower portion of the sealing tank. The nitrogen outlet is connected with the steel tube through a hose. The steel tube is connected with the spray gun head through the coupler. A gun nozzle part of the spray gun head extends into a cast tube erected on the upper portion of the supporting roller set. The end, close to the coupler, of the steel tube is supported by the supporting rack. Meanwhile, the middle of the steel tube is supported by the movable trolley and moves forwards and backwards along with the movable trolley. Steel emery is blown into the spray gun head from the steel tube through nitrogen flow, then blown out of the spray gun head and knocked on the inner wall of the cast tube, and the cleaning function is achieved. The cast tube inner wall cleaning device has the advantages of being novel in structure, easy and convenient to operate, low in machining cost, capable of reducing labor intensity of workers and improving work efficiency, obvious in cleaning effect and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

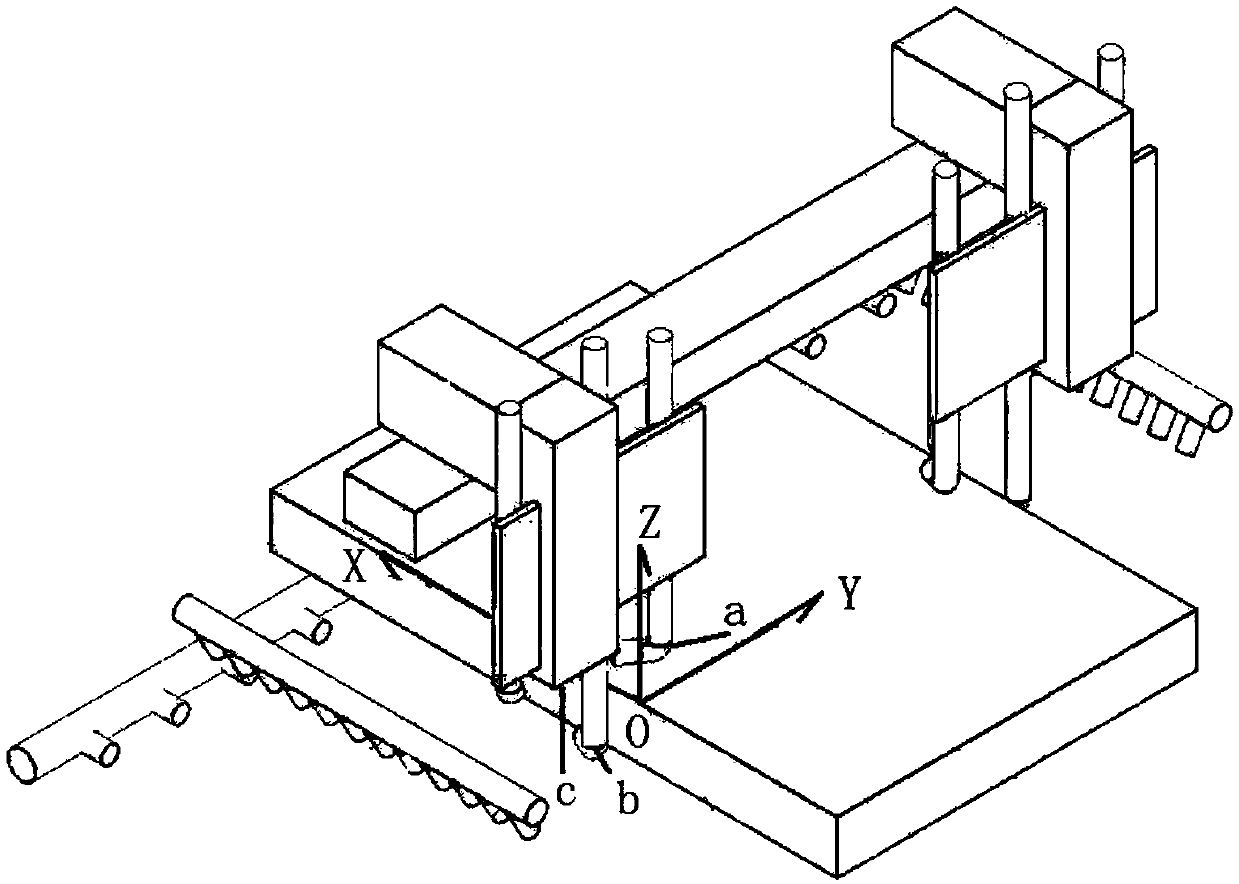

Rail beam type thermal centering machine

ActiveCN107350288ADoes not affect production rhythmShort timeGuiding/positioning/aligning arrangementsMetal rolling arrangementsMechanical engineeringEngineering

The invention provides a rail beam type thermal centering machine, and relates to the field of seamless steel pipes. The rail beam type thermal centering machine comprises a frame, and a stabilizing device, a support bracket and a centering device mounted in the frame; the frame comprises a rail beam horizontally arranged, and two support pieces vertically arranged; two ends of the rail beam are respectively supported on the two support pieces; the rail beam is positioned above a centering center line, and is parallel to the centering center line; the stabilizing device and the centering device are arranged along the centering center line, and are both mounted on the rail beam; and the support bracket is correspondingly arranged below the stabilizing device, and is lower than the position of the centering center line. The rail beam type thermal centering machine further comprises a distance adjusting device capable of adjusting the distance between the support bracket and the rail beam. The rail beam type thermal centering machine can selectively center pipe blanks to reduce influence on the production beat.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

Method for reducing shearing buckling occurrence rate of steel plate with thickness of 23 mm or above

ActiveCN113333464AReduce shear warpSolve clipping warp problemCooling bedsProfile control deviceEngineeringKnife blades

The invention discloses a method for reducing the shearing buckling occurrence rate of a steel plate with the thickness of 23 mm or above, and relates to the technical field of steel production. The method comprises the following steps that S1, after being discharged from a furnace, a steel billet is rolled through a roughing mill and a finishing mill, is straightened through a pre-straightening machine, is cooled through ultra-fast cooling, is straightened through a fine straightening machine and then reaches a sectioning shear to be prepared for shearing and sectioning; S2, according to the three-level steel plate size issued by an MES and the position of an on-site scaleplate, a sectioning shear operator inches an advancing or retreating roller way button, and the steel plate is conveyed to the corresponding position; S3, a shearing button is pressed down, and shearing is started; S4, an upper blade falls from the inner side to the outer side to shear the steel plate, when the steel plate is not sheared off after the upper blade falls for 1 second, a post-shearing swing table roller way is started, and after the steel plate is sheared off, a first sub-plate is conveyed to a cooling bed roller way; S5, after the steel plate is shorn off, the upper blade is lifted; and S6, a before-shearing roller way is started, and then a second sub-plate steel plate is conveyed to the cooling bed roller way. The downward bending degree of a shearing opening of the steel plate is effectively reduced, and shearing buckling caused by the fact that the inner side is pressed in the shearing process of the steel plate is reduced.

Owner:NANJING IRON & STEEL CO LTD

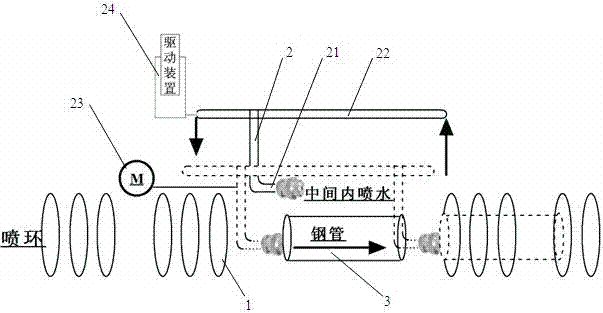

An online flatness quality evaluation device and method for skin pass unit

ActiveCN105363801BDoes not affect production rhythmTimely organization and regulationMeasuring devicesMetal rolling arrangementsWave shapeMarine engineering

The invention discloses an online strip shape quality assessment device and method for a temper mill and belongs to the technical field of hot rolling. The online strip shape quality assessment device for the temper mill comprises an online quality inspection platform, an observation ruler, and an operation table, wherein the online quality inspection platform is arranged at an outlet of the temper mill, the observation ruler is arranged on the online quality inspection platform, and the operation table is opposite to the online quality inspection platform. The online strip shape quality assessment device and method for the temper mill can be used for judging the status of the strip shape of flattened strip steel online in real time; measurement is carried out without a halt, the rhythm of production is not influenced, the status of the strip shape of the strip steel can be accurately judged, and operating personnel can organize regulation and control over the strip shape of the strip steel in time; thus, the strip shape quality is improved, the rhythm of production is improved, and the secondary flatting rate of the wave shape is lowered.

Owner:BEIJING SHOUGANG CO LTD

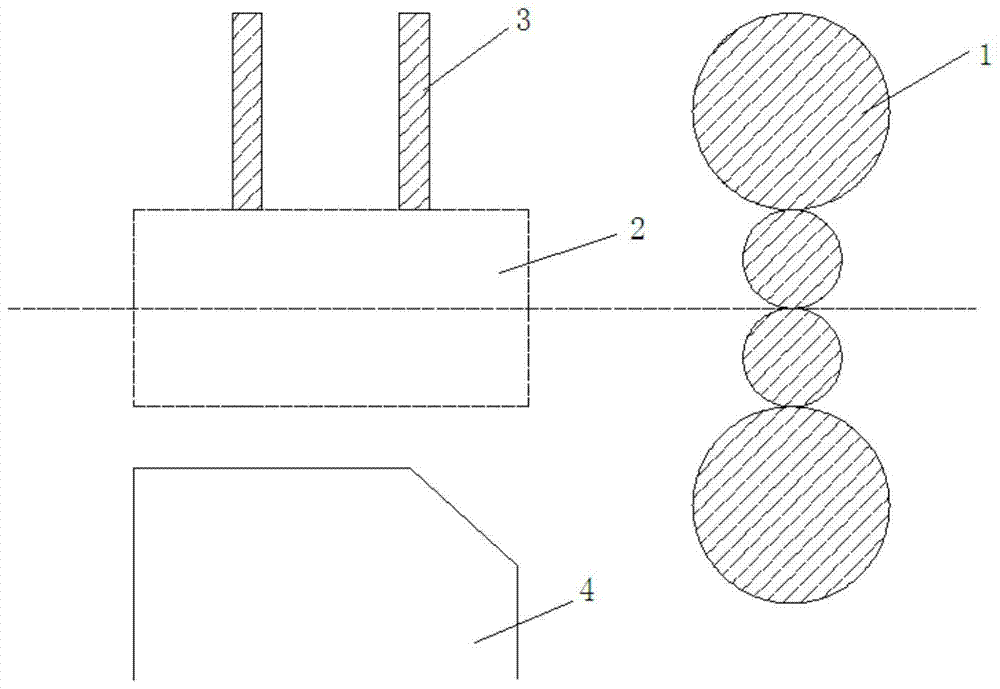

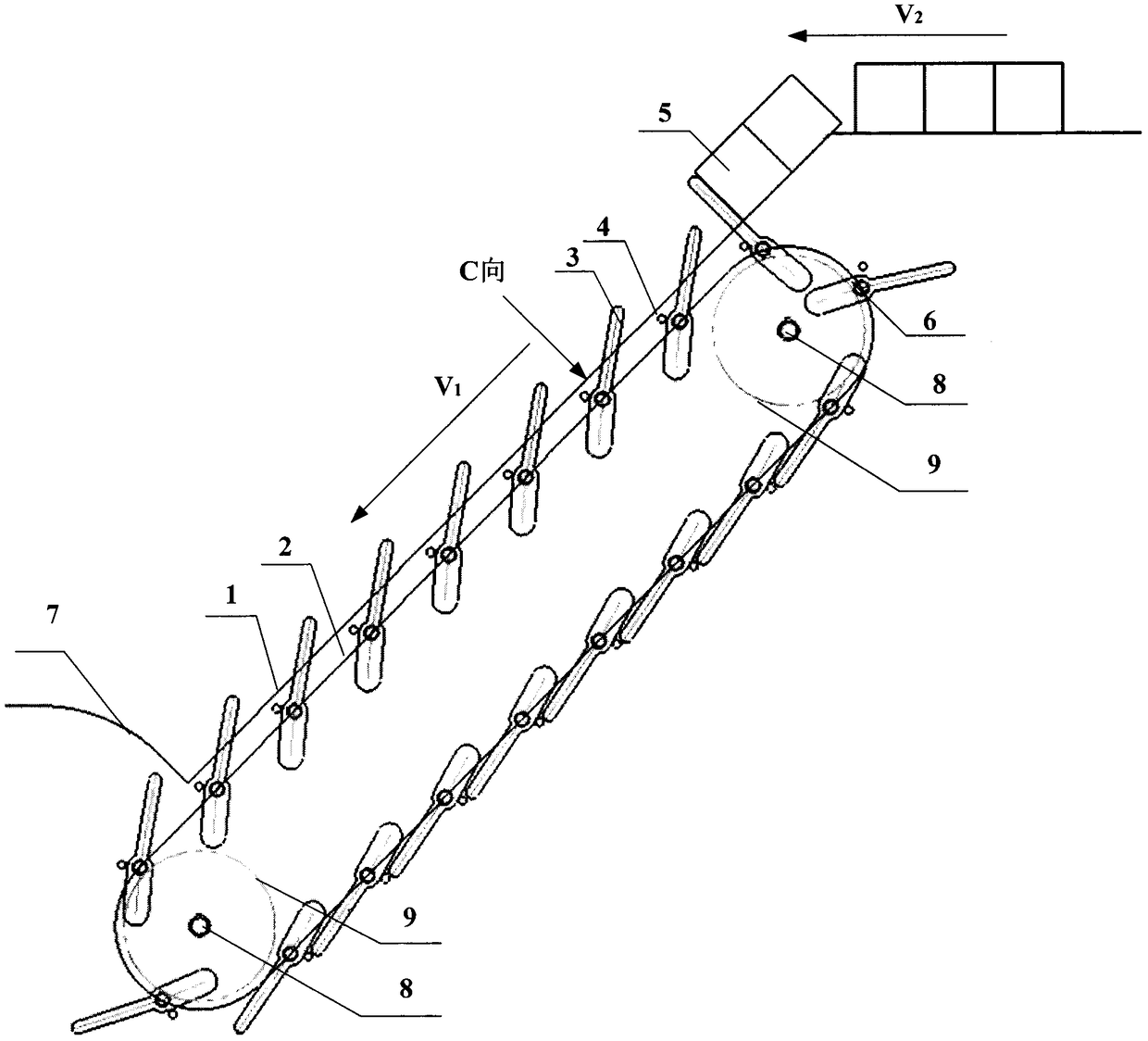

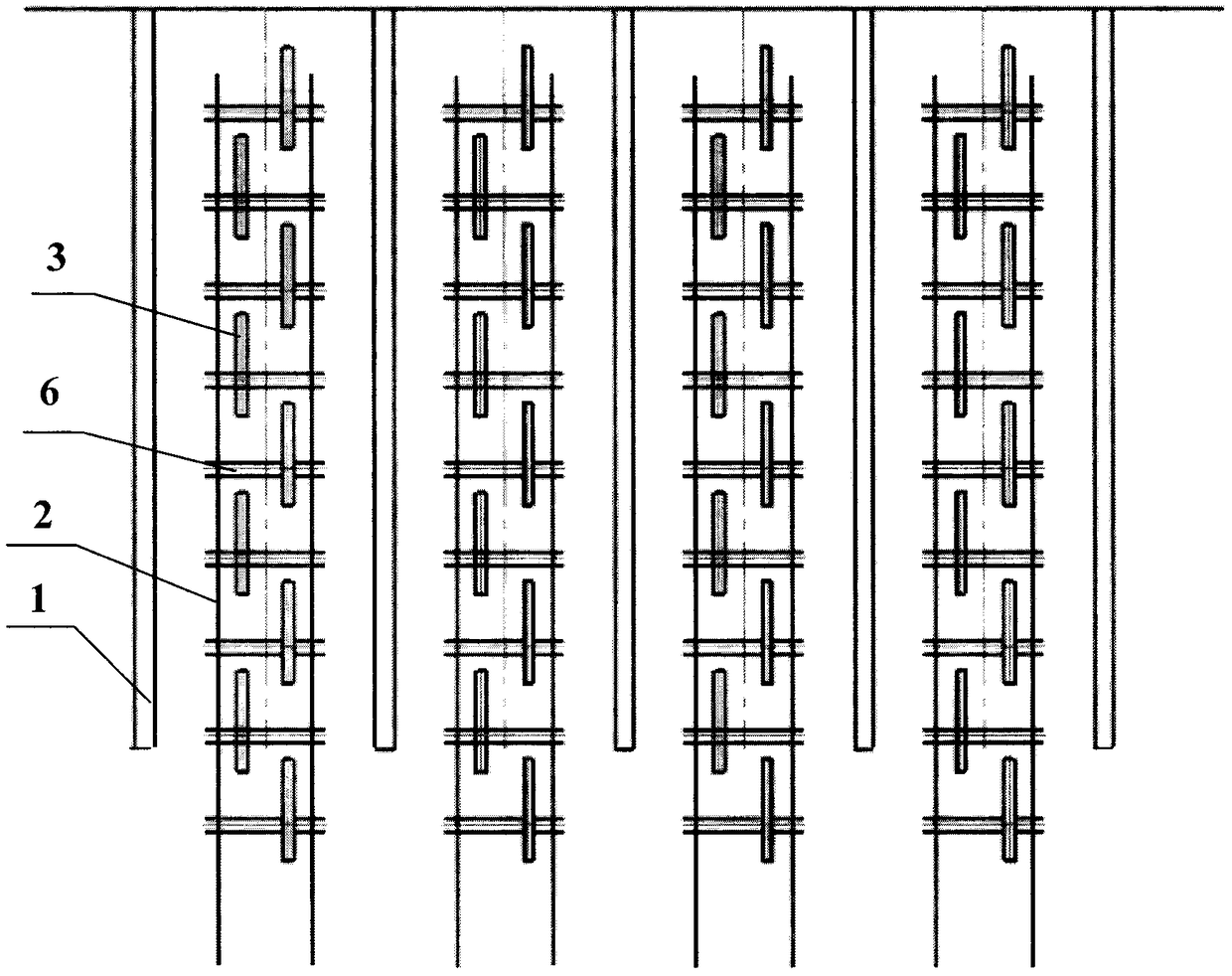

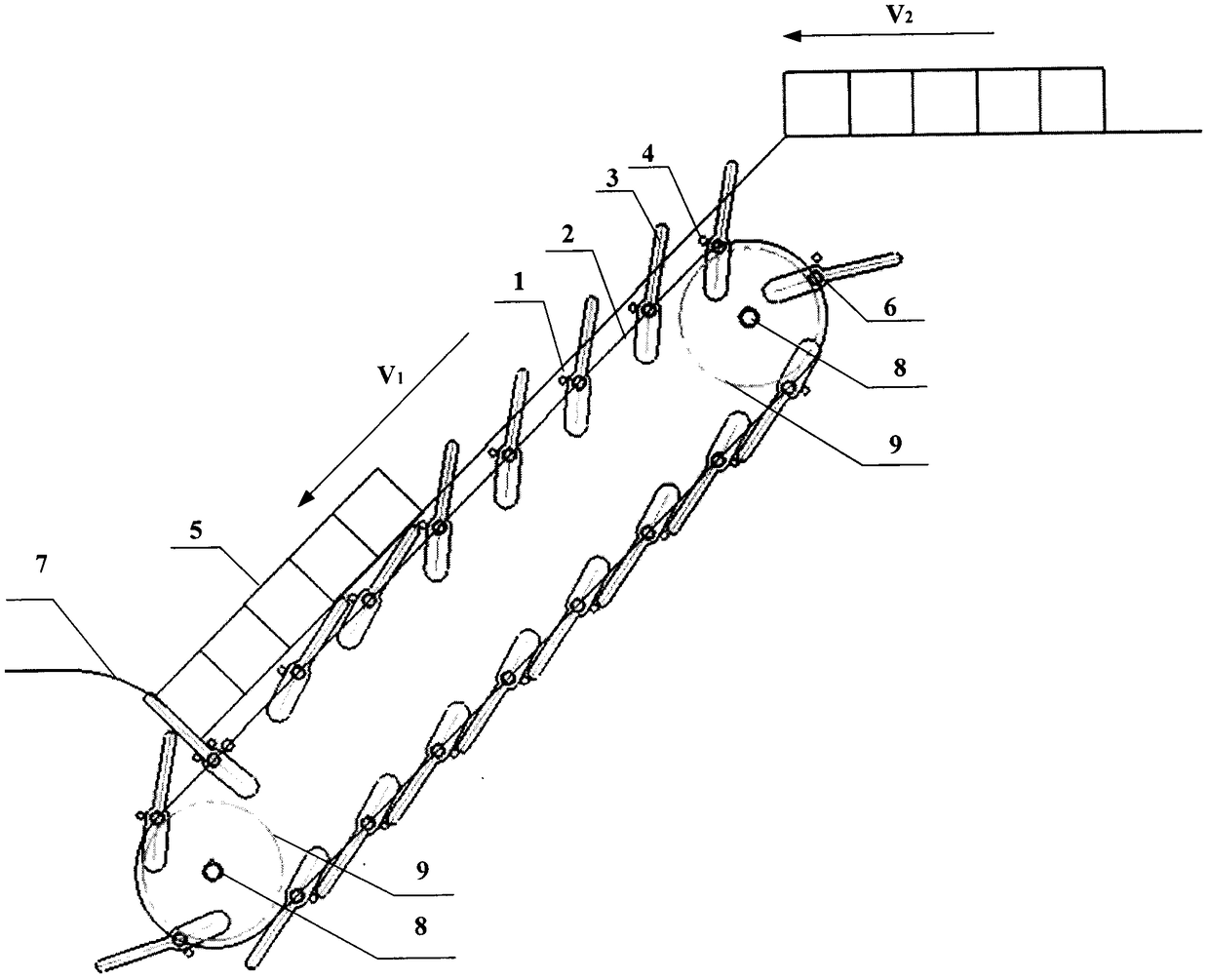

Lifting rotary type billet feeding device

The invention relates to the field of hot delivery of continuous casting billets, in particular to a lifting rotary type billet feeding device. The device is characterized by comprising an inclined face sliding rail (1), a chain (2), a rotating baffle (3), a shaft 1 (4) , a cast billet (5), a shaft 2 (6), a fixed sliding rail (7), a gear shaft (8) and a gear (9). The rotating baffle (3) is fixed to the chain (2) by the shaft 2 (6), and the cast billet (5) is supported by the rotating baffle (3) in the process of sliding down along the inclined face sliding rail (1) and conveyed to the lowest position of the fixed sliding rail (7) at a certain speed. The device is compact in structure, stable in operation, safe and reliable.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

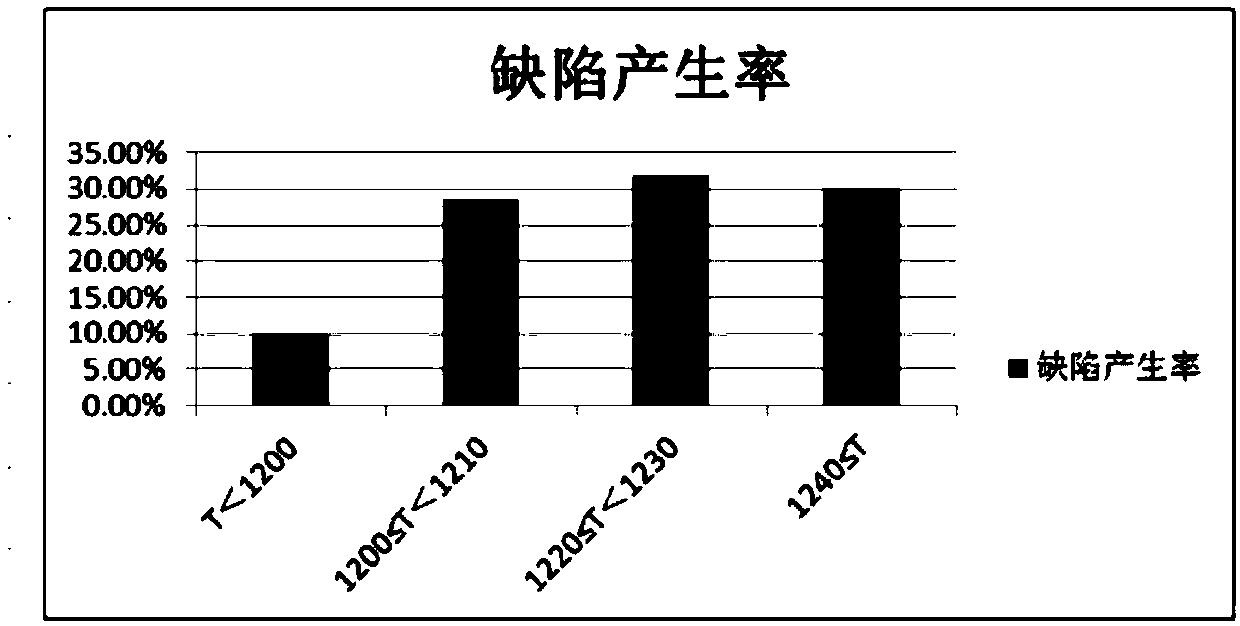

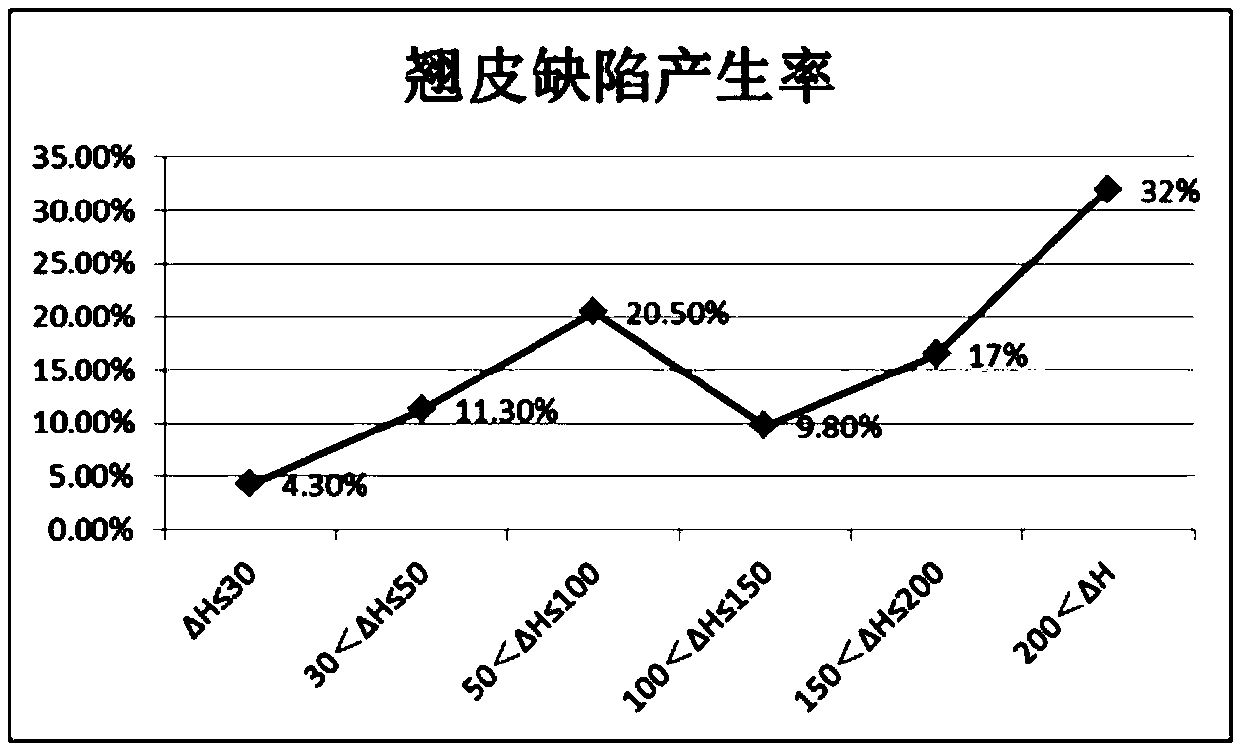

A control method for edge warping of hot-rolled steel plate

ActiveCN108246812BReduce the probability of warping and residual products on the edgeLow heating temperatureProfile control deviceHeating timeHeating temperature

The invention discloses a control method for edge skin upwarp of hot-rolled steel plates. The control method comprises the following steps: the heating temperature of plate blanks of the hot-rolled steel plates is controlled to be not higher than 1200 DEG C, and the heating time is not higher than 200 minutes; the width reducing quantity of a plate blank width determiner is adjusted; the width reducing quantity of a second-grade vertical roller is adjusted; and the plate blanks of the hot-rolled steel plates are rolled by adopting the adjusted temperature and width. The control method for edgeskin upwarp of the hot-rolled steel plates effectively reduces the heating energy consumption through reducing the heating temperature of the plate blanks and shortening the furnace time, meanwhile,can reduce the burning loss of the plate blanks, improves the yield, can reduce the production cost, optimizes the width reducing quantity of the plate blank width determiner and the width reducing quantity distribution of the second-grade vertical roller, is free of influencing normal production rhythm, and meanwhile, is free of additional requirements on the equipment precision and excellent inpopularization value.

Owner:内蒙古包钢稀土钢板材有限责任公司

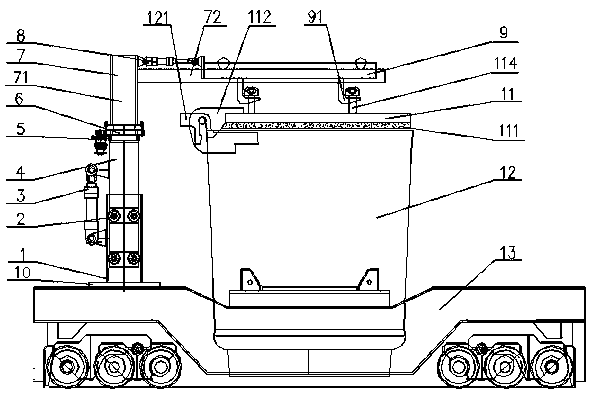

Online calibration device for bale weighing sensor of a continuous casting machine in a steel plant and use method

PendingCN113984173ARealize online calibrationDoes not affect production rhythmWeighing apparatus testing/calibrationProcess engineeringSteel mill

The invention relates to an online calibration device for a bale weighing sensor of a continuous casting machine in a steel plant. The online calibration device comprises a driving module arranged on one side of a bale arm and a calibration module arranged on the driving module, the driving module comprises a mechanical arm and a calibration part, the calibration part is arranged at the top end of the mechanical arm, and a calibration cavity convenient for placing the bale arm is formed in the calibration part; the calibration module comprises a hydraulic station and a hydraulic jack, an ejector rod of the hydraulic jack faces downwards, the bottom of the hydraulic jack is fixedly connected with the inner top of the calibration cavity, the hydraulic station is arranged on the outer side of the calibration part and located on the mechanical arm, and the hydraulic station communicates with the hydraulic jack through an oil pipe. The invention also discloses a use method of the online calibration device for the bale weighing sensor of the continuous casting machine in the steel plant, which is used for carrying out online calibration on an unloaded bale arm during normal production of the continuous casting machine. The weighing accuracy is improved on the premise that production is not affected, and normal production is facilitated.

Owner:GUANGDONG GUANGDONG SHAOGANG ENG TECH

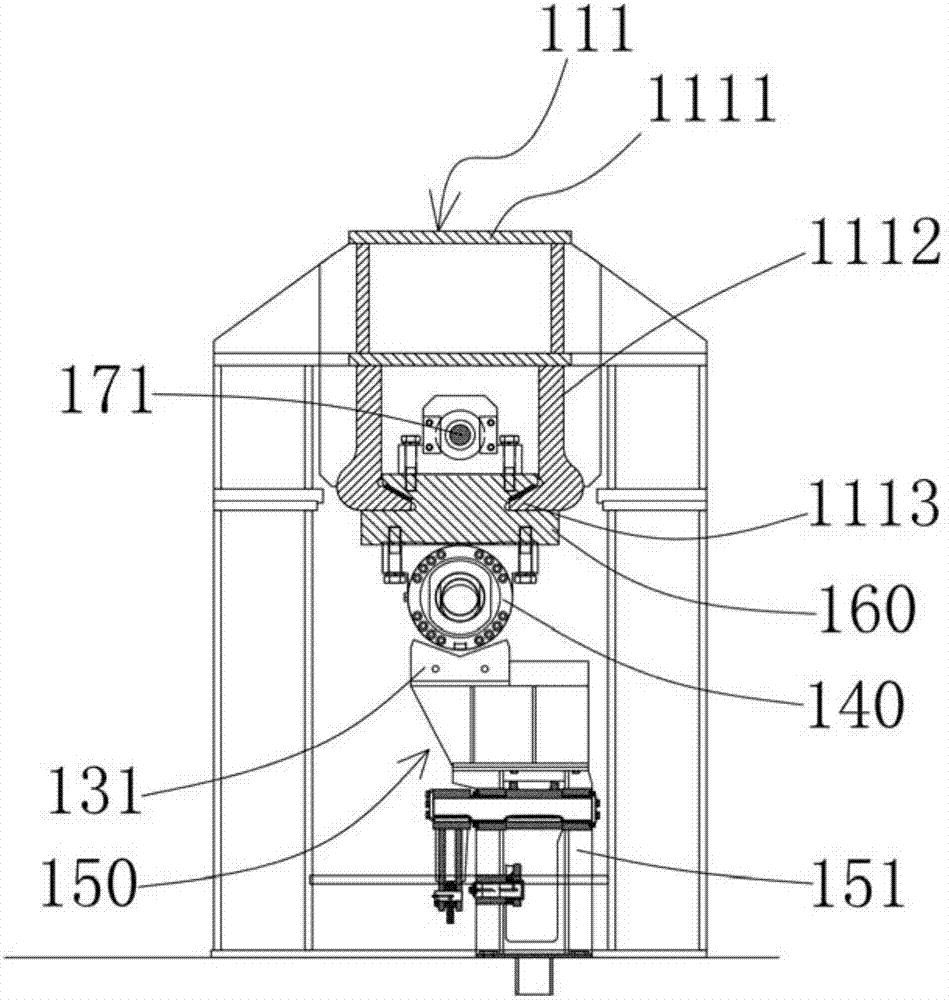

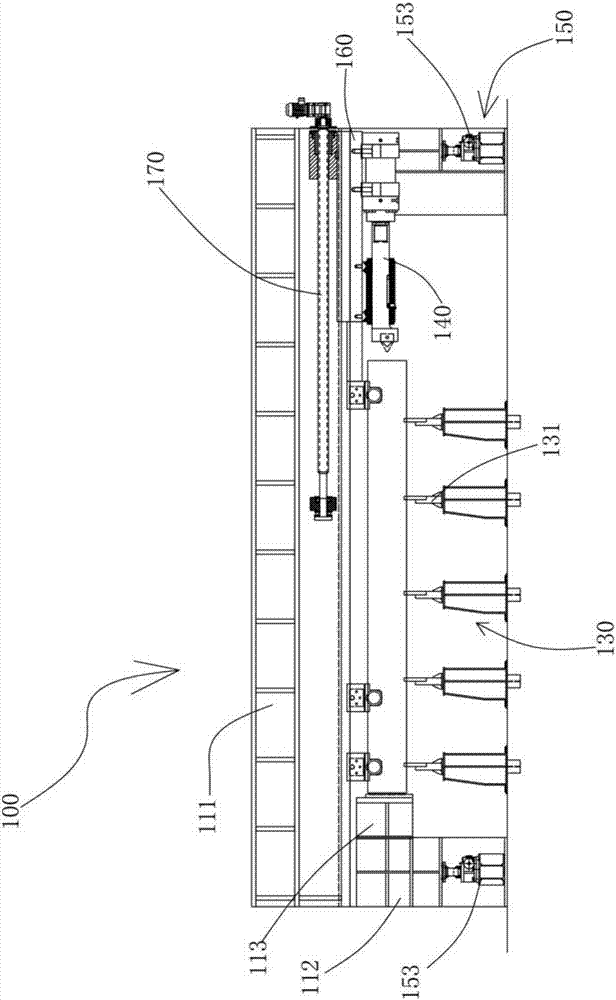

The ladle is fully covered with a cover device and a molten steel carrying device

ActiveCN107096914BLow headroom requirementsNo additional construction costs requiredMelt-holding vesselsHydraulic cylinderStructural engineering

The invention provides a steel ladle full-course covering and uncovering device and a molten steel carrying device. The steel ladle full-course covering and uncovering device comprises a fixed stand column, a lifting hydraulic cylinder, a lifting stand column, a rotation driving motor, a slewing bearing, a rotary frame, a transverse moving hydraulic cylinder and a transverse moving trolley. The fixed stand column is fixed on a platform; the lifting stand column is connected onto the fixed stand column in a sleeving manner; the lifting hydraulic cylinder drives the lifting stand column to go up and down along the fixed stand column; the rotary frame comprises a vertical rod and a horizontal rod connected with the vertical rod; the bottom of the vertical rod and the top of the lifting stand column are connected through the slewing bearing; the rotation driving motor is fixed on the lifting stand column and drives the slewing bearing to rotate so as to drive the rotary frame to rotate; the transverse moving trolley is positioned on the horizontal rod; and the transverse moving hydraulic cylinder drives the transverse moving trolley to move along the horizontal rod. The steel ladle full-course covering and uncovering device has low requirements for clearance above a steel ladle, is free of impact during covering and uncovering, and is low in equipment failure rate, small in maintenance quantity and smooth in production.

Owner:WISDRI ENG & RES INC LTD

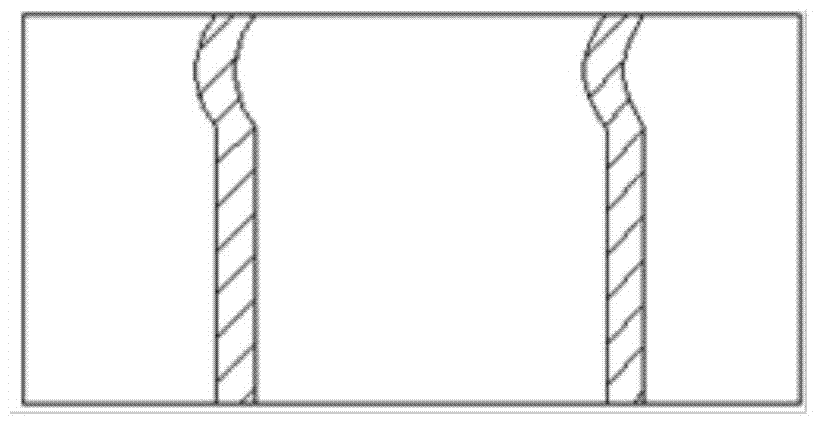

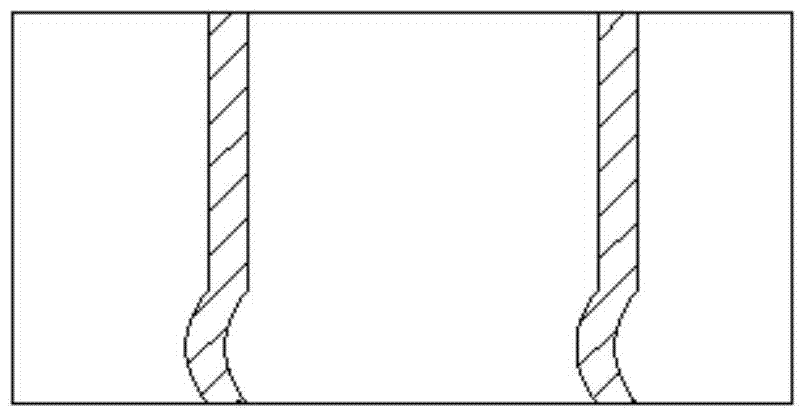

Metal circular saws for sawing small cross-sections of finished steel

ActiveCN105618846BDoes not affect production rhythmImprove rigidityMetal sawing devicesPositioning apparatusCircular discCircular saw

The invention discloses a metal disk saw for sawing small-section finished product steel, which is designed for improving the rigidity, the sawing precision and the sawing efficiency of a metal saw. The metal disk saw for sawing small-section finished product steel is of a box type frame structure, wherein a tabletop clamping device is arranged on one lateral side of the box type frame structure, and a saw head feeding device and a saw head assembling device are both embedded into the box type frame structure, so that the rigidity of equipment is increased, sawing force is converted into internal force, and influence to equipment foundation is reduced; a fixed pressing block and a movable pressing block which are mutually matched to clamp to-be-sawn steel are good in clamping effect, so that the sawing precision is improved; and a saw blade fixing mechanism is used for fixedly arranging a saw blade below a steel clamping plane, namely a saw head is in underneath type arrangement, and the saw blade cuts from bottom to top and quickly withdraws after sawing, thus avoiding influence to the production rhythm of a working face and improving production efficiency.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com