Inserting coil steel reel diameter measuring method and system

A technology for diameter measurement and steel coils, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor reliability, low precision of steel coil radius measurement, complicated operation, etc., and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment of the present application provides a method and system for measuring the diameter of the off-line steel coil, which solves the technical problems of low steel coil radius measurement accuracy, poor reliability, complicated operation, and high cost in the prior art; it achieves the improvement of measurement accuracy and reliability. Sexuality, the technical effect of simplifying the measurement operation.

[0031] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

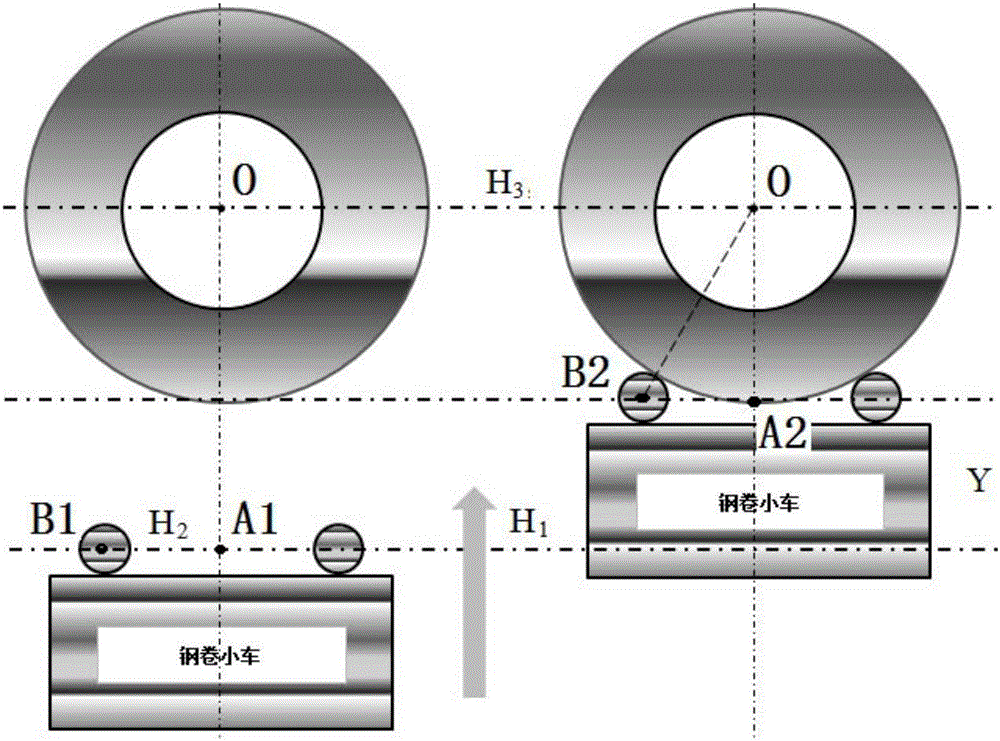

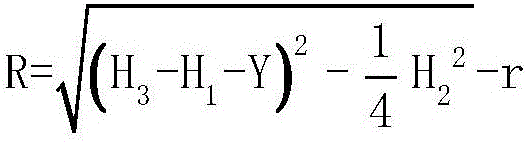

[0032] After the steel coil comes off the assembly line, the steel coil trolley lifts up to perform the coil receiving operation. When it touches the steel coil, the center of the steel coil, the center of the cradle roller of the steel coil trolley and the midpoint of the circular line connecting the two cradle rollers form a right triangle; Based on this, a mathematical calculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com