Method for controlling widmannstatten structure in upgrade of C-Mn steel

A technology of Widmanderman's structure and control method, applied in the field of steel rolling, can solve the problems of TMCP steel plate performance and other problems, and achieve the effect of improving the Widmancer's structure without affecting the production rhythm, and improving the toughness and plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

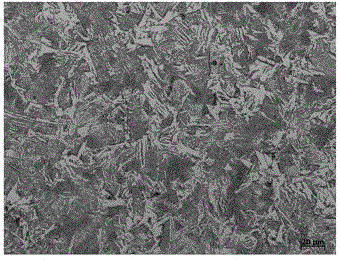

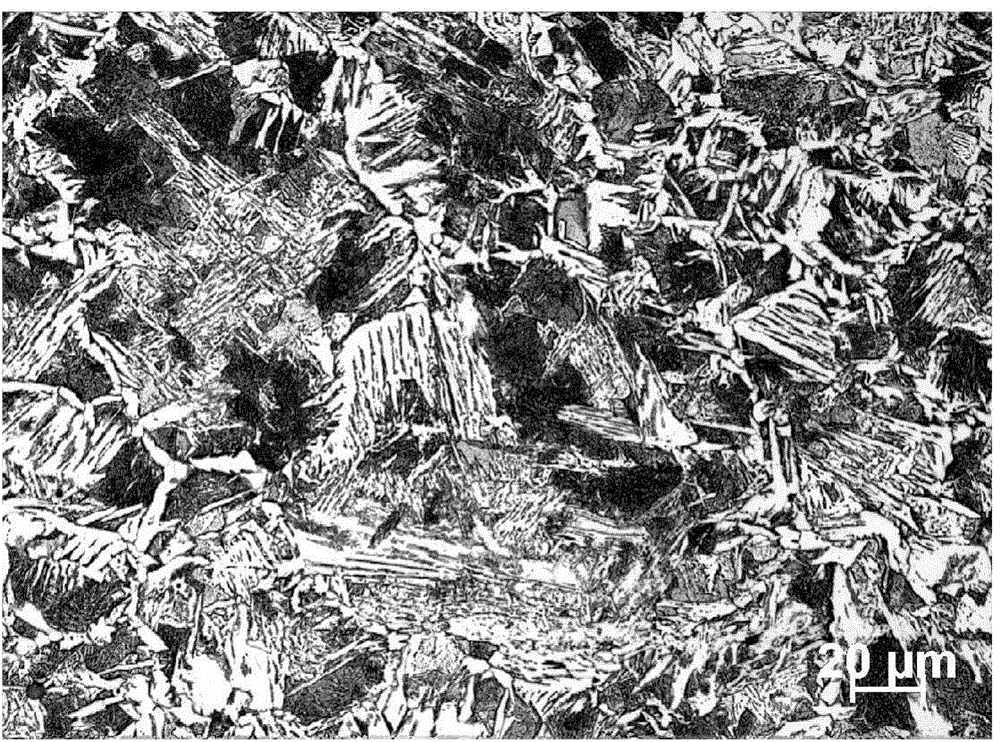

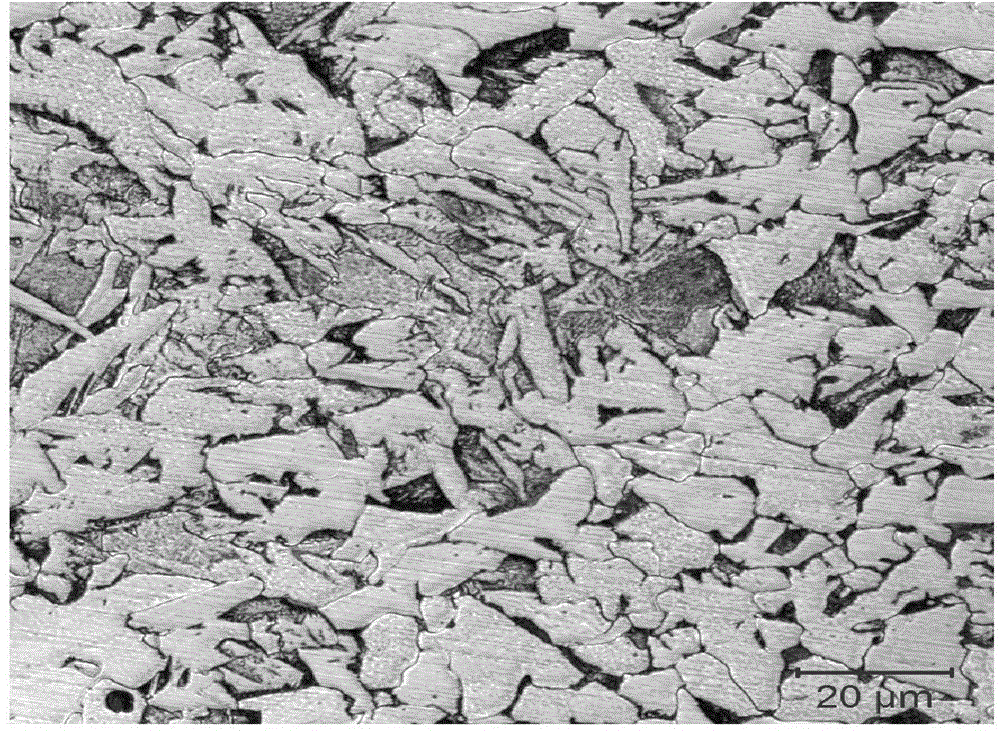

Image

Examples

Embodiment 1

[0029] The method for controlling the Widmanstatten structure of C-Mn upgraded steel in this embodiment, the chemical composition mass percentage of C-Mn upgraded steel is: C: 0.17%, Mn: 0.95%, P: 0.009%, S: 0.008%, Si: 0.22 %, Als: 0.025%, N is 0.0050%, the balance is Fe and unavoidable impurities;

[0030] The thickness of the steel billet taken is 180mm, and the thickness of the finished product is 14mm; the heating temperature is 1170°C, the soaking temperature is 1160°C, the heating time is 148min, and the furnace temperature is 1140°C; The stage cumulative reduction rate is 66.7% (42→14), the cooling start temperature is 761°C, the cooling rate is 10°C / s, the first 4 sets of headers are used for cooling, and the cooling intensity of the first 4 sets of headers is 2000m 3 / h, the last 6 sets of headers are weakly cooled, and the cooling strength of the last 6 sets of headers is 1500m 3 / h; the red temperature is 639°C.

Embodiment 2

[0032] The method for controlling the Widmanstatten structure of C-Mn upgraded steel in this embodiment, the chemical composition mass percentage of C-Mn upgraded steel is: C: 0.163%, Mn: 0.97%, P: 0.006%, S: 0.005%, Si: 0.24 %, Als: 0.030%, N is 0.0055%, the balance is Fe and unavoidable impurities;

[0033] The thickness of the steel billet taken is 180mm, and the thickness of the finished product is 22mm; the heating temperature is 1175°C, the soaking temperature is 1160°C, the heating time is 150min, and the furnace temperature is 1140°C; The stage cumulative reduction rate is 63.3% (60→22), the cooling start temperature is 775°C, the cooling rate is 12.5°C / s, the first 4 sets of headers are used for cooling, and the cooling intensity of the first 4 sets of headers is 2500m 3 / h, the last 6 sets of headers are weakly cooled, and the cooling strength of the last 6 sets of headers is 1900m 3 / h, the red temperature is 630°C.

Embodiment 3

[0035] The method for controlling the Widmanstatten structure of C-Mn upgraded steel in this embodiment, the chemical composition mass percentage of C-Mn upgraded steel is: C: 0.168%, Mn: 0.91%, P: 0.012%, S: 0.007%, Si: 0.21 %, Als: 0.036%, N is 0.0058%, the balance is Fe and unavoidable impurities;

[0036] The thickness of the steel billet taken is 220mm, and the thickness of the finished product is 30mm; the heating temperature is 1180°C, the soaking temperature is 1160°C, the heating time is 170min, and the furnace temperature is 1140°C; The cumulative reduction rate in the rolling stage is 58.3% (72→30), the starting cooling temperature is 770°C, and the cooling rate is 14°C / s. 3 / h, the last 6 sets of headers are weakly cooled, and the cooling strength of the last 6 sets of headers is 2300m 3 / h, the red temperature is 615°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com