Adjusting device for welding gun

A technology for adjusting devices and welding torches, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem that it cannot stably adapt to the welding of ultra-long section steel, cannot continuously maintain the optimal welding torch position, and affects the welding effect and quality of section steel. and other problems, to achieve the effect of easy maintenance, without affecting the production rhythm, and realizing automatic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

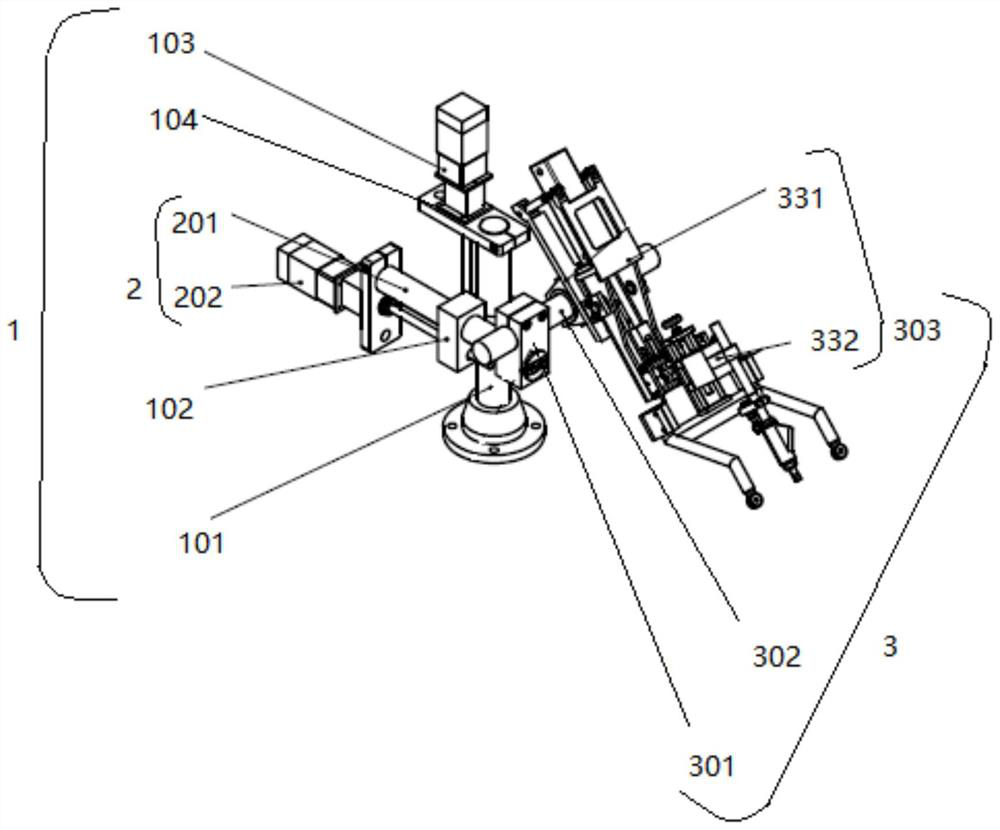

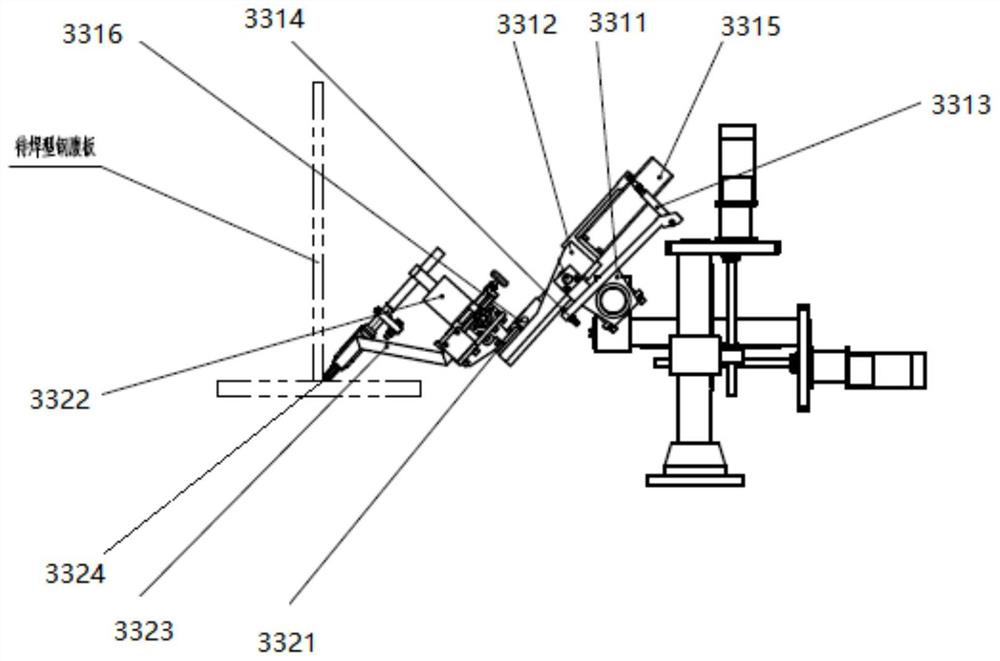

[0012] Such as figure 1 and figure 2 As shown, this embodiment provides an adjustment device for a welding torch, including: a lifting mechanism 1 for adjusting the height of the welding torch; a translation mechanism 2 arranged on the lifting mechanism 1 for adjusting the horizontal position of the welding torch; The mechanism 3 is arranged on the translation mechanism 2, and is used to adjust the inclination angle of the welding torch in real time.

[0013] The welding torch adjustment device of this embodiment adjusts the height and horizontal position of the welding torch by controlling the actions of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com