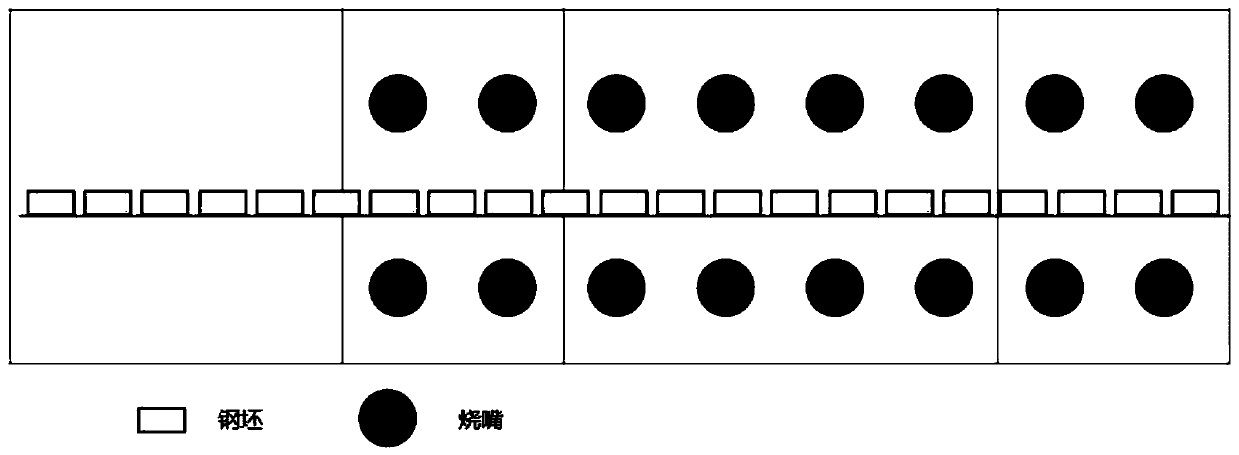

Automatic distinguishing control method for maximum heating temperature of steel rolling heating furnace

A technology of heating temperature and control method, applied in the field of steel rolling, can solve problems such as reducing productivity, affecting production rhythm, and lacking better management methods, and achieves the effect of improving product quality and realizing fine control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

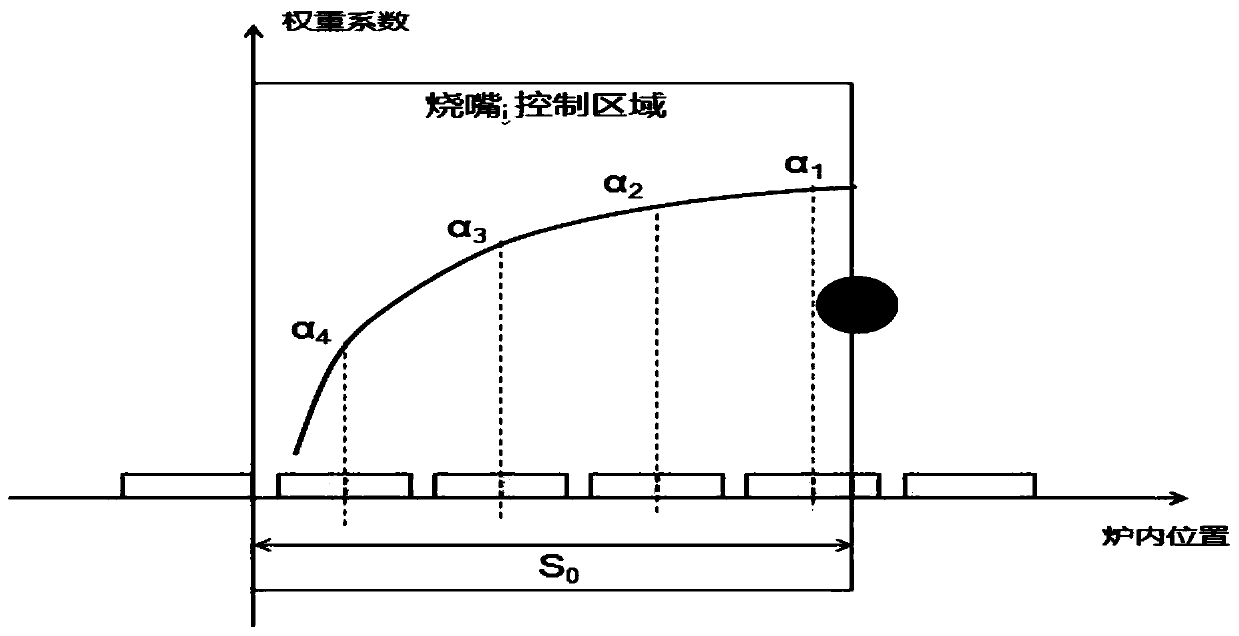

Method used

Image

Examples

Embodiment 1

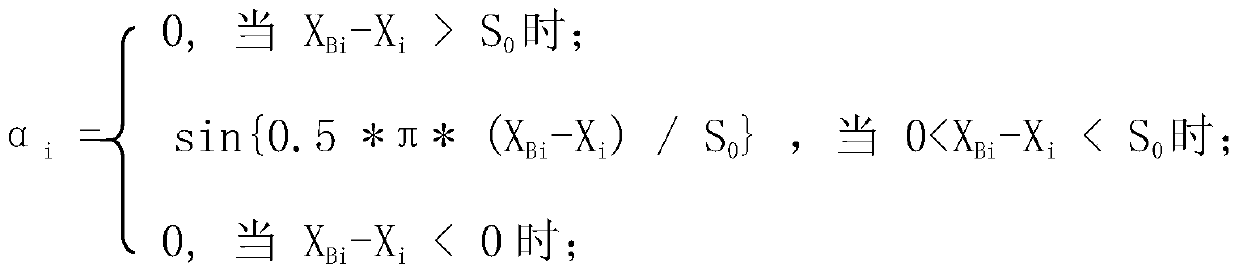

[0022] In this implementation, 20 billets are selected for testing, the first 10 are 304 steel billets, and the last 10 are 316L steel billets. Taking the last burner control area of the last section of the heating furnace as an example, the second-stage combustion control system of the heating furnace calculates the initial temperature setting T 0 = 1253°C. According to process requirements, the maximum heating temperature requirement of 304 steel grade is artificially given T im(304) =1245℃, 316L steel grade maximum heating temperature requirement T im(316L) = 1240°C. When the burner control area is all 304 steel:

[0023] T limit(304) =Σ(α i* T im(304) ) / Σα i =Σα i / Σα i *1245=1245℃;

[0024] According to the formula T final =min(T 0 , T limit(304) )

[0025] Get T final(304) =min(1253,1245)=1245℃

[0026] In the same way, when the burner control area is all 316L steel:

[0027] T limit(316L) =Σ(α i* T im(316L) ) / Σα i =Σα i / Σα i *1240=1240℃;

[0028] According to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com