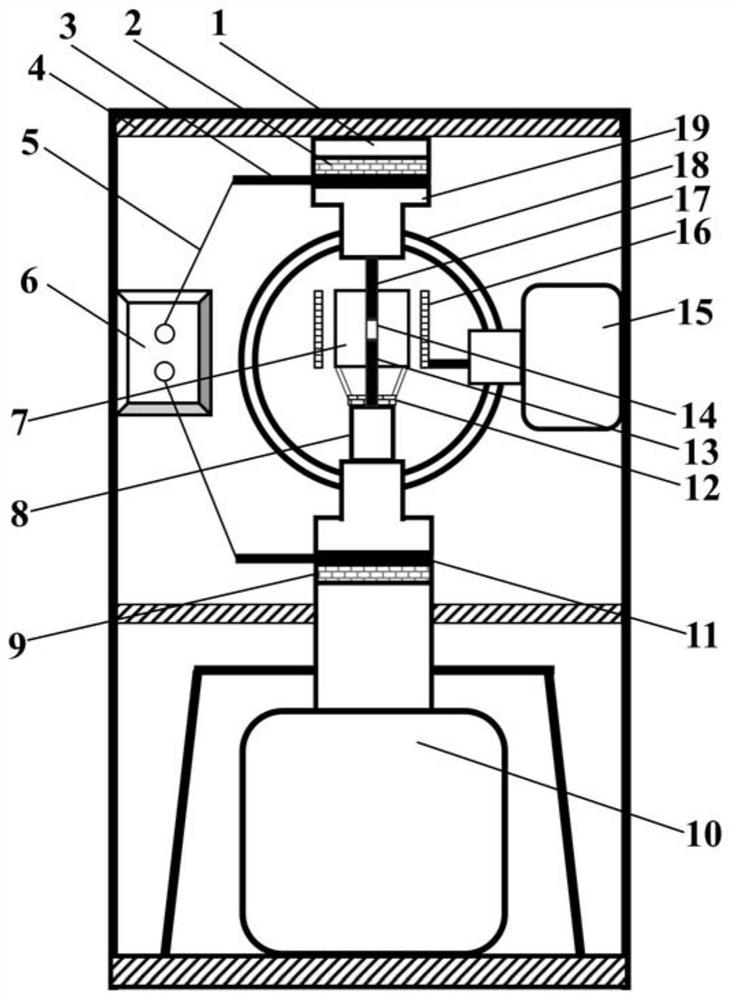

Pressure-assisted induction heating vacuum atmosphere flash sintering device

A technology of induction heating and sintering device, which is applied in the direction of electric furnace heating, maintenance of heating chamber, lighting and heating equipment, etc. It can solve the problems of large energy and achieve the effect of overcoming inherent shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

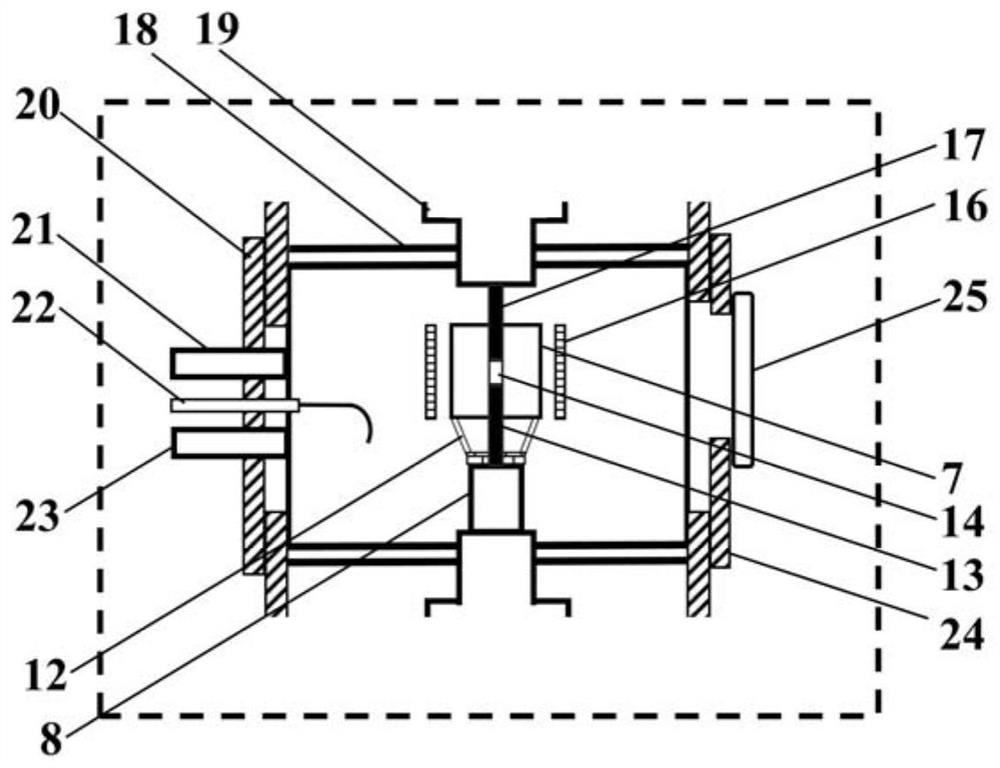

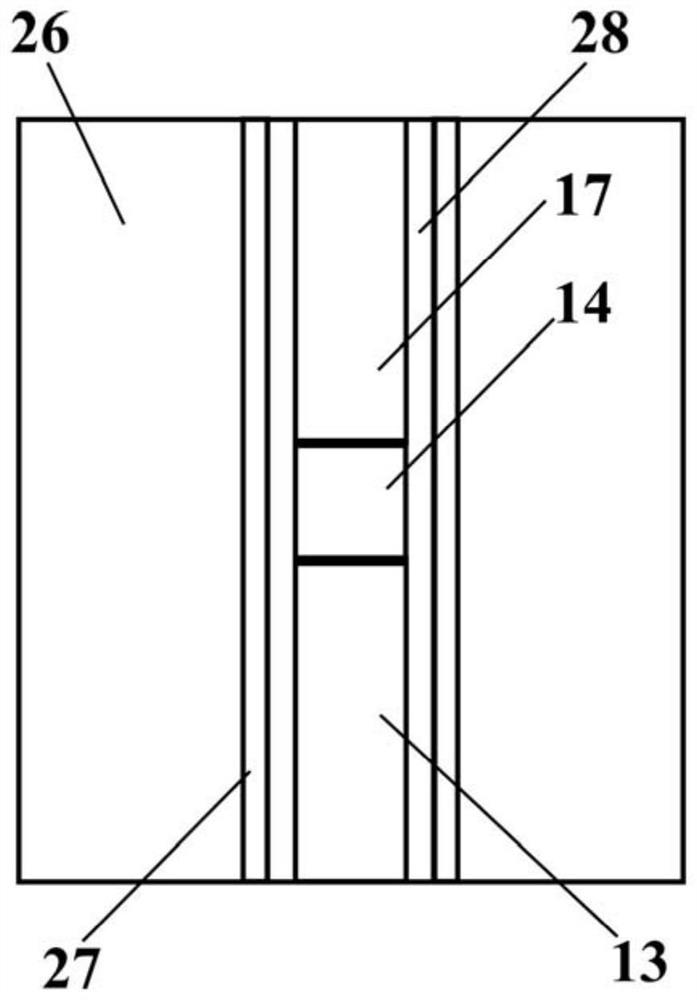

Method used

Image

Examples

Embodiment 1

[0049] This example is pressure assisted flash sintering of commercial ZnO powder. The induction heating preheating temperature is set to 770°C, the pressure is 26MPa, and the sample diameter is 6.4mm. The flash power supply uses a low-power pulsed DC power supply, the initial electric field strength is about 80V / cm, the frequency is 1000Hz, and the pulse width is 128μs. In this embodiment, the flash current is set to 0A (that is, the flash power supply is not turned on), and the temperature is kept at the preheating temperature and constant pressure for 30s. The photo of the appearance of the sample and the microstructure are as follows: Figure 5 As shown in (a), the density is 71.1%, and the grain size is 130.1nm.

Embodiment 2

[0051] This example is pressure assisted flash sintering of commercial ZnO powder. The induction heating preheating temperature is set to 770°C, the pressure is 26MPa, and the sample diameter is 6.4mm. The flash power supply uses a low-power pulsed DC power supply, the initial electric field strength is about 80V / cm, the frequency is 1000Hz, and the pulse width is 128μs. In this embodiment, the flash current is set to 50A, the power is turned on at the preheating temperature and constant pressure, and it is turned off immediately after 30s. The photos of the appearance of the sample and the microstructure are as follows: Figure 5 As shown in (b), the density is 77.3%, and the grain size is 200.7nm.

Embodiment 3

[0053]This example is pressure assisted flash sintering of commercial ZnO powder. The induction heating preheating temperature is set to 770°C, the pressure is 26MPa, and the sample diameter is 6.4mm. The flash power supply uses a low-power pulsed DC power supply, the initial electric field strength is about 80V / cm, the frequency is 1000Hz, and the pulse width is 128μs. In this embodiment, the flash current is set to 100A, the power is turned on at the preheating temperature and constant pressure, and it is turned off immediately after 30s. The appearance photos and microstructure of the sample are as follows: Figure 5 As shown in (c), the density is 91.9%, and the grain size is 687.5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com