Synthesis method of self-repairing microcapsule and spraying protective coating material capable of realizing self-repairing of scratches

A technology of self-healing microcapsules and a synthesis method, which is applied to the synthesis of self-healing microcapsules and the field of scratch self-repairing spray protective coating materials, can solve problems such as low repair efficiency, achieve rapid response, prolong service life, and improve mechanical properties. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of scratch self-repairing spray protective coating material that present embodiment proposes, comprises A component and B component;

[0059] The raw material mass fraction of described A component is as follows:

[0060] MDI-100 is 45 parts;

[0061] Polytetrahydrofuran diol is 45 parts;

[0062] 5 servings of self-healing microcapsules;

[0063] Dibutylbenzyl phthalate is 5 parts.

[0064] The mass parts of each composition in described B component is:

[0065] T-403 polyether amine is 50 parts;

[0066] Diaminodimethylthiotoluene is 40 parts;

[0067] Composite metal microcapsule emulsion is 8 parts;

[0068] Aluminum fine powder is 2 parts.

[0069] Preparation of self-healing microcapsules:

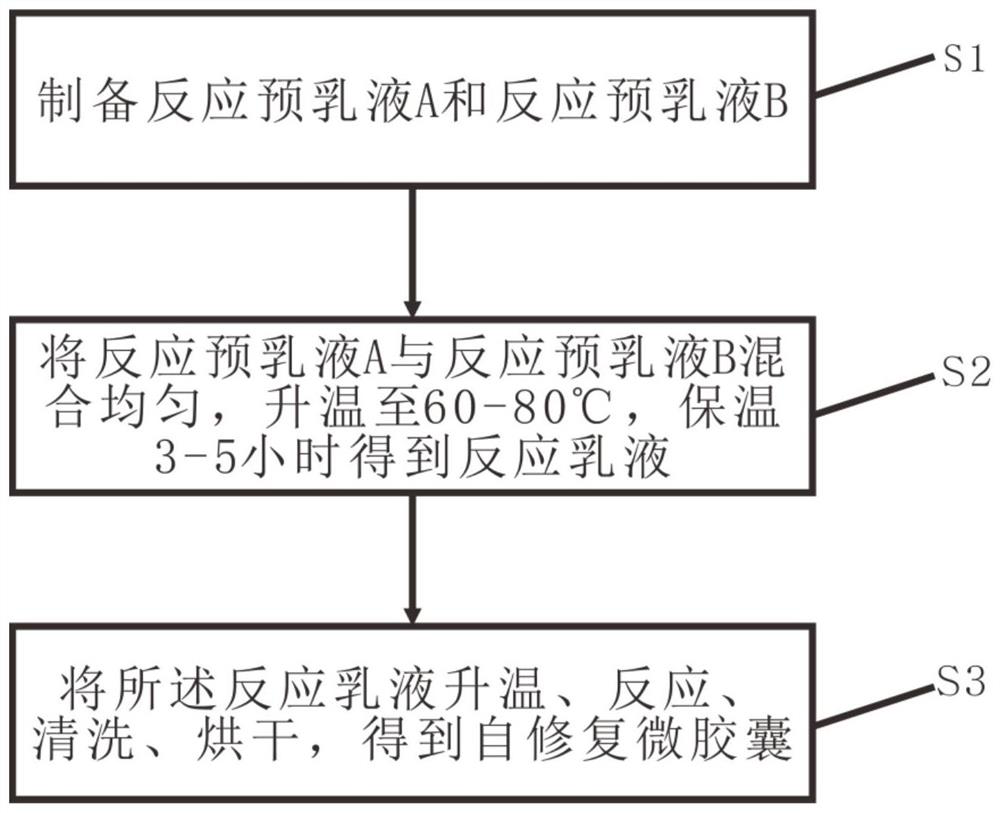

[0070] Take methyl methacrylate as the wall material, add 3.5g ethylene maleic anhydride copolymer (EMA) into 50mL deionized water and heat to dissolve to obtain 5.0% EMA aqueous solution; 9.80g methyl methacrylate, 1.0g peroxide Add benzoyl to a 500mL beaker, ...

Embodiment 2

[0077] A kind of scratch self-repairing spray protective coating material that present embodiment proposes, comprises A component and B component;

[0078] The raw material mass fraction of described A component is as follows:

[0079] MDI-50 is 45 parts;

[0080] Polytetrahydrofuran diol is 42 parts;

[0081] 8 servings of self-healing microcapsules;

[0082] Dibutylbenzyl phthalate is 5 parts.

[0083] The mass parts of each composition in described B component is:

[0084] T-403 polyether amine is 50 parts;

[0085] Diaminodimethylthiotoluene is 40 parts;

[0086] Composite metal microcapsule emulsion is 8 parts;

[0087] Aluminum fine powder is 2 parts.

[0088] Preparation of self-healing microcapsules:

[0089] Take methyl methacrylate as the wall material, add 3.5g ethylene maleic anhydride copolymer (EMA) into 50mL deionized water and heat to dissolve to obtain 5.0% EMA aqueous solution; 9.80g methyl methacrylate, 1.0g peroxide Add benzoyl to a 500mL beaker, a...

Embodiment 3

[0096] A kind of scratch self-repairing spray protective coating material that present embodiment proposes, comprises A component and B component;

[0097] The raw material mass fraction of described A component is as follows:

[0098] MDI-50 is 45 parts;

[0099] Polytetrahydrofuran diol is 45 parts;

[0100] 5 servings of self-healing microcapsules;

[0101] Dibutylbenzyl phthalate is 5 parts.

[0102] The mass parts of each composition in described B component comprises:

[0103] T-403 polyether amine is 45 parts;

[0104] Diaminodimethylthiotoluene is 45 parts;

[0105] Composite metal microcapsule emulsion is 8 parts.

[0106] Aluminum fine powder is 2 parts.

[0107] Preparation of self-healing microcapsules:

[0108] Take methyl methacrylate as the wall material, add 3.5g ethylene maleic anhydride copolymer (EMA) into 50mL deionized water and heat to dissolve to obtain 5.0% EMA aqueous solution; 9.80g methyl methacrylate, 1.0g peroxide Add benzoyl to a 500mL be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com