Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

887results about How to "Reduce iron loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

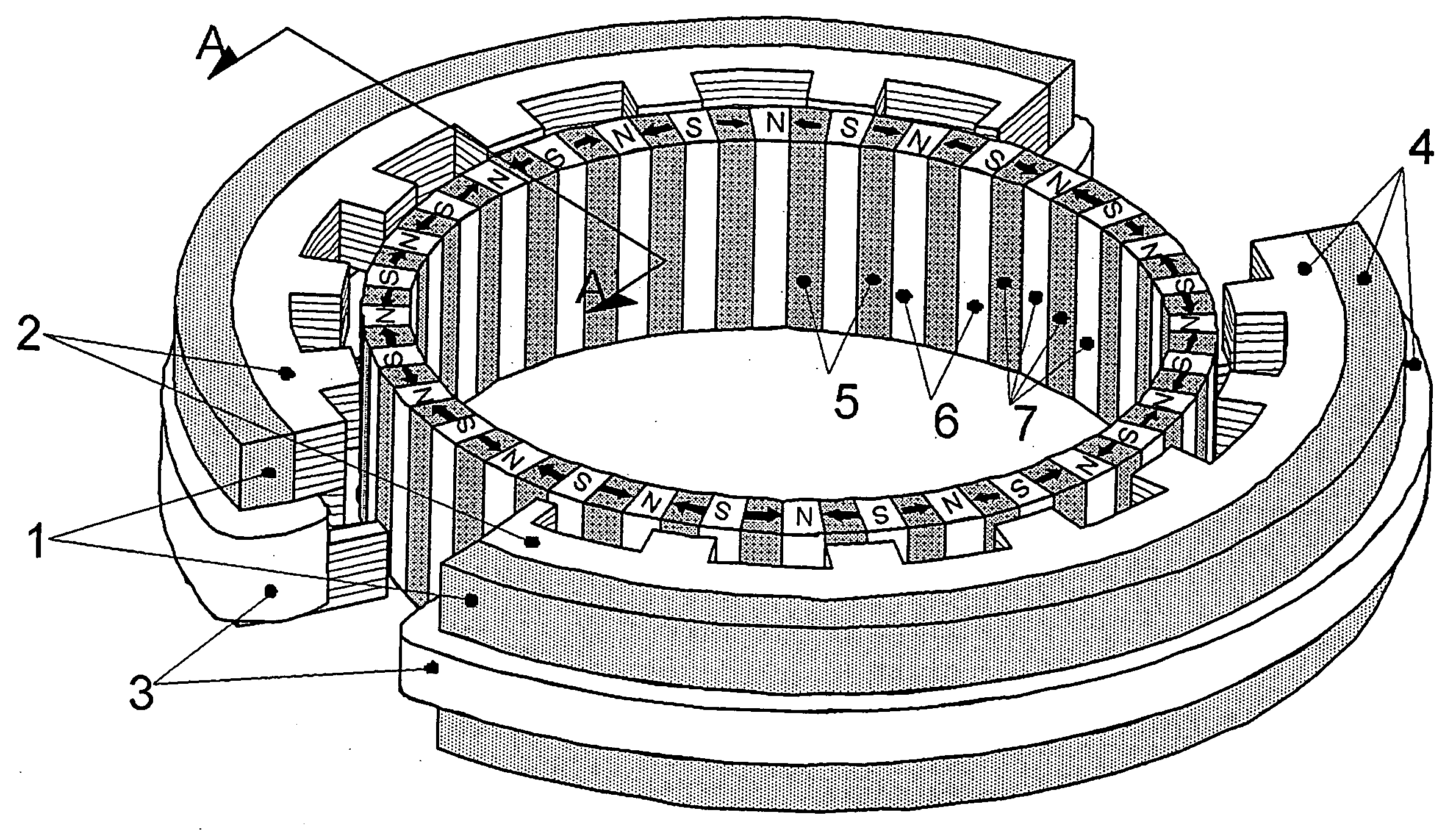

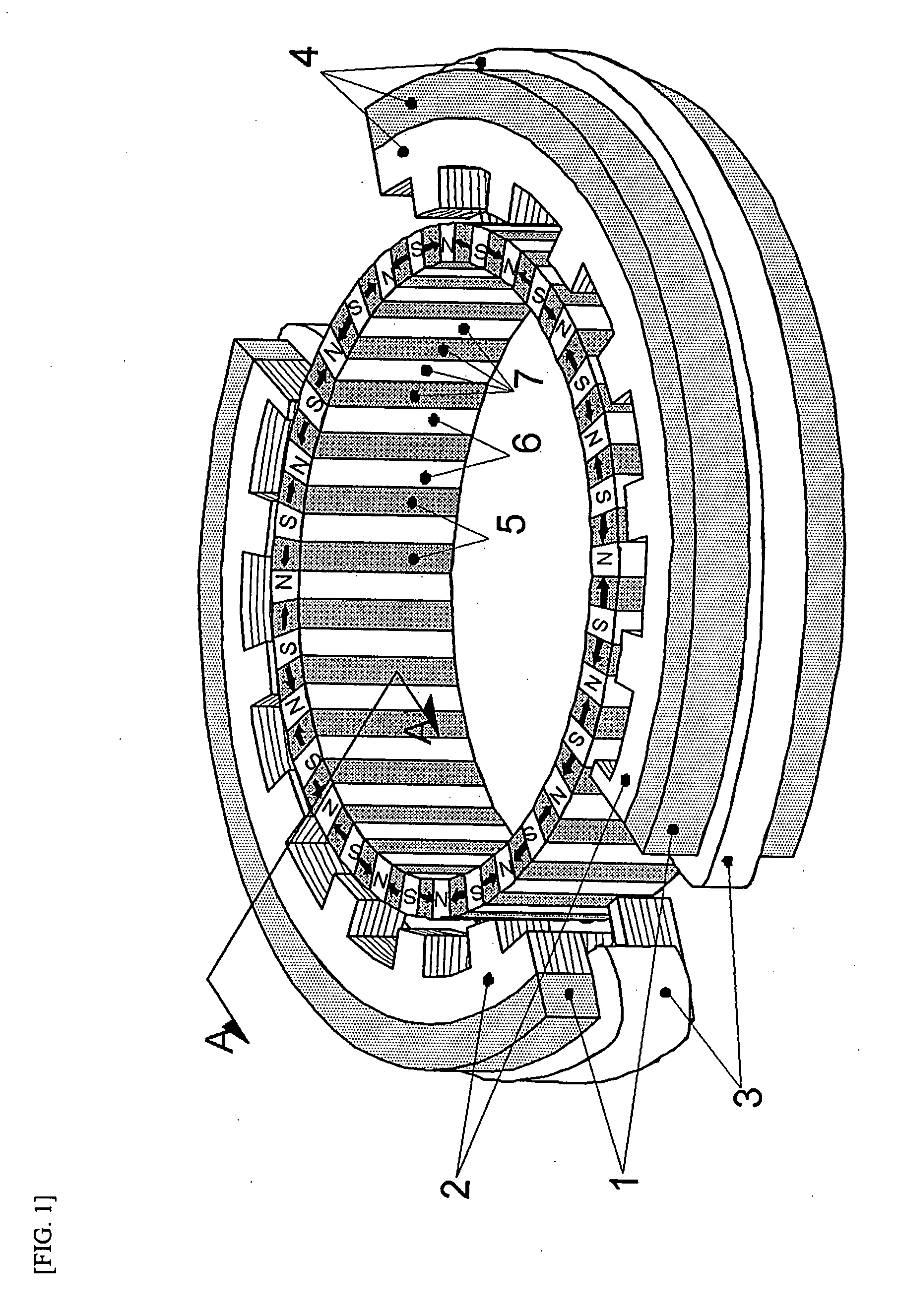

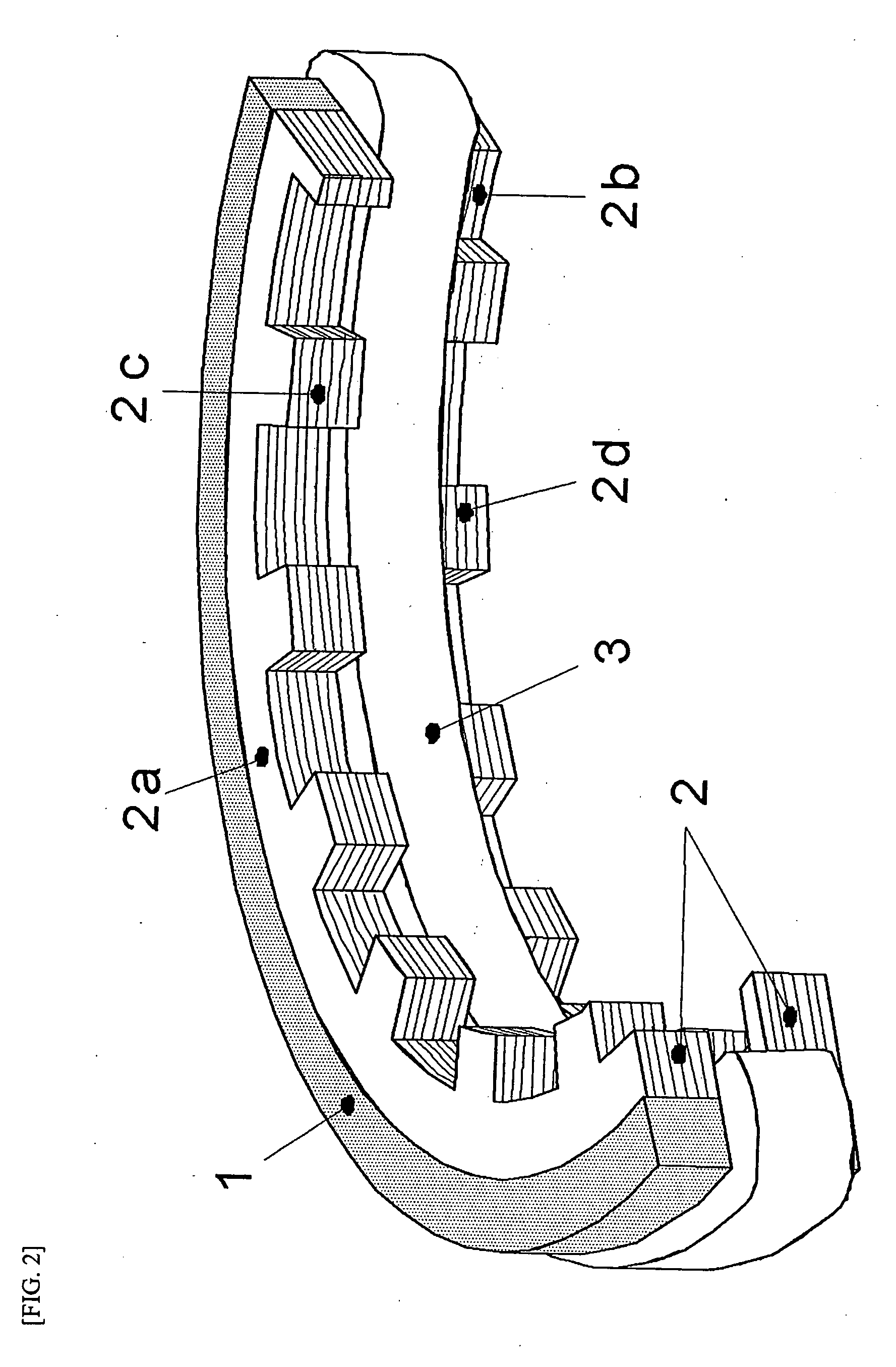

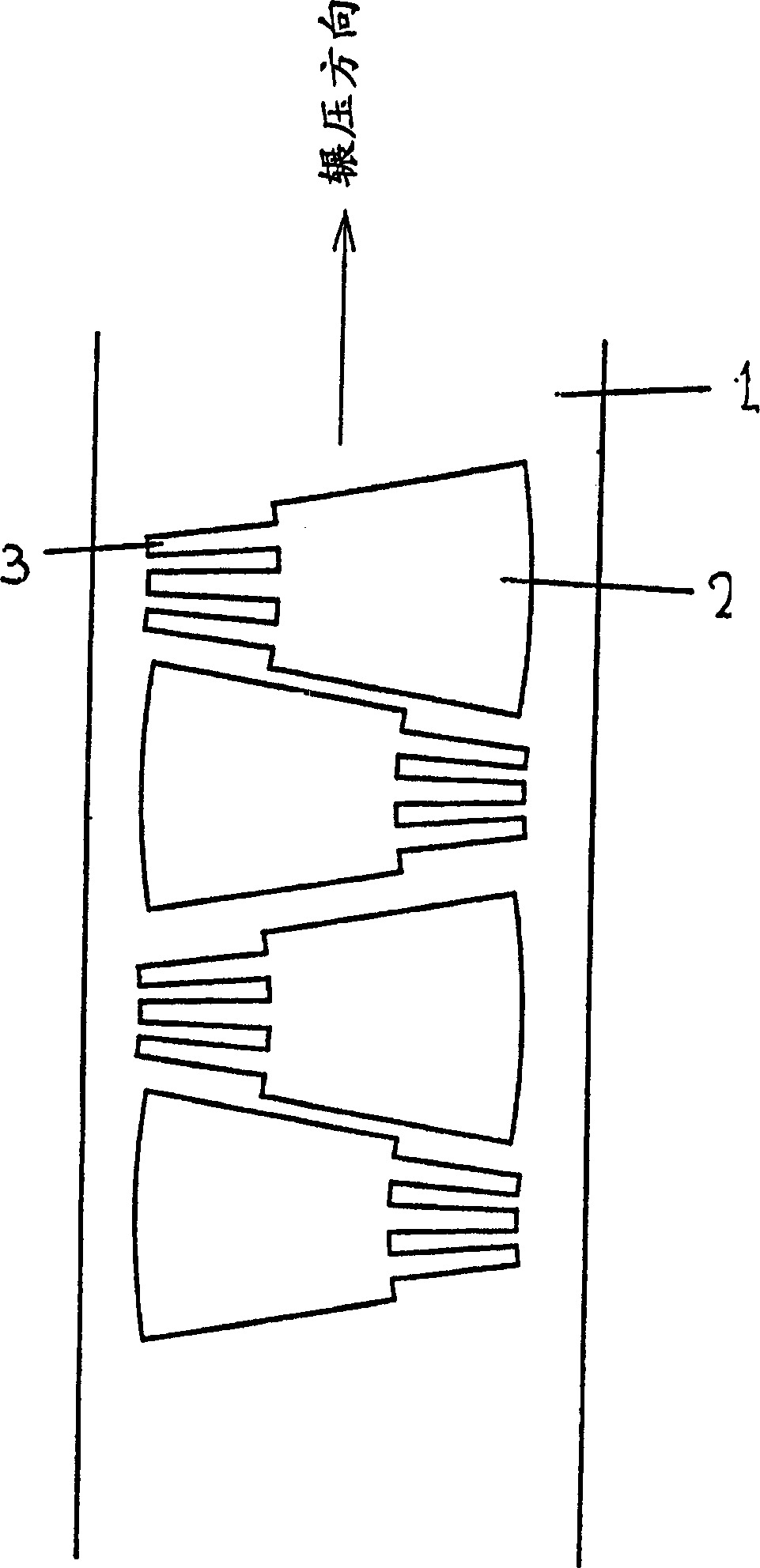

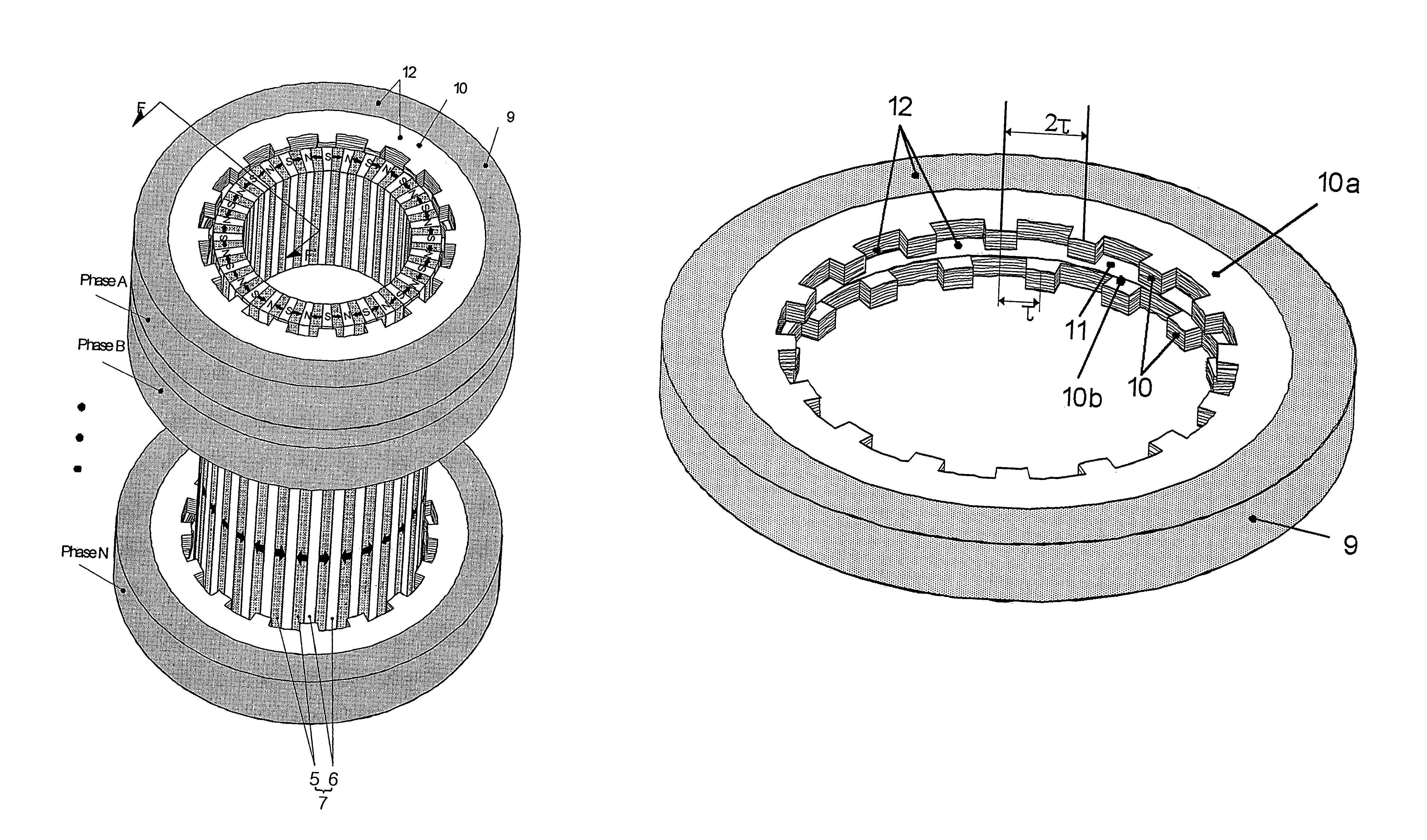

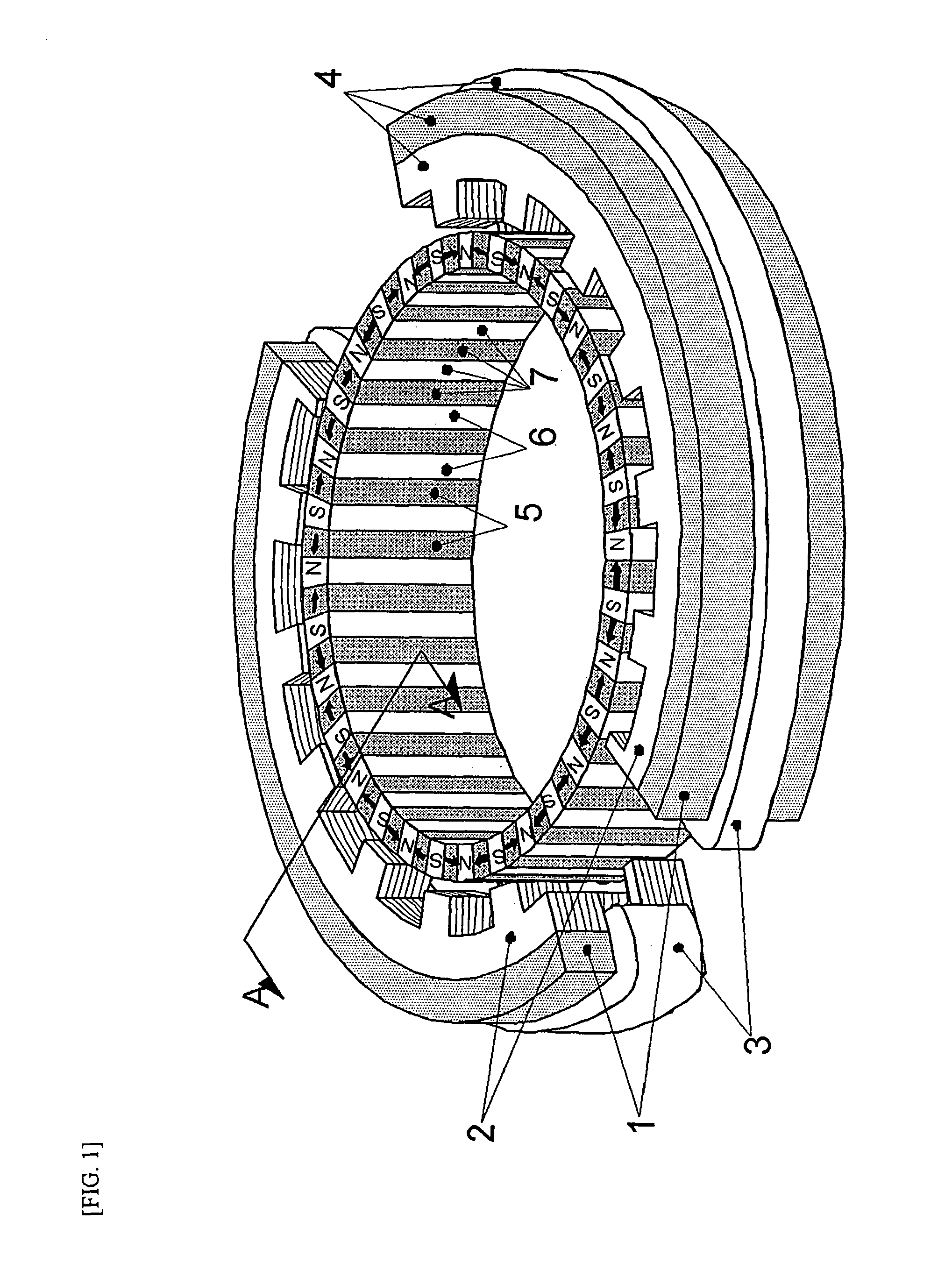

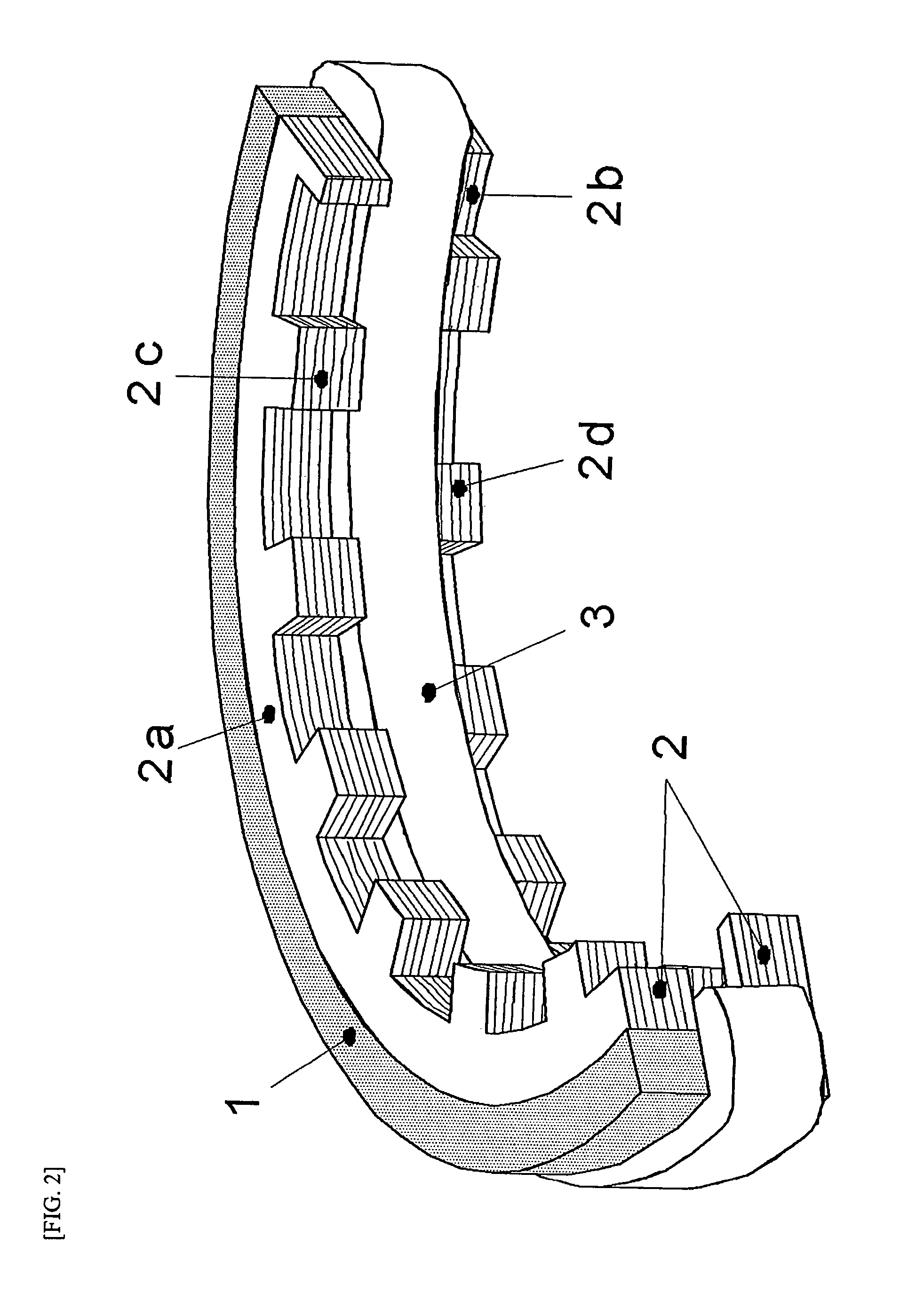

Inner rotor type permanent magnet excited transverse flux motor

ActiveUS20080211326A1Improve efficiencyIncrease output powerMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse fluxConductor Coil

Disclosed herein is an inner rotor type permanent magnet excited transverse flux motor, in which a laminated structure in an axial direction or in a radial shape is applied to a stator iron core so as to employ a small amount of permanent magnets compared with a conventional outer rotor type permanent magnet excited transverse flux motor, thus providing high output power, increasing the efficiency of power generation, and reducing noise and vibration.For this, the present invention provides an inner rotor type permanent magnetic excited transverse flux motor comprising: a stator including a stator powdered iron core press-molded using a mold, a stator laminated iron core laminated on upper and lower layer portions of the circumference of the stator powdered iron core at regular intervals, and a stator winding which winds the segmented stator powdered iron core in which a current flows is wound between the intervals; and a rotor in which a rotor permanent magnet and a rotor powdered iron core are arranged alternately to face each other.

Owner:KOREA ELECTROTECH RES INST

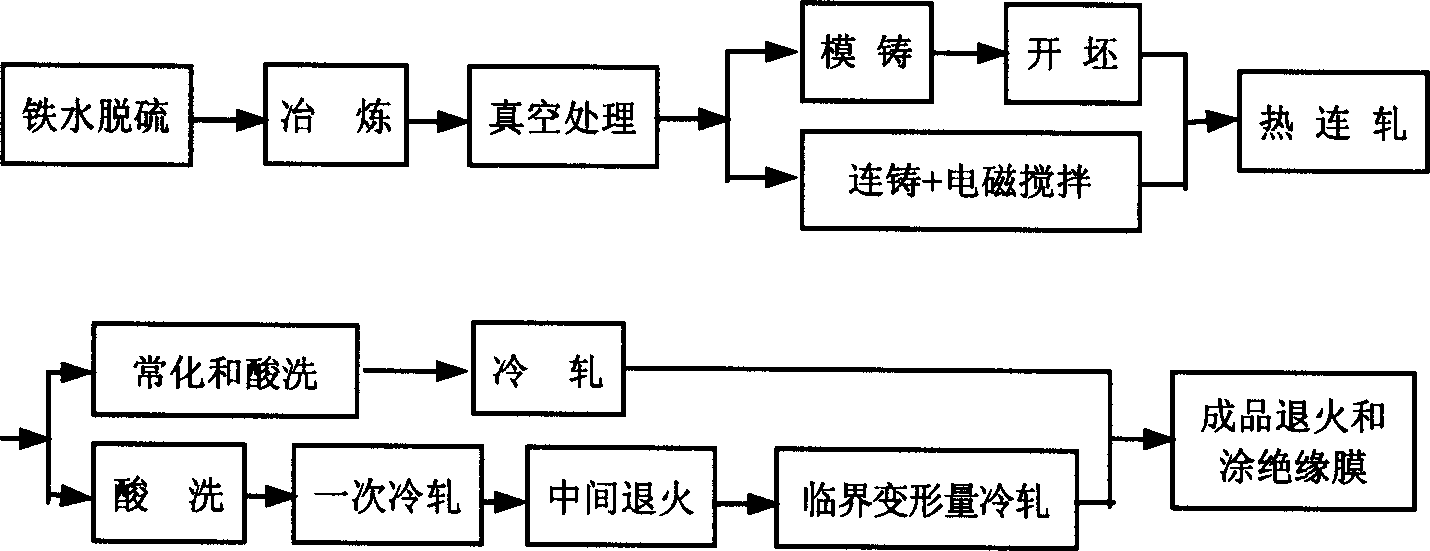

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

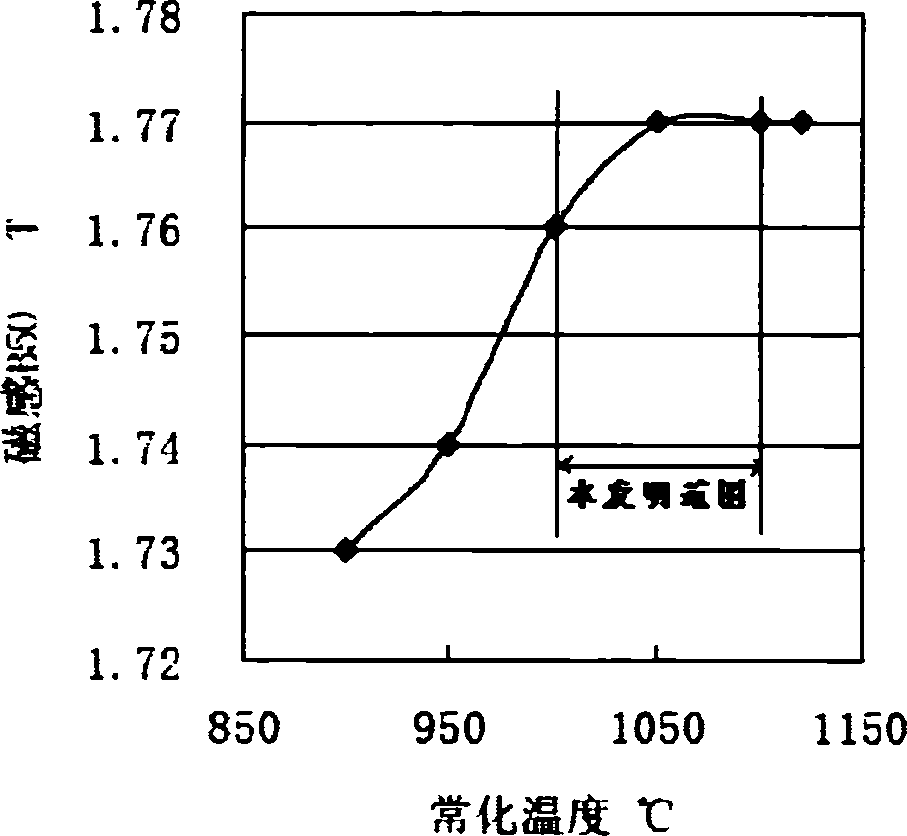

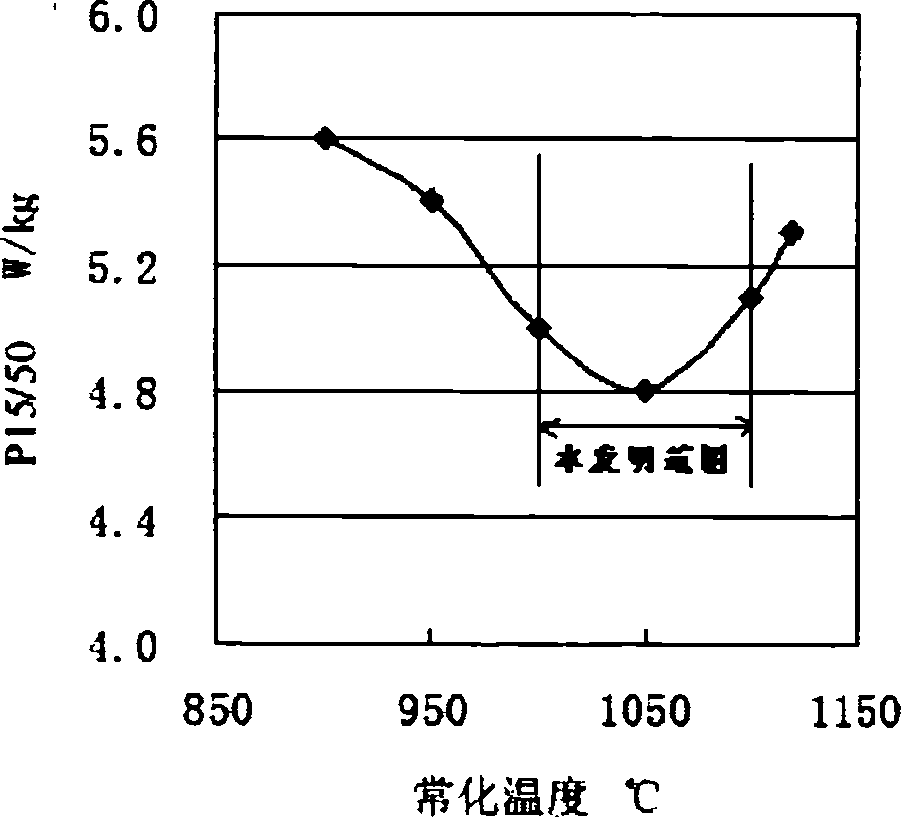

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

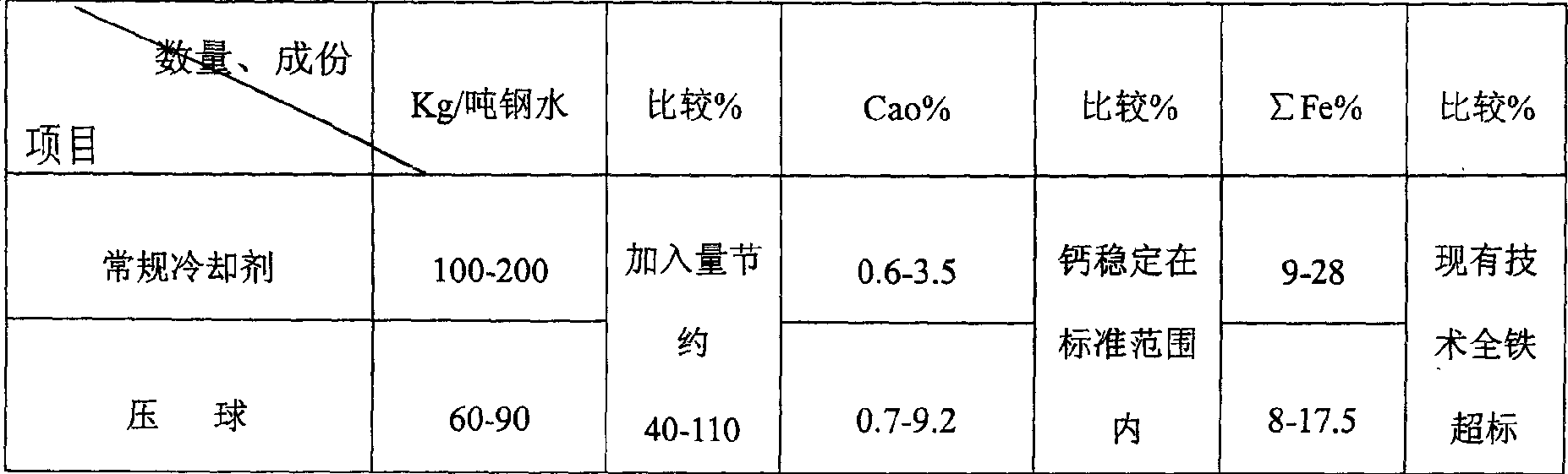

Molten iron vanadium-extracting calcium-controlling coolant and process therefor

The invention relates iron melt improving vanadium content and controlling calcium content cooling agent and the technology, specially relates the cooling agent of adjusting the proportion of cooling agent to stabilize calcium content in vanadium slag and the technology. The technology comprises the 56-60wt% iron scale, 30-40wt% iron concentrate powder containing vanadium, and 5-10wt% anchoring agent. The method stabilizes the calcium content and iron content in vanadium slag, and effectively solves the problems of great fluctuation of vanadium slag composition and superstandard calcium and iron. By controlling the thermoregulation material to meet the requirements of the improving vanadium temperature and calcium oxide content, the method improves the vanadium slag grade and extraction rate. The invention possesses the following characteristics: 1 shortening the converting time; 2 improving the vanadium slag grade and extraction rate, and stabilizing the calcium oxide content; 3 reducing the iron loss.

Owner:HEBEI LUANHE IND GROUP

Manufacture of directional electromagnetic steel plate

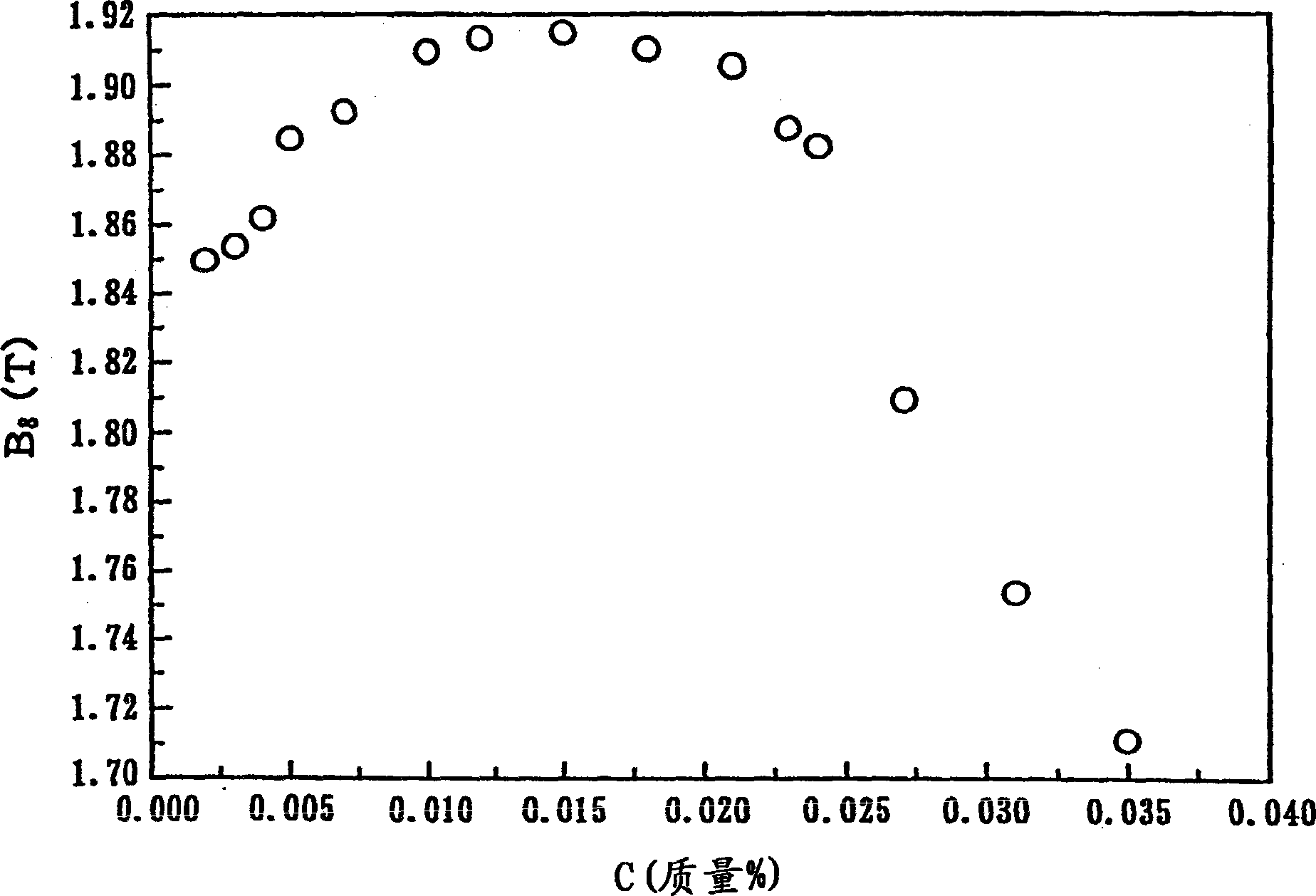

A method of manufacturing a grain-oriented steel sheet including hot-rolling a slab prepared using molten steel containing, by mass%, C of not more than about 0.08 %, Si of about 1.0 to about 8.0 % and Mn of about 0.005 to about 3.0 %; optionally annealing the hot-rolled steel sheet; performing cold rolling once, or twice or more with intermediate annealing therebetween; performing primary recrystallization annealing in a low- or non-oxidizative atmosphere and adjusting the C content in the steel sheet after primary recrystallization annealing to be held in the range of about 0.005 to about 0.025 mass%; performing secondary recrystallization annealing; decarburization annealing; and, preferably, performing additional high-temperature continuous or batch annealing. A grain-oriented electrical steel sheet having a sufficiently high magnetic flux density and a low iron loss can be advantageously obtained even when it is manufactured without using an inhibitor.

Owner:JFE STEEL CORP

Inner rotor type permanent magnet excited transverse flux motor

ActiveUS7952252B2Reducing iron lossImprove efficiencyMagnetic circuit stationary partsManufacturing dynamo-electric machinesTransverse fluxPower flow

Disclosed herein is an inner rotor type permanent magnet excited transverse flux motor, in which a laminated structure in an axial direction or in a radial shape is applied to a stator iron core so as to employ a small amount of permanent magnets compared with a conventional outer rotor type permanent magnet excited transverse flux motor, thus providing high output power, increasing the efficiency of power generation, and reducing noise and vibration. For this, the present invention provides an inner rotor type permanent magnetic excited transverse flux motor comprising: a stator including a stator powdered iron core press-molded using a mold, a stator laminated iron core laminated on upper and lower layer portions of the circumference of the stator powdered iron core at regular intervals, and a stator winding which winds the segmented stator powdered iron core in which a current flows is wound between the intervals; and a rotor in which a rotor permanent magnet and a rotor powdered iron core are arranged alternately to face each other.

Owner:KOREA ELECTROTECH RES INST

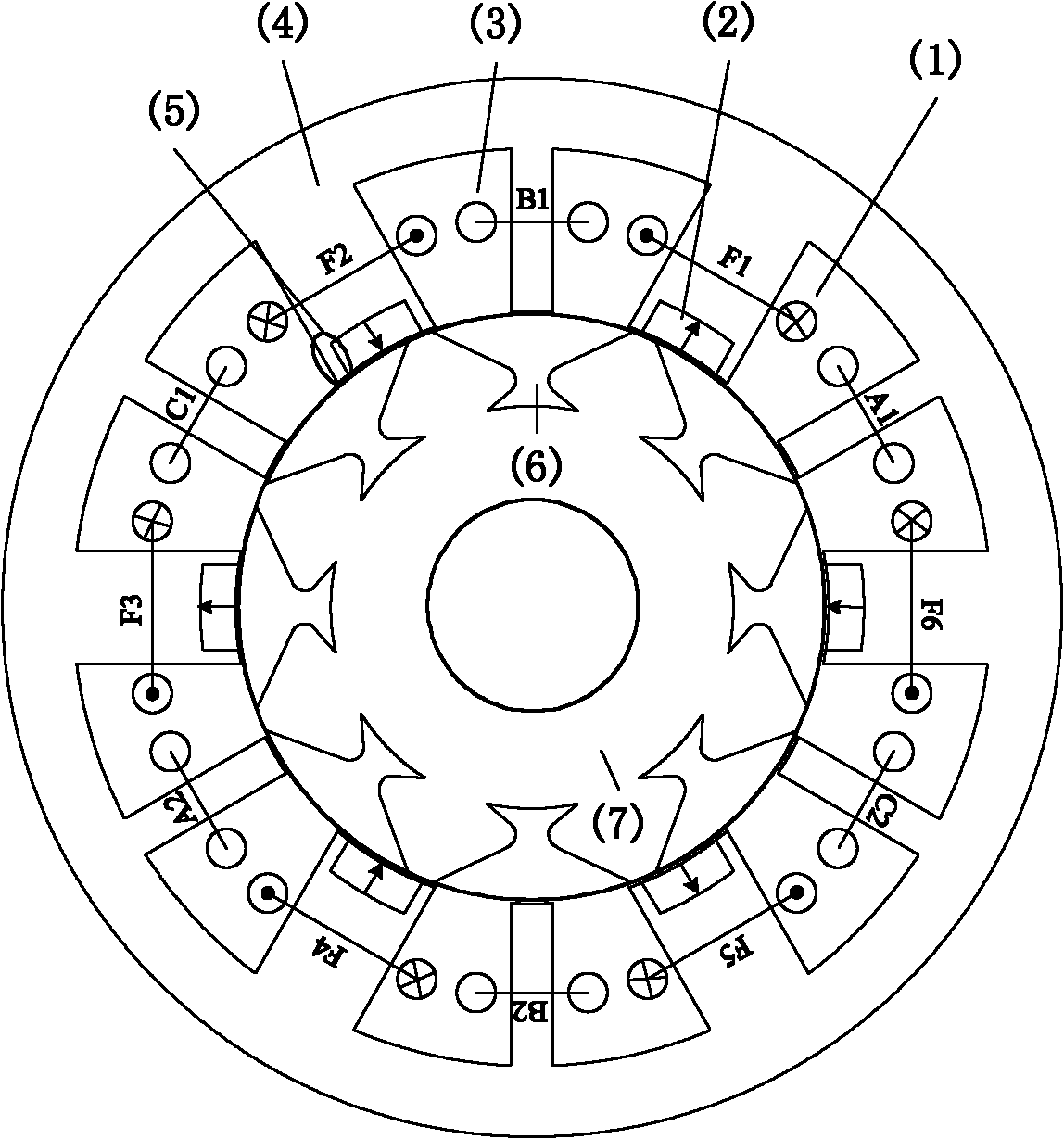

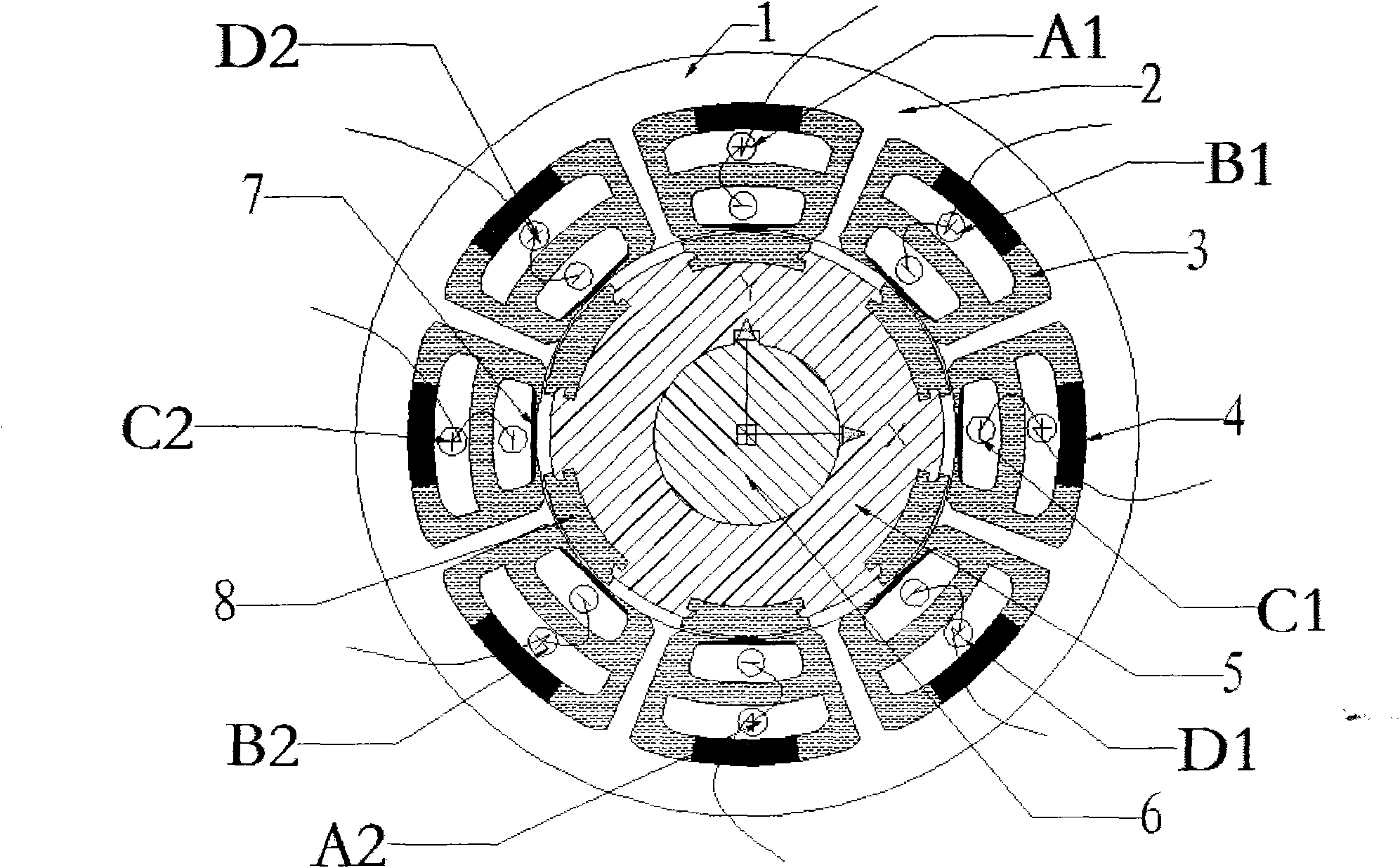

Segmented rotor type magnetic flux switching motor with hybrid excitation and magnetic adjustment method

InactiveCN102185451AReduce iron lossReduce interactionMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic flux

The invention discloses a segmented rotor type magnetic flux switching motor with hybrid excitation and a magnetic adjustment method. The motor comprises a stator yoke, a permanent magnet, an exciting winding, an armature winding, a segmented rotor and a non-concentrating flux sleeve, wherein the stator yoke is of a 12-tooth structure and formed by arranging excitation teeth and armature teeth in a staggered mode; the permanent magnet is arranged in the excitation teeth, one surface of the permanent magnet is opposite to the rotor, and two sides of the permanent magnet are provided with concentrating flux bridges; the armature winding and the exciting winding are integrated windings and respectively wound on the excitation teeth and the armature teeth; the segmented rotor is arranged in the non-concentrating flux sleeve, thus the whole rotor forms a cylinder structure; the concentrating flux bridges at the two sides of the permanent magnet provide return circuits for electro-exciting magnetic fields generated by the exciting winding, thus permanent magnet magnetic fields are closed after passing through the permanent magnet, the stator yoke, air gaps and the segmented rotor in sequence, and electro-exciting magnetic fields are closed after passing through the stator yoke, the air gaps and the segmented stator; and a current of the exciting winding is adjusted to realize wide-range magnetic adjustment. The motor has the advantages of wider magnetic adjustment range, good fault-tolerant capability and small wind resistance and oil resistance and can be applied to the field of high-speed aviation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

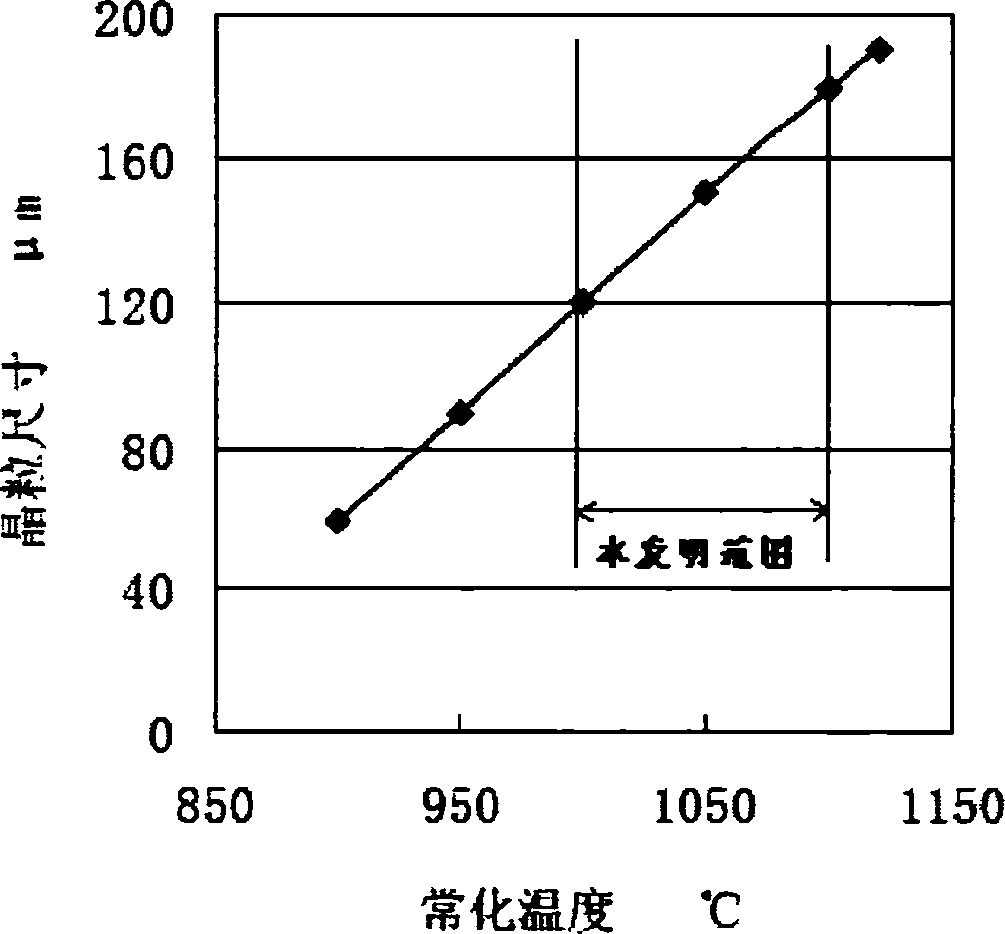

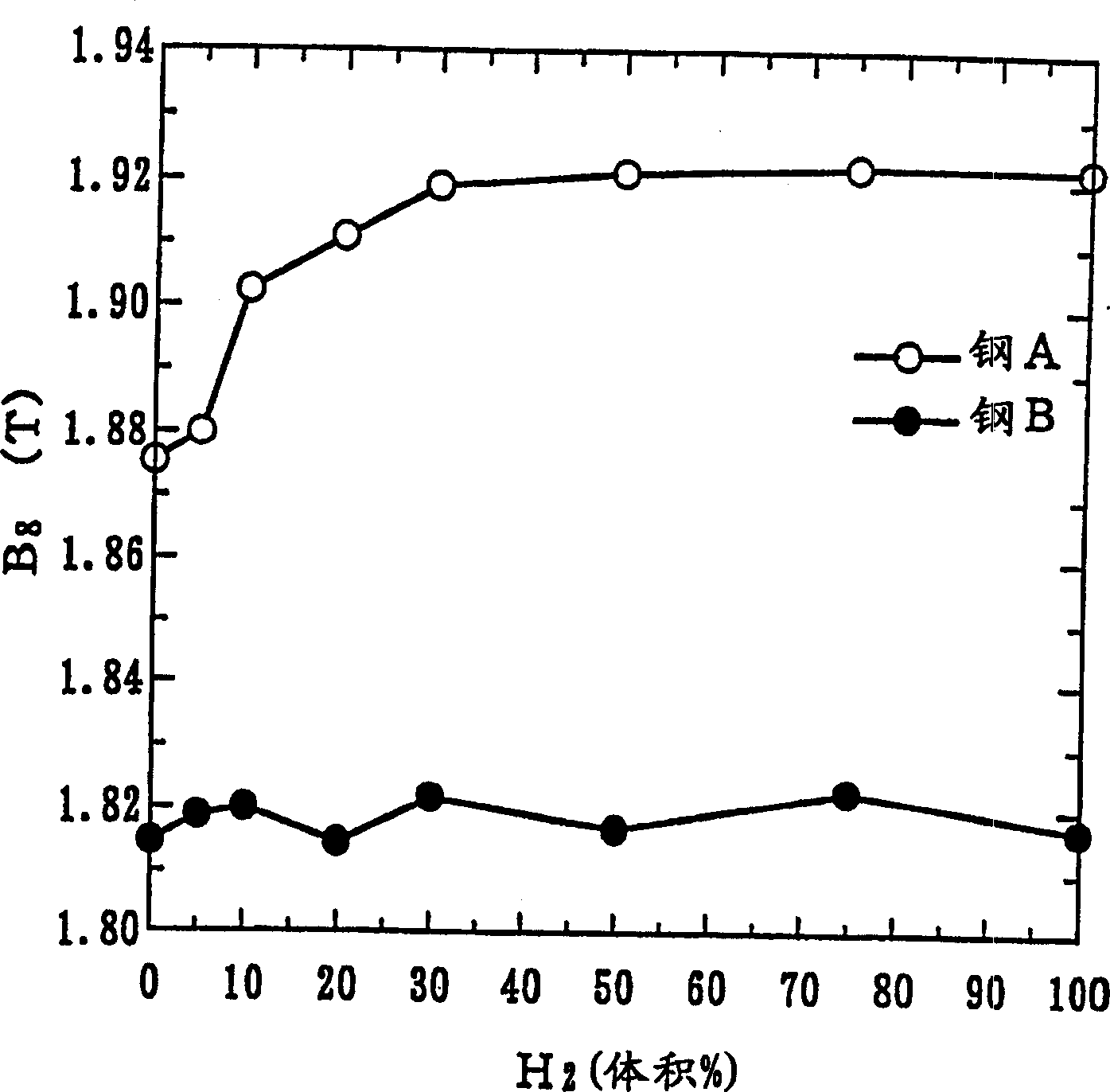

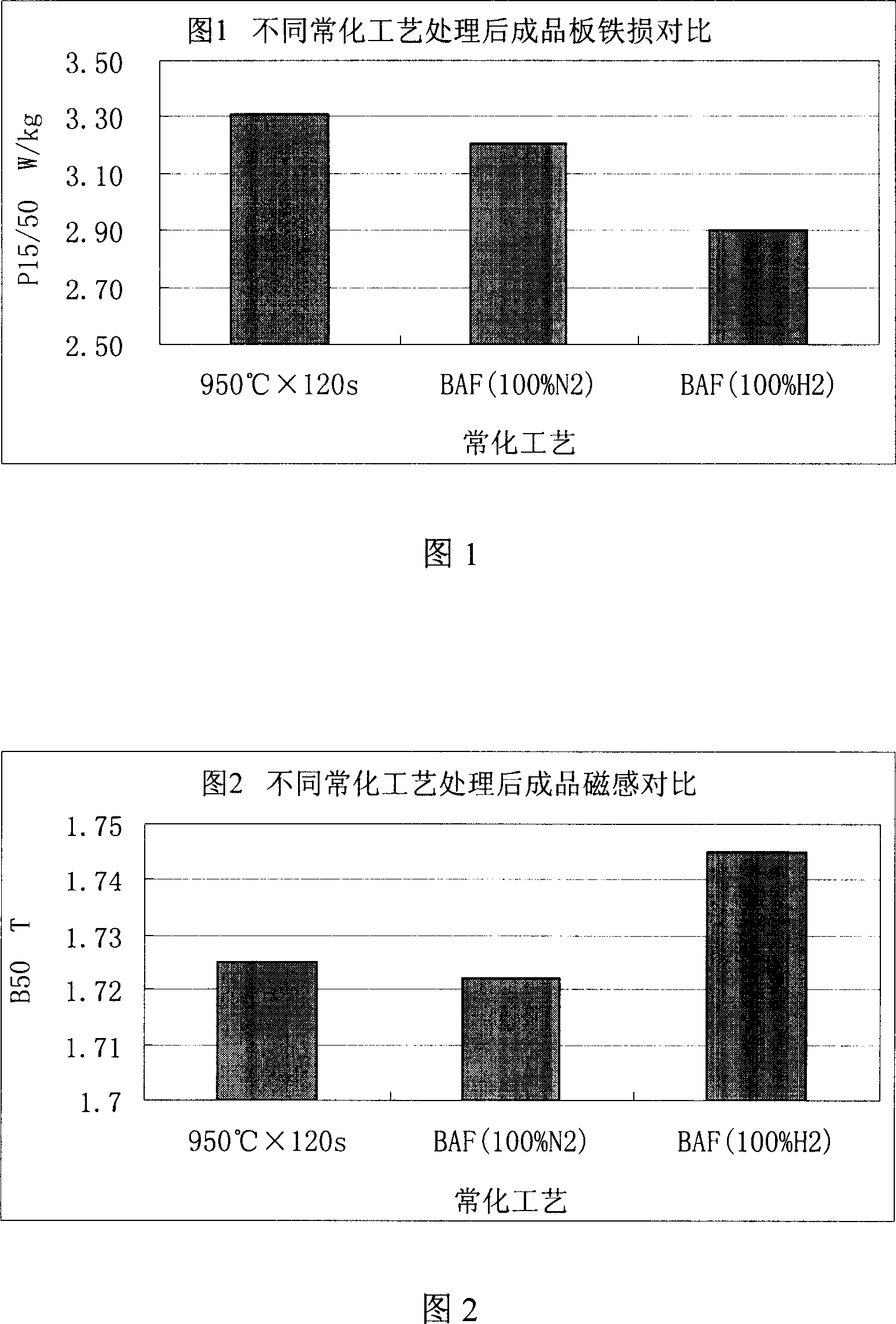

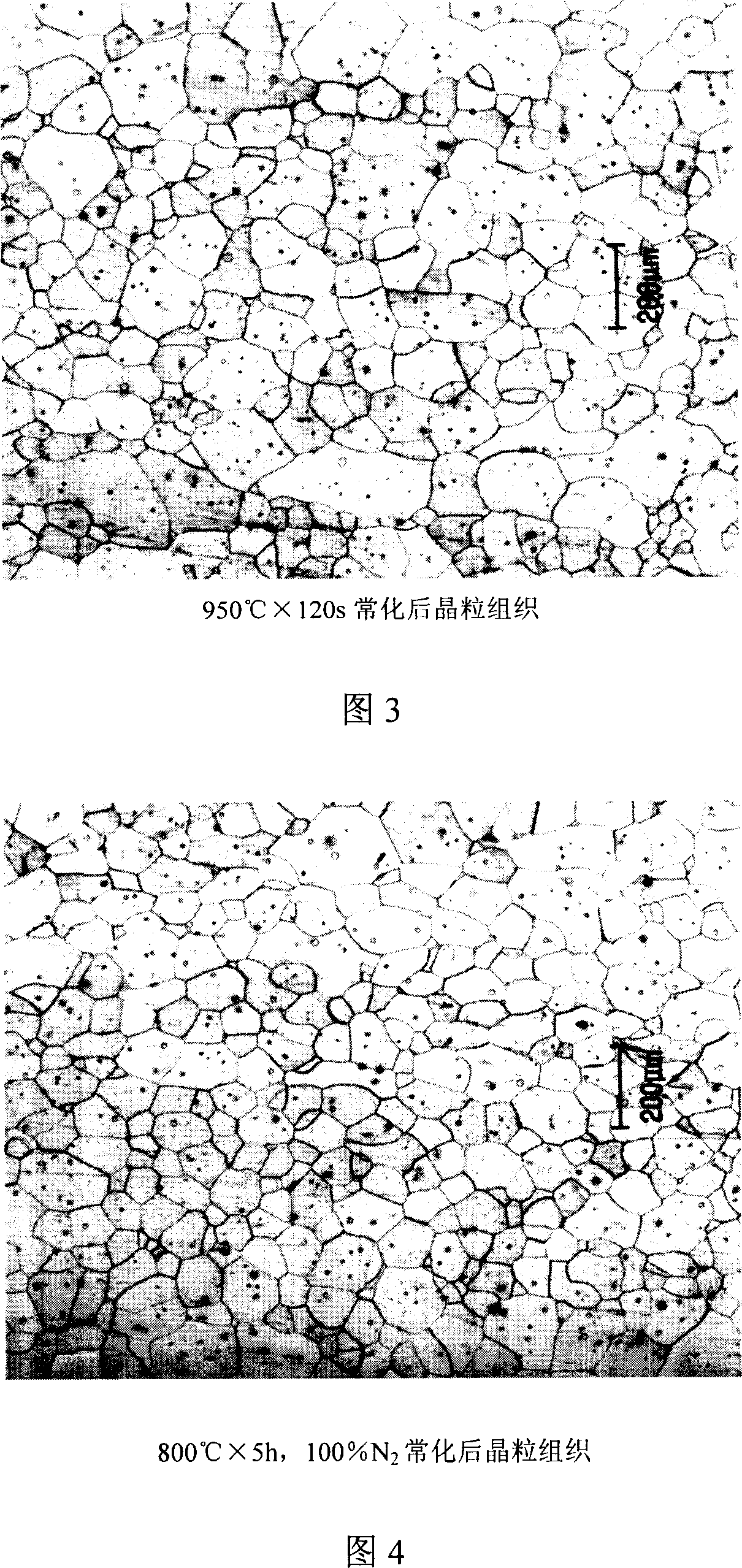

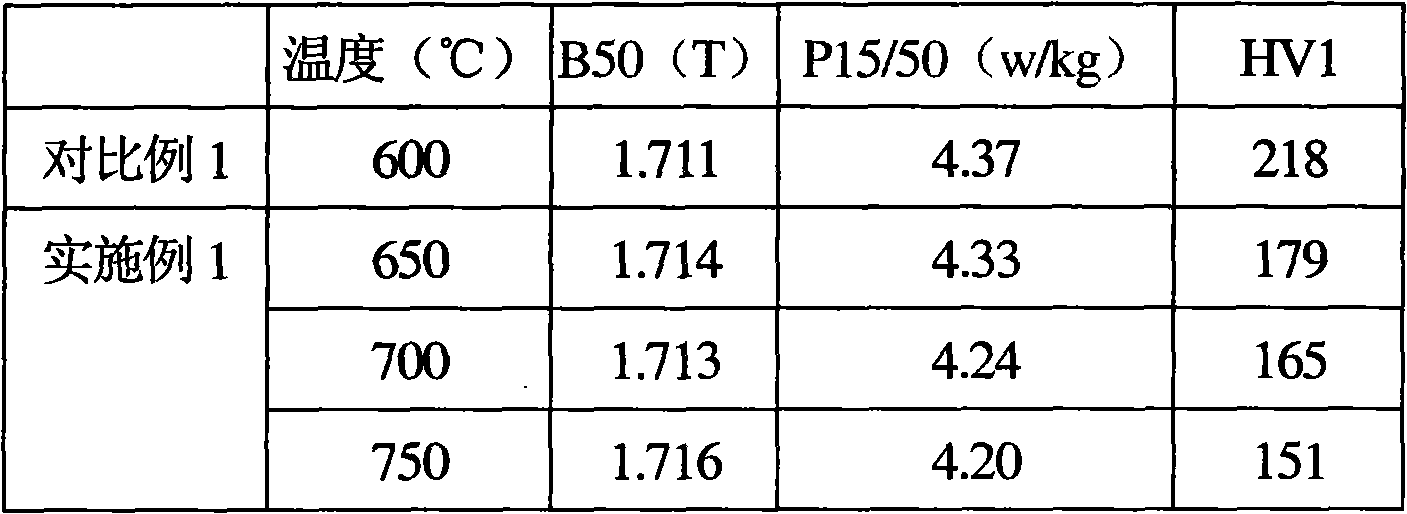

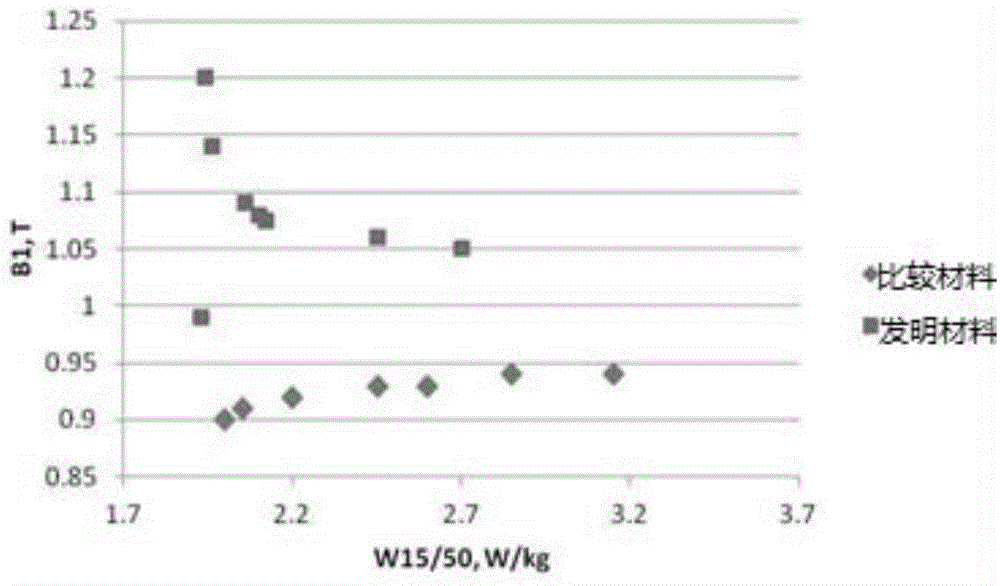

Production method of low iron loss high magnetic sensing cold milling orientation less electrical steel plate

InactiveCN100999050AImprove plasticityEasy to grow grainsOther manufacturing equipments/toolsCrystalliteSheet steel

The present invention relates to a method for producing low-iron-loss high-magnetic-induction cold-rolled non-oriented electrical steel strip by using cap cover furnace annealing treatment. Said method includes the following steps: (a), raw material preparation: including (by wt%) C, its content is loss than or equal to 0.010%; Si, its content is 0.1-3.50%; Al, its content is less than or equal to 1.5%; Man, its content is 0.10%-1.50%; P, is content is less than or equal to 0.20%; S, its content is less than or equal to 0.008%; N, its content is less than or equal to 0.0030%, and the rest is iron and inevitable impurity; (b), smelting, continuous casting and hot-rolling; (c), normalizing treatment, making hot-rolled sheet undergo the process of normalizing treatment, under the condition of cap cover furnace making full hydrogen annealing, annealing temperature is 700 deg.C-900deg.C; (d), cold-rolling to obtain cold-rolled sheet; and (e), annealing treatment, making cold-rolled sheet undergo the process of annealing treatment so as to obtain the invented product.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving magnetic property of oriented silicon steel through laser scribing

ActiveCN101979676AReduce iron lossMagnetic sense has not deterioratedInorganic material magnetismFurnace typesLaser scribingPower density

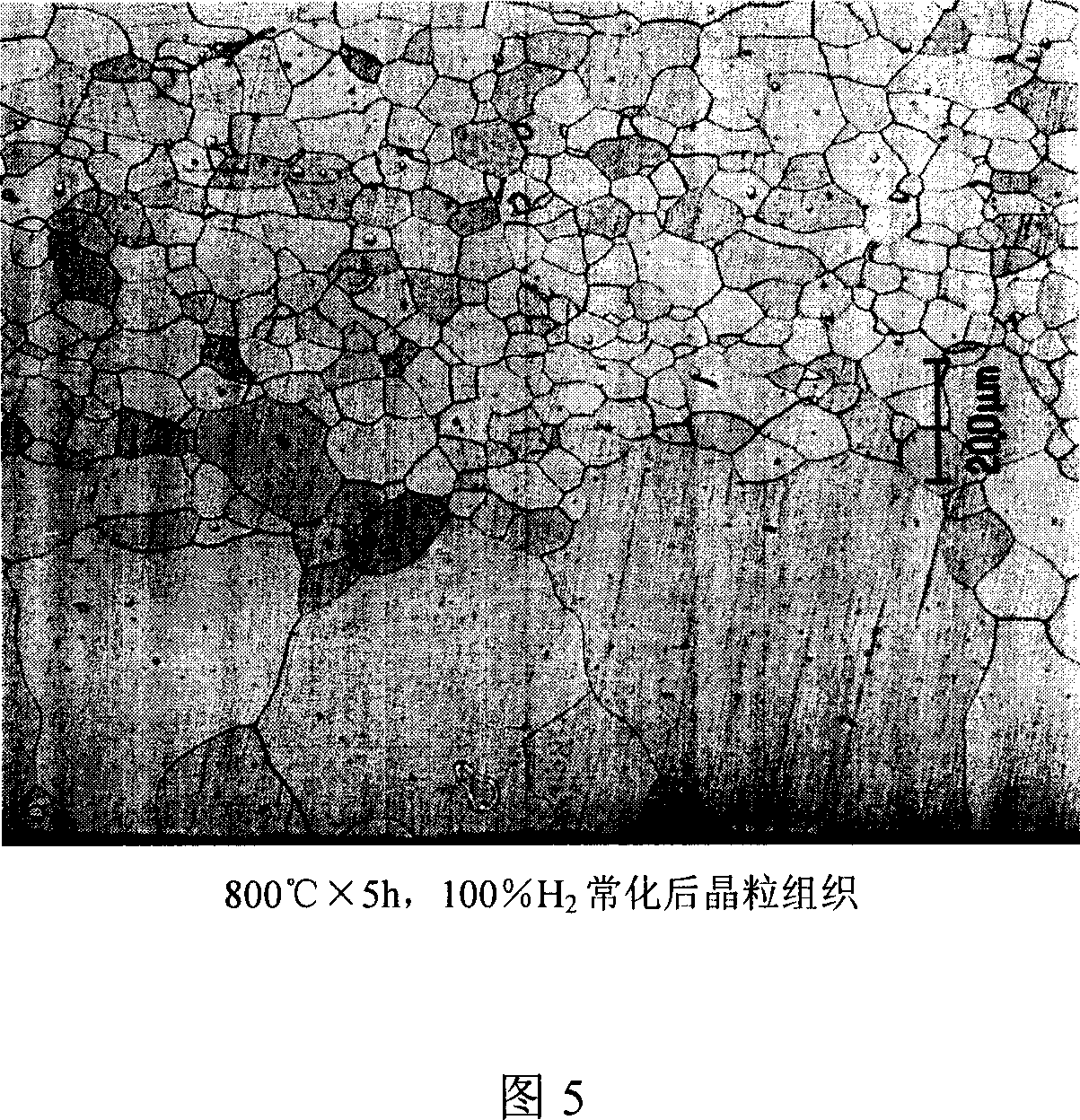

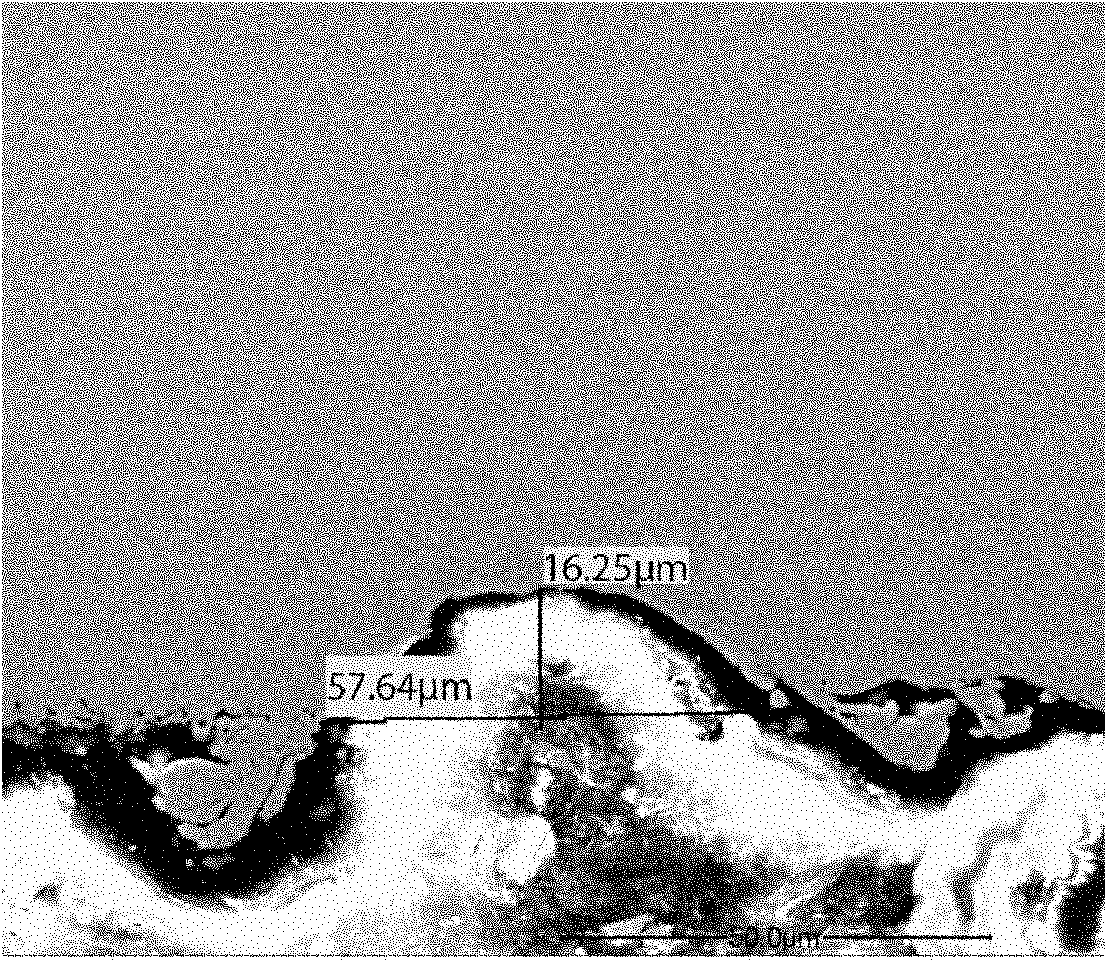

The invention discloses a method for improving the magnetic property of oriented silicon steel through laser scribing. In the method, a plurality of parallel line-shaped or dotted line-shaped grooves are scribed on the surface of an oriented silicon steel sheet subjected to high temperature annealing by adopting laser beam, the inclined angle alpha between each line-shaped or dotted line-shaped groove and the rolling direction of the oriented silicon steel sheet is 78 to 88 DEG, the distance d of adjacent line-shaped or dotted line-shaped grooves along the rolling direction of the oriented silicon steel sheet is 3 to 5 mm, the groove depth h is 15 to 30 mu m, and the groove width b is 50 to 65 mu m. The preferable working parameters of the laser beam are that: the diameter D of a light spot is 7 to 13 mu m, and the peak power density N of an irradiation point is 108 to 109 W / cm<2>. By adopting laser scribing, the plate type of the oriented silicon steel sheet is not damaged and iron loss also can be remarkably reduced, the iron loss reduction effect of the laser scribing cannot disappear after stress relieving annealing at the temperature of 800 DEG C for 2 hours, the lamination factor cannot be reduced, and the magnetic induction basically does not worsen. Meanwhile, the process of the method is simple, the production is easy to control, and the method is particularly suitable for improving the performance of the high-magnetic induction oriented silicon steel sheet, and the oriented silicon steel sheet can be used for a wound iron core transformer and also can be used for a laminated iron core transformer after being treated.

Owner:武汉钢铁有限公司

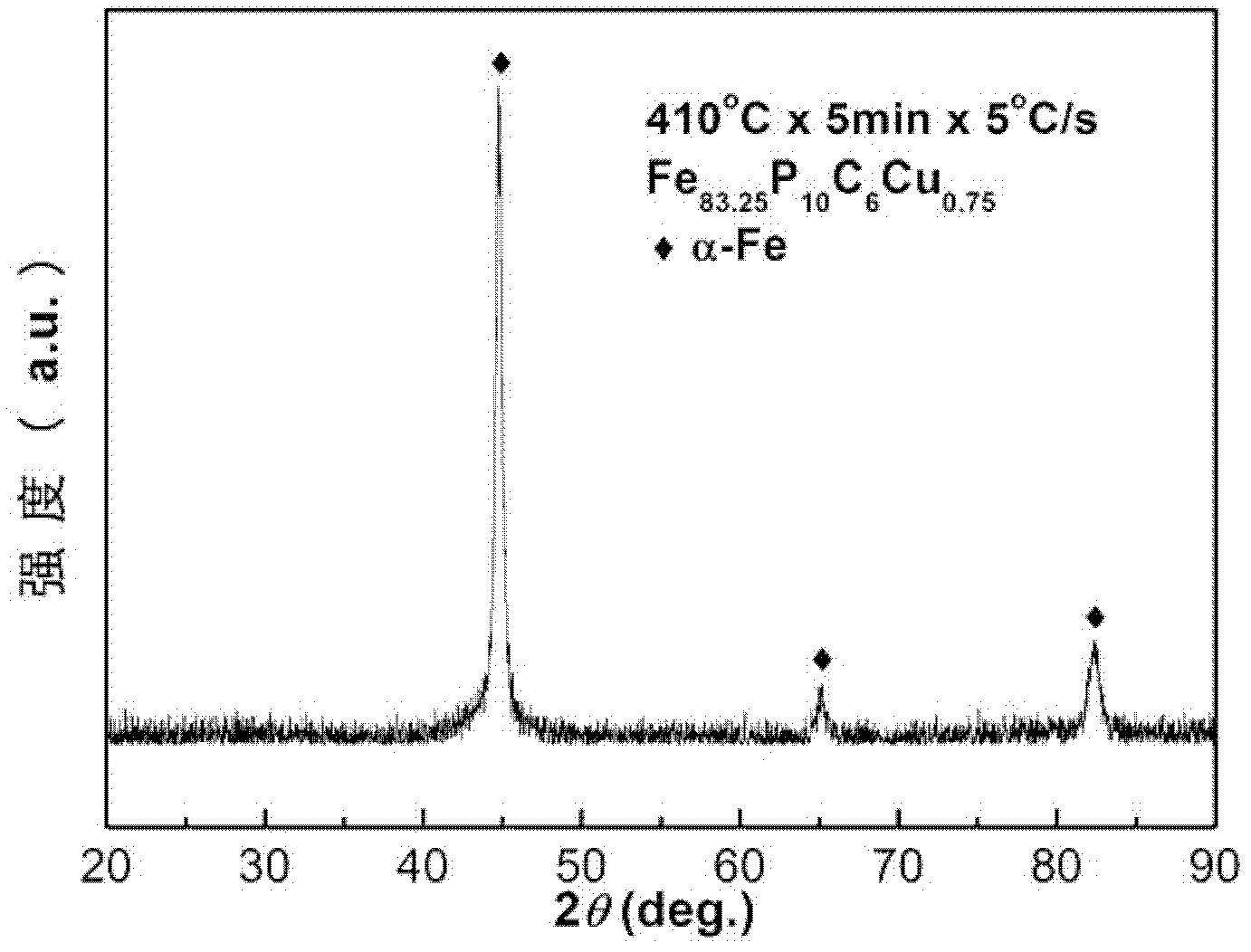

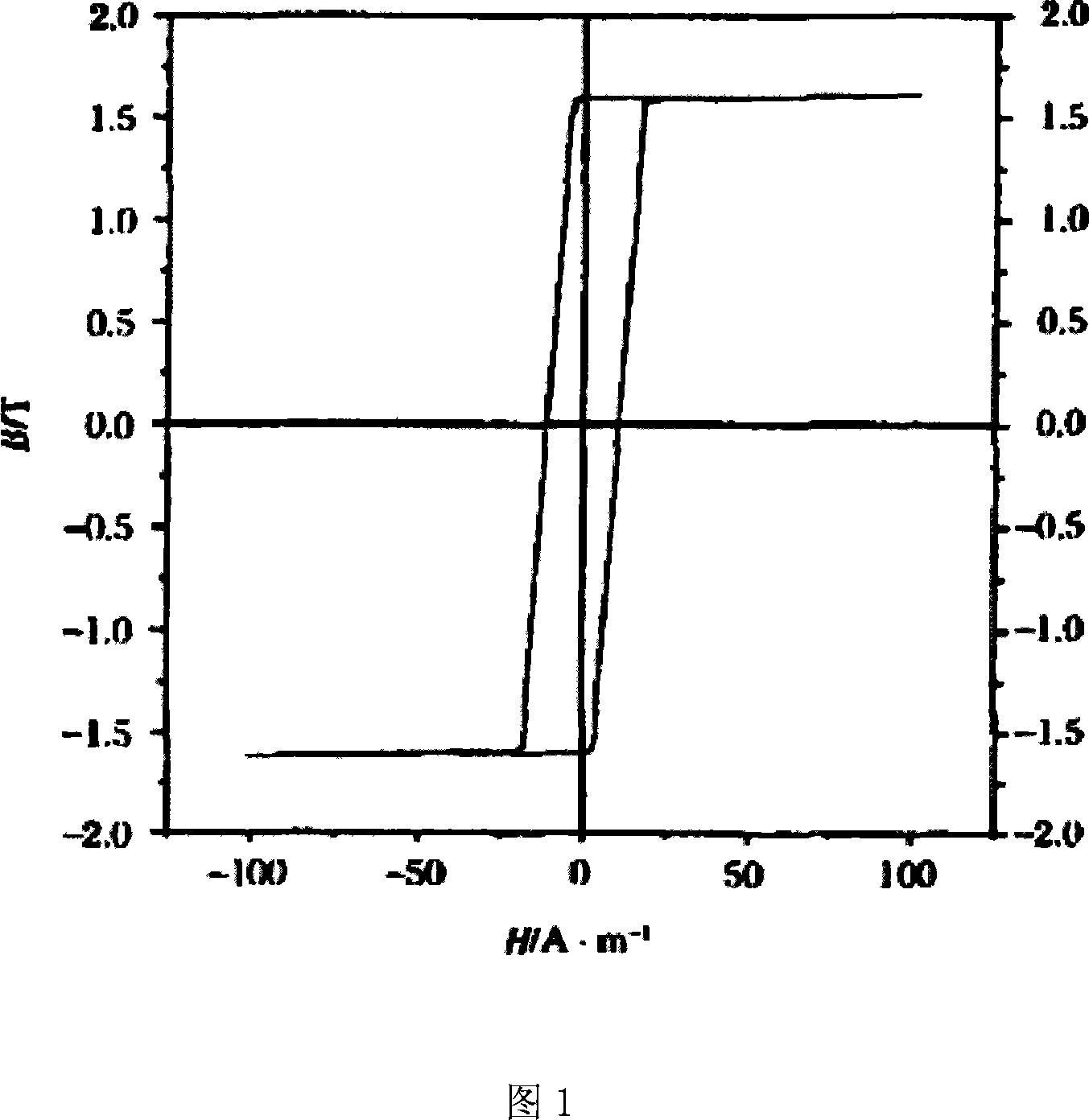

Iron-based nanometer crystal magnetically soft alloy and preparation method thereof

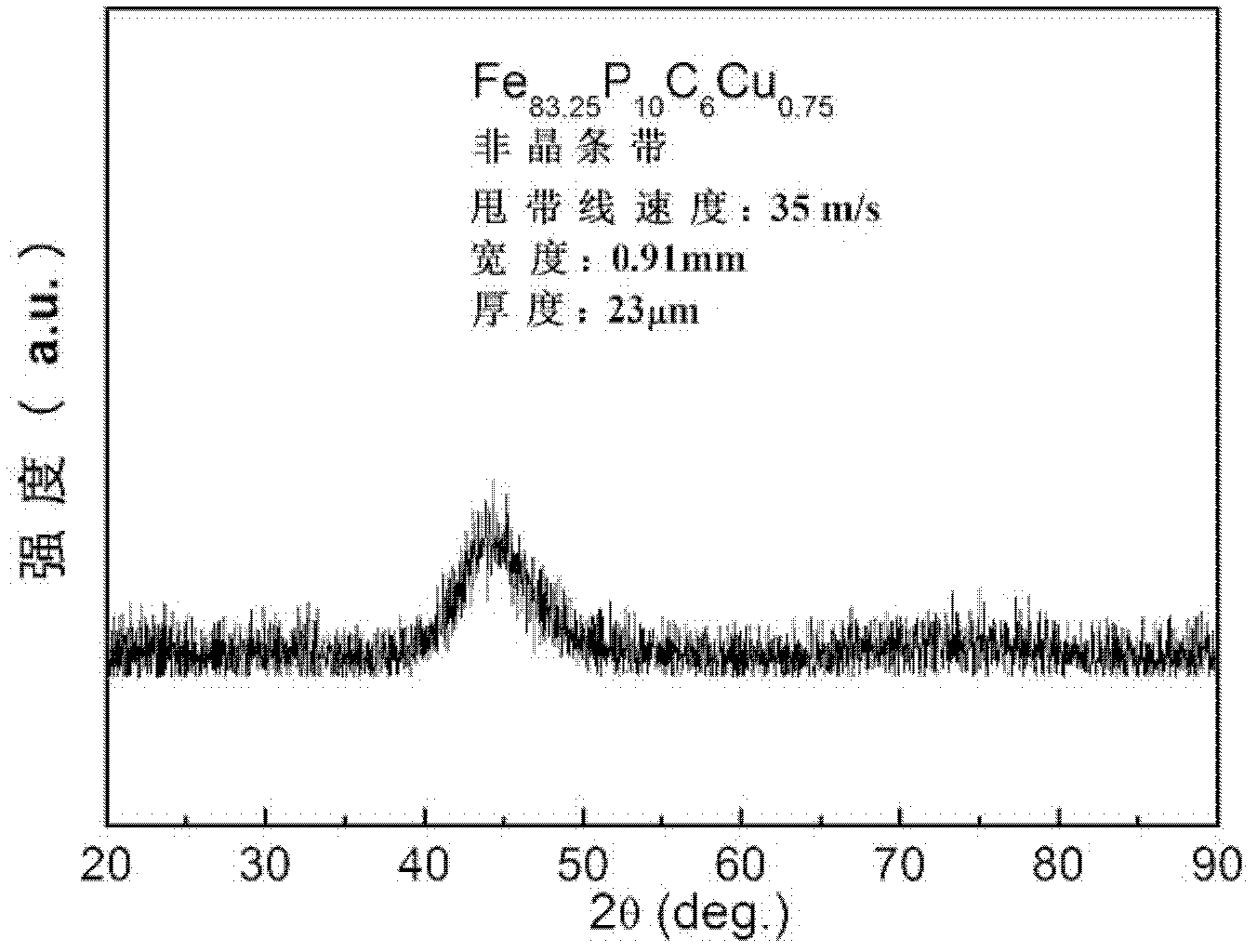

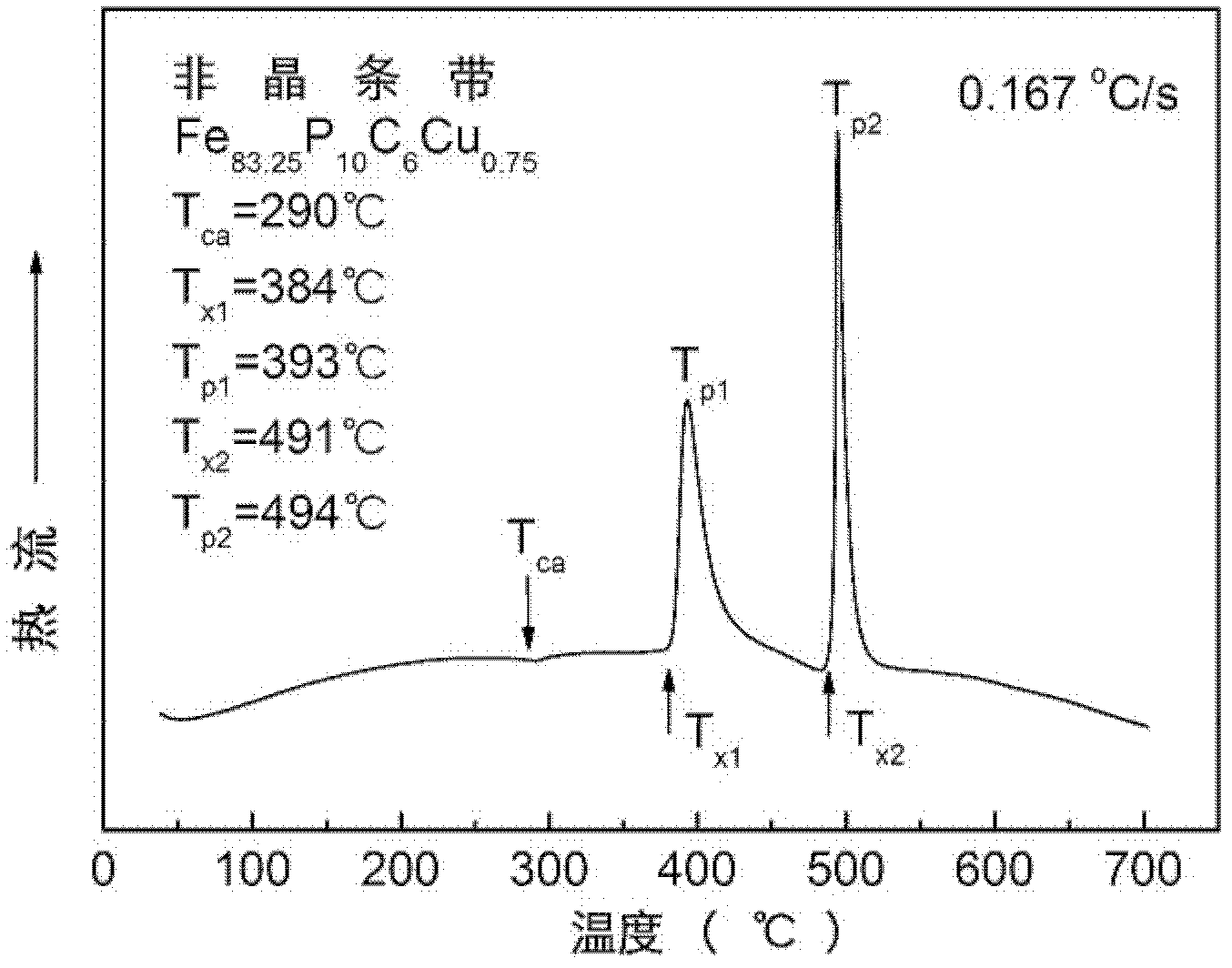

ActiveCN102543347AReduce processing costsHigh saturation magnetic inductionMagnetic materialsAmorphous phaseAlloy

The invention discloses a novel iron-based nanometer crystal magnetically soft alloy and a preparation method thereof. The molecular formula of the iron-based nanometer crystal magnetically soft alloy is FexPyCzMaCub, wherein the M in the molecular formula is one or more than one of B, Si, Al, Cr, Mn, Mo and Ge; x,y,z,a and b respectively represent atom percentage composition of each corresponding component, wherein 70<=x<=90, 1<=y<=20, 1<=z<=20, 0<=a<=10, 0.1<=b<=2, and x+y+z+a+b=100; and a microstructure is coexistence of a body-centered stand alpha-Fe nanometer crystalline phase the size of which is 5-40 nm and a rich phosphatic and carbon amorphous phase. Compared with the existing nanometer crystal magnetically soft alloy, the alloy disclosed by the invention meanwhile has the advantages of high saturation induction density, low coercive force, low iron loss and high magnetic permeability; and in addition, precious metals such as Nb, Zr, Co, Ni, Y and the like are not contained, thus the processing cost is greatly reduced and the application prospect is good.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for manufacturing cold rolling non oriented electrical steel through continuous casting and tandem rolling sheet bar

InactiveCN1796015AAvoid the problem of fine dispersed precipitationEasy to grow grainsOther manufacturing equipments/toolsMetal rolling arrangementsElectrical steelMolten steel

The method for producing cold-rolled non-oriented electrical steel by using sheet bar and adopting continuous casting and continuous rolling process includes the following steps: a). utilizing the following components: C is less than or equal to 0.005%, Si is less than or equal to 3.5%, Mn is less than or equal to 1.5%, Al is less than or equal to 1.5%, P is less than or equal to 0.2%, S is less than or equal to 0.010%, N is less than or equal to 0.005%, O is less than or equal to 0.02% and the rest is iron and smelting; b). continuous casting, continuously casting molten steel to obtain sheet bar; c). heating, the temperature of sheet bar before which is fed into the furnace is 700-900deg.C, retaining said temperature for 30s-5min; heating sheet bar in ferrite phase area and heating temperature is less than or equal to 1120deg.C; d). hot-rolling, rolling in ferrite phase area, final rolling temperature is 800deg.C-950deg.C; e). coiling, coiling temperature is 500deg.C-900deg.C; and f). normalizing treatment or non-annealing treatment, acid-pickling, first cold-rolling or secondary cold-rolling with intermediate annealing to target thickness, then making final annealing so as to obtain the invented product.

Owner:BAOSHAN IRON & STEEL CO LTD

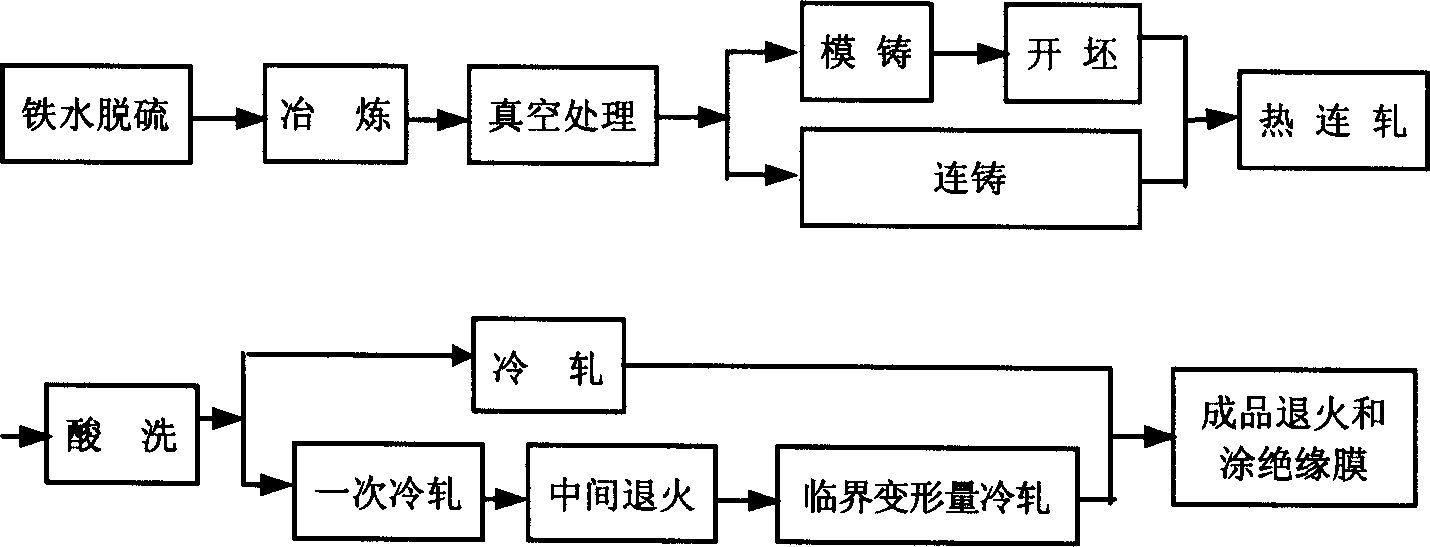

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

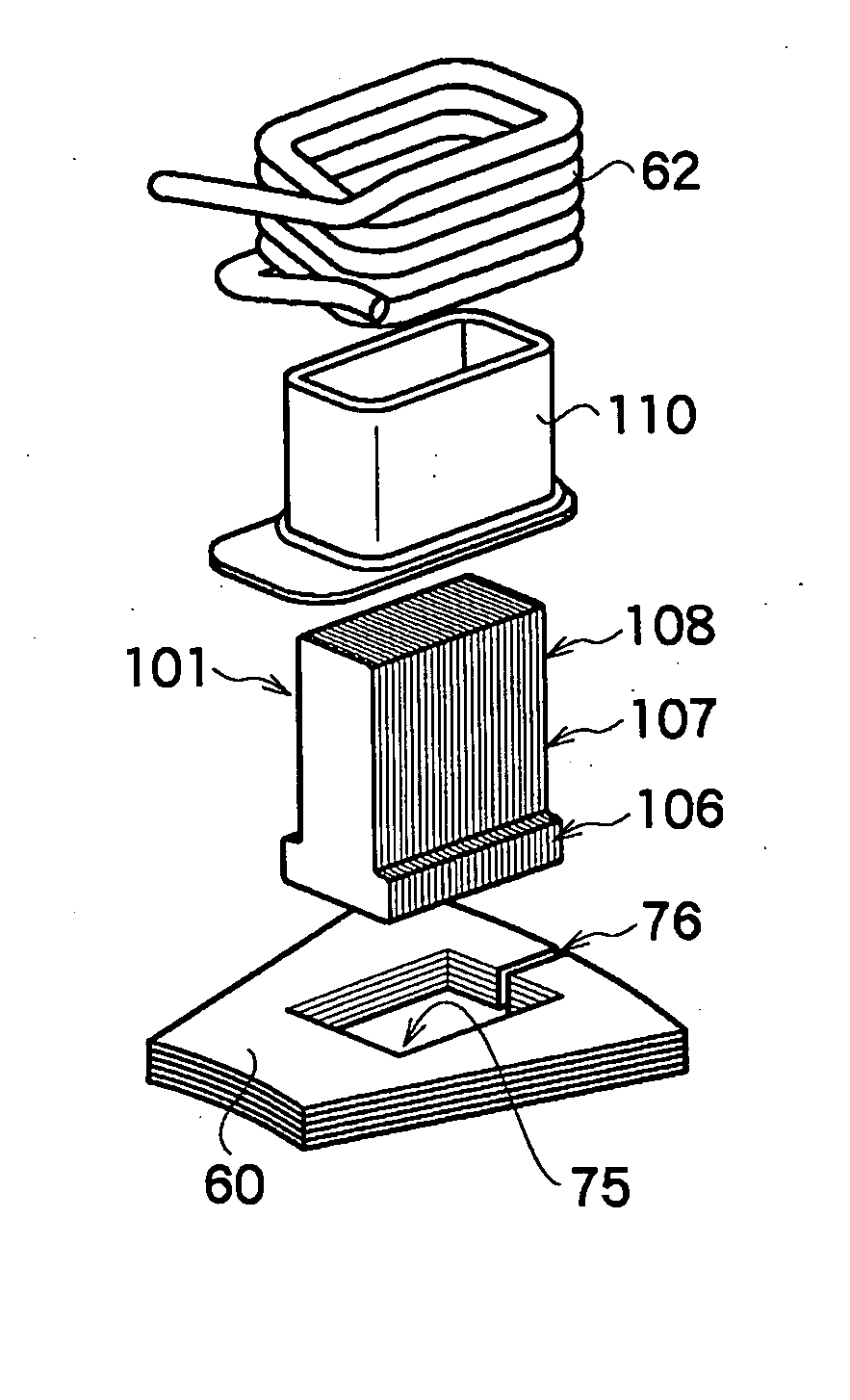

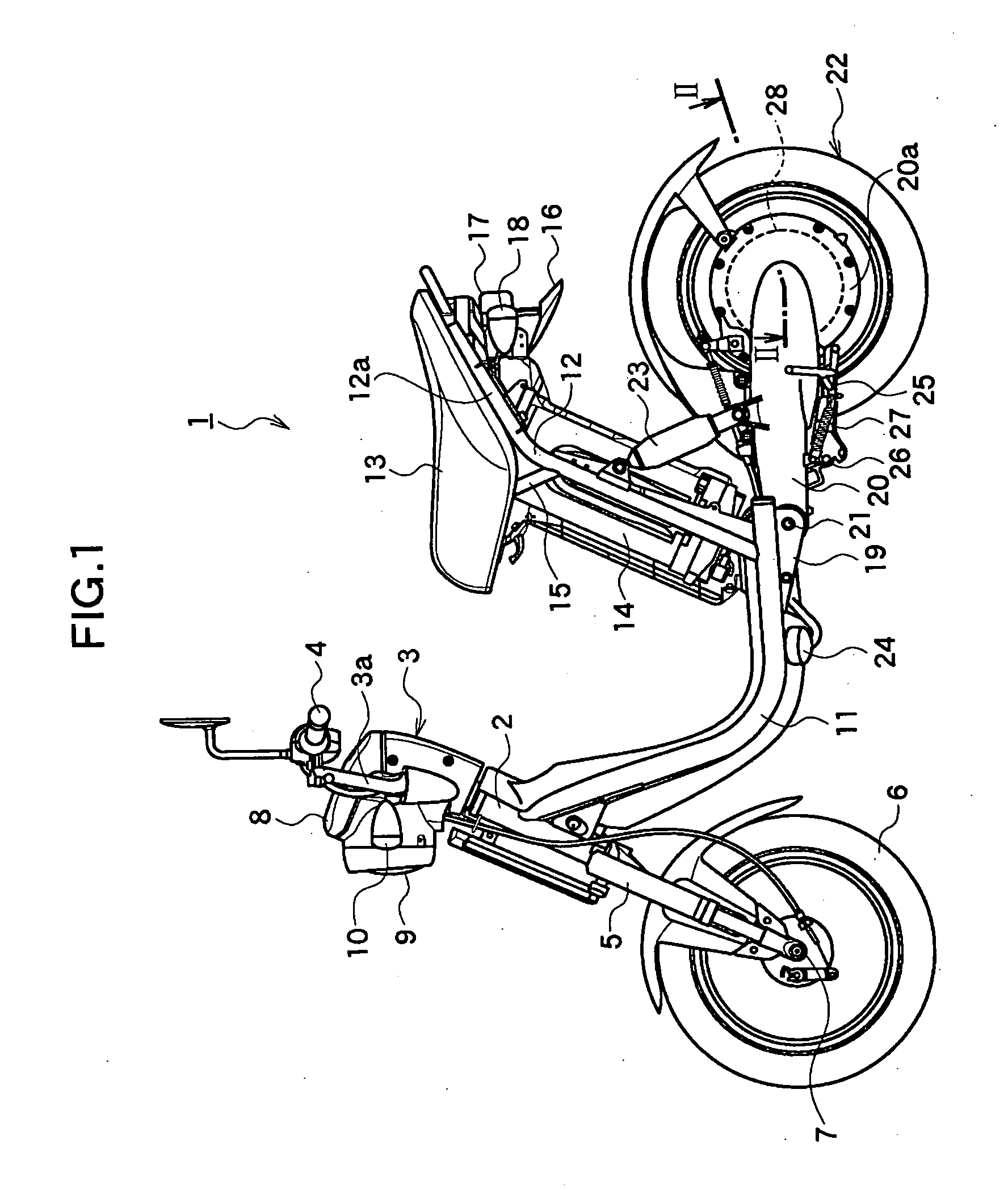

Rotating electric machine

InactiveUS20060103263A1Avoid it happening againTotal current dropPropulsion by batteries/cellsVehicular energy storageElectric machineEddy current

The present invention restrains generation of an eddy current caused by leaked magnetic flux, and reduces iron loss due to the eddy current. A tooth 61 is mounted to a stator yoke 60 in a state in which at least part of it (a portion 81 to be inserted into the yoke) is inserted into an insertion hole 75 formed through the magnet-opposed surface of the stator yoke 60, and the cross-sectional area S1 (See FIG. 6A) of the portion 81 of the tooth 61 to be inserted into the yoke, which is taken perpendicularly with respect to lines of magnetic force B1 generated at the tooth 61 when a coil 62 is energized, is larger than the cross-sectional area S2 (See FIG. 6B) of the portion 82 to be disposed within the coil of the tooth 61, which is taken perpendicularly with respect to the lines of the magnetic force B1.

Owner:YAMAHA MOTOR CO LTD

Preparation method for mu75 magnetic powder core of ferrosilicon aluminum

ActiveCN102360671AIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingFerrosilicon

The invention belongs to the field of preparation of metallic soft magnetic materials, and particularly relates to a preparation method for a mu75 magnetic powder core of soft magnetic ferrosilicon aluminum, which includes steps of smelting, rough smashing, heat treatment, fine smashing, annealing treatment, powder grading, powder insulating, compression molding, secondary heat treatment and coating treatment and requires components, by weight, 9.10% of silicon, 5.95% of aluminum and the rest iron. The preparation is performed with the smelting temperature of 1600 DGE C, the compression molding pressure ranging from 1700MPa to 2000Mpa, magnetic powder core pressing temperature ranging from 600 DEG C to 800 DEG C, and one hour for warm keeping in a nitrogen-oxygen mixed atmosphere. The magnetic powder core mu=75+-6 at 100kHz, the magnetic conductivity mu is smaller than 1% in variation under 1000kHz, the magnetic powder core loss is accordant to Pcv (powder loss) 50kHZ / 50mT<=100Mw / cm3, and the direct-current bias magnetic field is not lower than 70Oe when the magnetic conductivity is reduced to 50%. The preparation method for the mu75 magnetic powder core of soft magnetic ferrosilicon aluminum has the advantages that added binder is solid organic binder, the heat treatment after molding includes keeping warm for one hour in the nitrogen-oxygen mixed atmosphere, and the prepared magnetic powder core is free of pulverization, high in strength and stable in performance and has fine direct current bias characteristics, frequency stability and low loss.

Owner:TDG HLDG CO LTD

Manufacturing method of cold rolling electric steel special for compressor

InactiveCN1948517AHigh magnetic inductionIncrease stretch straighteningRoll mill control devicesHeat treatment process controlTemperature controlElectrical steel

The invention discloses a method to produce electrical steel by steel cold-rolling which is specially used for compressors. The method integrates the craft flows of hot rolling with traditional continuous metal cast process and hot rolling with continuous metal cast process of thin stock. It is characterized in that: The chemical constitution (percentage of weight) as follows is adopted: C<=0.03%,Si<=4.0%,Mn:0.1-1.0%,P<=0.16%, S<=0.01%,Al:0.1-0.8%, the rest is Fe and a little impurity. The craft feature is to control the batching temperature of hot rolling at 680-730deg.C. Cold rolling adopts endless rolling by laser welding, and its speed is 600-1000M / min. Crafts including cover annealing with full H2, flash heat and slow cool are introduced. Soaking time is 8 to 15 hours and the temperature is controlled at 670+-30deg.C. The annealing temperature is lower than recrystallization temperature. Crafts of leveling, tension and straightening under high pressure are adopted. The non-oriented electrical steel in this invention has high magnetic strength and low iron loss, which can produce various electrical steel with requirements of other breeds.

Owner:ANGANG STEEL CO LTD

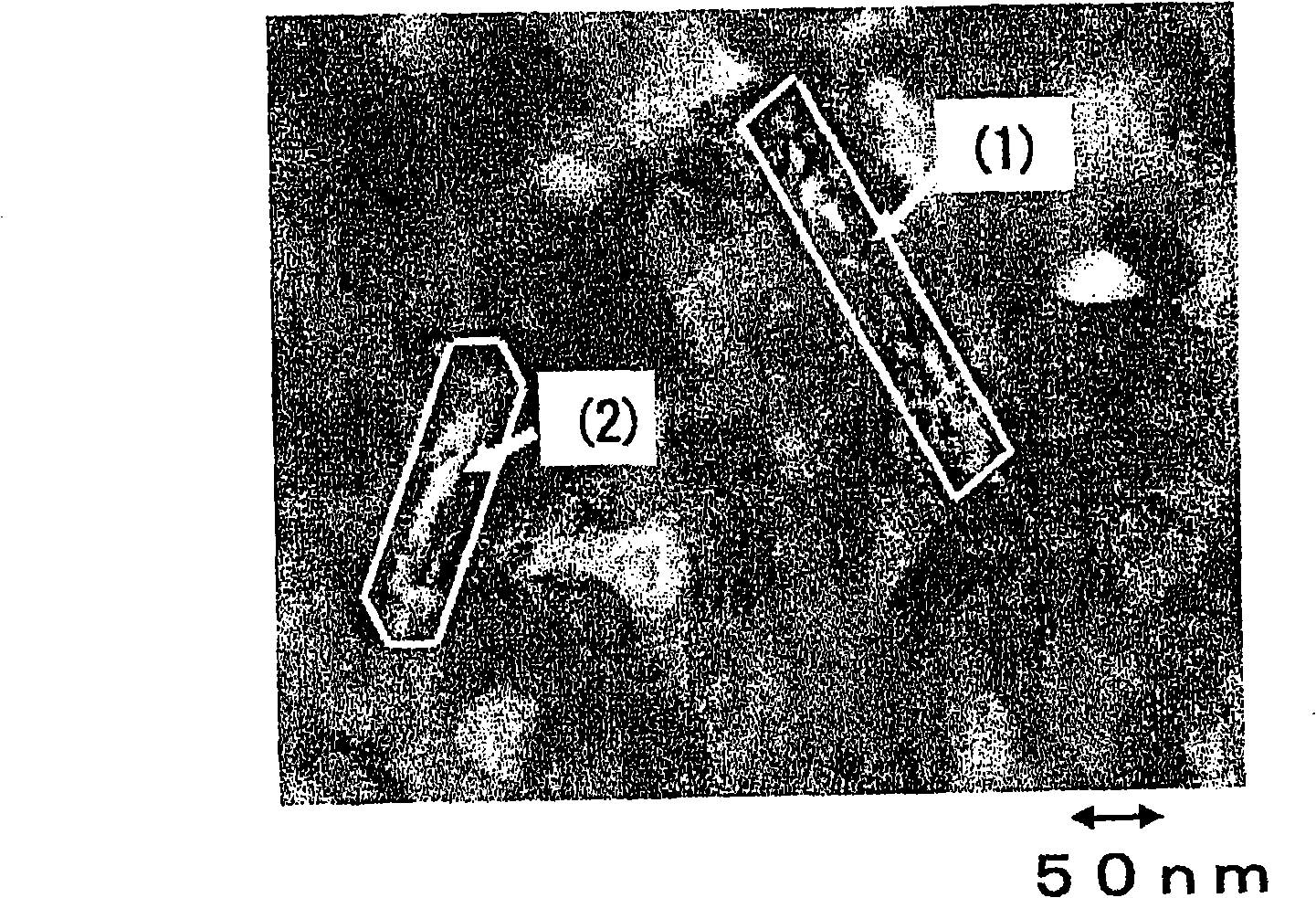

Rare earth magnet and manufacturing method thereof

InactiveCN101276665AHigh reluctanceHigh magnetic flux densityInorganic material magnetismEddy currentOxygen

A structure of a magnet wherein a magnet consisting of a magnetic body including iron and rare earths, a plurality of fluorine compound layers or oxyfluorine compound layers are formed interior of the magnetic body, and the fluorine compound layer or oxyfluorine compound layer has a major axis which is greater than the mean particle size of the crystal grains of the magnetic body.

Owner:HITACHI LTD

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

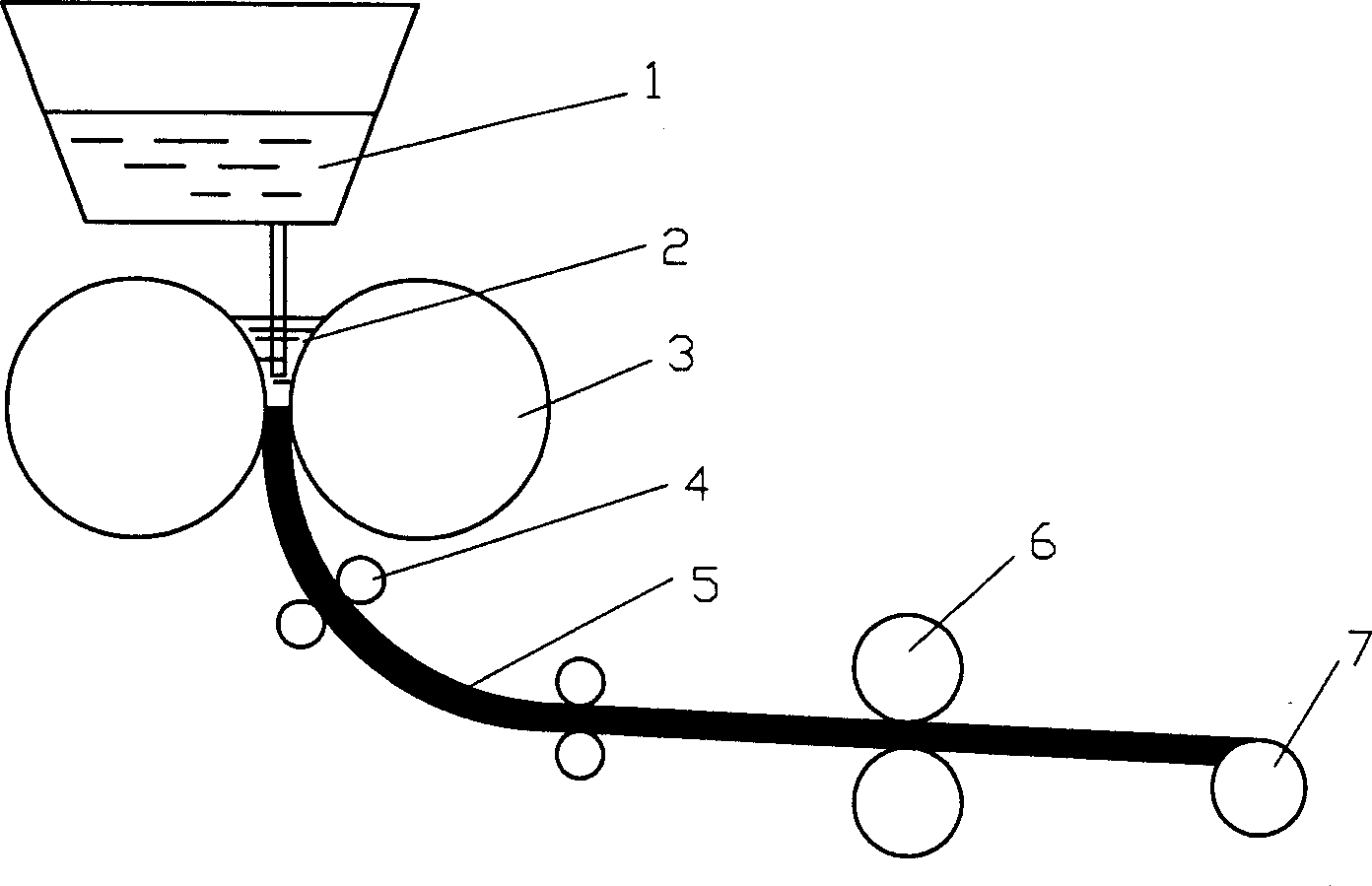

Method for production of non-oriented electrical steel

InactiveCN1463811AImprove surface qualityReduce defectsMetal rolling arrangementsElectrical steelMolten steel

The present invention is the double-roller thin belt continuous casting process of producing non-oriented electrical steel. Molten steel containing silicon in 0-3.5 % is made to pass through two crystallizing rollers to form coagulated shell and led out the crystallizing rollers to form cast belt; and the belt is hot rolled in a hot milling roll at 800-1000 deg.c to produce a hot rolling deformation of 5-25 % and wound. The simple technological process can produce high performance non-oriented electrical steel effectively.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for producing low-sulfur molten iron in one step by smelting and reducing copper slag

InactiveCN101824505ALower oxygen potentialReduce sulfur contentFluidised-bed furnacesMelting tankCyclone

The invention discloses a method for producing low-sulfur molten iron in one step by melting and reducing copper slag. The method is characterized in that the method includes the following processing steps that: the high-temperature molten copper slag is first reduced by reducing agent in a high-temperature reduction furnace, wherein, when the reduction reaction of iron is nearly finished, a certain amount of additive, which is theoretically calculated, is added in a melting bath based on the existing slag system in the reduction furnace, a jet gun is inserted into a slag-iron interface to blow carbon monoxide into the melting bath when the additive is completely molten, the blowing time is 30min to 40min, and desulphurization reaction is almost finished. The melting bath is kept still, and when slag and iron are completely separated, the high-temperature low-sulfur molten iron and the slag are respectively discharged out of a tap hole and a slag hole. In addition, after high-temperature flue gas passes through a secondary combustion chamber, a residual heat boiler recovers residual heat from the flue gas, dust is collected from the flue gas by cyclone, and the flue gas is washed. By sufficiently utilizing the high desulphurization of the refined slag and blowing the carbon monoxide, the invention solves the defect that the content of sulfur in the molten iron produced by melting and reducing the copper slag for ironmaking is high; the processing flow is short, the emission of pollutant is less, and moreover, the applicability is high.

Owner:KUNMING UNIV OF SCI & TECH

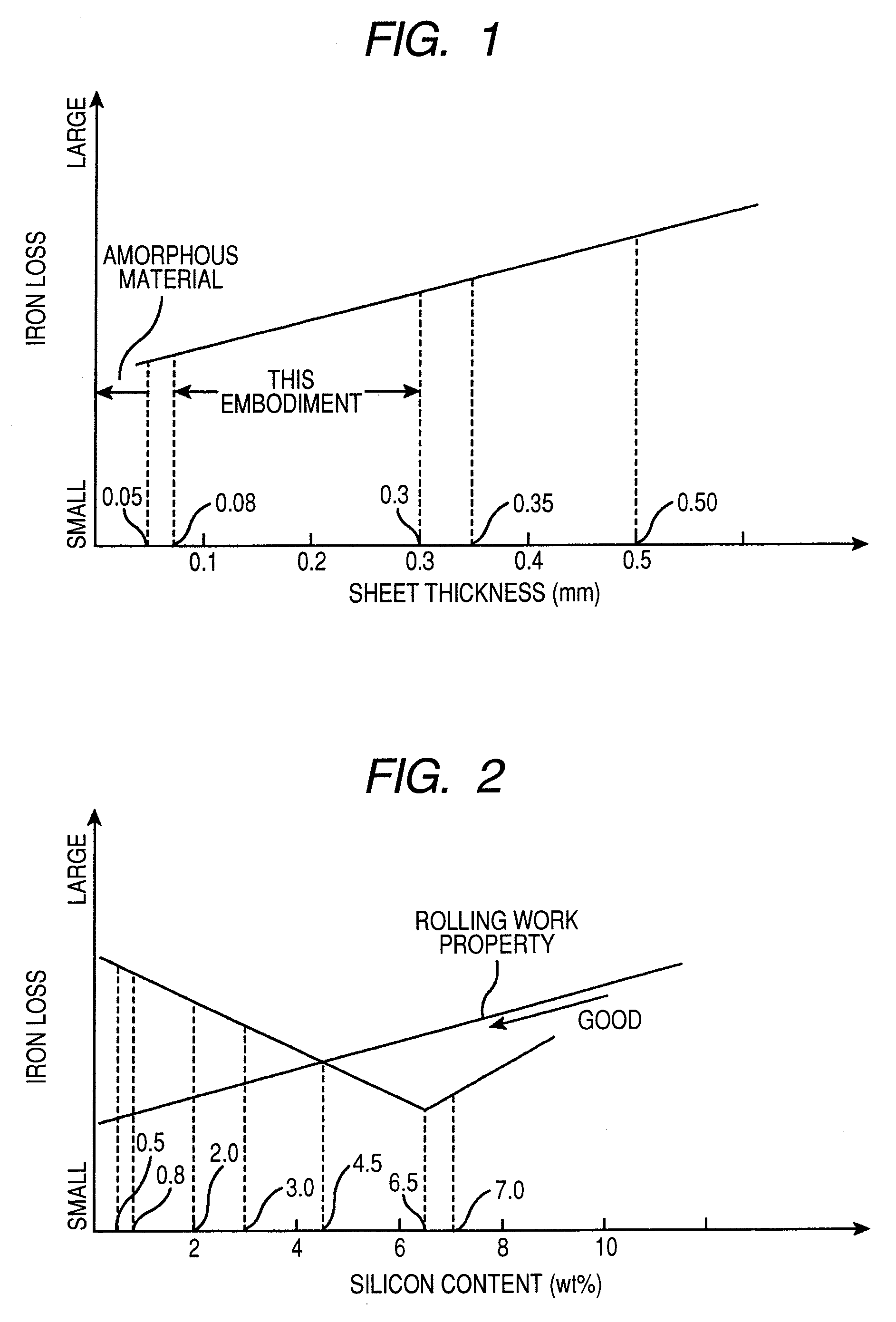

Rotating electrical machine

InactiveUS20080012445A1Reduce iron lossReduce eddy-current lossMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

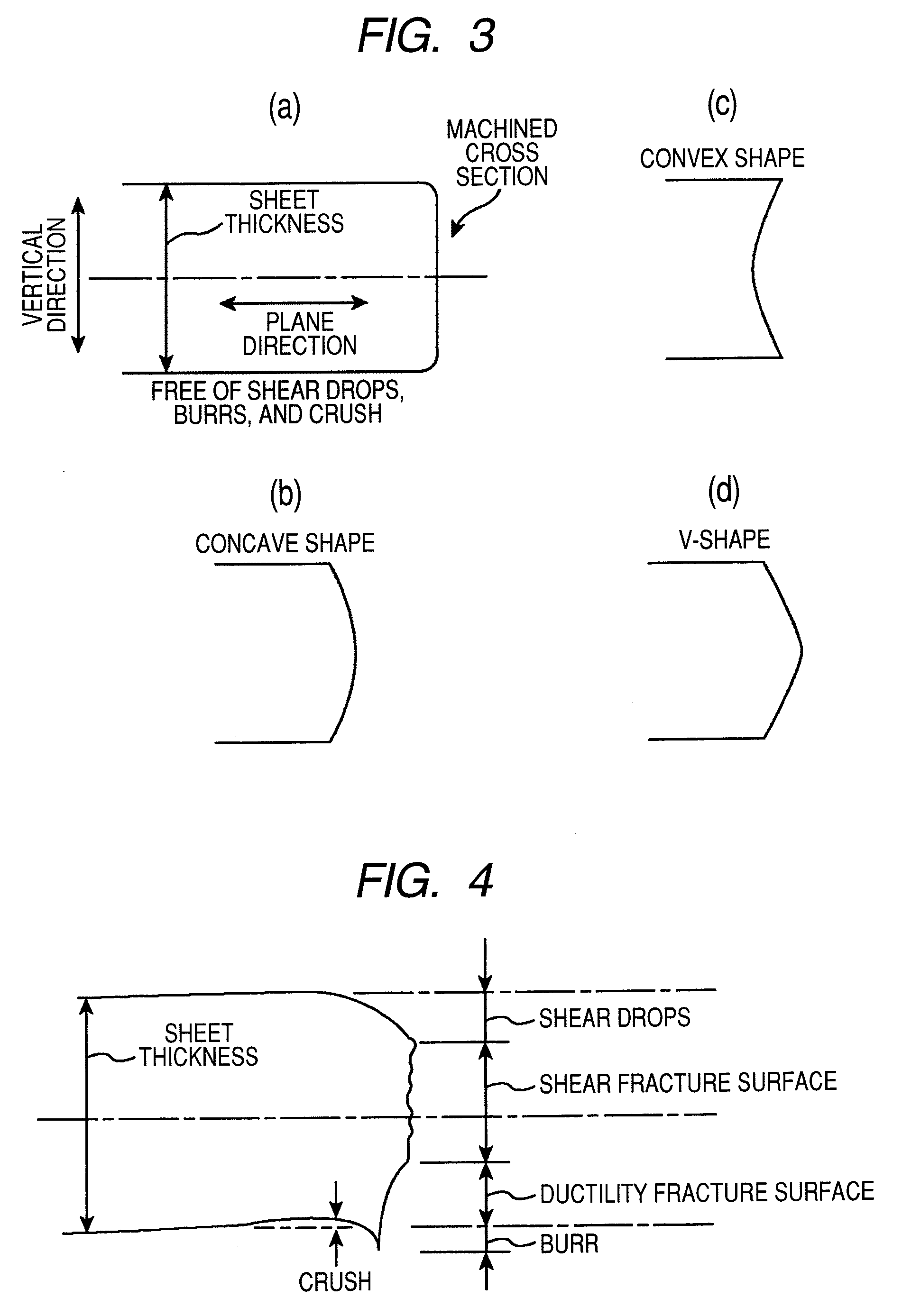

A rotating electrical machine comprises a stator and a rotor; the stator comprising a stator core having teeth and slots, and stator windings disposed in the slots, wherein the stator core is made of laminated steel sheets, teeth and slots of the steel sheet are made by etching, and the thickness of the steel sheet is between 0.05 mm and 0.30 mm. Specifically, it is preferable that the steel sheet used herein be a silicon steel sheet containing crystalline particles.

Owner:HITACHI LTD

Induction machine

InactiveUS20080238237A1Reduce iron lossImprove efficiencyWindingsMagnetic circuit rotating partsElectrical conductorConductor Coil

An induction machine has a stator and rotor. The stator comprises teeth and slots and stator winding disposed in the slots. The rotor comprises a rotor core having teeth and slots and a rotor-conductor disposed in the rotor slots. Both of the stator core and rotor core are made of laminated steel sheets, and the teeth and slots made of steel sheets are formed by etching.

Owner:HITACHI LTD

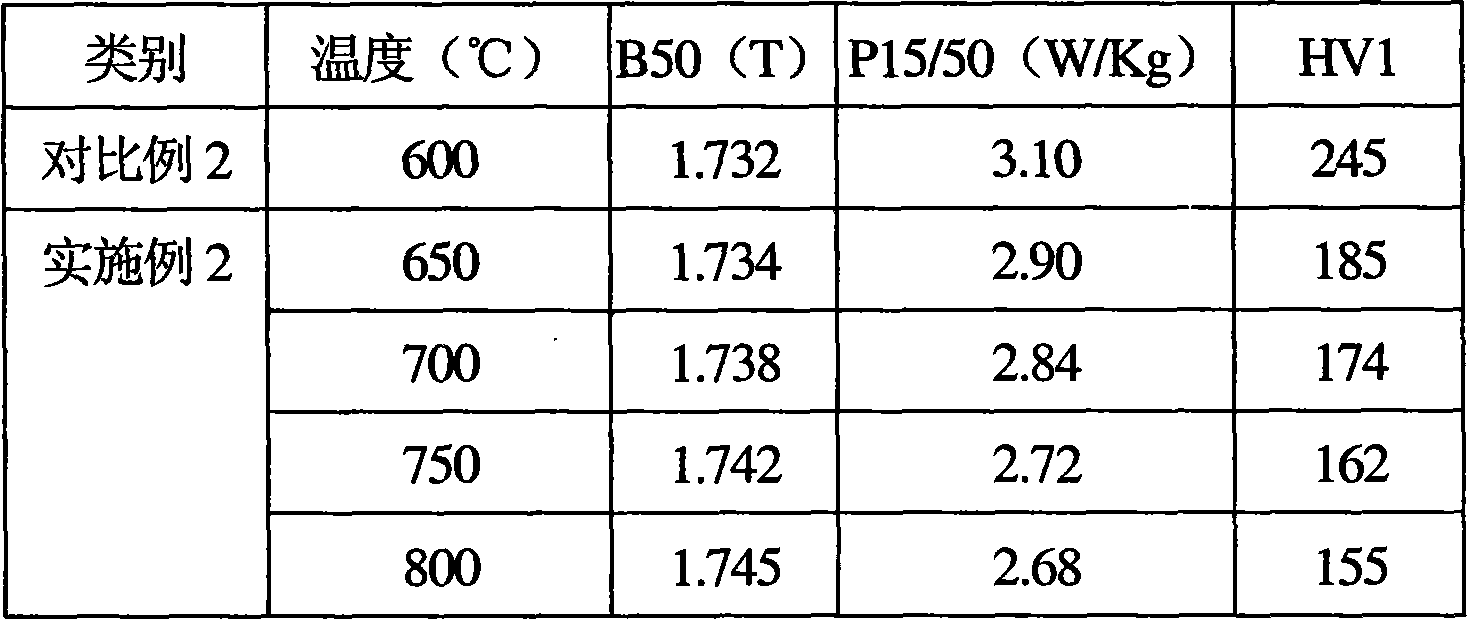

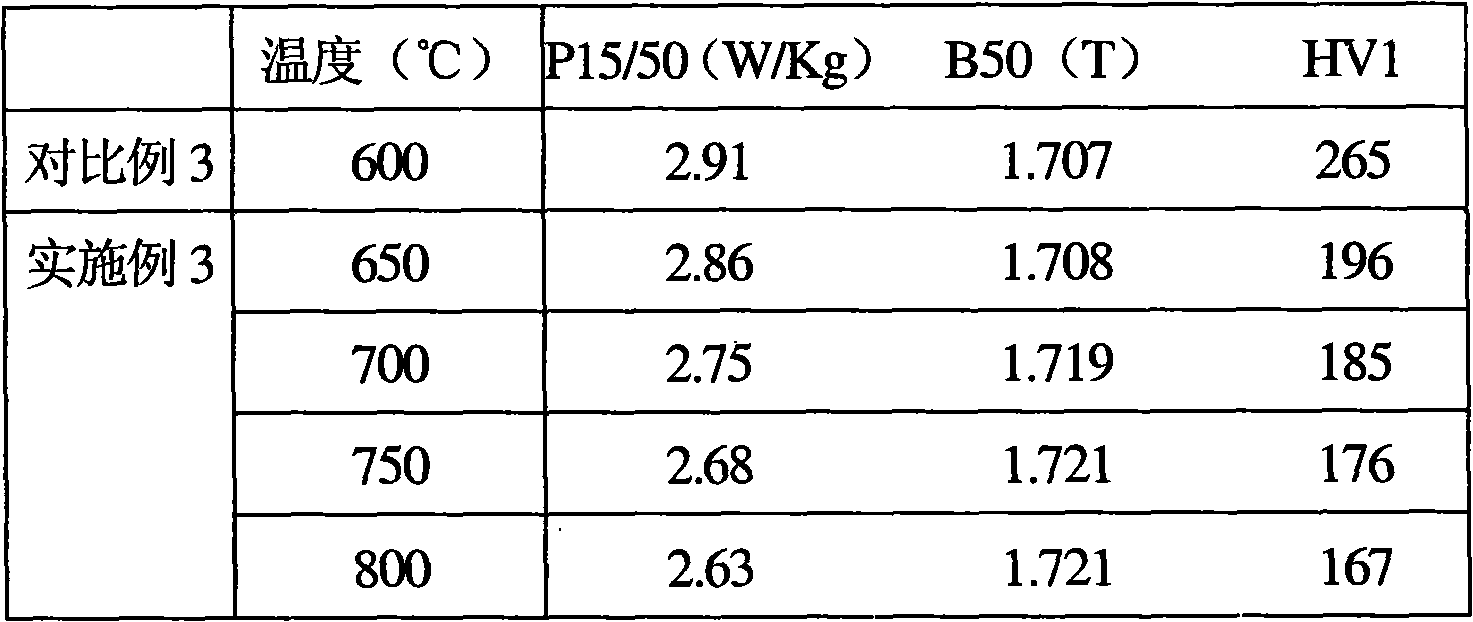

Coated semi-processed non-oriented electrical steel sheet and manufacturing method thereof

InactiveCN101654757AFulfil requirementsReduce iron lossFurnace typesHeat treatment furnacesChemical compositionSheet steel

The invention provides a coated semi-processed non-oriented electrical steel sheet and a manufacturing method thereof. The steel sheet comprises the following chemical compositions in percentage by mass: less than or equal to 0.003 percent of C, 1.00 to 2.30 percent of Si, 0.20 to 1.00 percent of Mn, 0.01 to 0.10 percent of P, 0.20 to 0.80 percent of Al, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method does not need electromagnetic stirring in slab continuous casting; when the content of Si is between 1.65 to 2.30 percent, a normalizing treatment procedure is added before the step of pickling; and an annealing condition is that: a temperature is between 650 and 800 DEG C, the annealing time is between 1 and 4 minutes and the annealing is carried out in a dry atmosphere of whole nitrogen. The coated semi-processed non-oriented electrical steel sheet has low iron loss, high magnetic induction, good mechanical property, simple procedure and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Fabrication method of soft magnetic alloy materials

ActiveCN104008844AReduce magnetic lossImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureProduction rateHigh intensity

The invention relates to a fabrication method of soft magnetic alloy materials. The fabrication method includes flattening, drying and annealing, and post-treating. The surface of soft magnetic alloy powder is provided with a metal oxide film, so that magnetic loss of the powder is reduced on the premise of not reducing magnetic conductivity of the powder and magnetic performance of the powder is improved. The fabrication method is simple, low in cost, and suitable for large-scale batch production; the soft magnetic alloy materials fabricated can meet the high requirements for high saturation flux density, high magnetic conductivity, low iron loss, high strength and high productivity.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

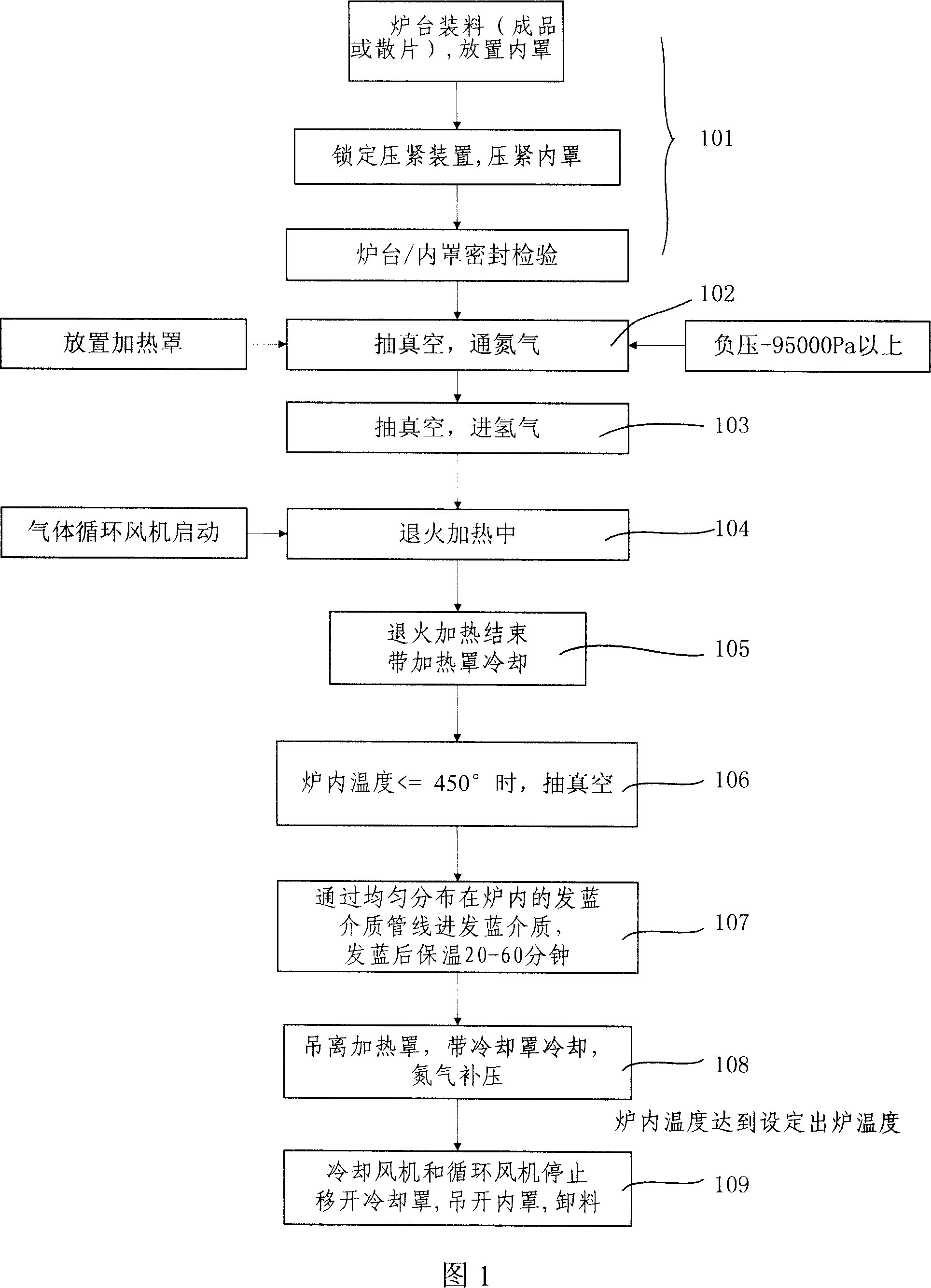

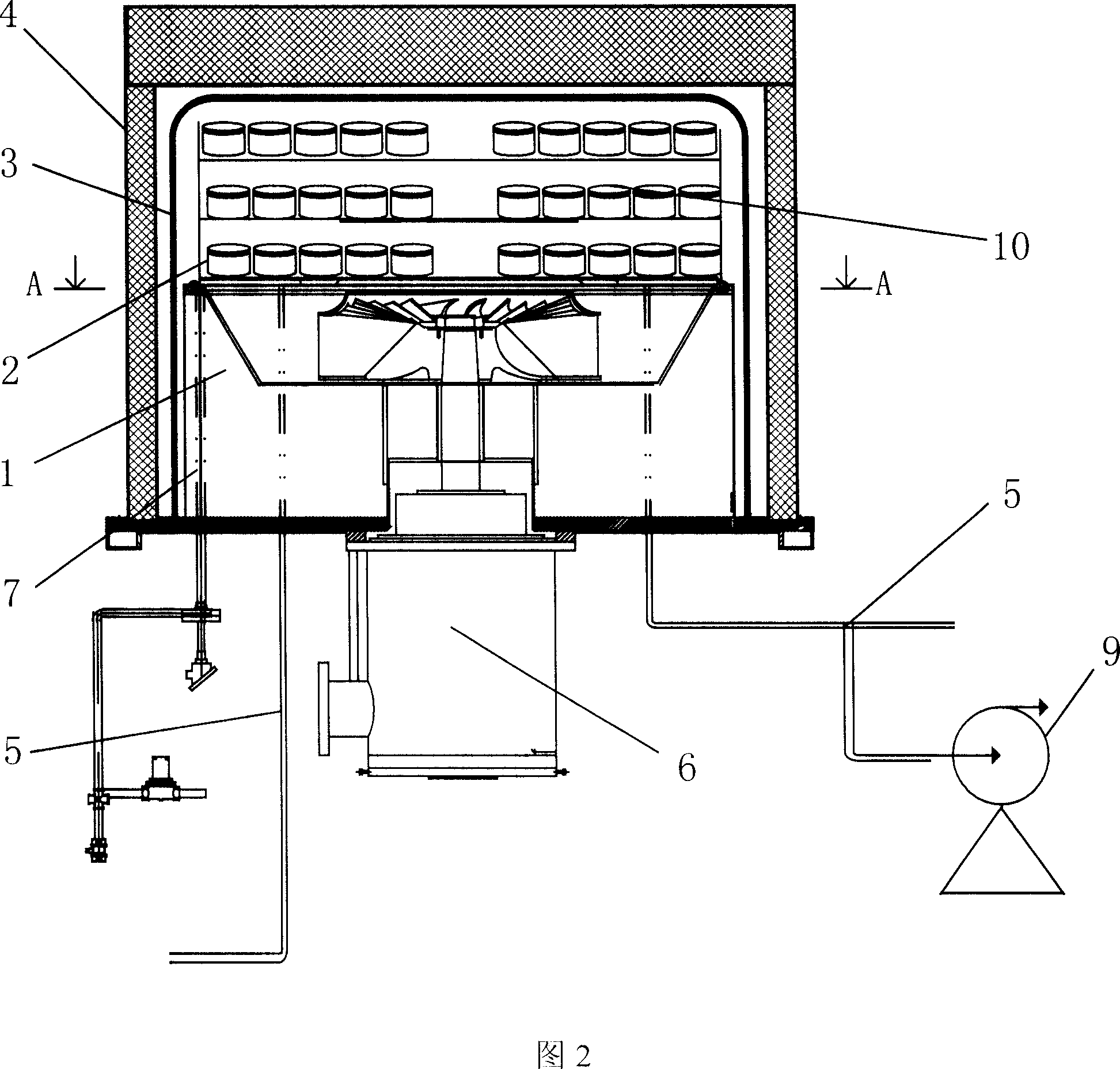

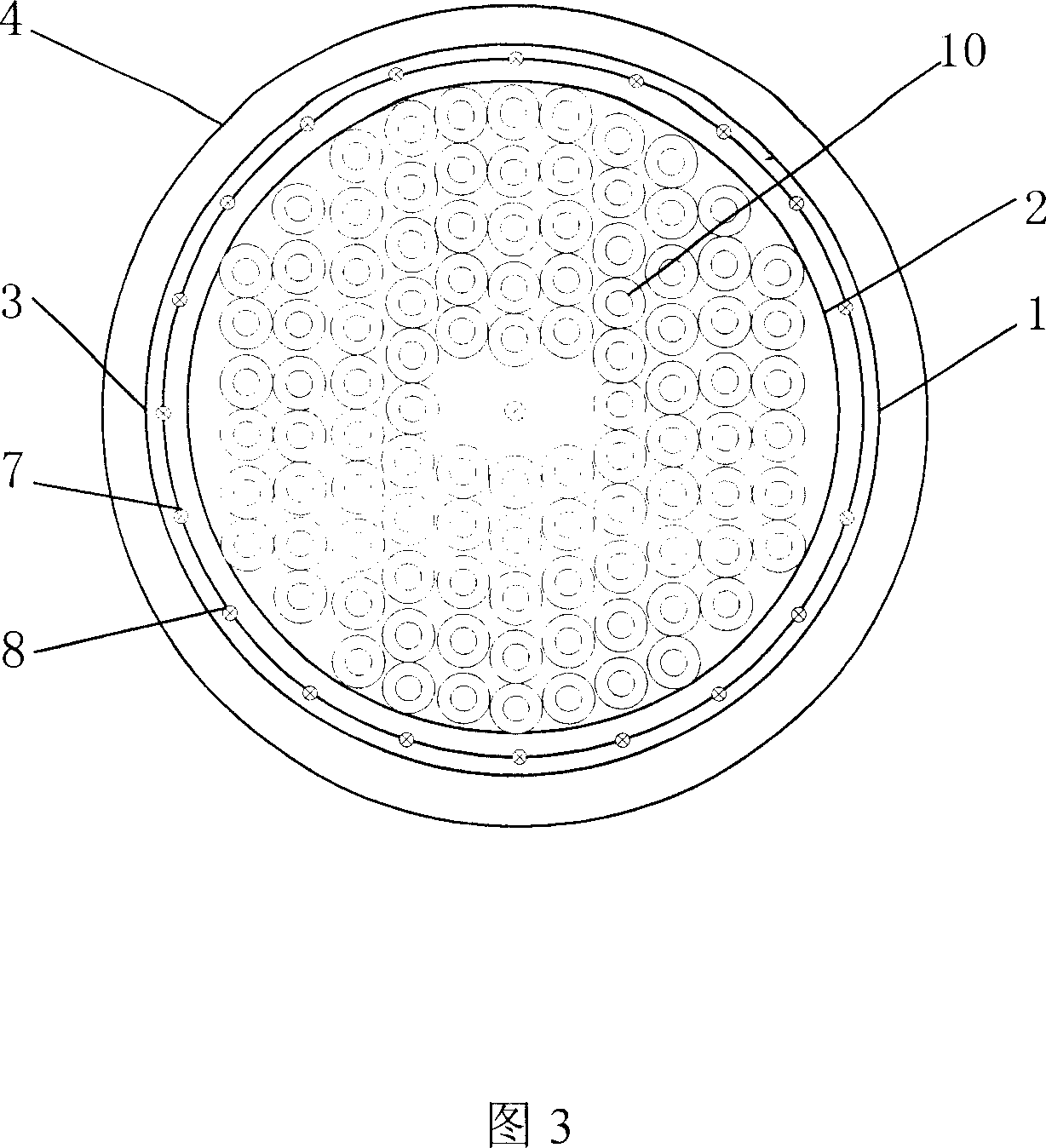

Process and device for coating-free electrical steel annealing and bluing

ActiveCN101082075AHigh magnetic inductionImprove efficiencyMetallic material coating processesHeat treatment process controlElectrical steelStress relieving

The no-coating electric steel sheet annealing and blueing process includes the following steps: 1. annealing laminated no-coating silicon steel sheets inside a bell type furnace under hydrogen atmosphere; 2. vacuumizing the bell type furnace to vacuum degree lower than 95000 Pa after the silicon steel sheets are cooled slowly to 300-450 deg.c, and leading blueing water solution to the furnace before maintaining the temperature for 20-60 min; and 3. vacuumizing for the second time, filling nitrogen for cooling and discharging in the temperature lower than 150 deg.c. The process has high annealing quality, homogeneous blueing effect, and capacity of raising the magnetic induction coefficient of silicon steel sheets and lowering their iron loss.

Owner:BAOSHAN IRON & STEEL CO LTD

Mixed excitation short-magnetic-circuit variable-reluctance motor

InactiveCN102315746AEasy to installFlexibleMagnetic circuit rotating partsMagnetic circuit stationary partsNoise levelElectrical polarity

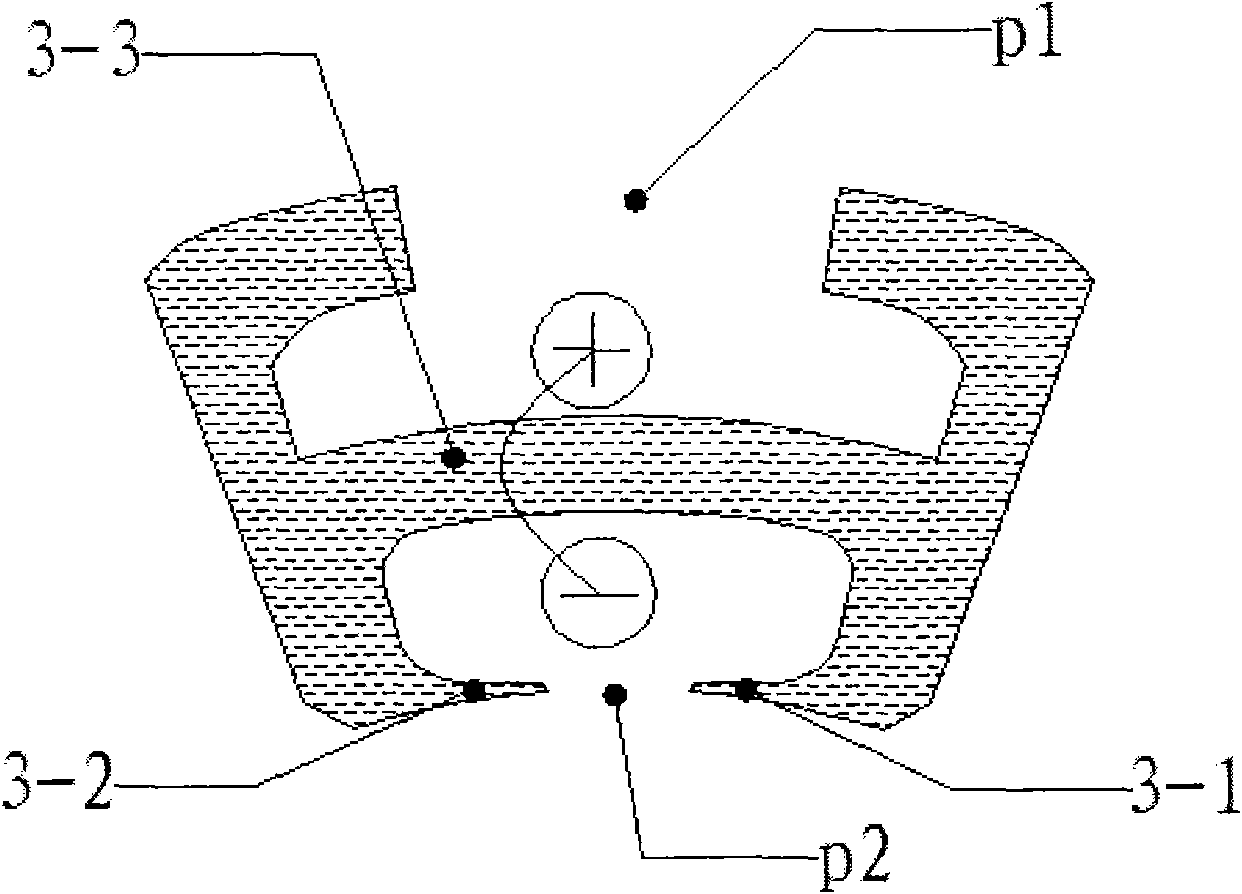

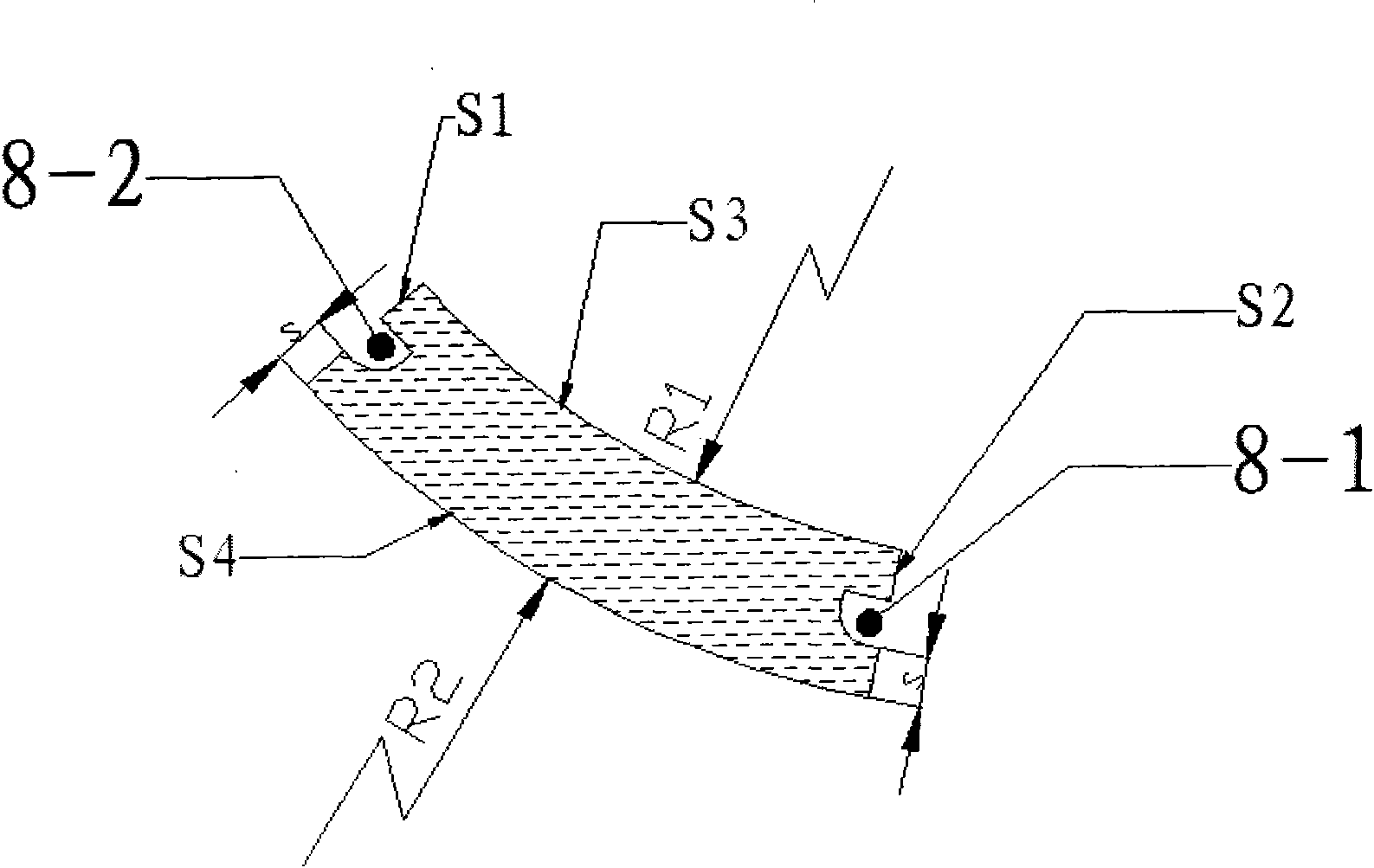

The invention discloses a mixed excitation short-magnetic-circuit variable-reluctance motor 1 as well as a stator structure and a rotor structure thereof. An inner circular face t of a base part 2 of the mixed excitation short-magnetic-circuit variable-reluctance motor is provided with modules 2-1 which protrude inwards in a preset interval angle; the stator part comprises a plurality of H-shaped stator sections 3 and first permanent magnets 4 (1) arranged at all the H-shaped stator sections p1, and the polarities of the permanent magnets of the stator sections are opposite; an exciting winding coil is embedded into two stator slots of each H-shaped stator section 3; and the rotor part comprises a rotor body 5 and a plurality of annular body rotor sections 8 arranged on the rotor body and / or second permanent magnets 4 (2), wherein the second permanent magnets are arranged on the s3 surfaces of the annular body rotor sections, and open grooves 8-1 and 8-2 are arranged on the lateral surfaces of the annular body rotor sections. According to the invention, the rotating force of the variable-reluctance motor can be increased, the energy density is improved, the torque ripple and the vibration and noise level are reduced, the performance is stable, and the size is smaller under the requirement of same output torque.

Owner:SOUTH CHINA UNIV OF TECH

High grade non-oriented silicon steel produced by continuous casting and rolling of sheet billet and production method thereof

High grade non-oriented silicon steel produced by continuous casting and rolling of sheet billet comprises the following components, by weight: no more than 0.003% of C, 2.20-3.20% of Si, 0.25-1% of Al, no more than 0.002% of S, no more than 0.002% of N, no more than 0.02% of Cu, 0.20-0.50% of Mn, and the balance of Fe and unavoidable impurities; besides, contents of the components satisfy the following relations: Si+Al<=4.2%, [Al]*[N]: 5+10<-8>-1.5*10<-7>, and [Mn]*[S]: 2*10 <-8>-1*10<-7>. The manufacture method comprises the steps of: smelting and vacuum treatment; continuous casting with liquid core reduction; billet heating; hot continuous rolling; flattening; normalizing treatment; conventional acid pickling; cold rolling; and finished product annealing. The steel plate provided by the invention has advantages of good surface quality, low iron loss, excellent magnetic, and no corrugated defects.

Owner:武汉钢铁有限公司

Method for manufacturing of insulated soft magnetic metal powder formed body

InactiveCN101213041AStable manufacturingReduce iron lossTransportation and packagingMetal-working apparatusMetal powderHeat treated

A method of manufacturing an insulating soft magnetic metal powder compact, by forming an inorganic insulating film on the surface of soft magnetic metal powder particles, compacting and molding the powder, and then performing heat treatment to provide an insulating soft magnetic metal powder compact, The method includes: compacting and forming the powder; then, at a high temperature higher than the Curie temperature of the soft magnetic metal powder and lower than the critical temperature for destroying the insulating film, in a non-oxidizing atmosphere such as vacuum, inert gas, etc., making the powder The powder is magnetically annealed; then further heat-treated in an oxidizing atmosphere such as air at a temperature of 400°C to 700°C.

Owner:MITSUBISHI STEEL MFG CO LTD

Iron-based soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN104078182AThickness controllable and adjustableGuaranteed uniformityInorganic material magnetismAlcoholHeat stability

The invention relates to an iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The invention adopts the technical scheme as follows: sequentially adding iron-based alloy powder, absolute ethyl alcohol, a silane coupling agent and distilled water into a reaction vessel according to the mass ratio of 1:(6-10):(0.04-0.10):(0.2-0.4), and stirring; adding tetraethyl orthosilicate or methyl silicate, then adding ammonia water, stirring continuously, washing, filtering and drying; placing the obtained composite powder with a core-shell heterostructure into an annealing furnace, performing heat preservation for 1-3 h under the condition of 600-800 DEG C, performing furnace cooling and performing compression moulding; sintering for 1-10 h under the condition of 900-1350 DEG C, so that the iron-based soft magnetic composite magnetic powder core is obtained after furnace cooling. The prepared iron-based soft magnetic composite magnetic powder core has the characteristics that the insulating property is good, the iron loss is low, high magnetic strength is achieved, the heat stability is good and the service life is prolonged when the iron-based soft magnetic composite magnetic powder core is used at a higher environment temperature.

Owner:WUHAN UNIV OF SCI & TECH

Non-oriented electrical steel sheet excellent in magnetic permeability and method for manufacturing the same

The invention relates to a non-oriented electrical steel sheet and a method for manufacturing the same, and more concretely relates to a non-oriented electrical steel sheet that includes 1.5-4.0 wt% Si, 0.01-0.50 wt% Mn, 0.0005-0.02 et% Al, 0.001-0.15 wt% P, less than 0.004 wt% (except 0 wt%) C, 0.0001-0.01 wt% S, less than 0.003 wt% (except 0 wt%) N, less than 0.003 wt% (except 0 wt%) Ti, 0.01-0.15 wt% Sn, less than 0.15 wt% Sb, and the balance F and other inevitable foreign matters. The Al, Sn, Sb and P in the sheet satisfies the relation: [Al]<[Sn]+[Sb] and [Al]<[Sn]+[P], wherein [Al], [Sn], [Sb] and [P] respectively represent contents of Al, Sn, Sb and P by means of wt%.

Owner:浦项股份有限公司

Fe based large block amorphous nano-crystal magnetic element preparation method

InactiveCN101145420AHigh densityImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsHigh densityNanocrystal

The invention discloses a preparation method of Fe-based bulk amorphous nano-crystal magnetic elements, which comprises the following steps: pre-crashing a Fe-based amorphous belt to flakes of (0.5-1)*(0.5-1)cm<2> size; placing the pre-crashed flakes to a ball mill for an appropriate period of time to obtain amorphous powder of 10nm-200nm size under the protection of inert gases or reducing gases, against sample oxidation; mixing the obtained amorphous powder with a binder; and applying a pressure within a temperature range of glass transition until the pressure is more than or equal to 100MP. For the rapid quenching of amorphous powder, under the reasonable control of temperature, pressure and solidification conditions, the high-density bulk is yielded and simultaneously a large quantity of nano-crystal bulk alloys, with uniform size distribution, are separated out of the amorphous matrix, forming a nano-crystal / amorphous composite phase structure, and the size of the nano-crystals is significantly less than that of those formed by the crystallization of amorphous bulk under normal pressure.

Owner:TONGJI UNIV

Process technology method for efficient and low-cost converter production of ultra-low phosphorus liquid steel

The invention relates to a process technology method for efficient and low-cost converter production of ultra-low phosphorus liquid steel. According to the method, liquid steel with a temperature of 1260-1350 DEG C is added to a converter, wherein P content in the liquid steel is less than or equal to 0.11%, Si content in the liquid steel is 0.3-0.5%, and Mn content in the liquid steel is 0.3-0.6%; a slag material is added, argon gas is blown from the bottom, oxygen gas is blown from the top, and then the 1 / 3-1 / 2 of the slag is removed, wherein the flow rate of the argon gas is more than or equal to 0.07 Nm<3. / t.min, the pressure of the oxygen gas is less than or equal to 0.8 MPa, the bath temperature is less than or equal to 1450 DEG C, and the early stage converting time is 7-10 minutes; in the middle stage, a high lance position operation is adopted, the slag material is complementally added, and then 40-60% of the slag is removed, wherein the C content in the liquid steel is 0.30-0.60%, and the temperature is 1520-1560 DEG C; in the later stage, per ton of the steel is complementally added with 2-5 kg of lime and 2-5 kg of a cooling agent, a large amount of the argon gas is blown from the bottom, a stirring treatment is performed for more than or equal to 1.5 minutes, and the steel is discharged when the end point C content is 0.025-0.08% and the temperature is 1600-1630 DEG C. According to the present invention the ultra-low phosphorus liquid steel with the phosphorus content less than or equal to 50 ppm is produced.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com