Mixed excitation short-magnetic-circuit variable-reluctance motor

A hybrid excitation and variable reluctance technology, applied in the field of electric drives, can solve problems such as difficulty in heat dissipation, reducing the service life of permanent magnets, and limiting the energy density of motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

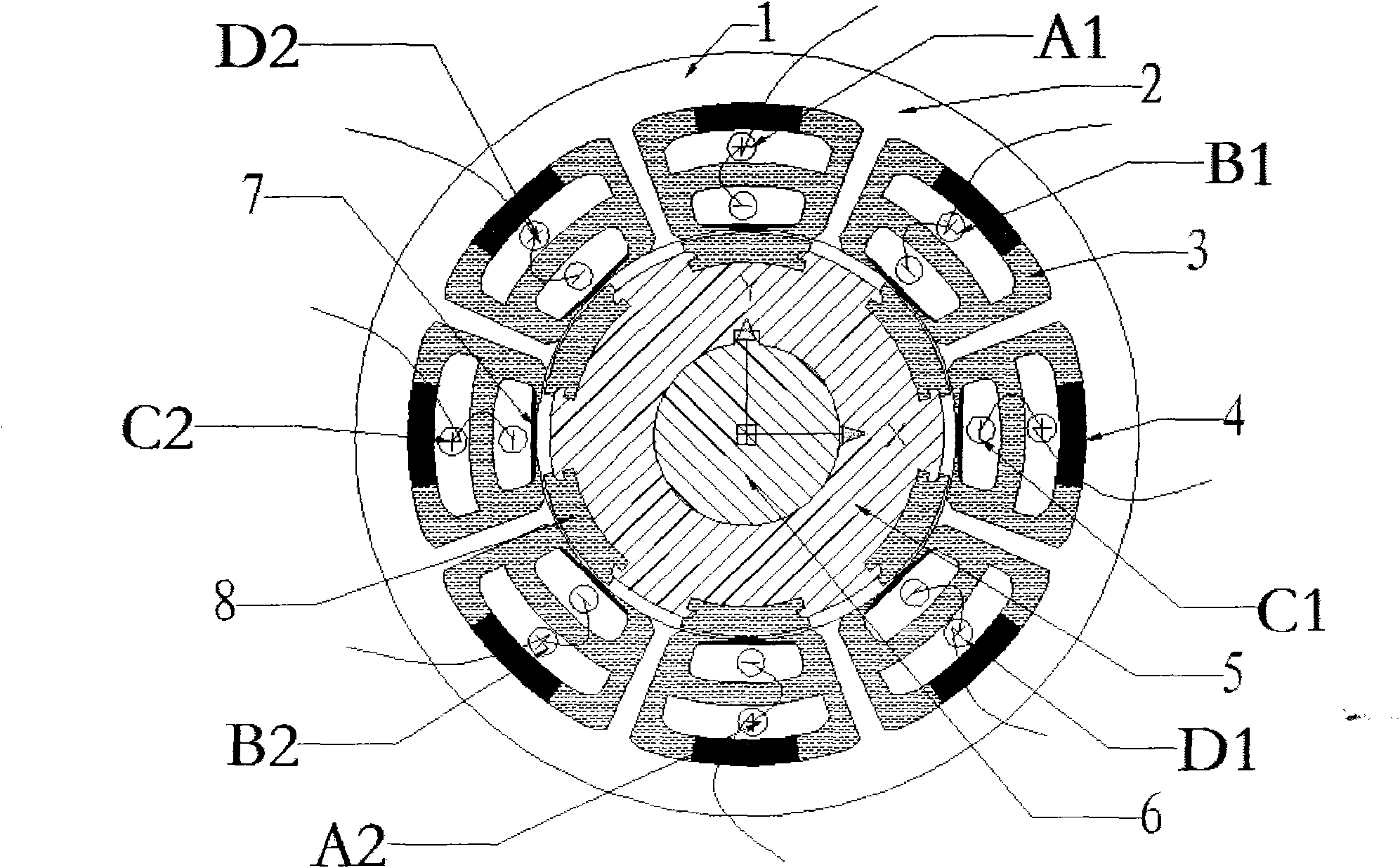

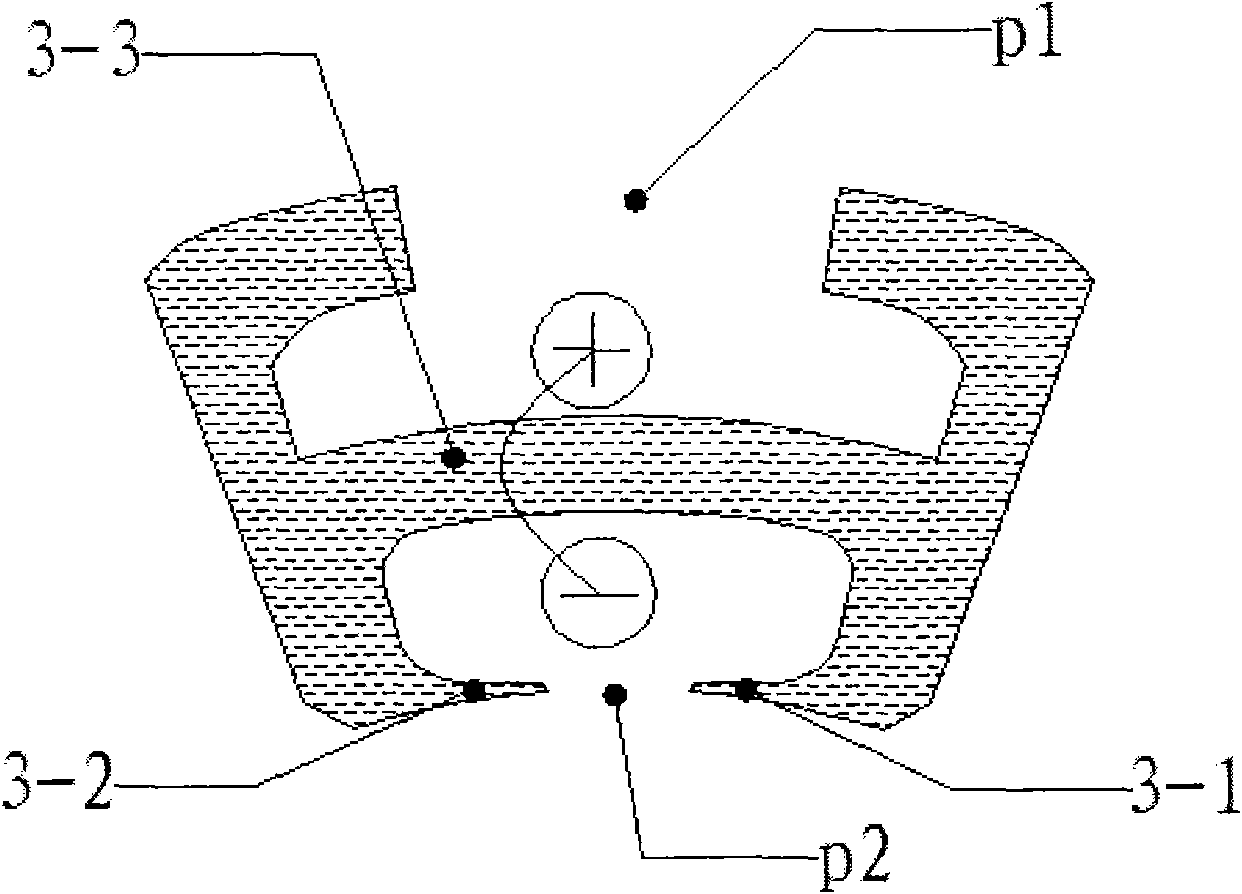

[0027] The core of the present invention is to re-plan the magnetic circuit and propose an H-shaped stator structure to prolong the service life of the permanent magnet and reduce the iron loss, thereby increasing the energy density; the same as the technical characteristics of the general motor, the hybrid excitation short-magnet of the present invention The road variable reluctance motor (1) also includes an organic base (2), a stator part, a rotor part and an excitation winding, but crucially, the stator part in the present invention includes a plurality of H-shaped stator segments (3) and is placed in each stator segment The first permanent magnet (4) at p1, the permanent magnets on each stator segment have opposite polarities, and the field windings (A1-A2, B1-B2, C1-C2, D1-D2) of each phase are embedded in each stator segment (3 ) in the stator slot.

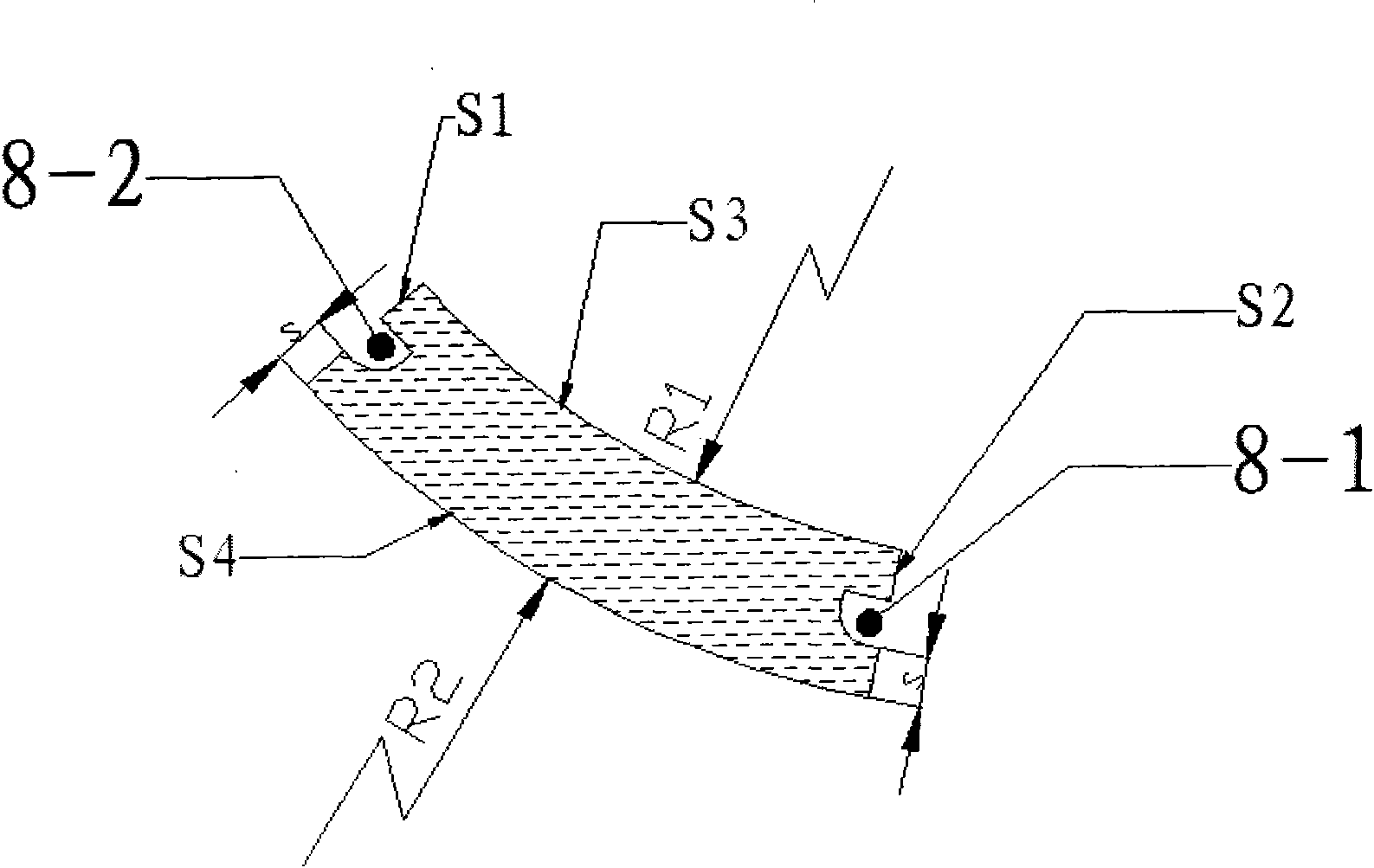

[0028] The rotor part includes a rotor body (5), a rotor segment assembly (8) and / or a second permanent magnet 4 (2), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com