Process and device for coating-free electrical steel annealing and bluing

A non-coating, electrical steel technology, applied in the field of heat treatment, can solve problems such as sticking, oxidation and punching deformation, affecting lamination, punching and scrapping, etc., to achieve the effect of reducing iron loss, improving efficiency, and eliminating sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

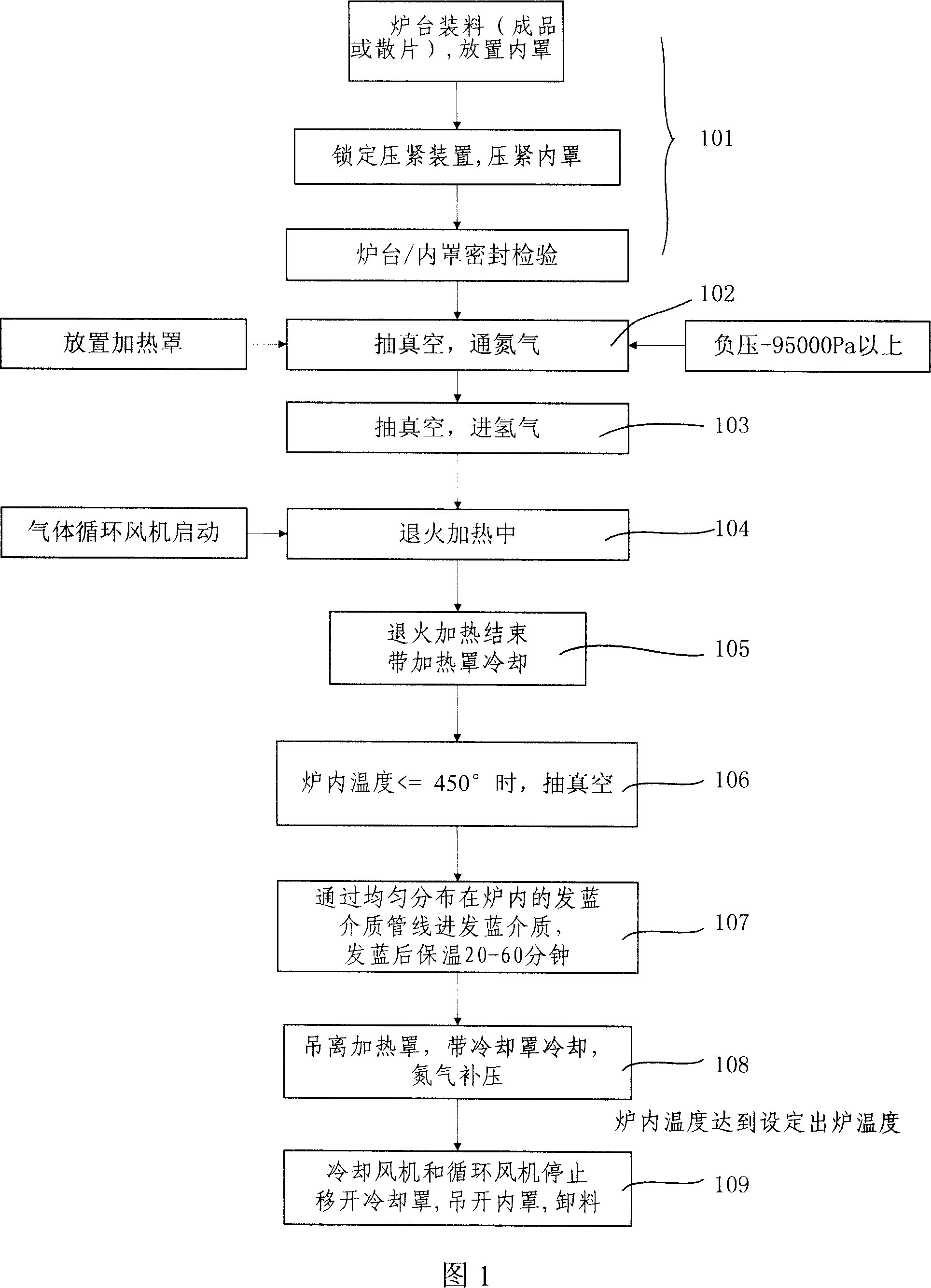

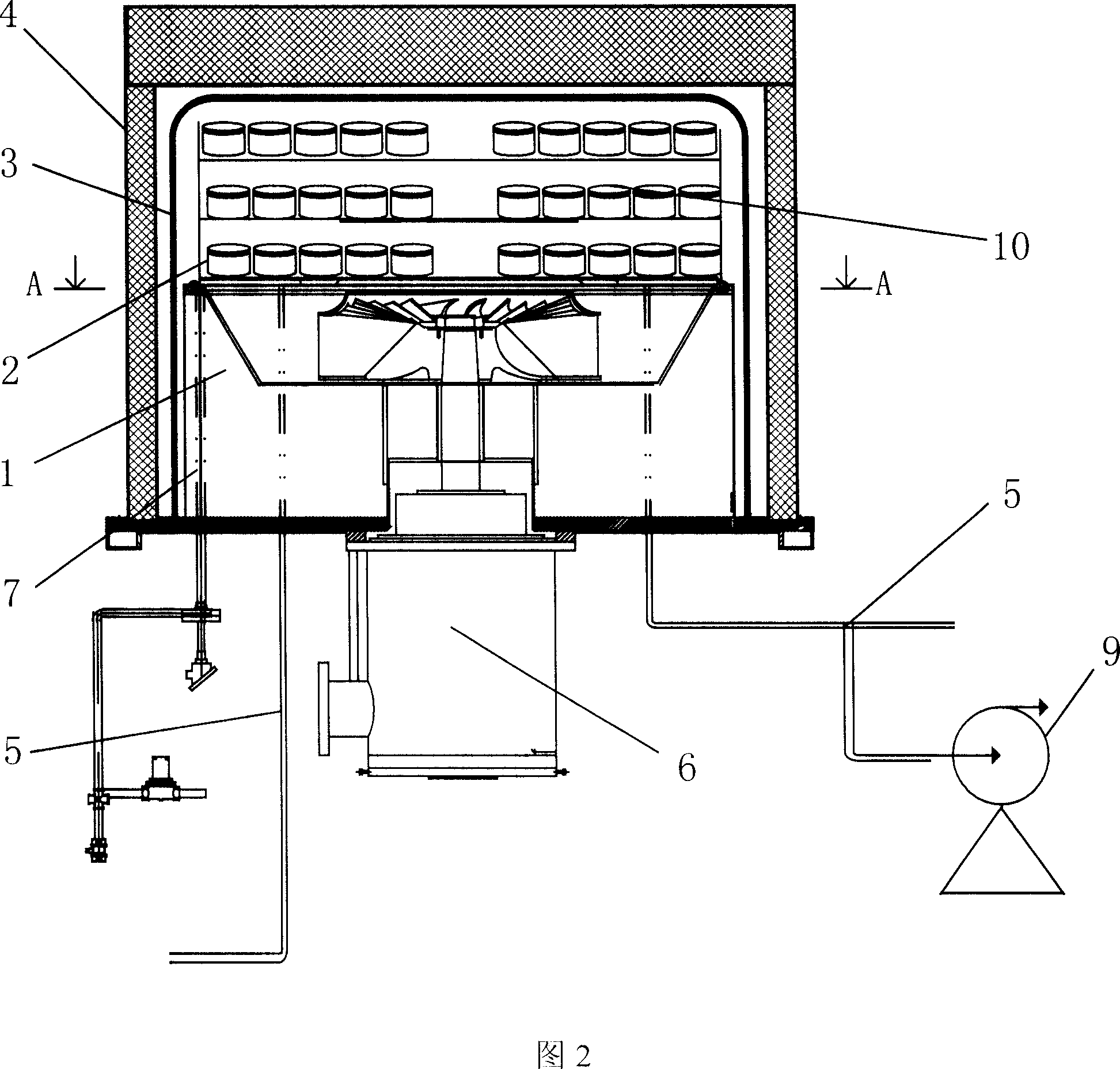

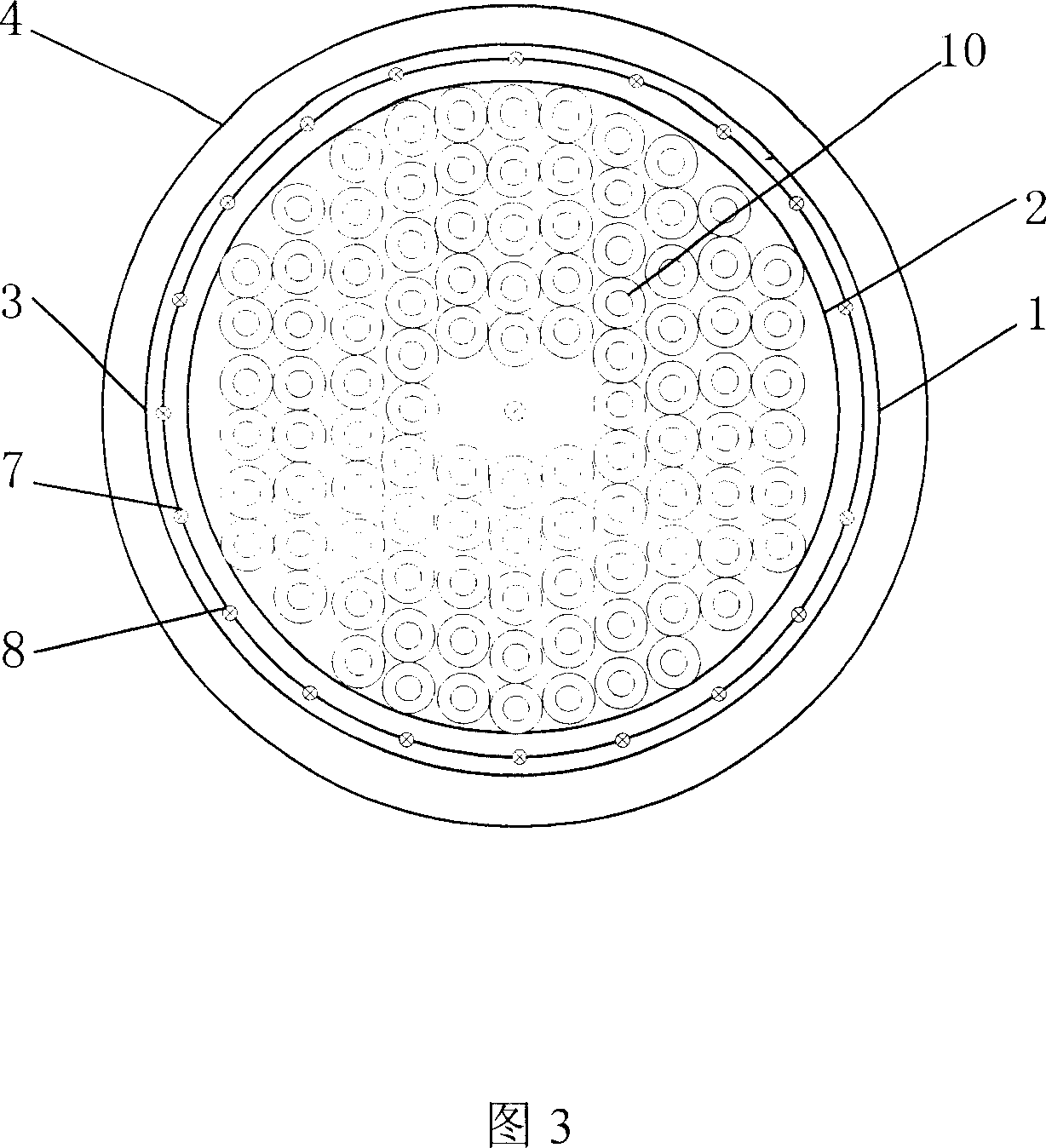

[0023] Referring to Fig. 1, the uncoated electrical steel annealing and bluing process of the present invention, the semi-process that is the uncoated silicon steel sheet is punched and the finished iron core after stacking the sheets is placed in the bell furnace (step 101), and carried out After the sealing inspection, set the heating cover, vacuumize the atmosphere in the inner cover, and fill it with nitrogen (step 102), then pump the nitrogen out again by the vacuum pump system, feed hydrogen and start heating (step 103); under the hydrogen atmosphere, half the process-- The uncoated silicon steel laminate product is annealed and kept at a high temperature of 700-820°C for 2-3 hours (step 104); when the finished iron core is slowly cooled to 300-450°C (step 105), the inner cover Carry out vacuuming (step 106), after vacuum <-95000Pa, pass into the furnace with an aqueous solution medium for bluing (water or water vapor, or a reagent for bluing), (step 107); simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com