Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improve annealing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process and device for coating-free electrical steel annealing and bluing

ActiveCN101082075AHigh magnetic inductionImprove efficiencyMetallic material coating processesHeat treatment process controlElectrical steelStress relieving

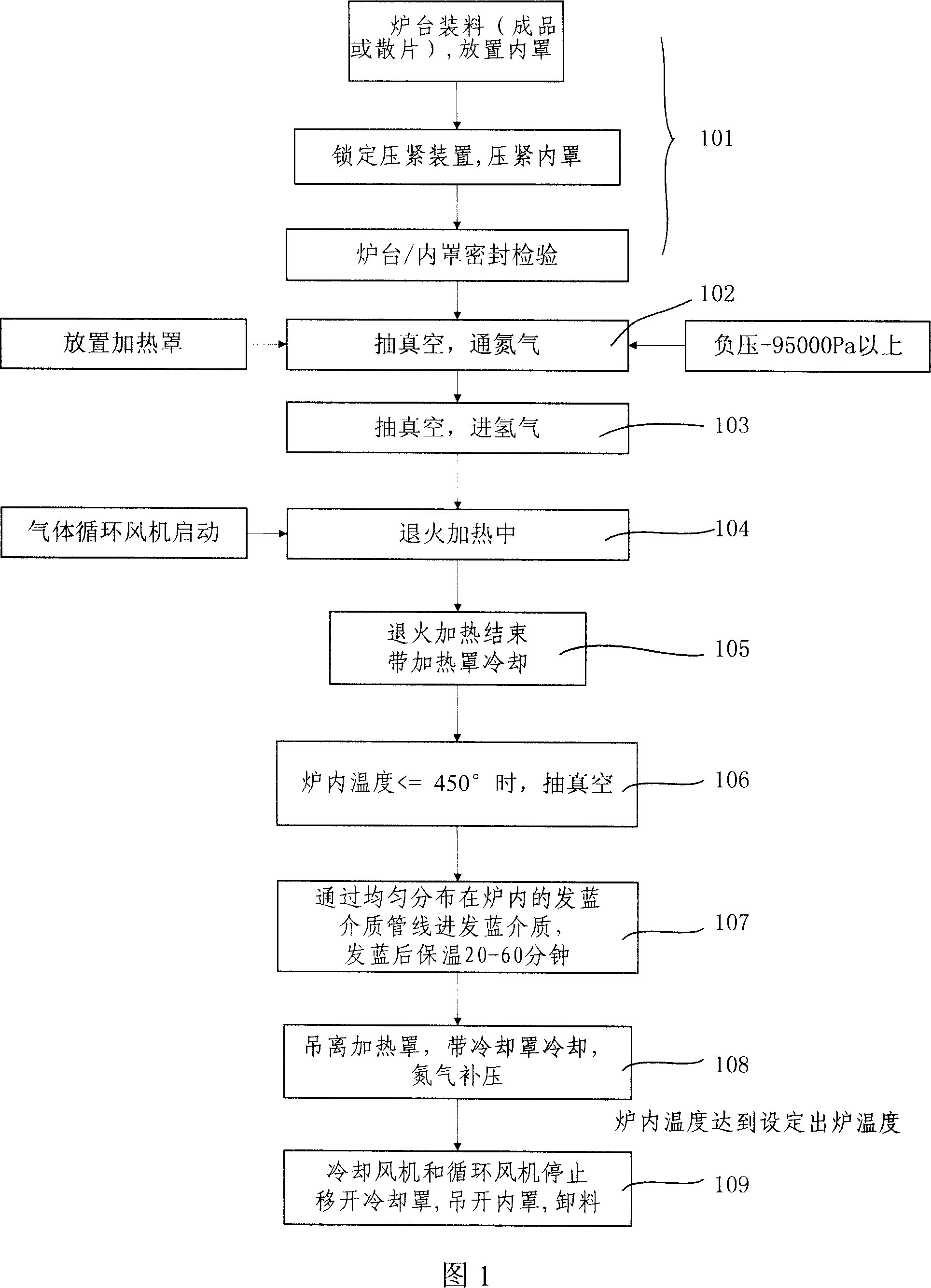

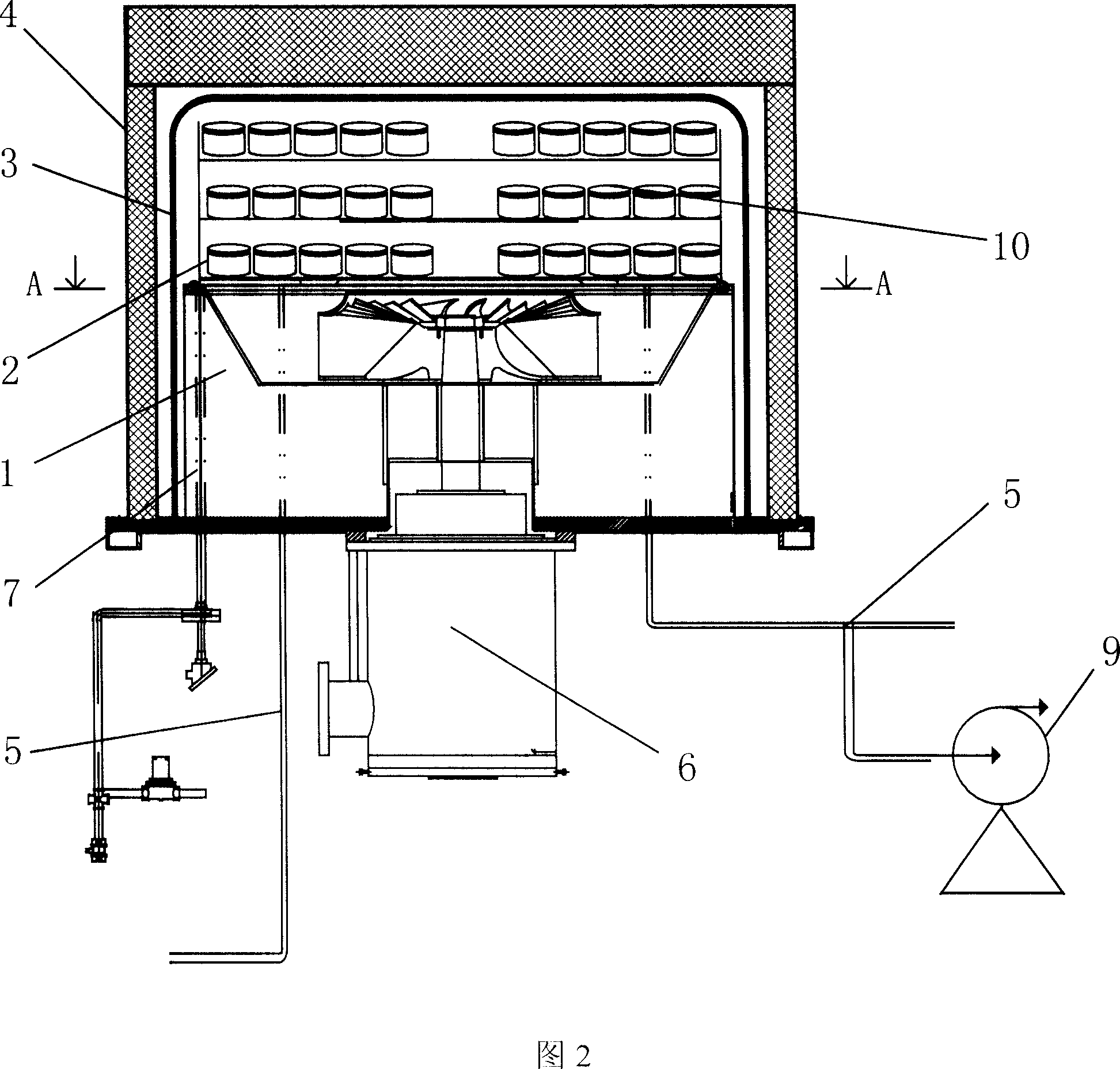

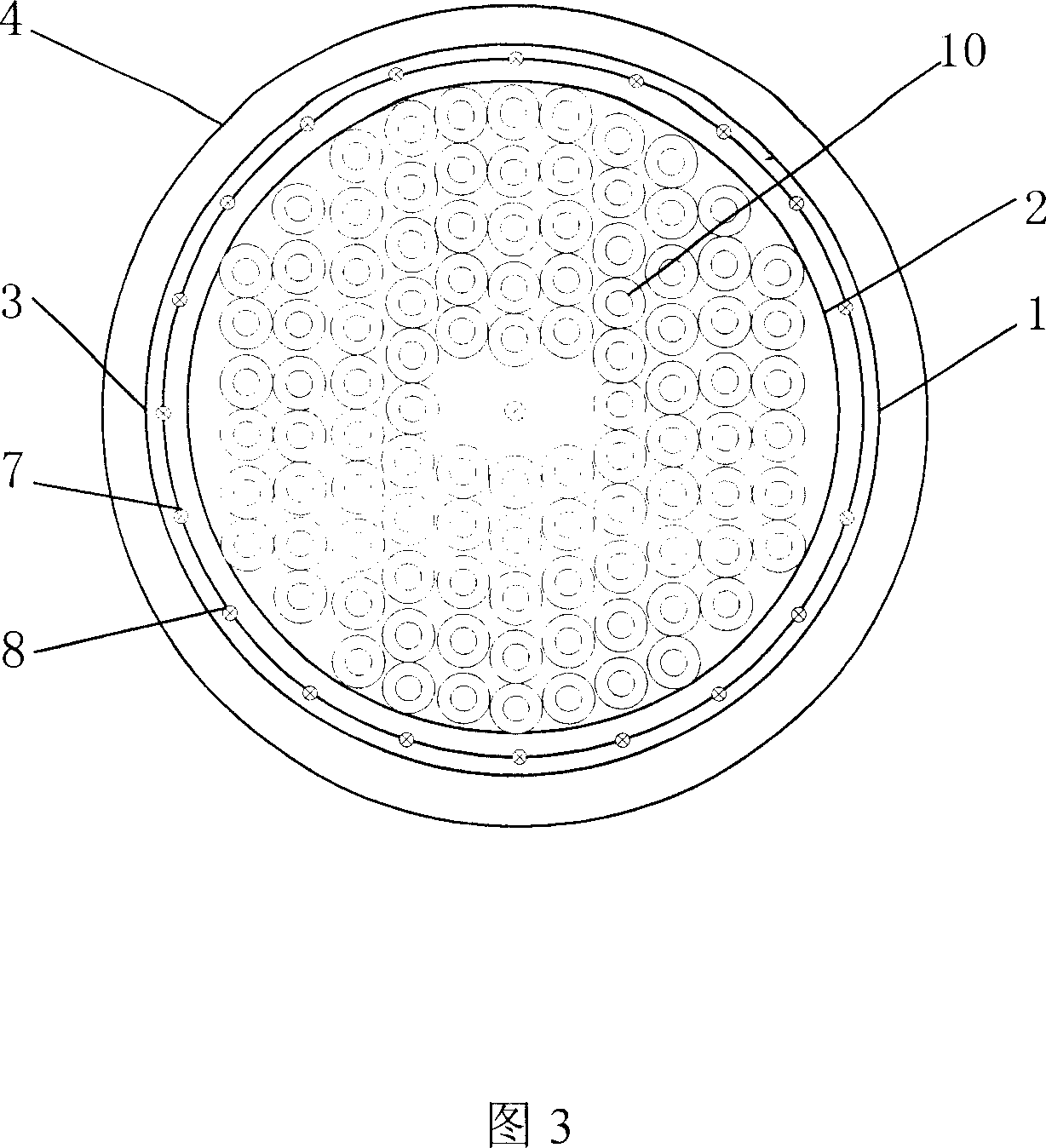

The no-coating electric steel sheet annealing and blueing process includes the following steps: 1. annealing laminated no-coating silicon steel sheets inside a bell type furnace under hydrogen atmosphere; 2. vacuumizing the bell type furnace to vacuum degree lower than 95000 Pa after the silicon steel sheets are cooled slowly to 300-450 deg.c, and leading blueing water solution to the furnace before maintaining the temperature for 20-60 min; and 3. vacuumizing for the second time, filling nitrogen for cooling and discharging in the temperature lower than 150 deg.c. The process has high annealing quality, homogeneous blueing effect, and capacity of raising the magnetic induction coefficient of silicon steel sheets and lowering their iron loss.

Owner:BAOSHAN IRON & STEEL CO LTD

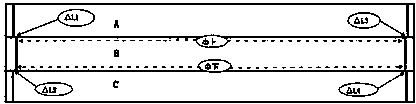

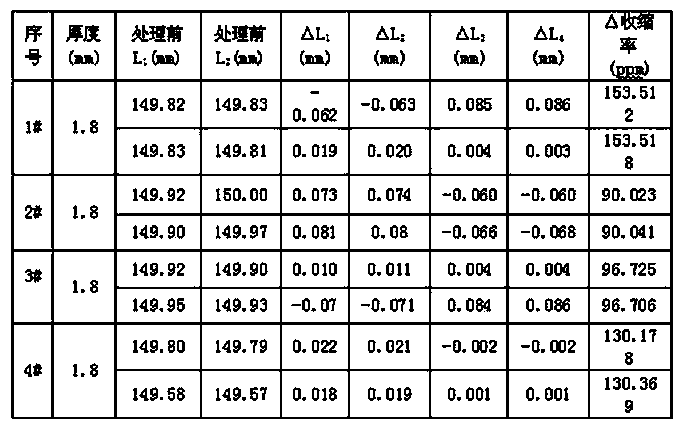

Method for testing shrinkage rate of electronic flat glass

InactiveCN104237298AImprove annealing qualityHigh measurement accuracyMaterial thermal coefficient of expansionUsing optical meansReference sampleFlat glass

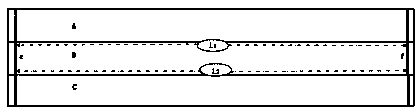

The invention mainly relates to a method for testing the shrinkage rate of electronic flat glass. The method comprises the following steps: drawing measurement reference lines e and f at the two ends of a sample to be tested of the electronic flat glass in the length direction; averagely dividing the sample to be tested into reference samples A and C and a measurement sample B in the width direction; measuring the distance between the measurement reference line e and the measurement reference line f on the sample B, performing reheating-cooling treatment on the sample B through a precision annealing furnace, measuring the displacement of the measurement reference lines of the sample B under an optical microscope, and calculating the shrinkage rates X1 and X2 of the middle upper edge and the middle lower edge of the sample B and the average shrinkage rate X of the sample B. According to the method, the measurement sample is subjected to reheating-cooling treatment through the precision annealing furnace, so that the annealing quality of the glass is improved; the shrinkage rate of the glass is calculated by measuring the length change of the glass sample before and after treatment in the precision annealing furnace through the optical microscope; the method has the characteristics of simplicity for operation and high measurement accuracy.

Owner:AVIC (HAINAN) SPECIAL GLASS MATERIALS CO LTD

Finished product annealing process for double zero aluminum foils

ActiveCN106521372ASmall mechanical propertiesSpeed up the oil removal rateHeating timePre treatment

The invention discloses a finished product annealing process for double zero aluminum foils. The finished product annealing process for the double zero aluminum foils comprises the following steps: a, standing on the outside of a furnace; b, pretreating in the furnace; c, heating slowly; d, annealing at the medium temperature; e, annealing at the low temperature; f, cooling in the furnace; and g, cooling in air out of the furnace. The heating rate in the step of heating slowly is 6-12 h / 100 DEG C; the heating time of the step of annealing at the medium temperature is 8-20 hours, insulating time is 10-175 hours, and the temperature is 195-225 DEG C; and in the step of annealing at the low temperature, the annealing time is 15-100 hours, and the annealing temperature is 150-185 DEG C. In the finished product annealing process, the temperature is raised slowly, performance is reduced and oil is removed at the medium temperature, the oil is then removed at the low temperature, so that the quality of the double zero aluminum foils is improved, the mechanical properties of the aluminum foils, the oil removal effect, the adhesion property and the effect of controlling indexes of a hot drum are remarkable, and demands of downstream users are met.

Owner:LUOYANG WANJI ALUMINUM PROCESSING CO LTD

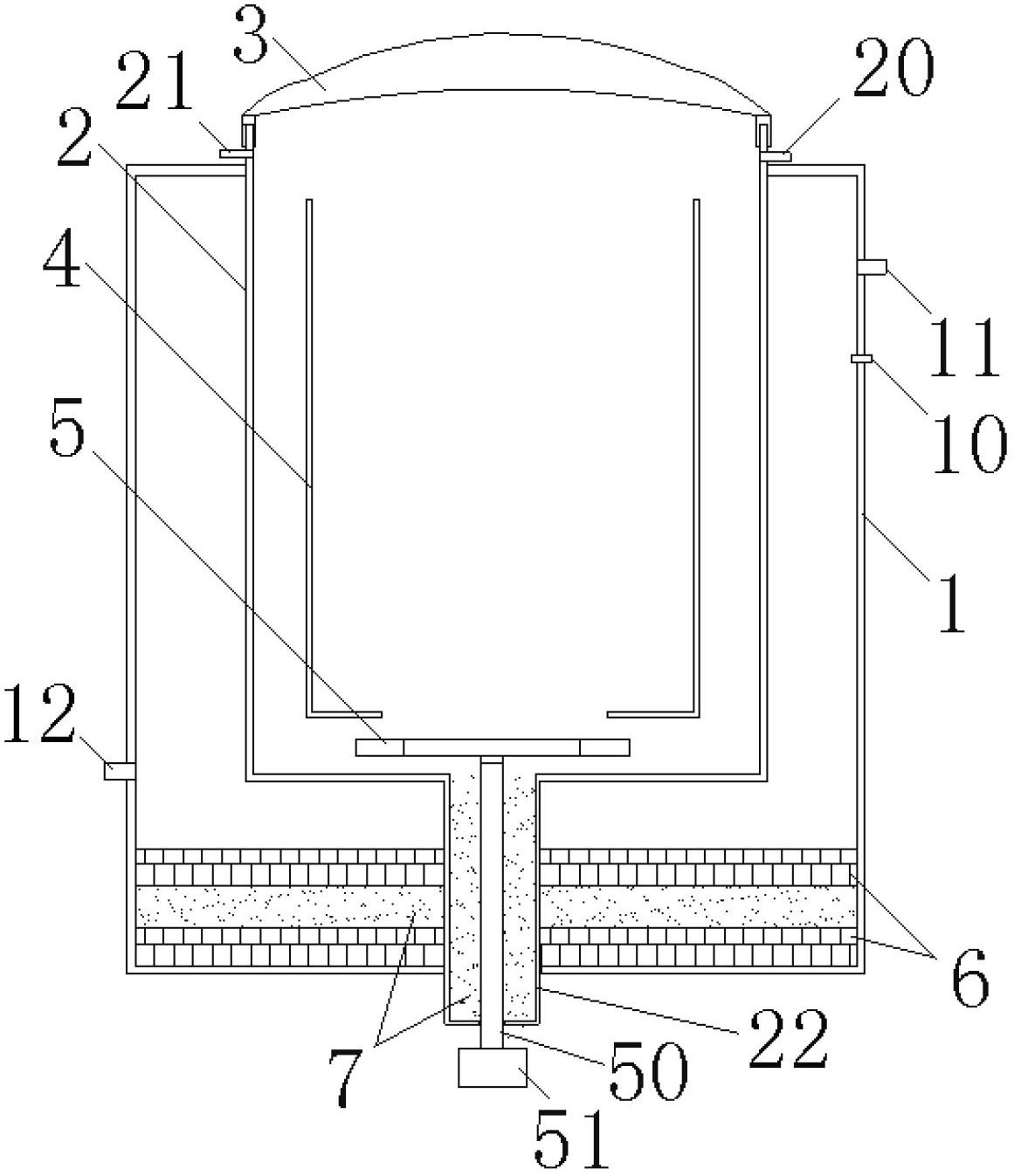

Spheroidizing annealing furnace and annealing process for steel wire

InactiveCN102676762APrevent decarbonizationImprove annealing qualityFurnace typesHeat treatment furnacesDecarburizationCombustion chamber

The invention discloses a spheroidizing annealing furnace for a steel wire. The spheroidizing annealing furnace comprises a furnace body, an inner cylinder and a furnace cover, wherein a coal gas heating point is arranged on the furnace body; a fan is arranged in the inner cylinder; a motor for driving the fan is arranged below the furnace body; a shaft barrel at the bottom of the inner cylinder extends out of the furnace body; and a rotating shaft for connecting the motor with the fan penetrates through the shaft barrel. In the production process for a long time, heat insulating cotton and refractory bricks are aged; waste gas in a combustion chamber is exhausted out of the furnace body from the outer wall of the shaft barrel without entering the inner cylinder; and the steel wire is positioned in the annealing furnace and methanol gas is introduced into the annealing furnace at high temperature, so that the decarburization of the steel wire is prevented and the annealing quality of the steel wire is improved.

Owner:WUHU JINYU FASTENER

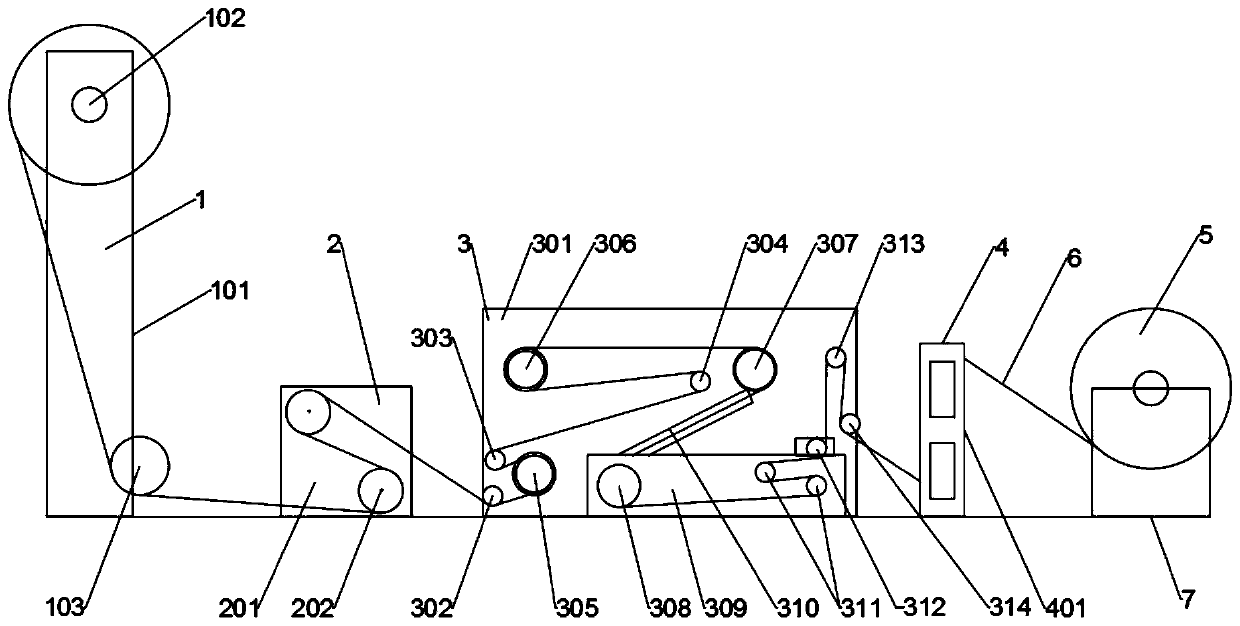

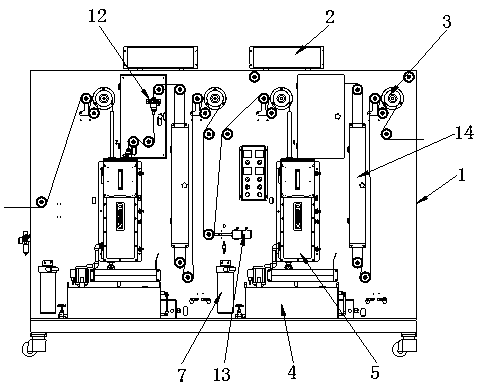

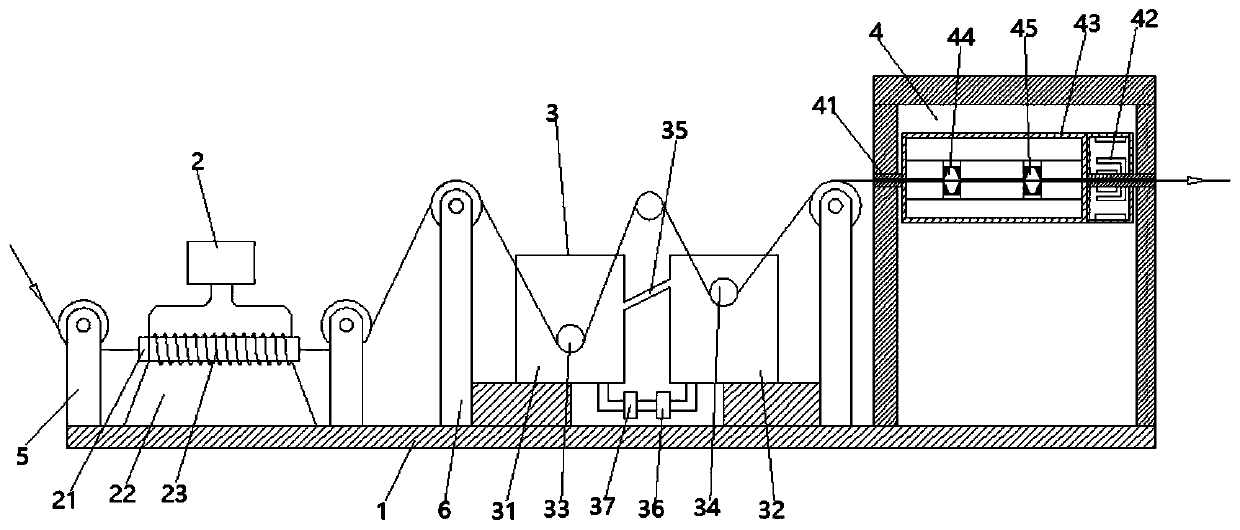

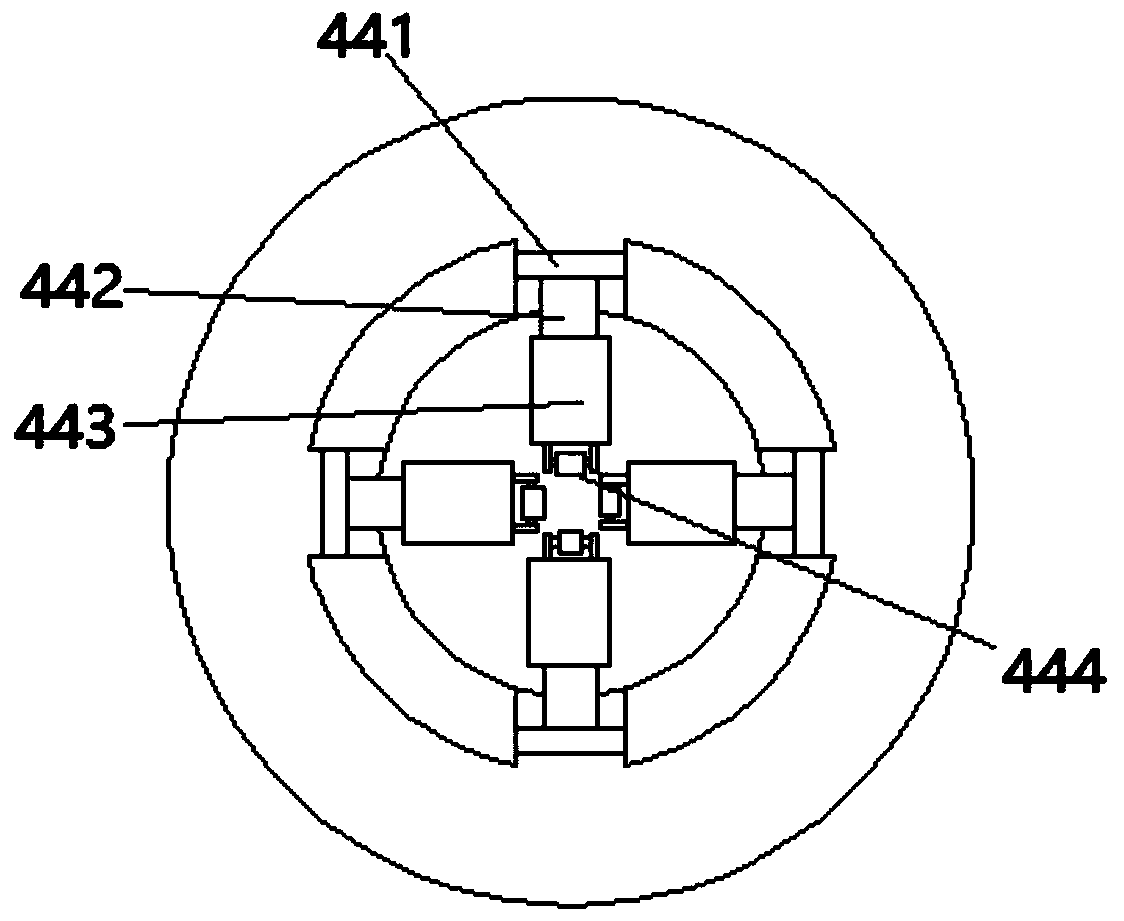

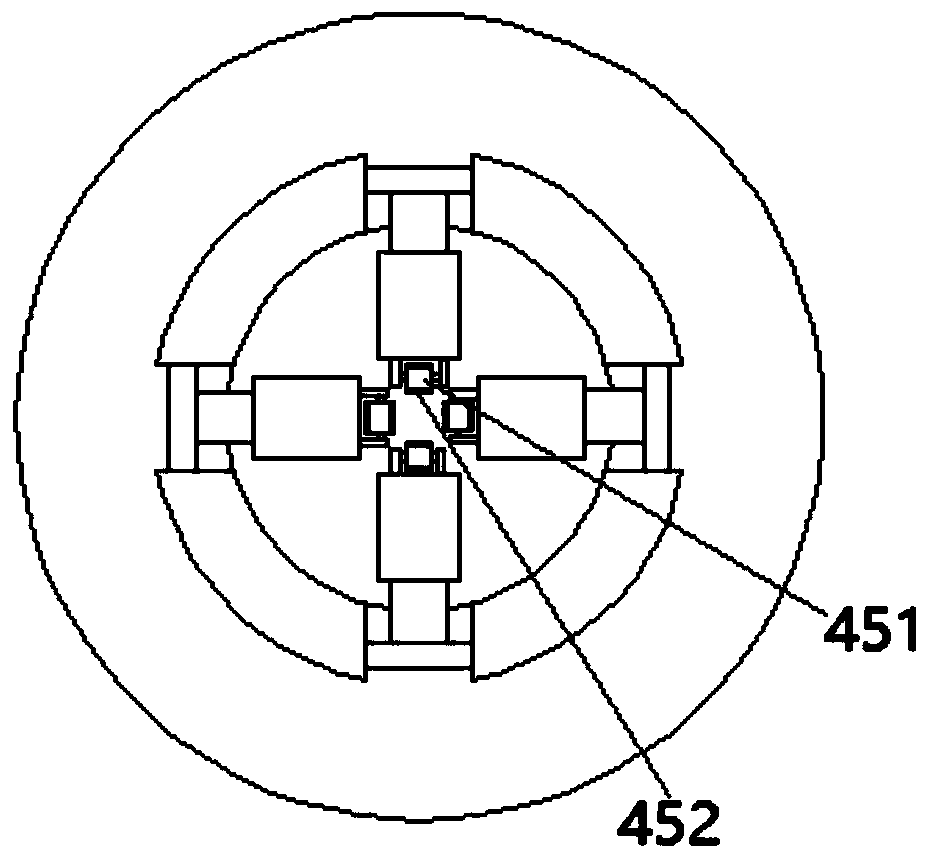

Annealing system for multi-strand superfine copper wires and annealing method of annealing system for multi-strand superfine copper wires

ActiveCN102787232AIncrease production speedSimplify the subsequent weaving processFurnace typesHeat treatment furnacesElectricityCopper wire

The invention discloses an annealing system for multi-strand superfine copper wires. The system comprises a wire payoff rack, a first capstan, a first drying oven, a water tank, a felt, a second capstan, a second drying oven, a cooling gas blowing kettle and a wire winding disc, wherein a gas outlet of the cooling gas blowing kettle is located on an outlet of the second drying oven. The invention also discloses an annealing method by the annealing system for multi-strand superfine copper wires. With the adoption of the method provided by the invention, the time, electricity and power can be saved and large output is obtained; and meanwhile, the produced superfine copper wires is strong in antioxidant capability and long in service life.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

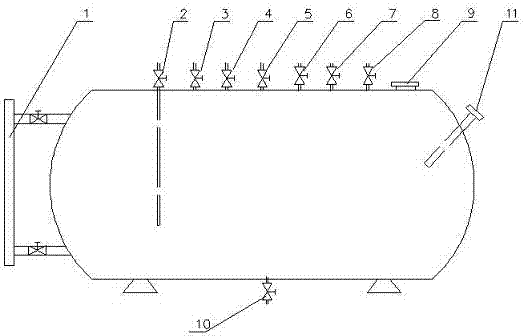

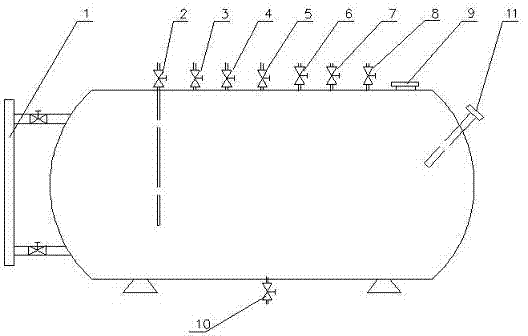

Ammonia storage tank with gas ammonia valve and method for ammonia supply by gas ammonia/liquid ammonia conversion

InactiveCN102418837AStable pressureStress easyContainer filling methodsPressure vesselsAmmonia storagePhysical chemistry

The invention relates to an ammonia storage tank with a gas ammonia valve and a method for ammonia supply by gas ammonia / liquid ammonia conversion. The ammonia storage tank is characterized in that a gas ammonia output valve is further installed on the top surface of a conventional ammonia storage tank. The method for ammonia supply by gas ammonia / liquid ammonia conversion, in which the ammonia storage tank with the gas ammonia valve is used, has the characteristic of switching along with the rise and drop of external temperature: when the external temperature is higher than 20 DEG C and the pressure in the ammonia storage tank is from 0.6 MPa to 0.8 MPa, the gas ammonia output valve is opened to supply gas ammonia to an evaporation tank; and when the external temperature is not higher than 20 DEG C and the pressure in the ammonia storage tank is from 0.4 MPa to 0.6 MPa, a liquid ammonia output valve is opened to supply liquid ammonia to the evaporation tank. The method can reduce the temperature and pressure in the ammonia storage tank, thus avoiding overpressure and ensuring safe production.

Owner:XINYU IRON & STEEL CO LTD

Double strong copper strip production technology for automobile connector

The invention discloses a double strong copper strip production technology for an automobile connector, and belongs to the technical field of a copper strip production technology. The double strong copper strip production technology comprises the following steps of (1), smelting and ingot casting; (2), hot rolling; (3), milling; (4), rough rolling; (5), once annealing; (6), once cleaning; (7), medium rolling; (8),twice annealing and cleaning; (9), finish rolling; (10), three times annealing and cleaning; (11), finish rolling; (12), four times cleaning; (13), leveling; and (14), examining and delivering; and specified thickness of strip coil after rough rolling is 2.5 mm. According to the technical scheme, brass products can meet the double requirements of tensile strength and elongation index of automobile connector industry.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

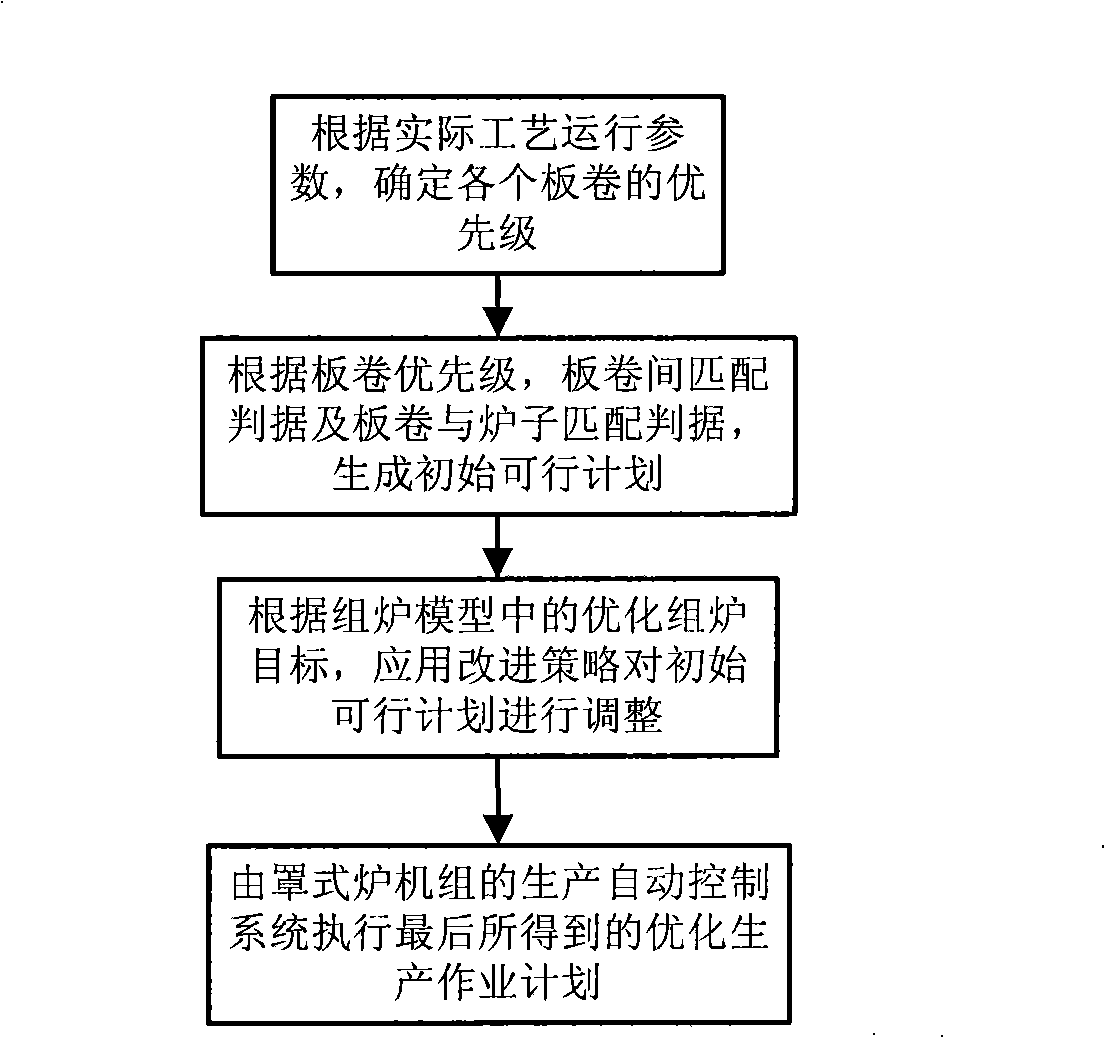

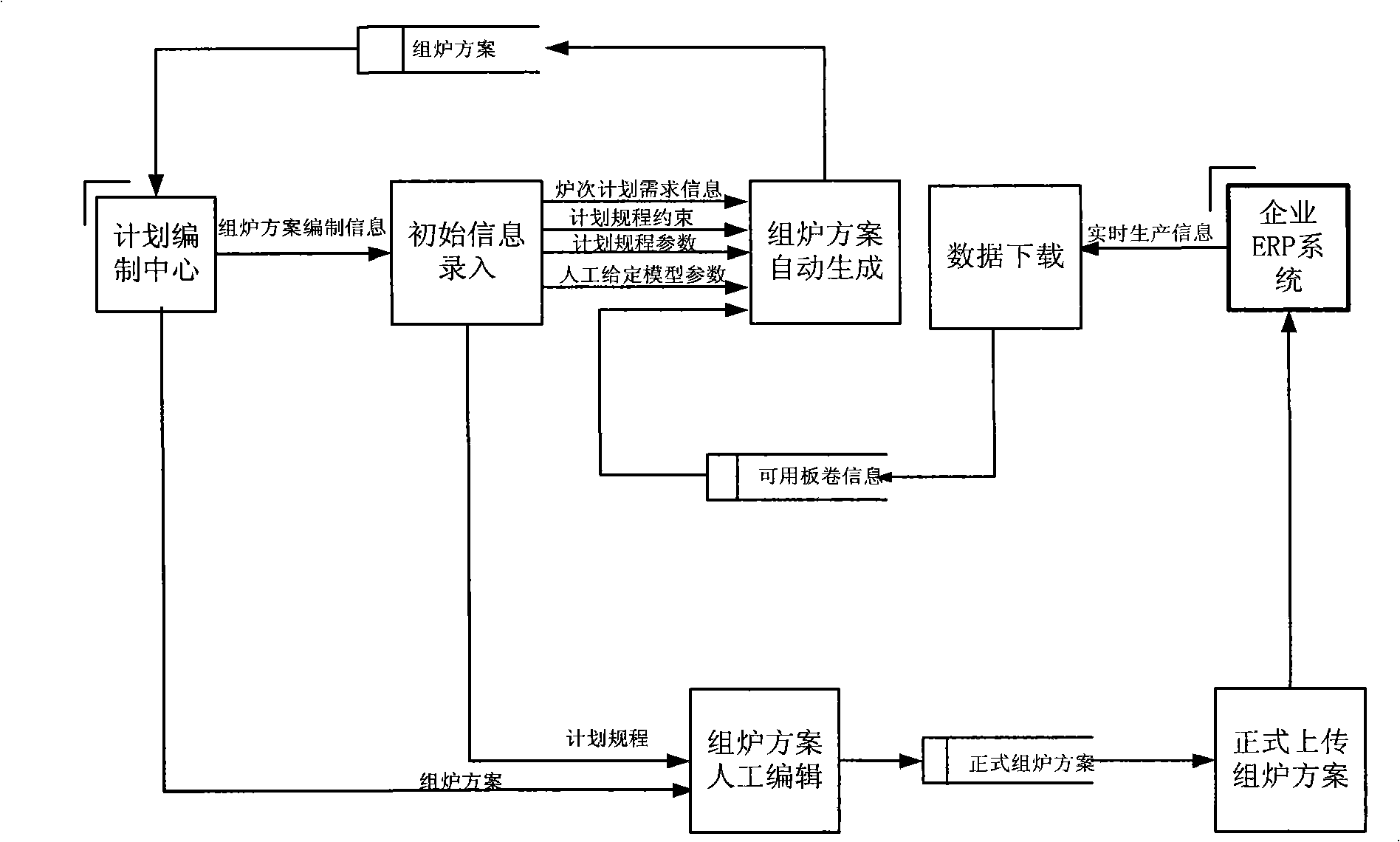

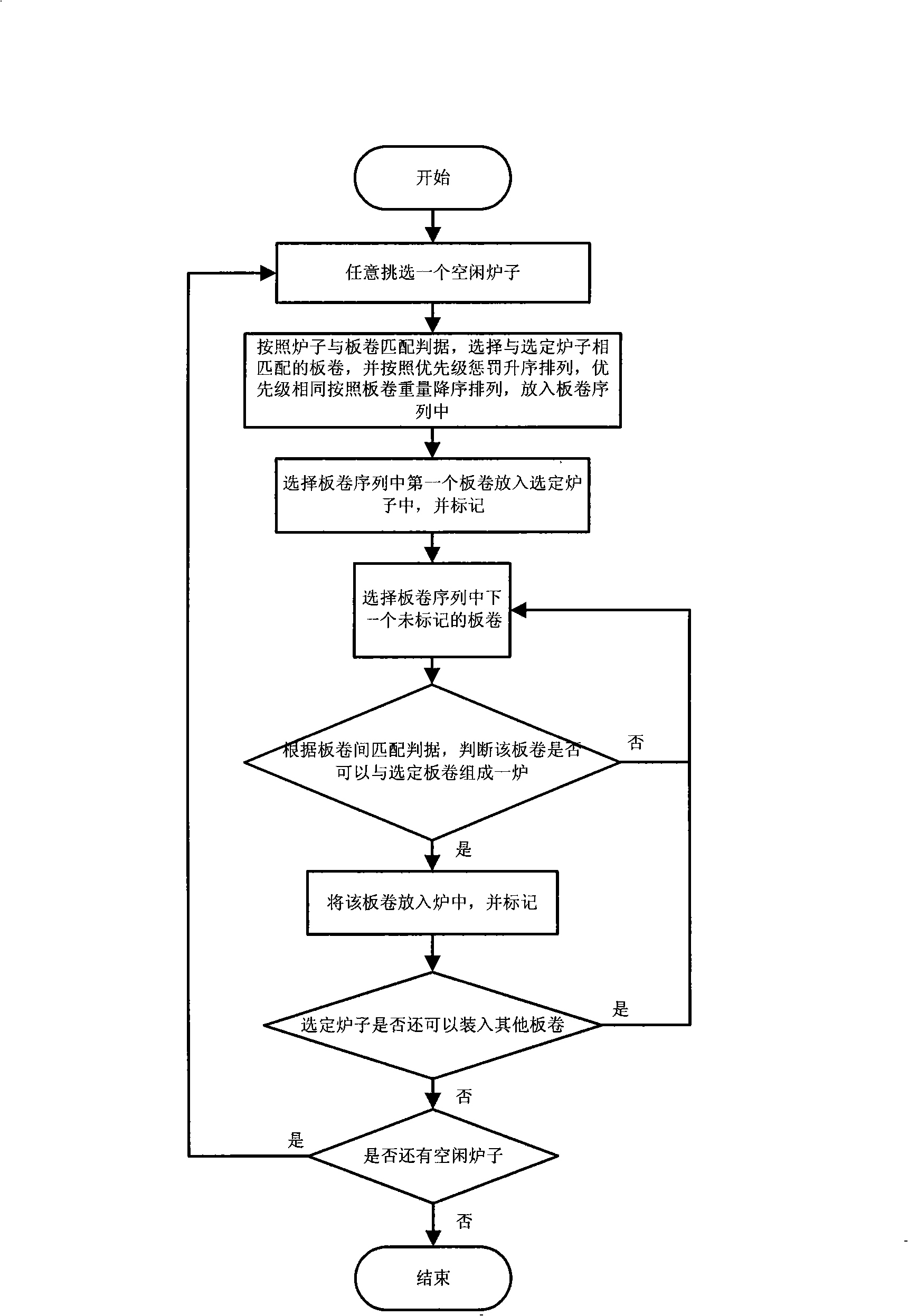

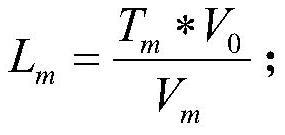

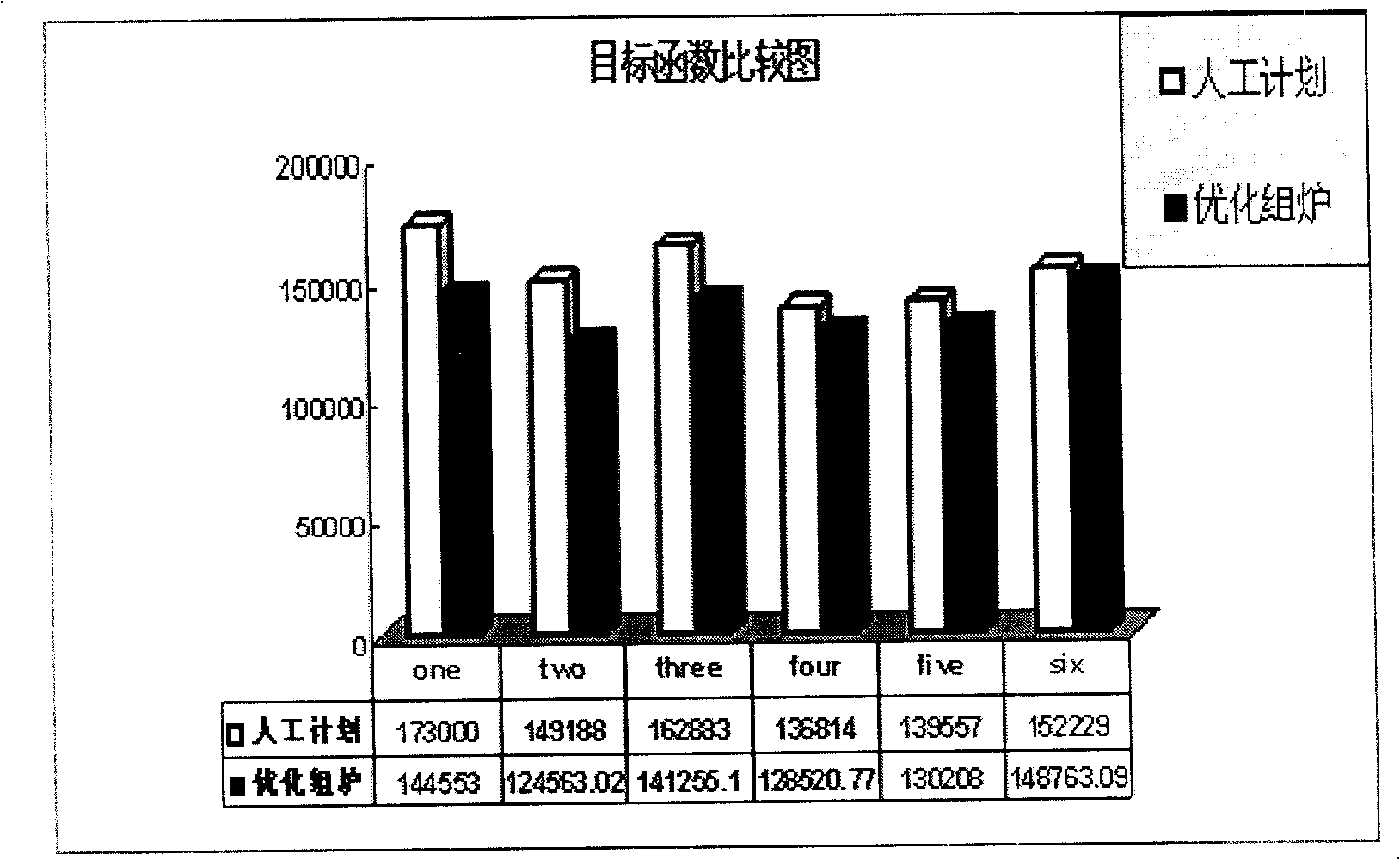

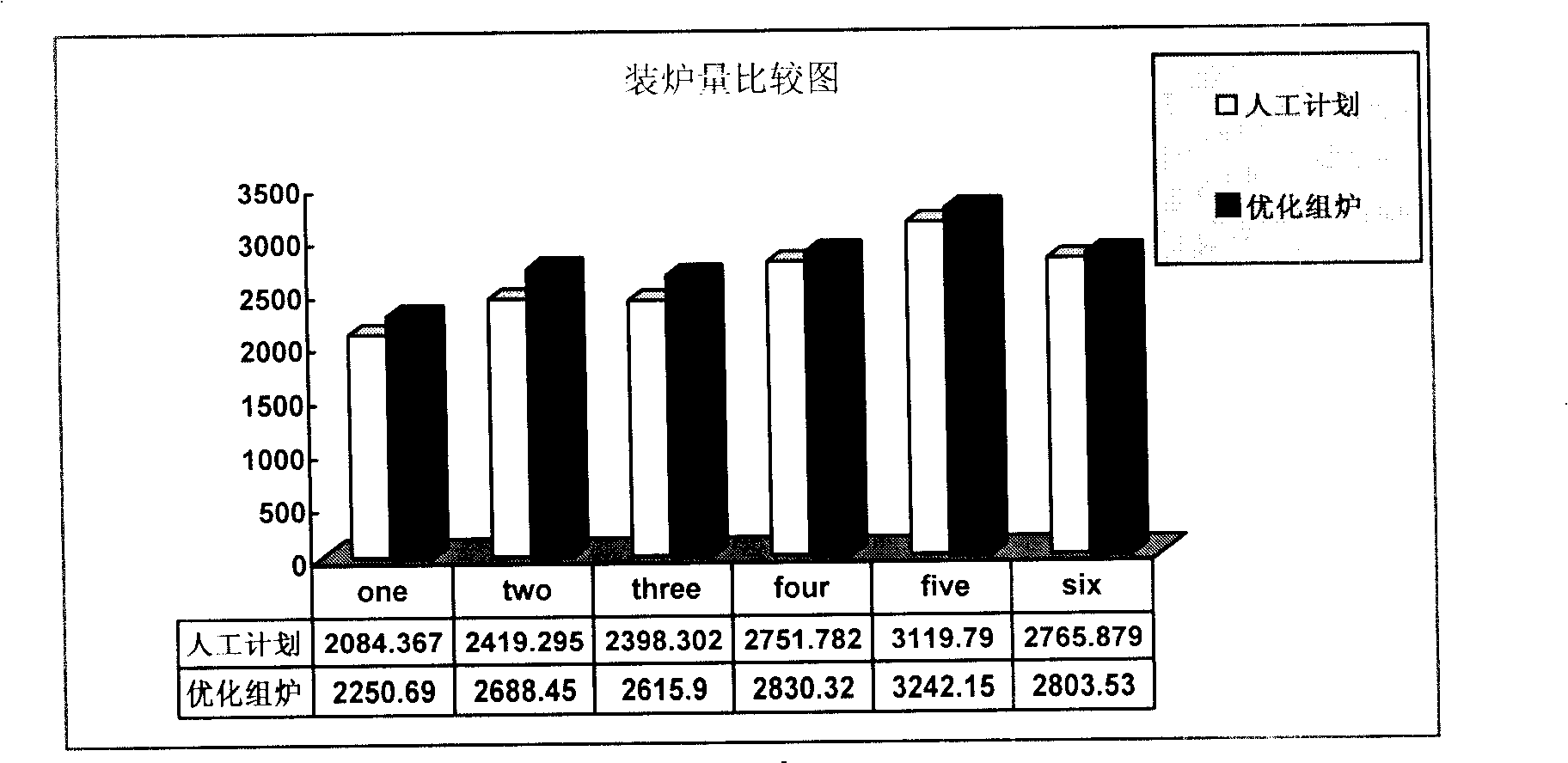

Optimized furnace combination method and system for cold rolling hood type annealing furnace unit

ActiveCN101344780AHigh-efficiency group furnace methodFeasible Group Furnace MethodTotal factory controlProgramme total factory controlManufacturing execution systemNitrogen gas

A furnace group optimizing method and a system for cold-rolling bell annealing furnace sets belong to the field of steel material processing information technology. The method comprises the following steps of: (1) according to practical technological parameters, performing priority settings on coiled sheets to be annealed; (2) furnace pre-grouping: arranging coiled sheets according to priority penalty values in ascending order; placing the coiled sheet with the minimum priority into a furnace according to the coiled sheet-furnace matching criteria; according to the coiled sheet-coiled sheet matching criteria, selecting, from the residual coiled sheets, coiled sheets that can form a furnace group with the coiled sheet in the furnace sequentially, and when the height reaches the maximum height of the bell furnace, forming a furnace grouping scheme; repeating the procedure until the demanded furnace group scale is formed; (3) adjusting the initial feasible furnace grouping scheme; and (4) using the developed system to upload the obtained optimized furnace grouping scheme to the manufacture execution system for implementation. The method and the system of the invention increase the productivity of the bell furnace set, improve the annealing quantity of the coiled sheets and effectively lower the consumption of energy resources such as hydrogen, nitrogen, water, coal and power, etc.

Owner:NORTHEASTERN UNIV

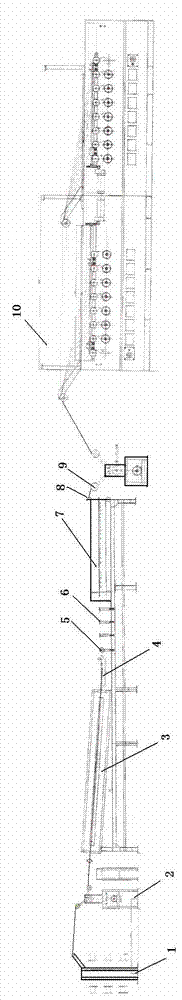

Cable copper core continuous annealing production line

PendingCN111363891AOmit annealingIncrease productivityFurnace typesHeat treatment furnacesStructural engineeringCopper-wiring

The invention provides a cable copper core continuous annealing production line. A pay-off mechanism, a tensioning mechanism, a continuous annealing mechanism, a drying mechanism and a take-up mechanism are fixedly arranged on the ground in sequence. A cable core is let out from the pay-off mechanism, tensioned through the tensioning mechanism, fed into the continuous annealing mechanism, dried through the drying mechanism and coiled by the take-up mechanism. The cable copper core continuous annealing production line provided by the invention is a single-line electrified continuous annealing device. The annealing device is generally mounted between a final cable tensioning wheel and a take-up reel on a cable tensioner to form a cable tensioning-annealing-take-up continuous production unit.The cable copper core continuous annealing production line improves labor conditions, improves the production efficiency, is uniform in heating and high in annealing quality, reduces heat taken awayby a furnace body, a bracket and the like during coiling and coiled cable annealing, greatly saves fuel or electric energy and reduces the production cost.

Owner:砀山红旗电缆有限公司

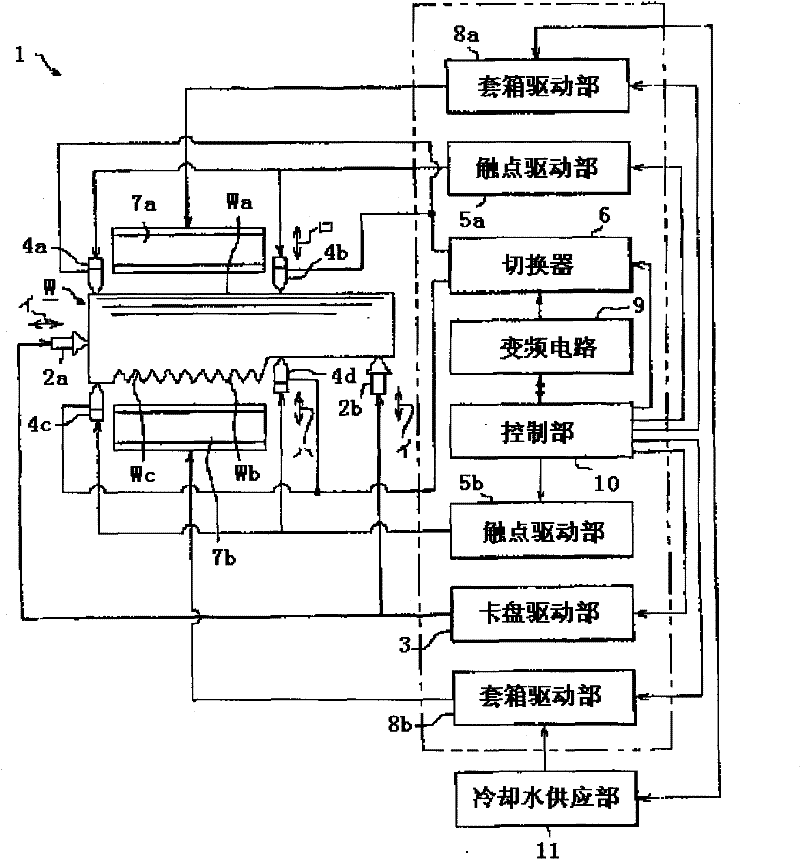

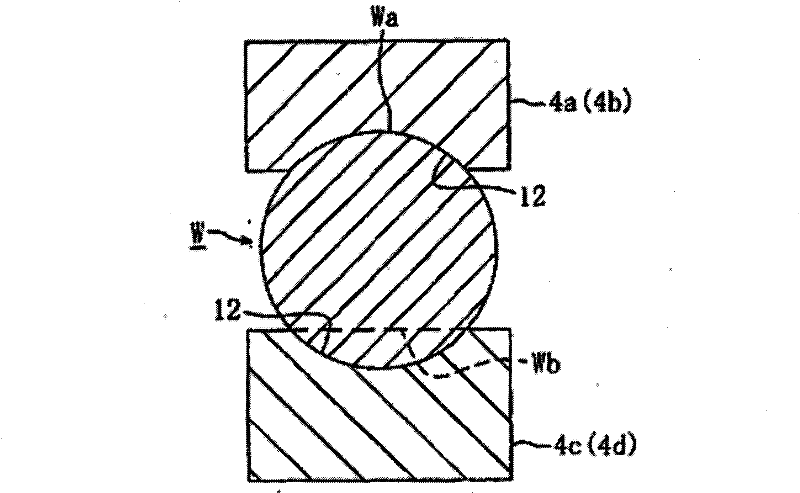

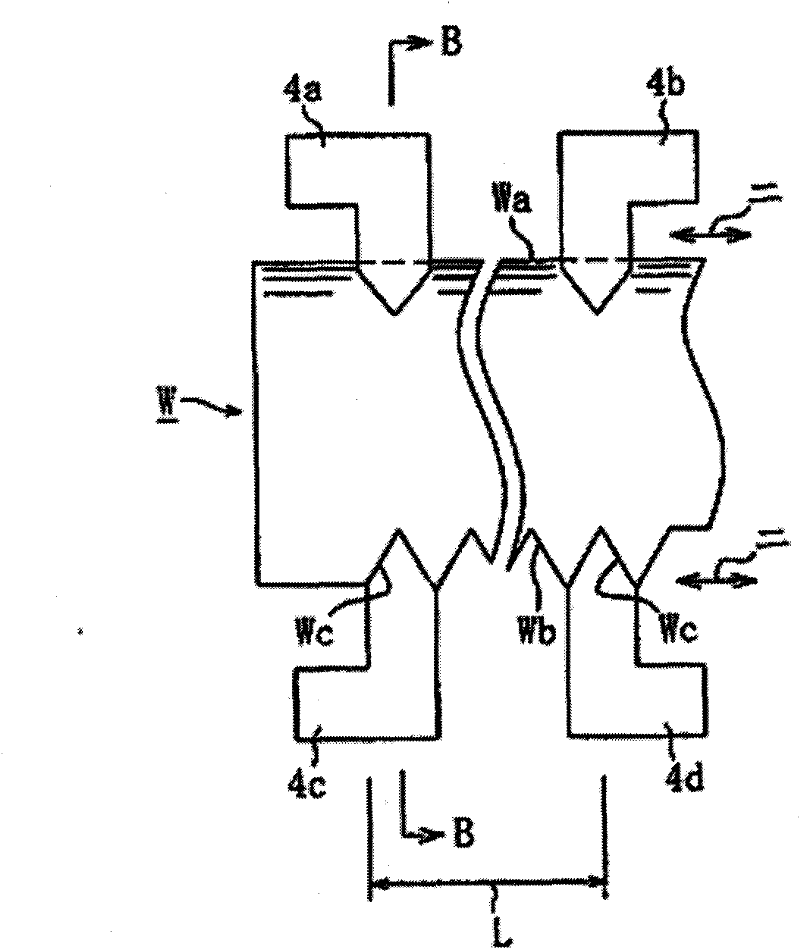

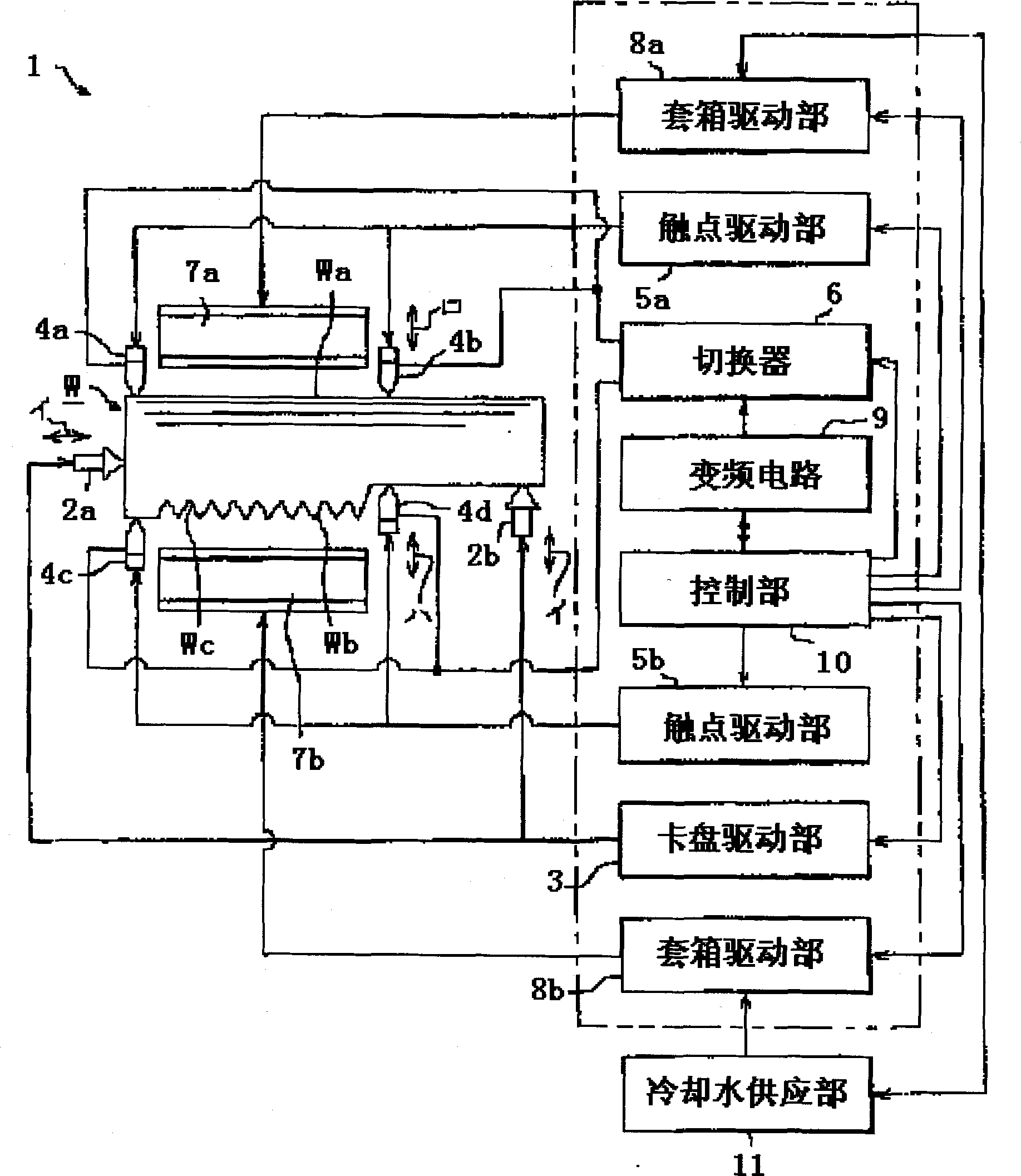

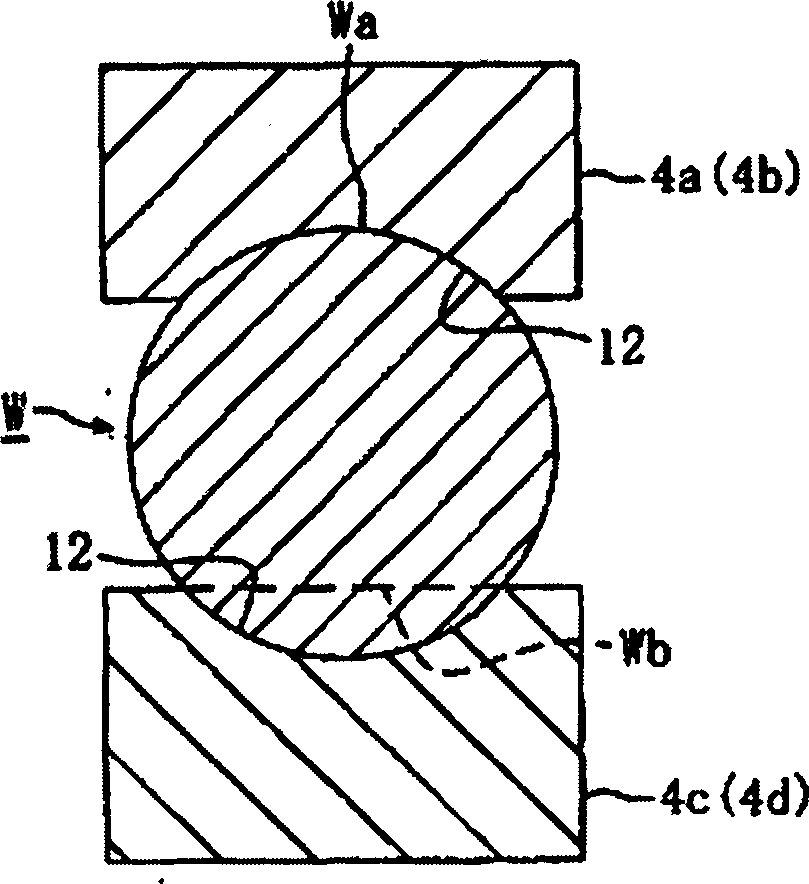

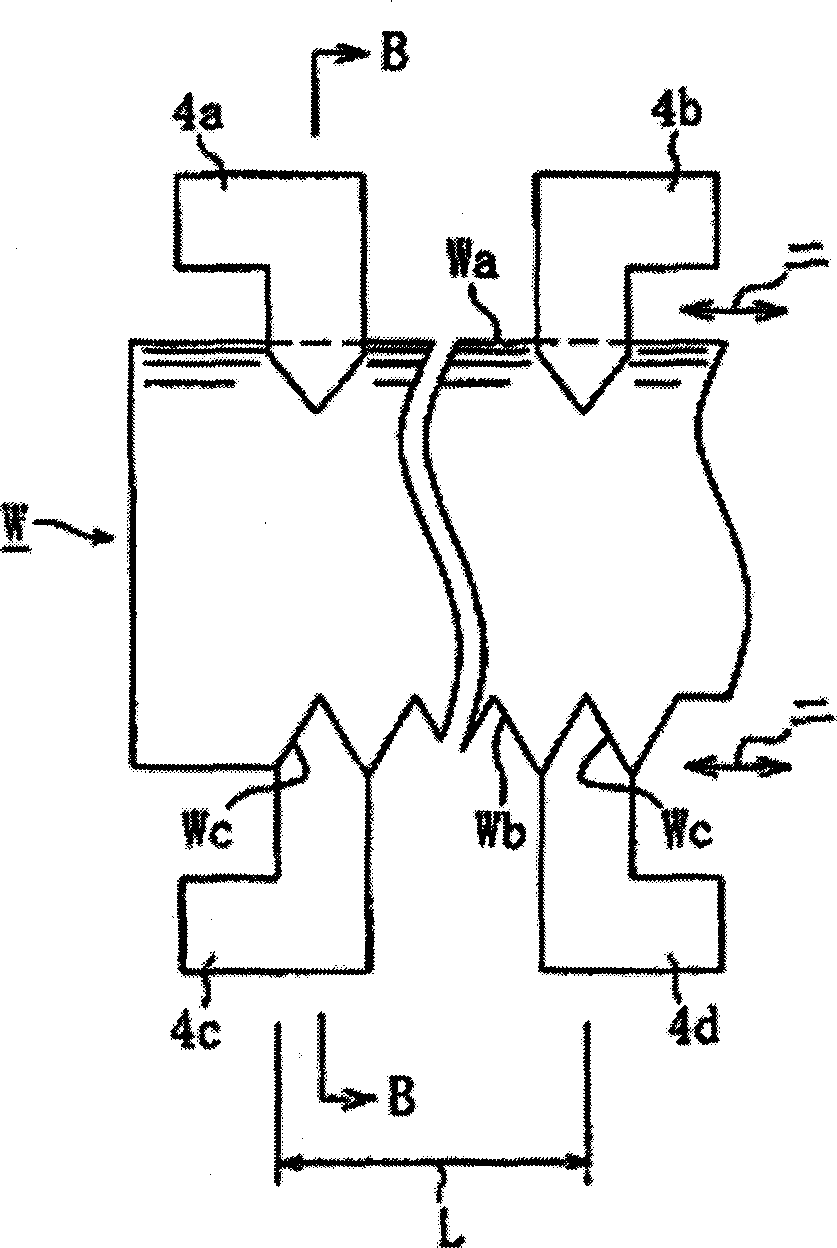

Ohmic heating method and ohmic heating device

ActiveCN102234710AAccelerated quenchingImprove efficiencyFurnace typesHeat treatment furnacesPower flowContinuous operation

The invention relates to an ohmic heating method and an ohmic heating device. Through the ohmic heating method and the ohmic heating device, the quenching or annealing of the back surface and tooth surface of a workpiece can be carried out in a roughly continuous operation period, and the high-precise quenching or annealing quality is easily obtained on the back surface or tooth surface while striving to improve the efficiencies of quenching or annealing. The ohmic heating method is characterized by comprising the following steps that a switching device is switched to a back surface side, so that one pair of first touch points contact the two ends of the heating range in the length direction of the back surface of the workpiece supported by a support device, the regulated frequency and output current for the back surface are supplied to the touch points from a power supply device, and then ohmic heating is carried out on the back surface; and after the step, the switching device is switched to a tooth surface side, so that one pair of second touch points contact the two ends of the heating range in the length direction of the tooth surface of the workpiece, the regulated frequency and output current for the tooth surface are supplied to the touch points from the power supply device, and then the ohmic heating is carried out on the tooth surface.

Owner:宫电高周波设备(上海)有限公司

Vacuum electric annealing furnace

The invention discloses a vacuum electric annealing furnace comprising a rack, a furnace body and an annealing cavity arranged in the furnace body, wherein two ends of the furnace body are open; a conveying device is arranged in the furnace body; openings at two ends of the furnace body are respectively provided with a sealing furnace cover; a vacuum pumping pipeline and a nitrogen filling pipeline are arranged on one of the furnace covers and respectively connected with a vacuum pumping device and a nitrogen filling device; an aluminum silicate fiber cotton liner is arranged in the annealing cavity; annular shelf bricks are uniformly embedded and laid on the liner along the length direction; resistance wires are arranged on the shelf bricks. The vacuum electric annealing furnace disclosed by the invention has the advantages that (1) through vacuumizing the airtight furnace cavity and filling the cavity with nitrogen, the annealing quality of die steel is increased and the heat loss in the furnace body is reduced; (2) the structures of the furnace covers are further improved, so that the sealing performance and the heat insulating performance of the furnace are increased and the service life of sealing materials is prolonged.

Owner:WANSHITAI METAL IND KUNSHAN

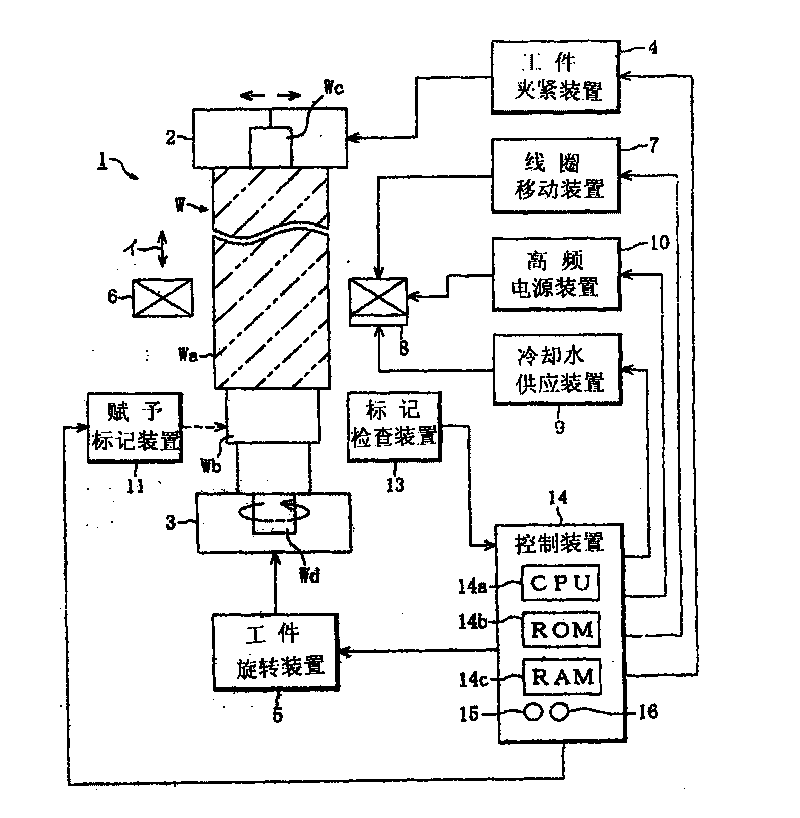

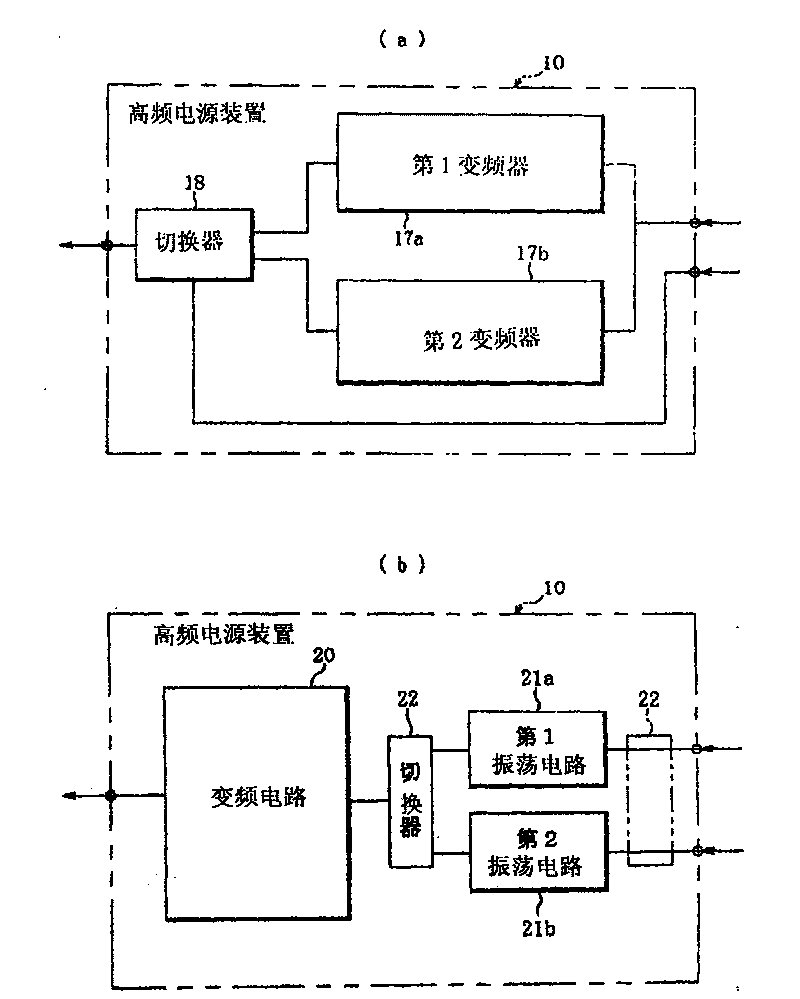

High-frequency induction heating device

InactiveCN101717845APrevent quenching and annealing defective partsImprove quenching qualityFurnace typesIncreasing energy efficiencyPower flowHigh frequency power

The invention provides a high-frequency induction heating device which can simply and continuously carry out quenching and annealing on a workpiece on a heating device and feasibly carry out quenching and annealing with specified conditions so as to easily and stably obtain a workpiece with favorable quenching and annealing quality. The high-frequency induction heating device comprises a heating coil, a high-frequency power supply, a cooling device, a mark endowing device and a control device. The control device is characterized by providing high-frequency currents for quenching to the heating coil from the high frequency power supply, carrying out quenching on a quenching part of the workpiece, providing high frequency currents for annealing to the heating coil from the high frequency power supply after quenching, carrying out annealing on an annealing part of the workpiece, and then running the mark endowing device after the annealing of the workpiece so as to endow a prescriptive mark to a non-quenching and non-annealing part of the workpiece. The high-frequency power supply is equipped with a first power supply part which can provide the high frequency currents for the quenching to the heating coil and a second power supply part which can provide the high frequency currents for the annealing to the heating coil.

Owner:宫电高周波设备(上海)有限公司

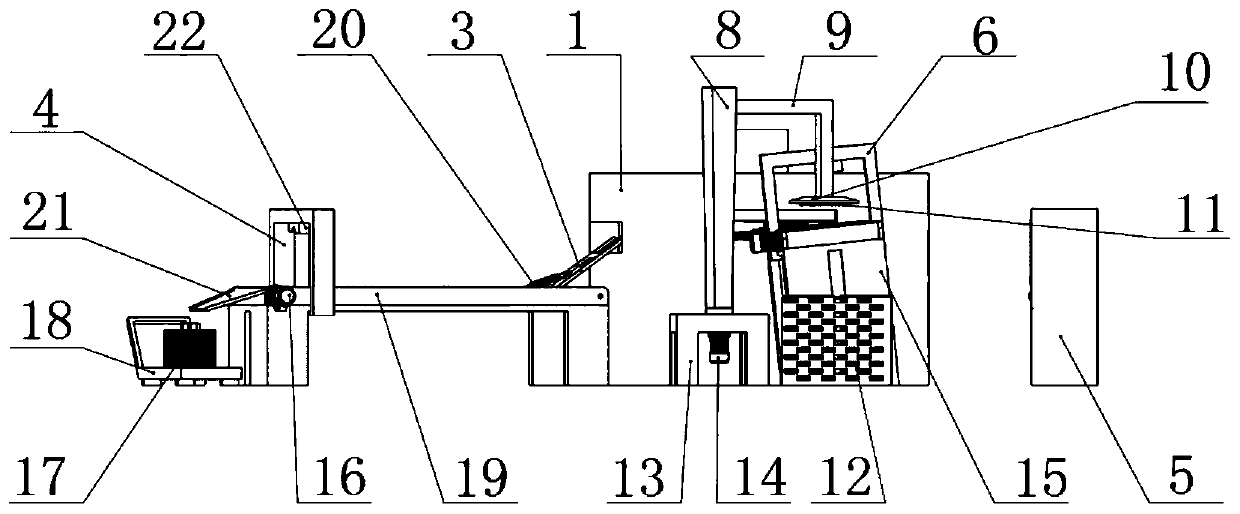

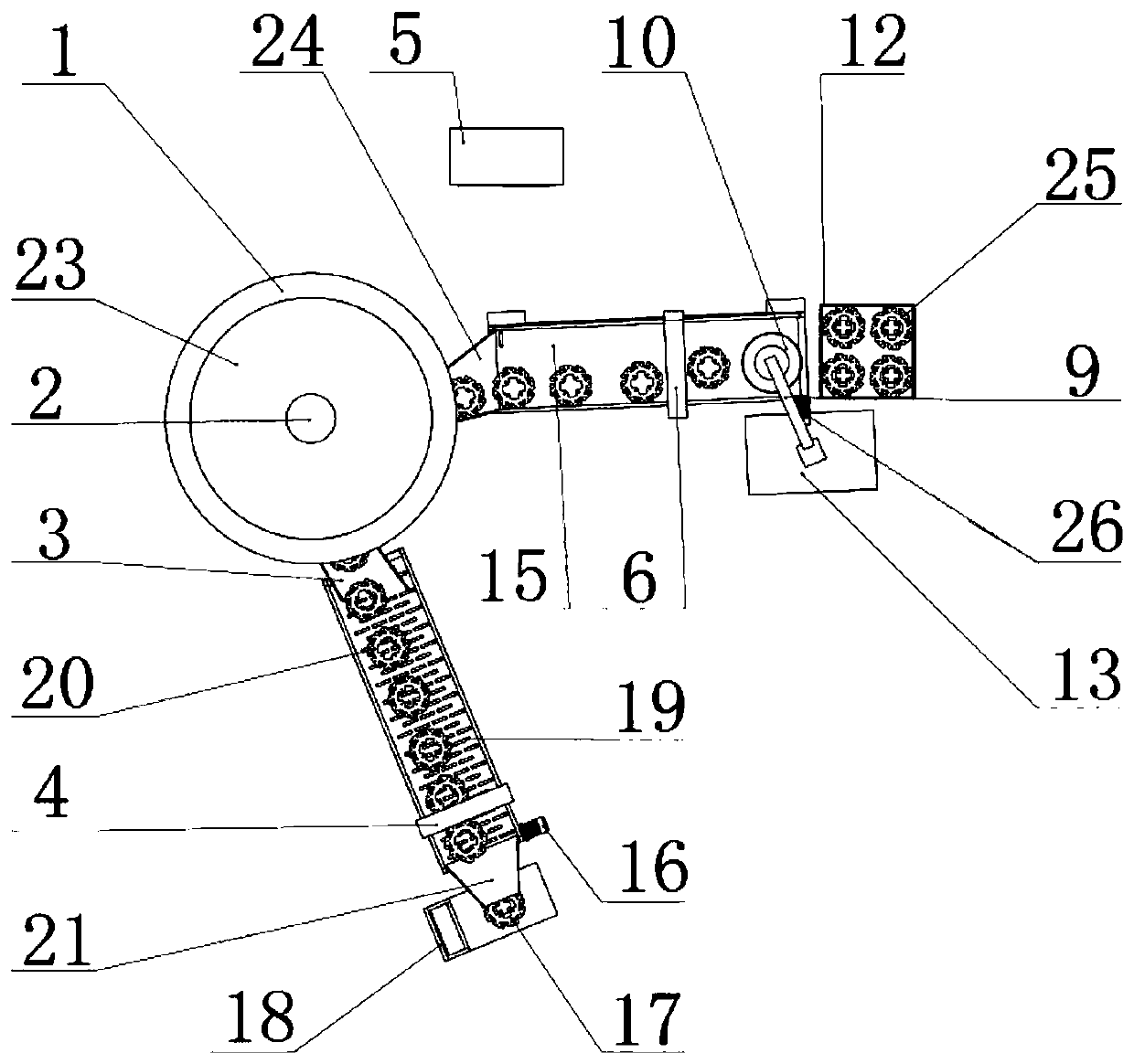

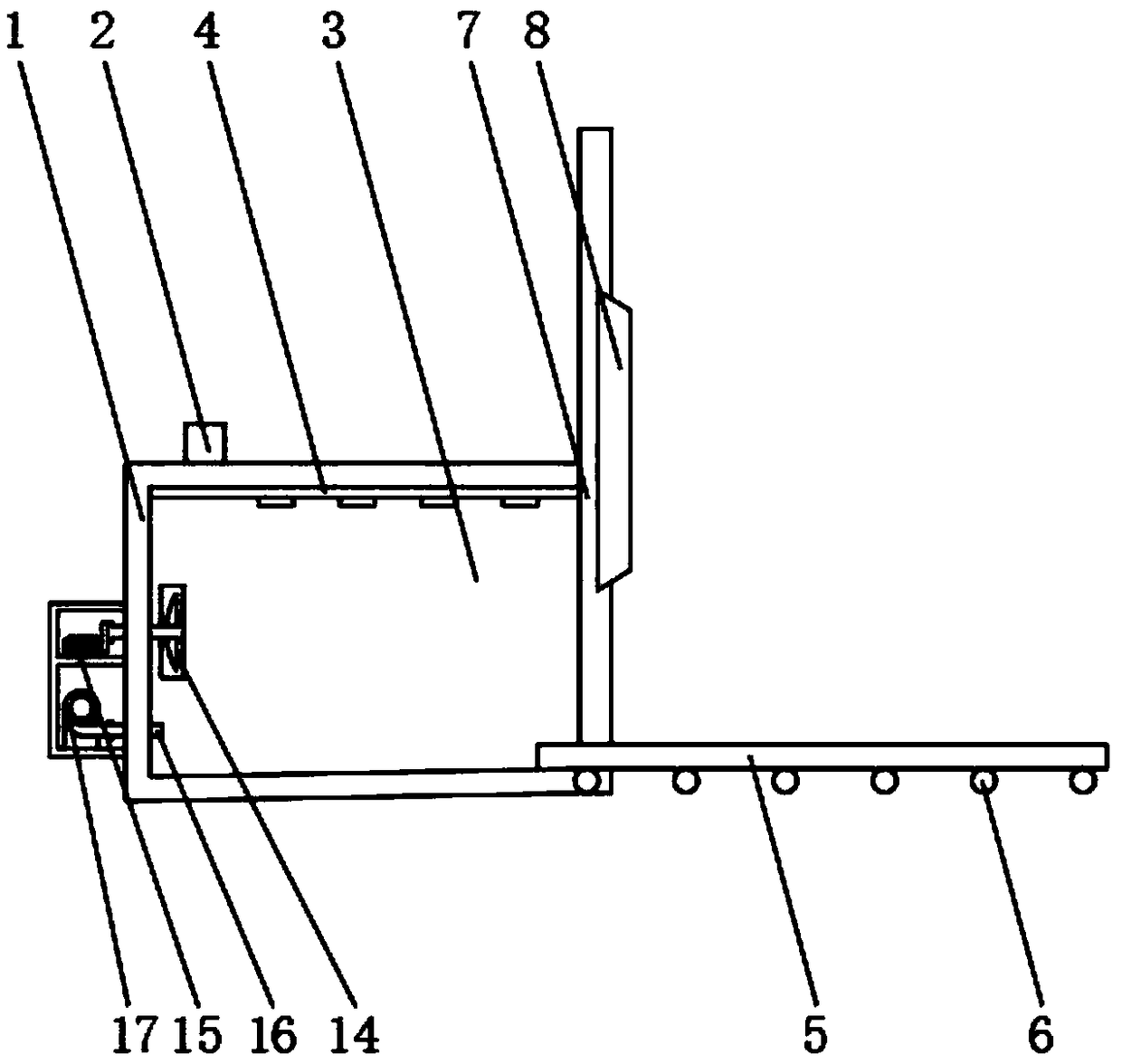

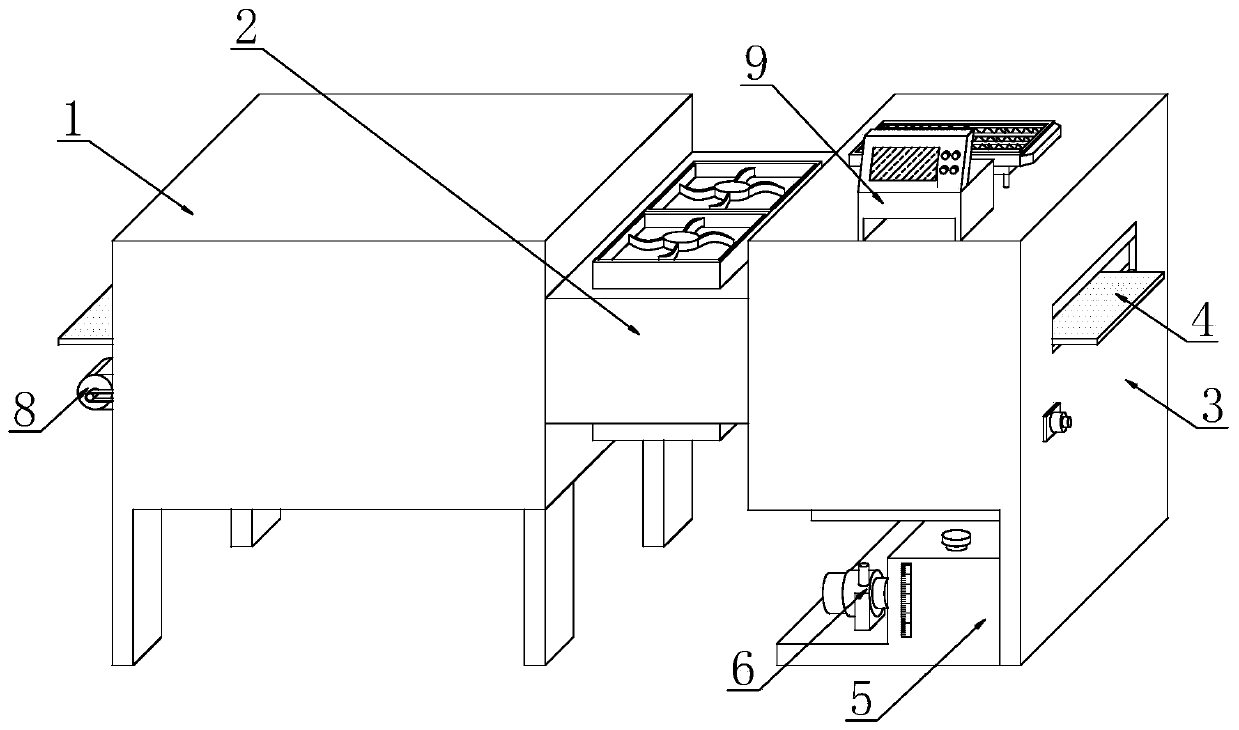

Integral waveform piece automatic annealing device for clutch and application method

PendingCN111286595AImprove yieldAvoid the situation where the molding size changesFurnace typesHeat treatment process controlTemperature controlProcess engineering

The invention discloses an integral waveform piece automatic annealing device for a clutch and an application method. A feeding device, an annealing furnace device, a discharging device, a temperaturecontrol system and a center control module are included. Under unmanned intervention, the feeding device and the discharging device are reasonably arranged to finish the automatic feeding and discharging procedure, and the automatic annealing device integrates automatic feeding and discharging, waveform piece heat preservation and pressure maintaining, waveform piece key forming area monitoring functions. The heat preservation and pressure maintaining annealing procedure is provided, a waveform piece annealing sizing lower die, a waveform piece annealing sizing upper die and four waveform piece sizing high-temperature-resisting springs are in one group to sequentially form an annealing start feeding station, a pressure maintaining start station, a pressure maintaining annealing station,a pressure maintaining finish station and an annealing finish discharging station, all the stations are different in procedure and purpose, and the annealing procedure is finely divided. The annealingfurnace device is combined with the center control module, the temperature control system is controlled under processing of the center control module, the related machining heat preservation temperature value is provided, and fine treatment is conducted for waveform piece annealing.

Owner:GUILIN UNIV OF ELECTRONIC TECH

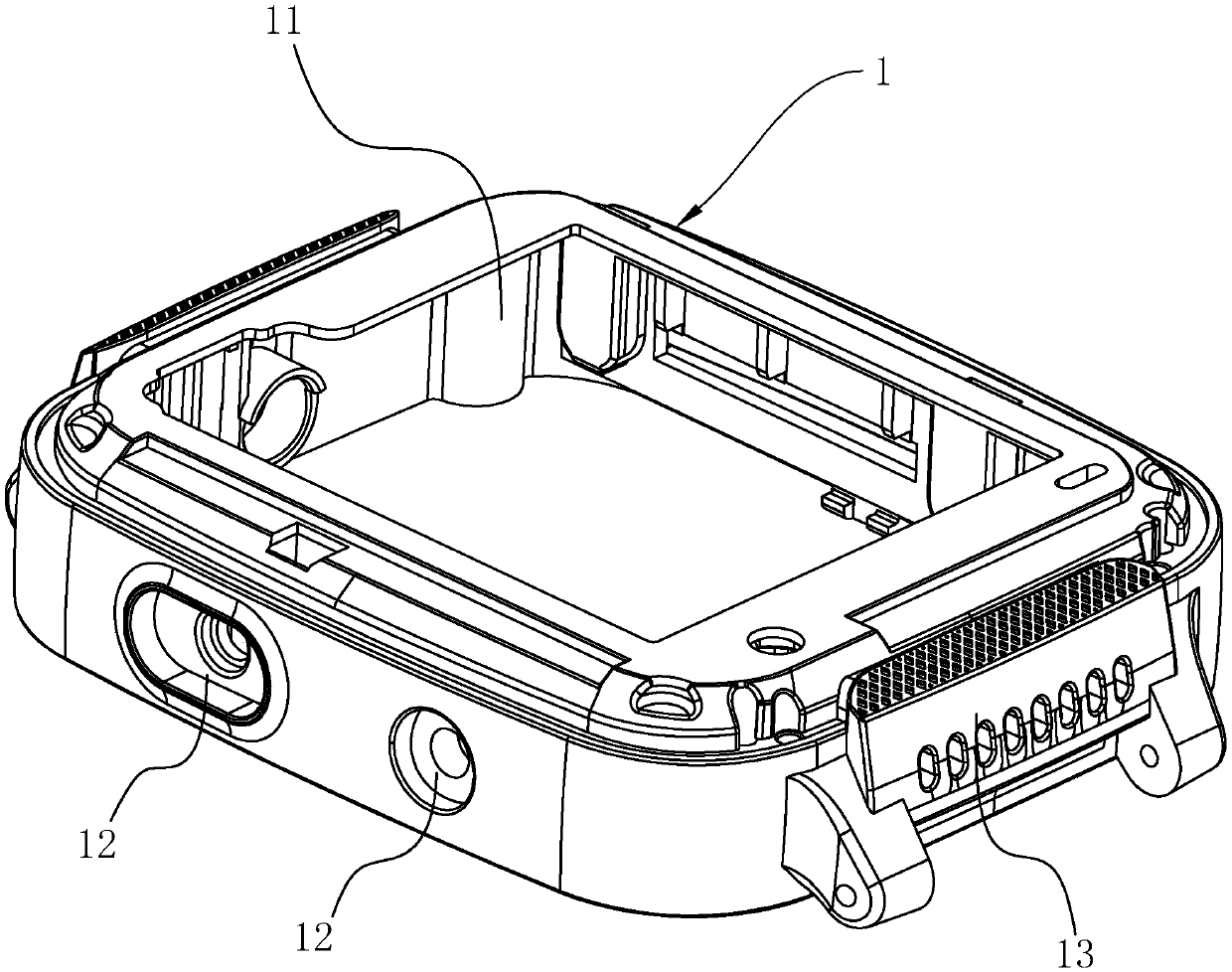

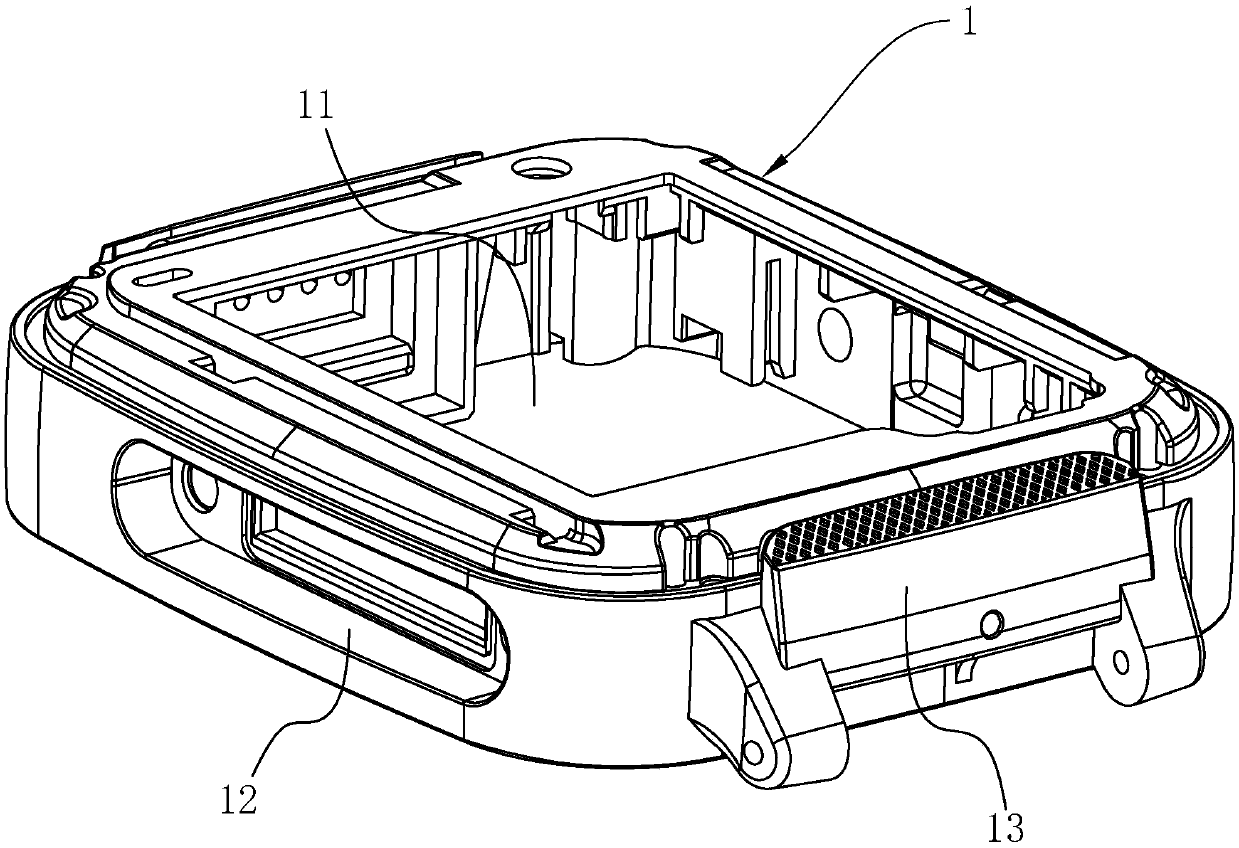

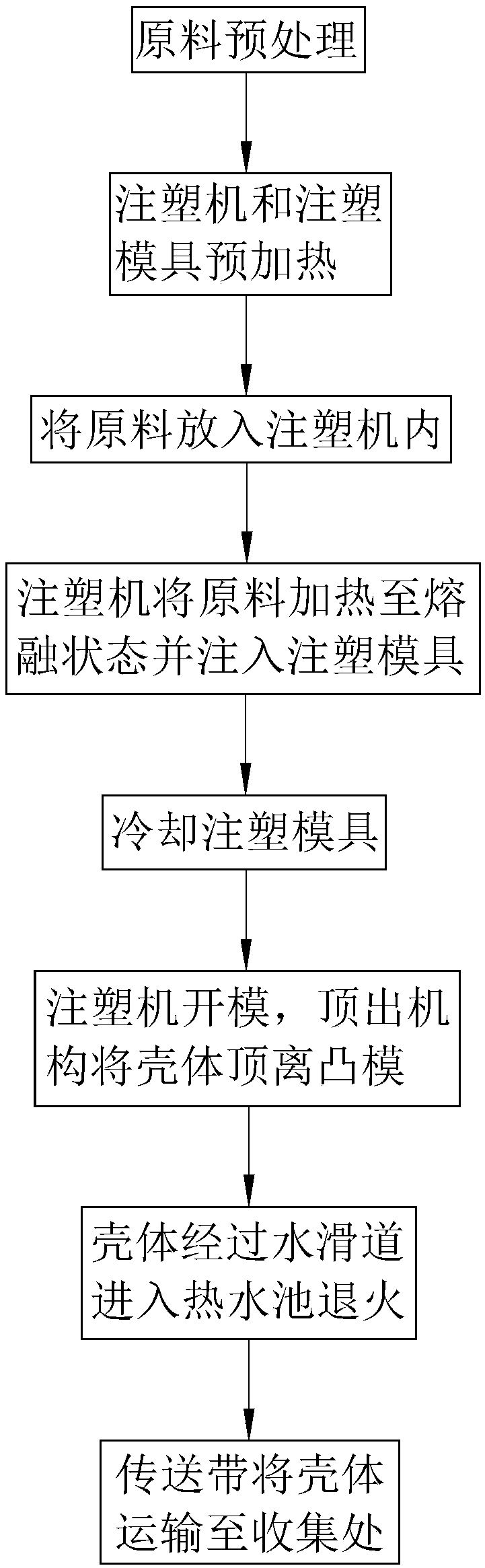

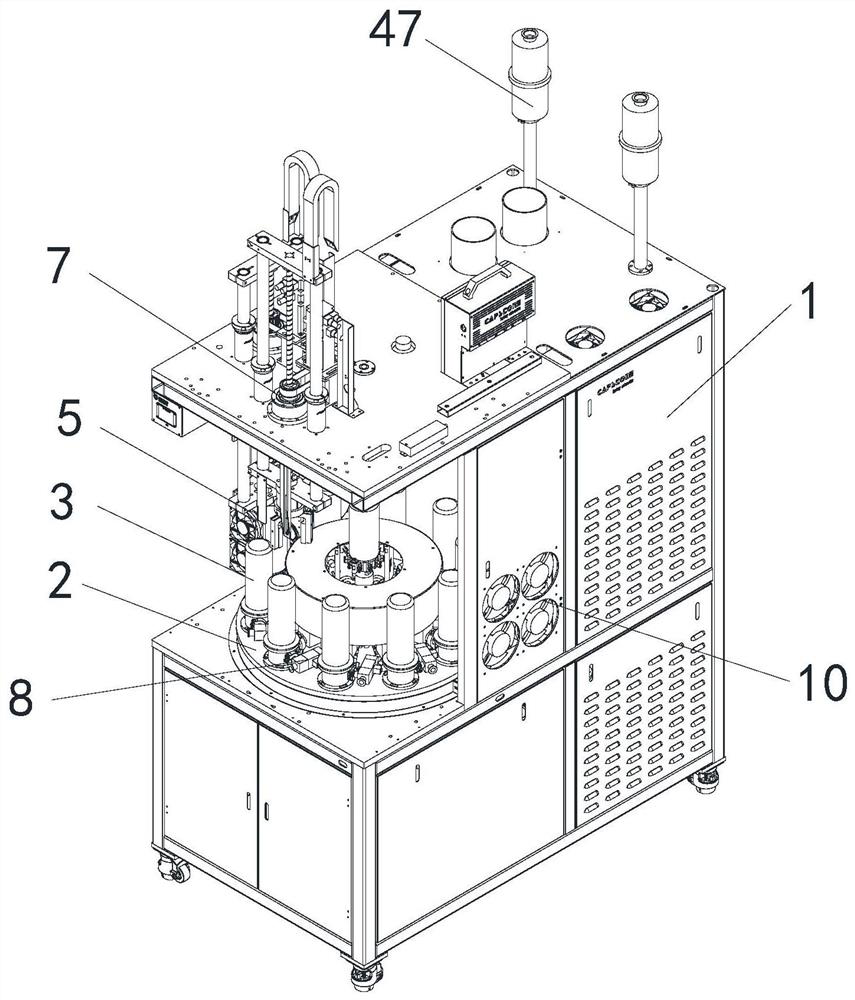

Injection molding production line and injection molding process of ABS watch shell

The invention discloses an injection molding production line and injection molding process of an ABS watch shell, and belongs to the field of ABS injection molding. According to the technical scheme,the molding production line and injection molding process is characterized by comprising a drying oven, an injection molding machine and an annealing device. The injection molding process comprises the following steps that firstly, ABS plastic raw materials are put into the drying oven to be dried, meanwhile, the injection molding machine and an injection mold are pre-heated, then the raw materials are placed in a screw barrel of the injection molding machine, the injection molding machine is used for heating the raw materials to be in a molten state, the raw materials are injected into the injection mold to be formed into finished products, the injection mold is cooled, then opening the mold is conducted, an ejection mechanism ejects the finished products out of the male mold so as to make the finished products fall into a water slide way of the annealing device, and the finished products pass through the water slide way and slide to a hot water tank for annealing and are conveyed toa collecting box through a conveying belt. According to the injection molding process, the problems that the ABS watch shell is not convenient to anneal after being just subjected to injection moldingand annealing time is not good to control are solved, so that the effects that the ABS watch shell can be automatically annealed after being just subjected to the injection molding and the annealingtime can be accurately controlled when the ABS watch shell is transported through the conveying belt is achieved.

Owner:SHENZHEN CARES PLASTIC ELECTRONICS

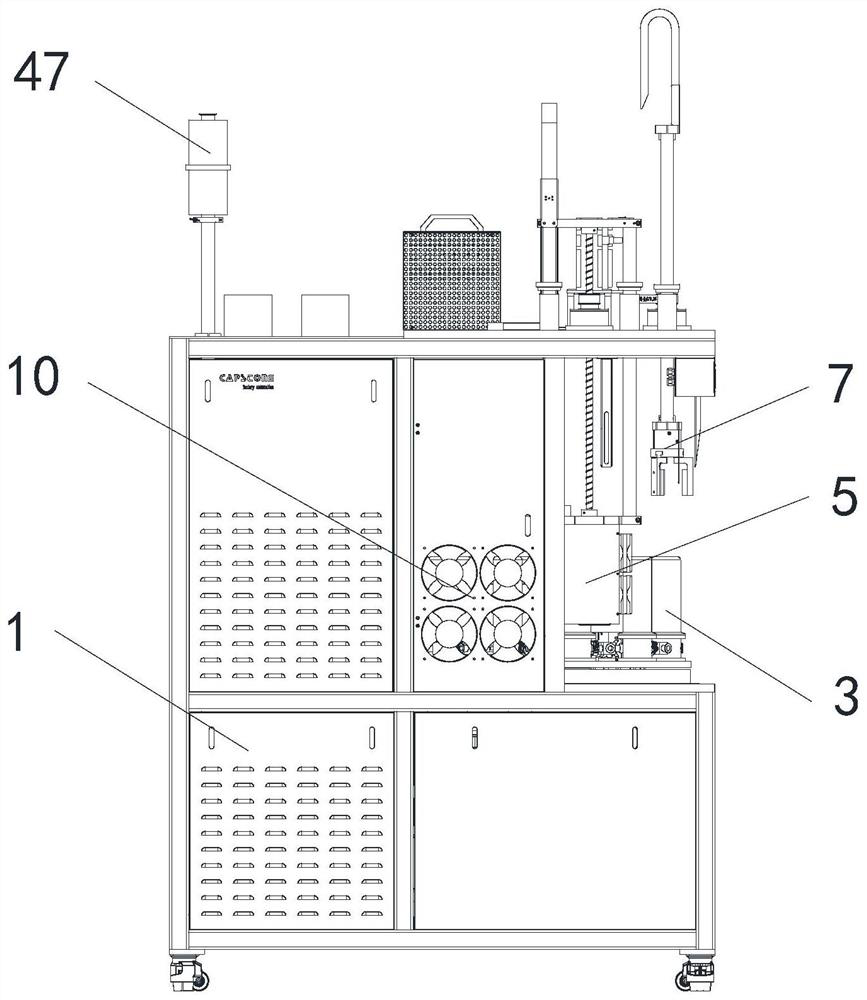

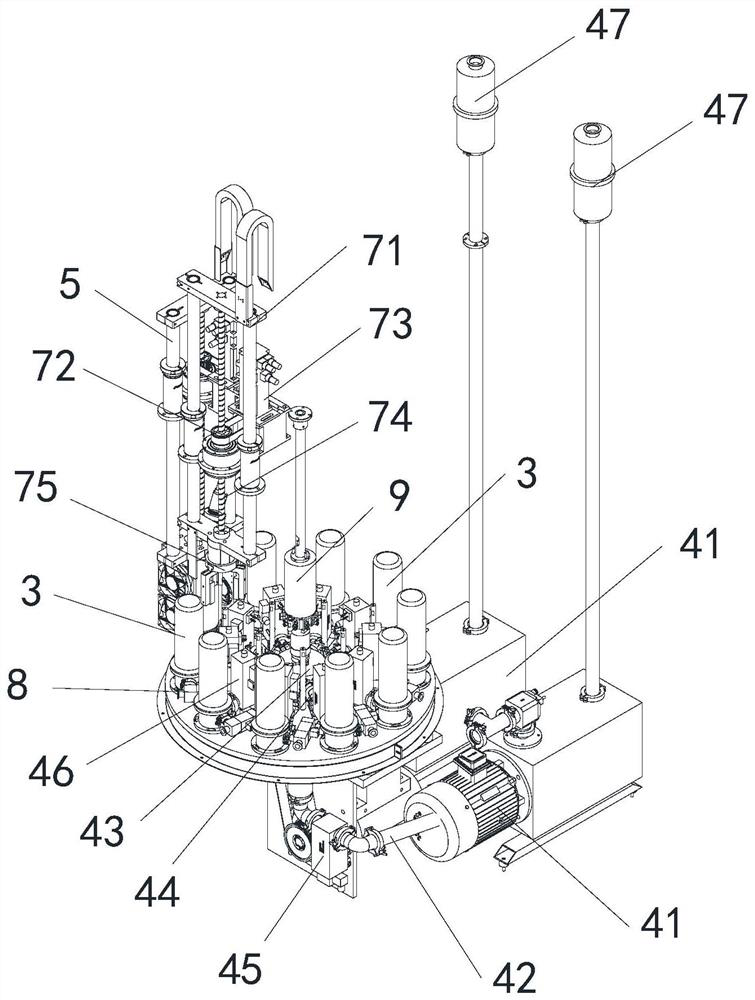

Multi-station vacuum annealing machine

A multi-station vacuum annealing machine comprises a machine frame, a workbench, a plurality of vacuumizing chambers, vacuumizing mechanism, a heating mechanism and a driving mechanism, wherein the workbench is arranged on the machine frame, the multiple vacuumizing chambers are arranged on the workbench, the vacuumizing mechanisms are communicated with the vacuumizing chambers correspondingly, the heating mechanism is used for heating one or more vacuumizing chambers, and the driving mechanism is used for driving the vacuumizing chambers and the heating mechanism to move relatively. Each vacuumizing chamber comprises a base arranged on the workbench and an upper cover cap capable of being matched with the base in a sealed manner, and each base is communicated with the corresponding vacuumizing mechanism. The heating mechanism comprises a lifting module and an electromagnetic heating coil arranged at the lower end of the lifting module, and the electromagnetic heating coils are locatedright above the one or more vacuumizing chambers. According to the multi-station vacuum annealing machine, a workpiece can be independently heated and annealed, so that the workpiece to be annealed is uniformly heated, and the annealing quality is improved; and circulation and uninterrupted automatic operation of heating annealing, heat preservation, cooling and heating annealing can be conducted, the production is planned, manual intervention is not needed, the production efficiency is high, the energy consumption is low, and the environment friendliness is achieved.

Owner:THERMOS JIANGSU HOUSEWARES

Double annealing mechanism

InactiveCN110408768AImprove the heating effectEasy to handleFurnace typesHeat treatment furnacesEngineeringToughness

The invention discloses a double annealing mechanism. The double annealing mechanism comprises a fixed box and annealing power sources. The number of the annealing power sources is two. The bottoms ofthe annealing power sources are fixedly connected with the top of the fixed box through supporting legs. The two sides of the back face of the inner wall of the fixed box are fixedly connected with heating devices. The two sides of the bottom of the inner wall of the fixed box are fixedly connected with water boxes. The positions, located at the tops of the water boxes, of the two sides of the back face of the inner wall of the fixed box are fixedly connected with water cooling circulating devices. The invention relates to the technical field of the metal heat treatment process. According tothe double annealing mechanism, the annealing effect of a copper wire can be greatly improved through double heating and double annealing treatment of the copper wire; a temperature sensor is arranged, the heating temperature can be controlled, the temperature of the copper wire is increased slowly, and the problems that due to sudden increase of the temperature, the surface of the copper wire isrough, and toughness is poor are avoided; and meanwhile, continuous operation is achieved, contact of the copper wire and air is avoided, the oxidation phenomenon is avoided, and the annealing qualityof the copper wire is improved.

Owner:东莞市营特电子科技有限公司

Annealing device for copper wire processing

PendingCN111304564AImprove annealing qualityQuality improvementFurnace typesHeat treatment furnacesCopper wireHeat conservation

The invention discloses an annealing device for copper wire processing. The annealing device comprises a base, wherein a heat preservation mechanism, a cooling mechanism, a cleaning mechanism, a firstguide wheel and a second guide wheel are arranged on the base; the heat preservation mechanism comprises heat preservation cotton, a heat preservation cotton base is arranged at the lower end of theheat preservation cotton, and an induction coil is wound around the heat preservation cotton; the cooling mechanism comprises first annealing grooves and second annealing grooves, wherein the first annealing grooves are provided with first fixed pulleys, the second annealing grooves are internally provided with second fixed pulleys, flow guide pipes are arranged between the first annealing groovesand the second annealing grooves, and a circulating water pump and a cooling device are arranged at the bottoms of the first annealing grooves and the bottoms of the second annealing grooves; and thetwo ends of the cleaning mechanism are connected with fixing shafts in an inserted mode, the outer side of the fixing shaft at the right end of the cleaning mechanism is provided with an outer rotormotor in a sleeved mode, the output end of the outer rotor motor is connected with a scrubbing pipe, and a first scrubbing device and a second scrubbing device are arranged in the scrubbing pipe. Theannealing device is simple in structure, high in annealing quality, and simple and convenient to operate due to the provision of a cleaning device.

Owner:江西远桥电磁线科技协同创新有限公司

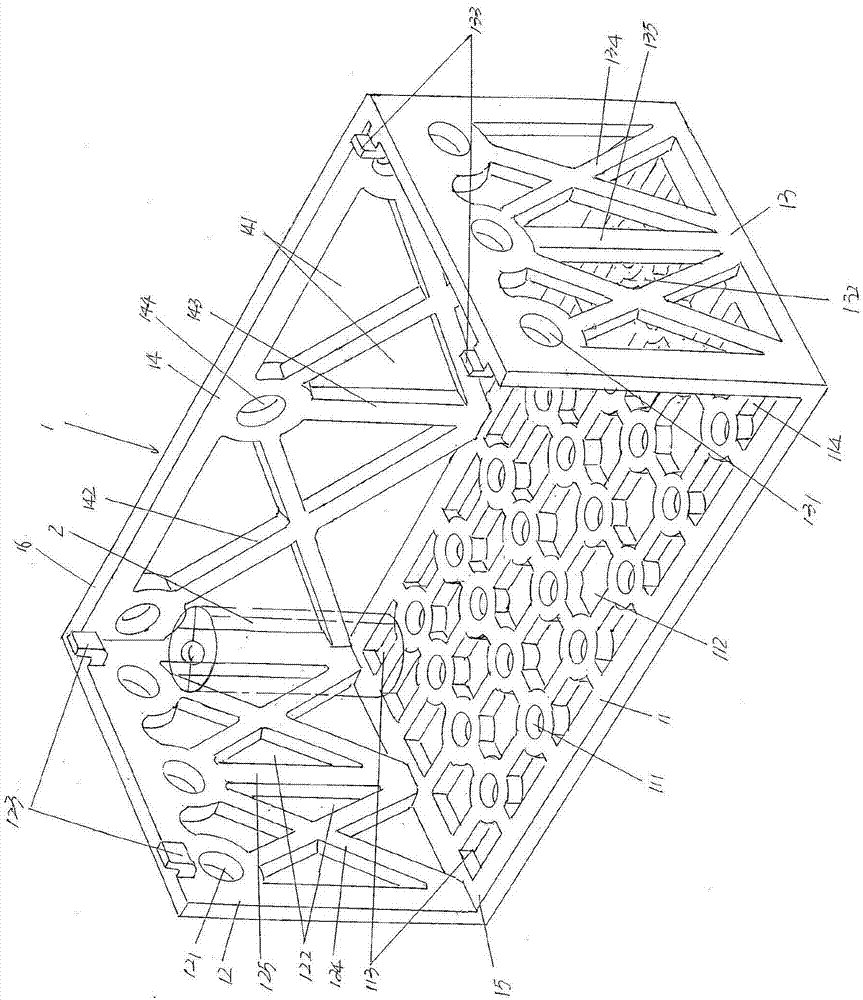

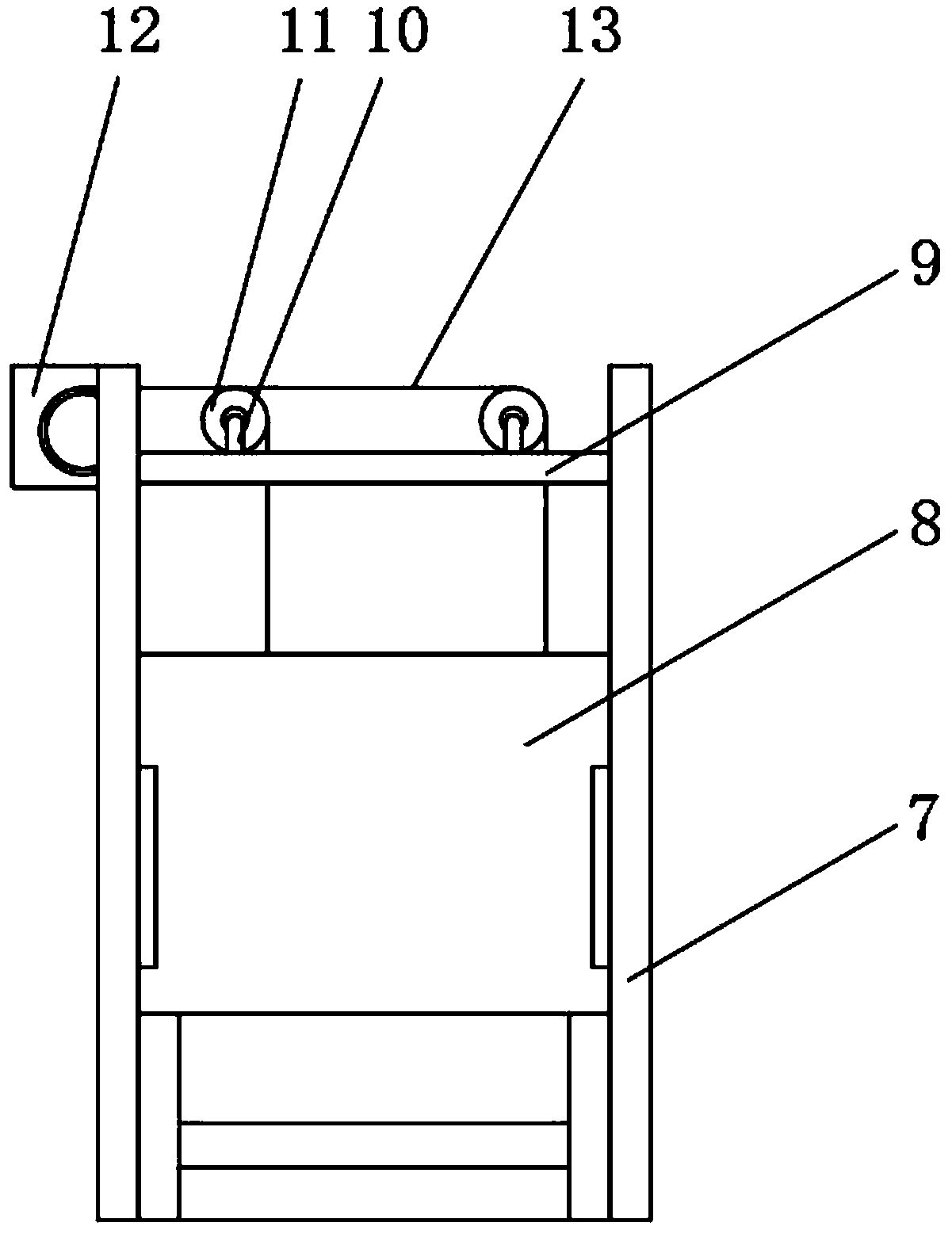

Furnace inlet circulation frame for glass mold annealing

PendingCN107881298AGuarantee your own strengthMeet the support strength requirementsFurnace typesHeat treatment furnacesEngineeringShovel

A furnace inlet circulation frame for glass mold annealing comprises a frame body composed of a bottom frame piece, a left frame piece, a right frame piece and a rear frame piece; the circulation frame is characterized in that a frame body front opening is formed in the front side of the frame body, a frame body top opening is formed in the top of the frame body, a bottom frame piece round heat transmitting cavity and a bottom frame piece polygonal heat transmitting cavity are formed in the bottom frame piece, a pair of left frame piece limiting foot bolt closing holes are formed in the left end of the bottom frame piece, a pair of right frame piece limiting foot bolt closing holes are formed in the right end of the bottom frame piece, left frame piece round and triangular heat transmitting cavities are formed in the left frame piece, a pair of left frame piece limiting feet are arranged on the upper portion of the left frame piece, the upper portions of the left frame piece limiting feet stretch out of the upper plane of the left frame piece, a right frame piece round heat transmitting cavity and a right frame piece triangular heat transmitting cavity are formed in the right framepiece, a pair of right frame piece limiting feet are arranged on the side, facing the left frame piece, of the upper portion of the right frame piece, the upper portions of the right frame piece limiting feet stretch out of the upper plane of the right frame piece, and a rear frame piece triangular heat transmitting cavity is formed in the rear frame body. Annealing quality is improved, work efficiency is high, accidents caused by collapsing are avoided, and a shovel car can conveniently carry out shovel transportation operation.

Owner:CHANGSHU JIANHUA MOLD TECH

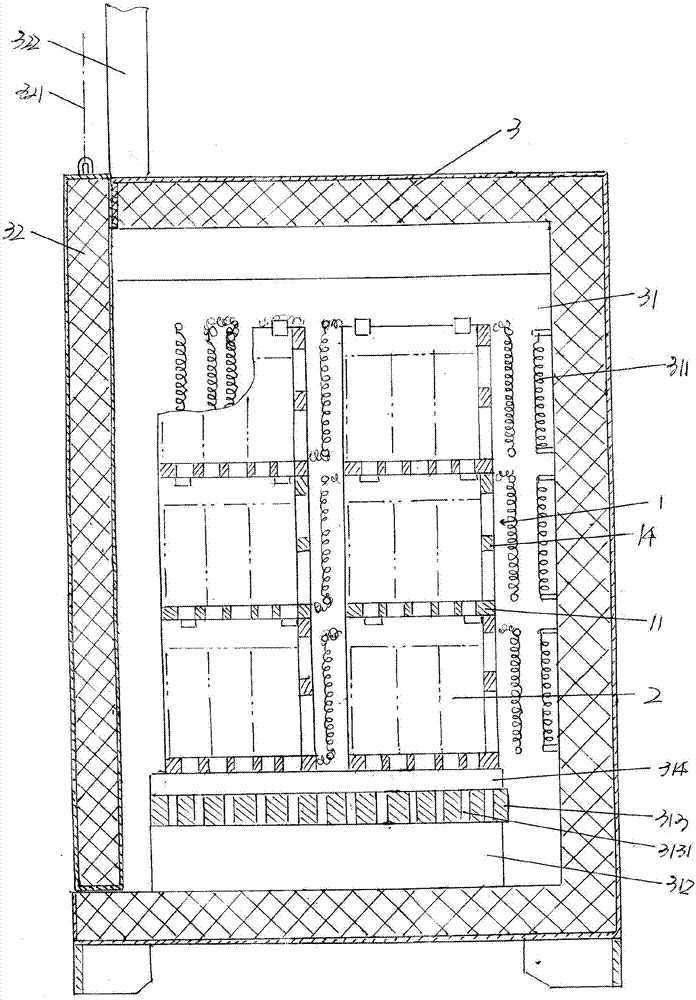

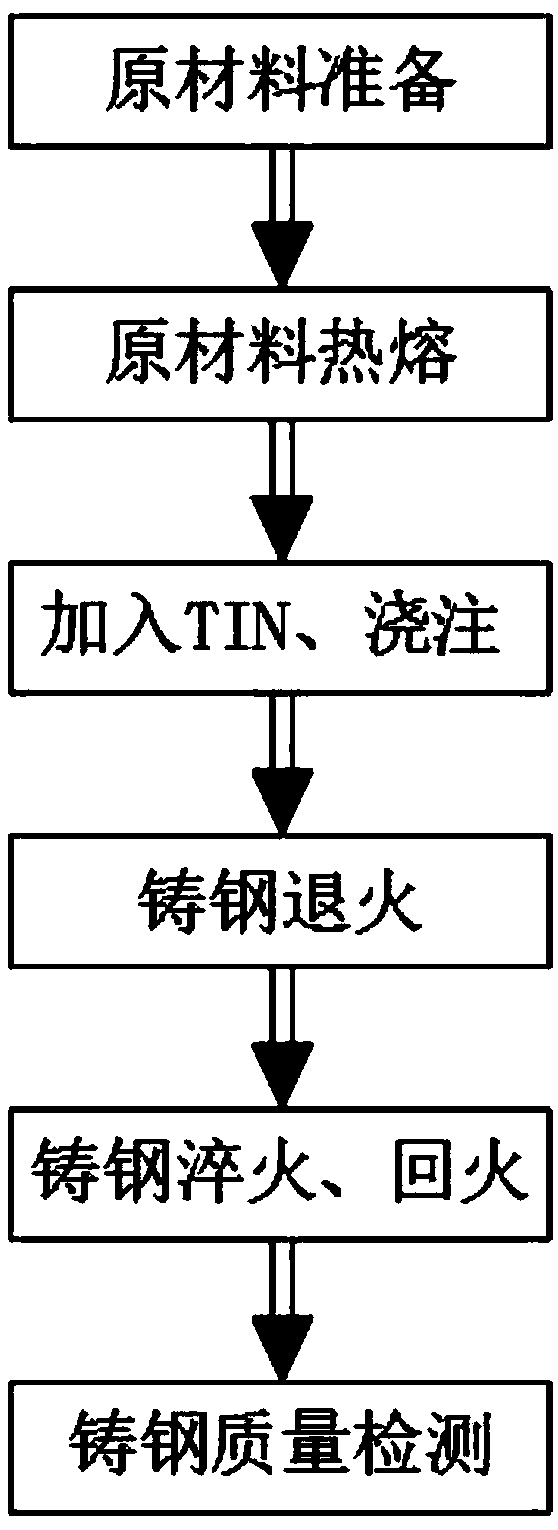

High-tenacity high-strength cast steel wear-resistant material and preparation method thereof

The invention discloses a high-tenacity high-strength cast steel wear-resistant material and a preparation method thereof. The method comprises the technology steps of raw material preparation, raw material hot melting, TIN adding according to a ratio, cast steel annealing, cast steel quenching and tempering and cast steel quality detection, through a series of thermal treatment technologies of isothermal quenching, high-temperature tempering and the like, the high-tenacity high-strength cast steel wear-resistant material has good tensile performance, and is not prone to deform or break, and by adding an appropriate amount of TIN in a hot melting process, the elongation at break is higher than or equal to 12%; V shape impact energy is higher than or equal to 45 J, the rockwell hardness HRCis 40-45, cast steel has higher impact resistance, the wear resistance performance of the cast steel is 1.5 times the wear resistance performance of an NM450 wear-resistant plate, the cast steel hasthe good wear resistance performance, wear resistance degrees of the cast steel are even, by conducting annealing in an annealing furnace at 900+ / -3 DEG C in cooperation with a fan and blades, the produced cast steel is even in wear resistance, and the problems that cast steel is poor in weldability, high in welding stress and prone to break, and has many welding defects due to the fact that various portions are made from different materials are solved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Copper wire drawing process

The invention discloses a copper wire drawing process. The process comprises alkaline electrolysis, cleaning, oxygen content measuring, wire drawing, annealing, winding and inspection. A copper rod issubjected to electrolysis in an alkaline solution containing sodium hydroxide and sodium tartrate, and a copper oxidation film is removed; after reaching the schedule time, cleaning is carried out, after drying, a pulse melting infrared absorption method is used for measuring the oxygen content of a copper rod with an oxidation film removed, when the oxygen content is lower than 6000 PPM, the copper rod can be used, a large wire drawing machine, a medium wire drawing machine and a micro wire drawing machine are adopted in wire drawing, the large wire drawing machine and the medium wire drawing machine carry out wire drawing, then, annealing treatment is carried out, and after micro wire drawing, the winding machine is adopted for winding, conductive, aging stability, and thermal stabilitytests are carried out. The oxide layer is removed, alkaline electrolysis is adopted, pollution and poisonousness of chemical removal strong acid and strong base can be avoided, the pulse melting infrared absorption method is adopted for detecting the oxygen content, after wire drawing, copper thorn or fragments can be avoided, the wire yield is improved, the cost is reduced, the annealing qualityis high, and electric energy is saved.

Owner:江苏景昇新材料有限公司

Heat treatment process for knuckle bearing

InactiveCN105734259AUniform particle sizeEvenly distributedFurnace typesHeat treatment furnacesHeat stressMartensite

The invention discloses a heat treatment process for a knuckle bearing. The heat treatment process is characterized by comprising the following steps that (1) material selection of a part is conducted, and W18Cr4V is selected; (3) preheating treatment is conducted; (4) quenching treatment is conducted, and (5) tempering treatment is conducted. According to the heat treatment process for the knuckle bearing, preheating is conducted at first, so that large heat stress is avoided, and about 30% of residual austenite which is not converted into martensite is still reserved in the internal structure after quenching; and the process parameters of all stages are strictly controlled, procedures are remarkably reduced, the process is simple, operation is convenient, and energy consumption is low.

Owner:CHONGQING JINSHENG MACHINERY PARTS MFG CO LTD

Special-shaped copper alloy strip and production method thereof

The invention relates to a special-shaped copper alloy strip and a production method thereof. The special-shaped copper alloy strip contains, by weight, 0.075%-0.14% of iron, and 0.025%-0.04% of phosphorus, has higher hardness and conductivity, and can meet the ever-increasing requirement of the performance of the lead wire frame. The production method for the special-shaped copper alloy strip is also disclosed, the production method includes the following steps of preparation of a mother belt, high speed forging, continuous annealing, surface washing and lapping, surface oil washing, roller type rolling, on-line detection and interleaving paper coiling, specifically, after the mother belt is forged at high speed and is preliminarily formed, and continuous annealing is used for fully releasing the internal stress of the forged strip material, accordingly the annealing quality is improved, and cracks generated at the thick-thin junction of the strip material are prevented; the strip is ground and polished while surface washing is conducted, accordingly the flatness of the belt surface is greatly improved, and the strip surface can evenly make contact with roiling oil when the surface is washed with oil, and accordingly the antioxidant treatment effect is guaranteed and the machining quality of the copper alloy strip is improved.

Owner:铜陵格里赛铜冠电子材料有限公司

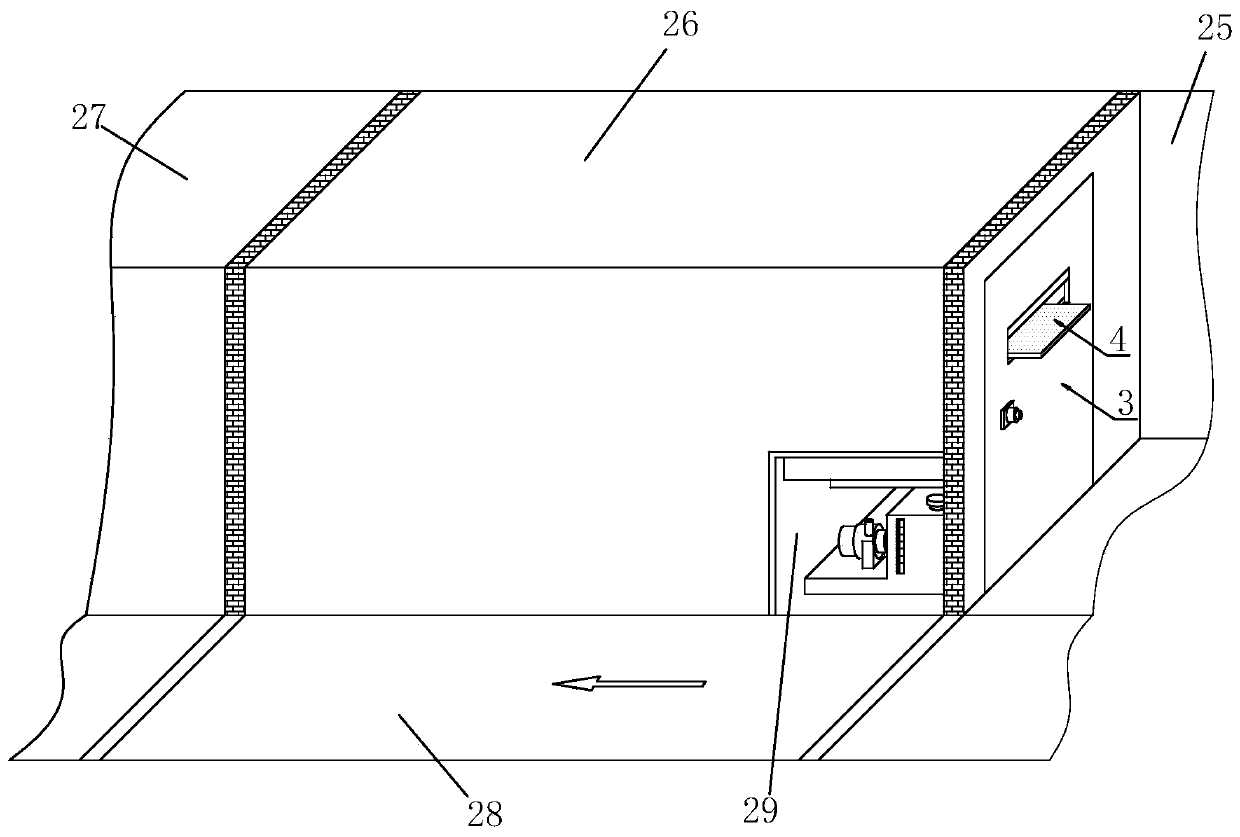

Efficient annealing system suitable for heat treatment of amorphous nano steel

InactiveCN110923419AAvoid blowingAvoid affecting the quality of annealingElectric machineryEngineering

The invention discloses an efficient annealing system suitable for heat treatment of amorphous nano steel. The efficient annealing system comprises a feeding chamber, a treatment chamber for centralized annealing treatment and a material taking chamber for receiving treated materials. An annealing device is arranged in the treatment chamber. The annealing device comprises a heating box. A heat dissipation box is welded to one side of the heating box in a penetrating mode. A cooling box is welded to one side of the heat dissipation box in a penetrating mode. Materials are placed in the heatingbox, the heat dissipation box and the cooling box. A water tank is installed below the cooling box. A water pump is installed on one side of the water tank. A transparent window is installed on the front surface of the water tank. A control box is installed on the upper surface of the cooling box. Chains are installed on the front surfaces of the heating box, the heat dissipation box and the cooling box. A motor is installed on one side of the heating box. A heat dissipation fan is installed on the upper surface of the heat dissipation box. According to the efficient annealing device for heattreatment of amorphous nano steel, the heating box, the heat dissipation box and the cooling box are arranged, the annealing structure is reasonable, the cooling device is provided with a heat dissipation structure, and the structure of the device is simple.

Owner:WUHU DINGHENG MATERIAL TECH

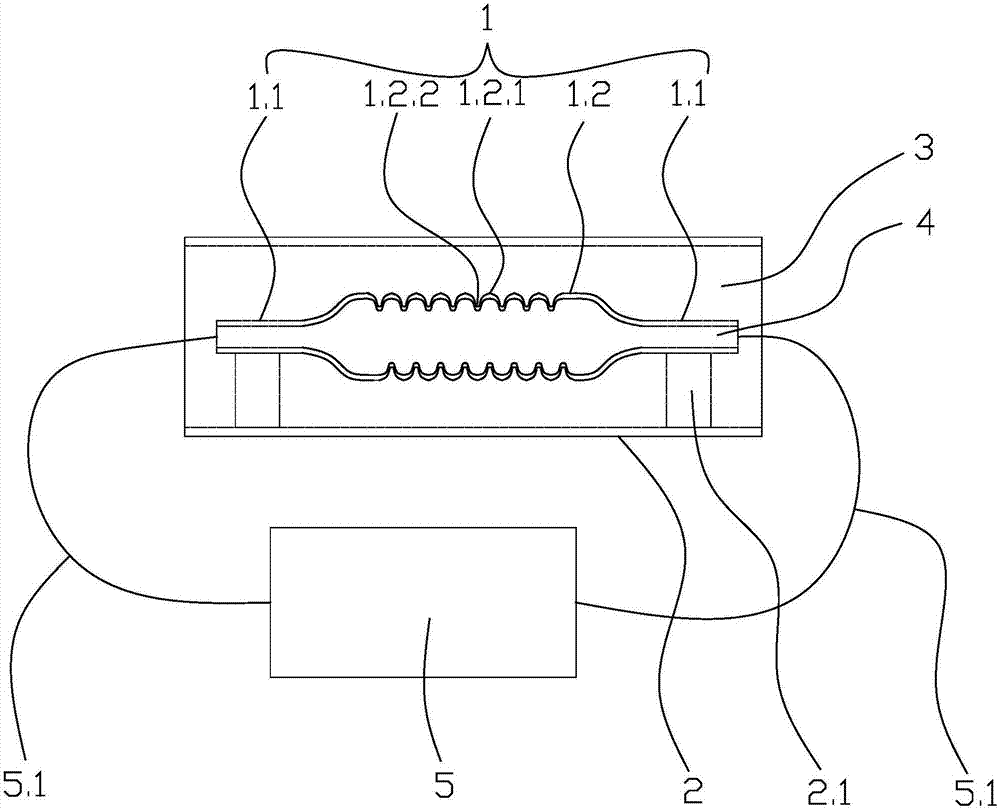

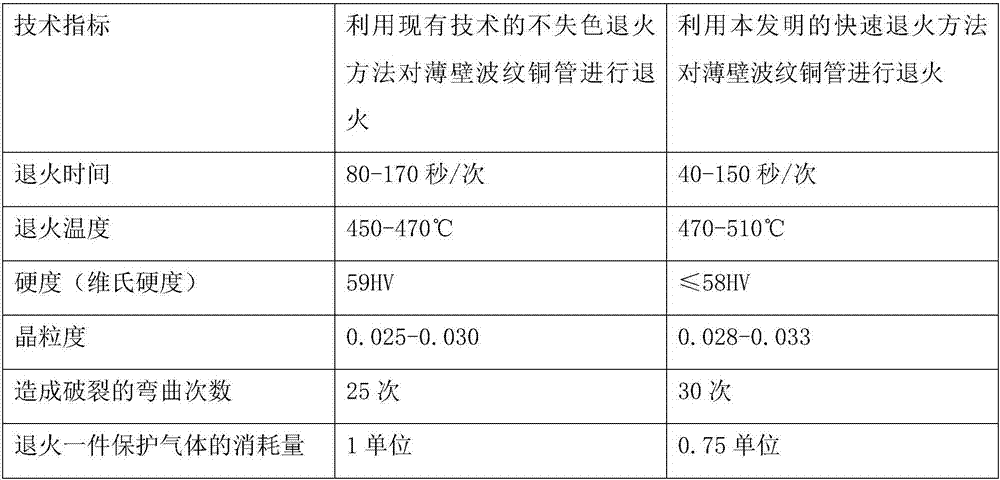

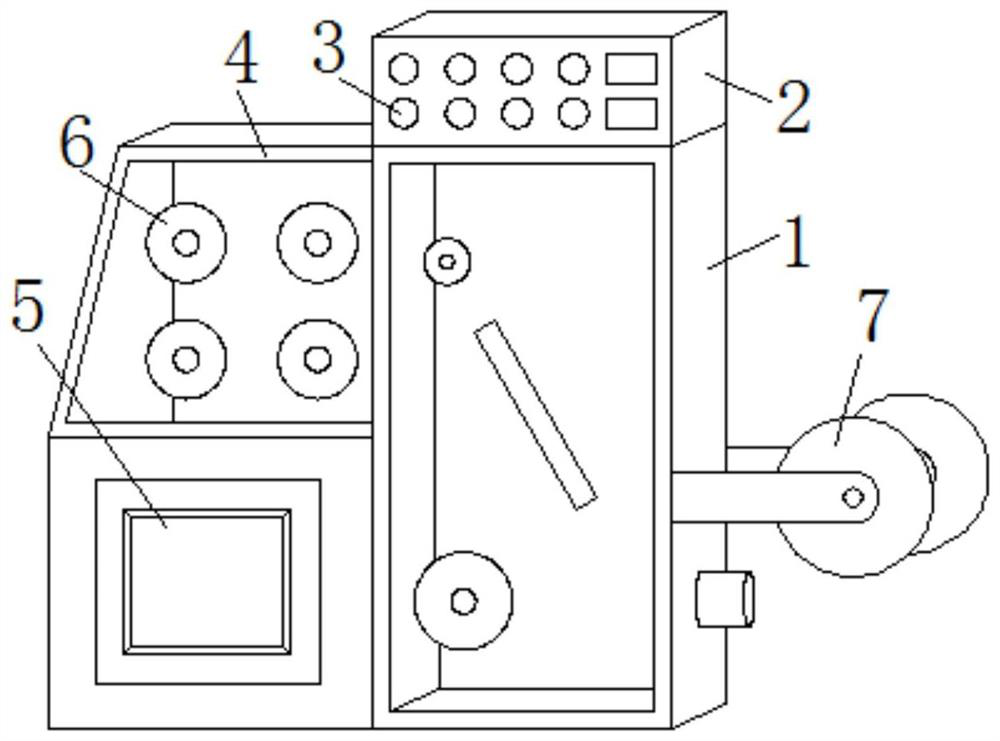

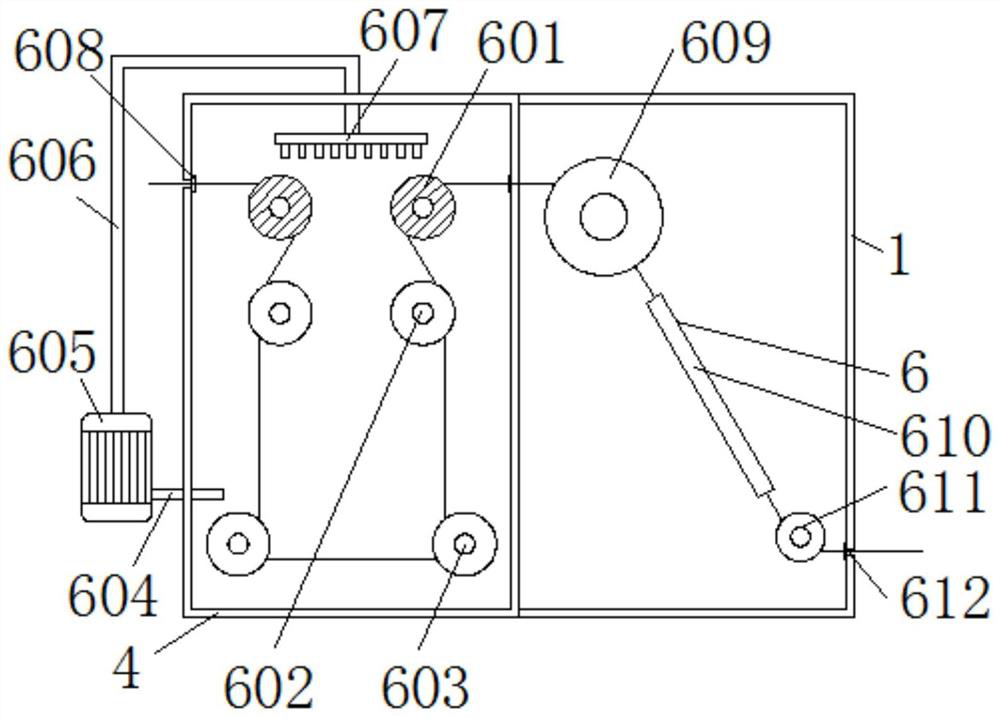

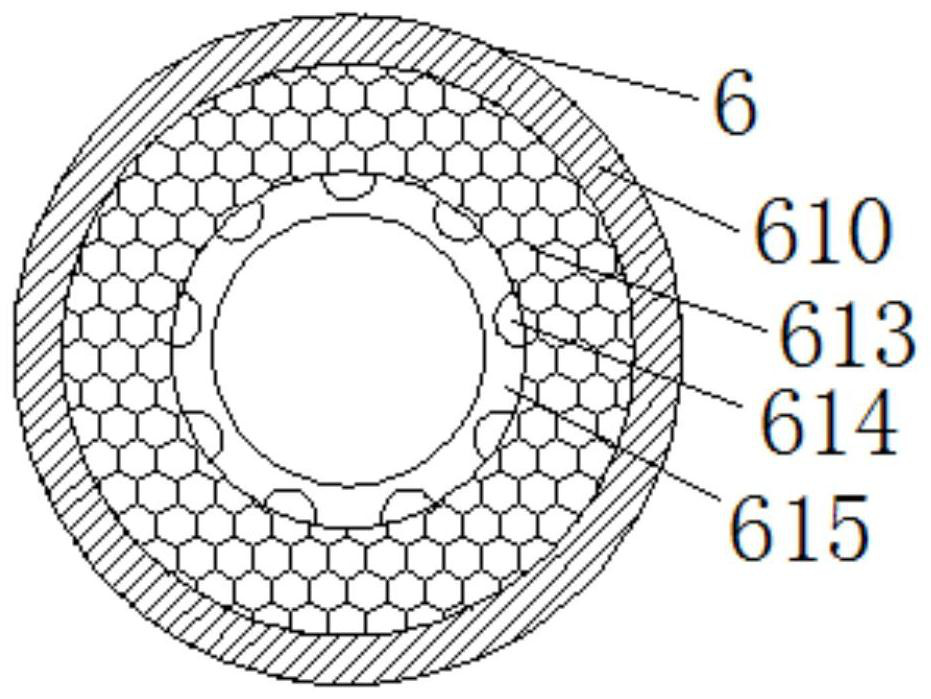

Fast annealing method for thin-wall corrugated pipe

ActiveCN107142369AEasy annealingStrong enoughFurnace typesHeat treatment furnacesShielding gasNitrogen

A fast annealing method for a thin-wall corrugated pipe comprises the steps of putting the thin-wall corrugated pipe into an annealing bin, performing electrifying and heating, performing protection through protective gas, performing outage cooling and performing taking-out. By the adoption of the annealing method, the heating and annealing can be completed fast, the speed of the annealing operation can be matched with the speed of the following machining processes, meanwhile the copper thin-wall corrugated pipe can be subjected to good annealing treatment, and the annealed thin-wall corrugated pipe not only has the enough strength, but also has certain flexibility; the annealing bin is open in work, the annealing treatment speed is high, taking and putting are convenient, the product to be treated is conveyed into the annealing bin from one end, and meanwhile the product obtained after the annealing treatment is completed can be taken out from the other end, so that the annealing operation can be performed in a streamlined manner, and the speed of the annealing operation is further increased; and the introducing time of the protective gas is shortened, the consumption of the gas is lowered, besides, the thin-wall corrugated pipe can be taken out from the annealing bin faster, the annealing operation speed is further increased, inert gas can be adopted as the protective gas, nitrogen can be adopted as the protective gas as well, and the cost of the annealing operation is lowered greatly.

Owner:左铁军 +2

Annealing device for producing copper wires

InactiveCN112410694APrevent oxidationImprove annealing qualityFurnace typesHeat treatment furnacesCopper wireEngineering

The invention discloses an annealing device for producing copper wires. The annealing device comprises a body; a control box is fixedly installed at the top end of the body; a button is connected to the front end surface of the control box; a machine body is installed on one side of the body; a cabin door is connected to the bottom of the machine body; an annealing mechanism is installed in the machine body; a heating cylinder is arranged in the annealing mechanism; a first wire guide wheel is installed at the bottom of the heating cylinder; and a second wire guide wheel is connected to the bottom of the first wire guide wheel. According to the annealing device, under the action of the annealing mechanism, a copper wire enters the machine body through a first rubber ring, the copper wiresare heated through the heating cylinder, and thus the copper wires can be evenly heated; the copper wires enter an antioxidant pipe through the first wire guide wheel, the second wire guide wheel anda third wire guide wheel, and the inner wall of the antioxidant pipe is filled with an antioxidant, so that the copper wires are effectively prevented from being oxidized in the air, and the annealingquality of the copper wires is improved.

Owner:江西辰镶金属制品有限公司

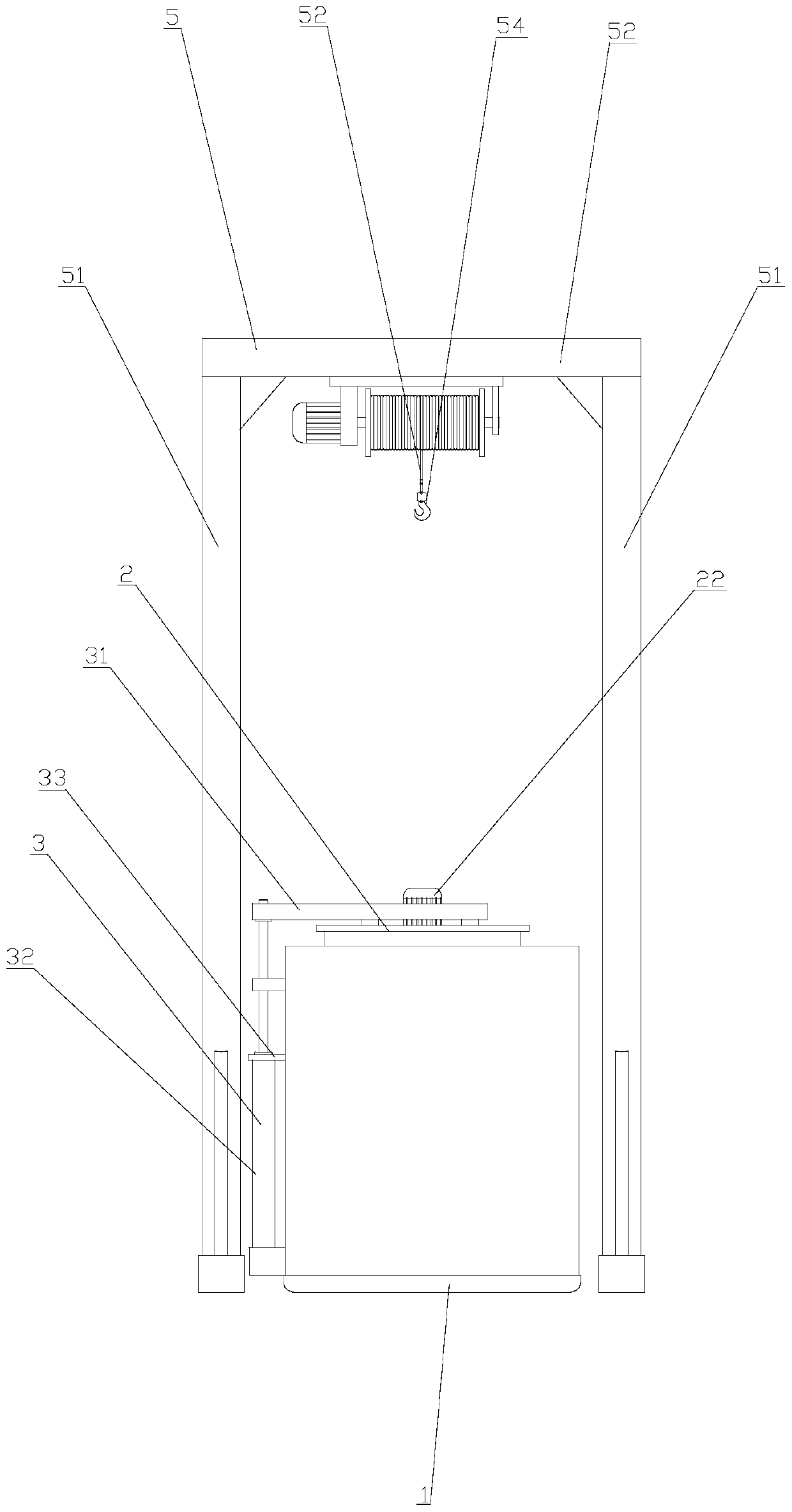

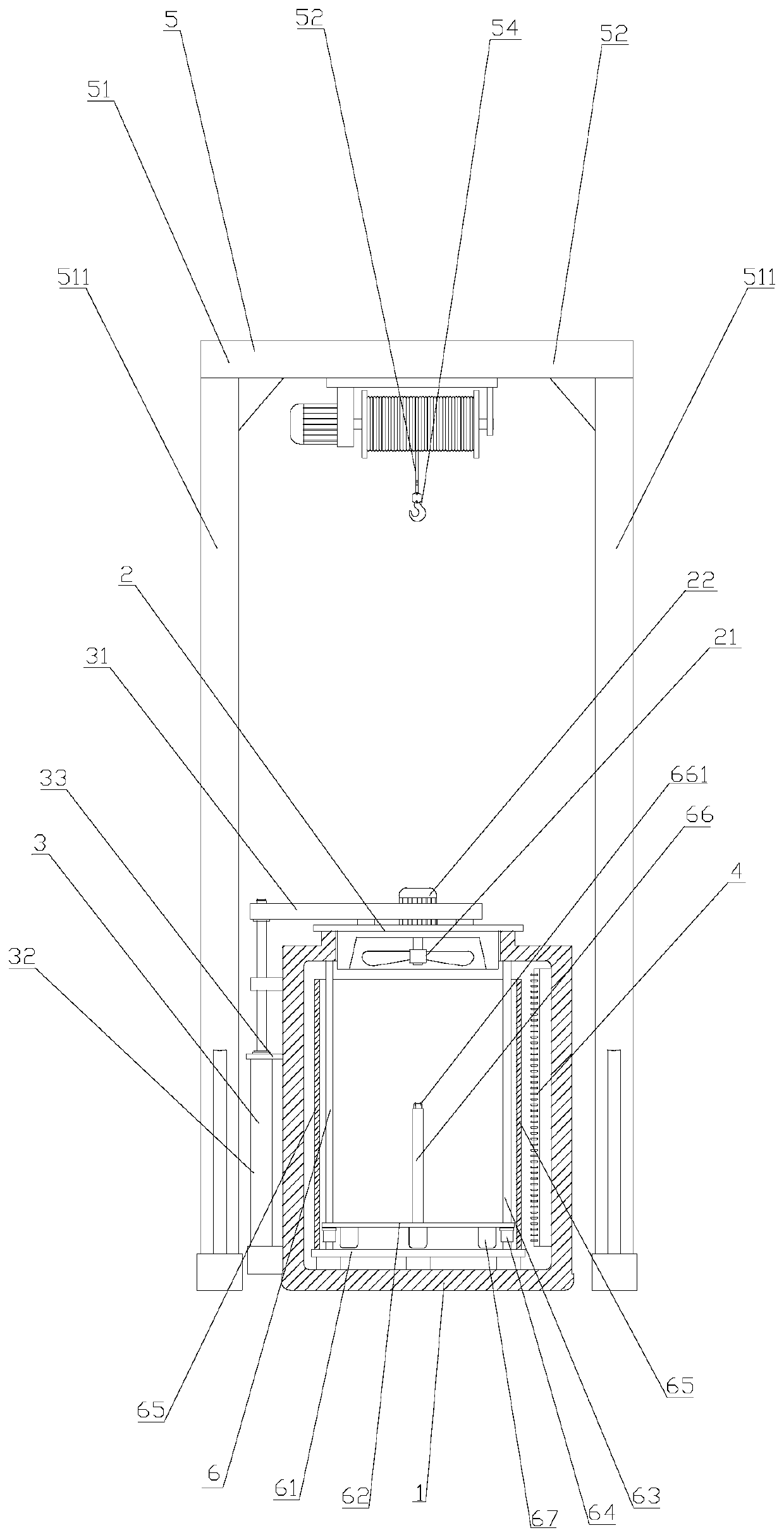

Spheroidizing annealing device for high-tenacity fastener wire rods

PendingCN111485073AEasy to unloadEasy to take outFurnace typesHeat treatment furnacesWire rodFastener

The invention discloses a spheroidizing annealing device for high-tenacity fastener wire rods. The spheroidizing annealing device comprises an annealing furnace, an annealing furnace upper cover, a furnace cover lifting device, an in-furnace heater, a gantry lifting device and an annealing furnace movable inner container, wherein the annealing furnace is a tank body with an upward opening, the annealing furnace upper cover capable of being matched with the annealing furnace upper cover is arranged at the opening in the upper end of the annealing furnace, the annealing furnace upper cover is detachably connected with the annealing furnace, the furnace cover lifting device capable of being matched with the annealing furnace upper cover is arranged on the annealing furnace upper cover, and the lower end of the furnace cover lifting device is fixedly connected with the side edge of the annealing furnace. The annealing furnace movable inner container capable of moving up and down and the gantry lifting device capable of being matched with the annealing furnace movable inner container are arranged in the annealing furnace, the annealing furnace movable inner container is driven by the gantry lifting device to ascend and descend up and down, discharging and taking in the annealing furnace can be facilitated, the annealing efficiency is improved, the annealing quality is improved, thelabor intensity of workers is reduced, and the safety is improved.

Owner:嘉兴兴通五金科技股份有限公司

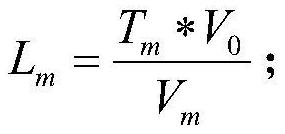

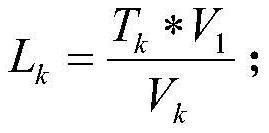

A kind of annealing process of tft substrate glass and tft substrate glass prepared by the same

The invention belongs to the technical field of TFT substrate glass processing, and specifically discloses a TFT substrate glass annealing process based on a cooling and shaping rate, which forms a theoretical basis for the processing parameters of the existing three stages: heat preservation stage, slow cooling stage and fast cooling stage , provides data support for the annealing process, and provides great convenience for the industry. After the annealing process of the present invention is adopted, the annealing quality of the TFT substrate glass produced by the overflow method is greatly improved, the reheat shrinkage rate and the maximum stress value are reduced by more than 75%, and the reheat shrinkage rate of the TFT substrate glass for OLED display is 5- 8ppm, the reheat shrinkage rate of the TFT substrate glass for LCD display is 24-45ppm, and the maximum stress on the surface of the TFT substrate glass is 30-60PSI.

Owner:BEIJING UNIV OF TECH +1

Optimized furnace combination method and system for cold rolling hood type annealing furnace unit

ActiveCN101344780BHigh-efficiency group furnace methodFeasible Group Furnace MethodTotal factory controlProgramme total factory controlElectricityHydrogen

A furnace group optimizing method and a system for cold-rolling bell annealing furnace sets belong to the field of steel material processing information technology. The method comprises the following steps of: (1) according to practical technological parameters, performing priority settings on coiled sheets to be annealed; (2) furnace pre-grouping: arranging coiled sheets according to priority penalty values in ascending order; placing the coiled sheet with the minimum priority into a furnace according to the coiled sheet-furnace matching criteria; according to the coiled sheet-coiled sheet matching criteria, selecting, from the residual coiled sheets, coiled sheets that can form a furnace group with the coiled sheet in the furnace sequentially, and when the height reaches the maximum height of the bell furnace, forming a furnace grouping scheme; repeating the procedure until the demanded furnace group scale is formed; (3) adjusting the initial feasible furnace grouping scheme; and (4) using the developed system to upload the obtained optimized furnace grouping scheme to the manufacture execution system for implementation. The method and the system of the invention increase the productivity of the bell furnace set, improve the annealing quantity of the coiled sheets and effectively lower the consumption of energy resources such as hydrogen, nitrogen, water, coal and power, etc.

Owner:NORTHEASTERN UNIV LIAONING

Ohmic heating method and ohmic heating device

ActiveCN102234710BAccelerated quenchingImprove efficiencyFurnace typesHeat treatment furnacesPower flowContinuous operation

The invention relates to an ohmic heating method and an ohmic heating device. Through the ohmic heating method and the ohmic heating device, the quenching or annealing of the back surface and tooth surface of a workpiece can be carried out in a roughly continuous operation period, and the high-precise quenching or annealing quality is easily obtained on the back surface or tooth surface while striving to improve the efficiencies of quenching or annealing. The ohmic heating method is characterized by comprising the following steps that a switching device is switched to a back surface side, so that one pair of first touch points contact the two ends of the heating range in the length direction of the back surface of the workpiece supported by a support device, the regulated frequency and output current for the back surface are supplied to the touch points from a power supply device, and then ohmic heating is carried out on the back surface; and after the step, the switching device is switched to a tooth surface side, so that one pair of second touch points contact the two ends of the heating range in the length direction of the tooth surface of the workpiece, the regulated frequency and output current for the tooth surface are supplied to the touch points from the power supply device, and then the ohmic heating is carried out on the tooth surface.

Owner:宫电高周波设备(上海)有限公司

Annealing process for high-strength hardware bolts

ActiveCN108300846AGuaranteed strength performanceImprove annealing qualityFurnace typesHeat treatment furnacesRoom temperatureFree cooling

The invention discloses an annealing process for high-strength hardware bolts. The multiple hardware bolts are put into a high-temperature furnace for preheating treatment at first, and the preheatingtemperature is 120-160 DEG C; then the temperature inside the high-temperature furnace is controlled with the heating speed of 50-90 DEG C / h to conduct heating for 1-2 hours and then stop heating, cooling with the furnace is conducted for 10-15 min, heating is conducted for 1-2 hours with the heating speed of 50-90 DEG C / h, cooling with the furnace is conducted for 15-20 min, then heating is conducted with the heating speed of 100-120 DEG C / h till the temperature is 680-720 DEG C finally, and heat preservation is conducted for 2-3 hours; and cooling with the furnace is conducted for 1.5-2.5 hours, then the temperature inside the high-temperature furnace is controlled with the cooling speed of 10-30 DEG C / h to conduct cooling for 20-40 min, cooling with the furnace is conducted till the temperature is below 540-560 DEG C, and then the high-temperature furnace is opened and naturally cooled to the room temperature. In this way, the annealing quality can be greatly improved, the machining difficulty is reduced for the subsequent process, and the strength performance of the hardware bolts is further ensured.

Owner:SUZHOU TEXIN PRECISION ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com