Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Meet the tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano artificial dura mater capable of being used as medicine sustained-release system and preparation method thereof

The invention provides a nano artificial dura mater capable of being used as a medicine sustained-release system, having the structure which comprises at least two layers, i.e. a hydrophobic anti-blocking electro-spun layer which faces the cerebrum, and a hydrophilic nano cytoskeleton layer which backs on to the cerebrum; and cell factors and / or medicines are arranged in any layer of the artificial dura mater by way of blended spinning. The invention also provides a method for preparing the nano biomimic artificial dura mater. Compared with an artificial mater prepared by the single utilization of the electro-spinning technology, the artificial mater to which the medicines and the cell factors are added by blending technology can effectively prevent infection and faster promote the regeneration process of the artificial mater. The invention also provides a novel medicine loading and releasing mode for treating cerebral diseases, the loaded medicines can be directly and efficiently transferred into the cranial cavity along with the implantation of the dura mate and can be released according to requirements, and therefore the invention realizes favorable treatment effect and has broad application prospect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

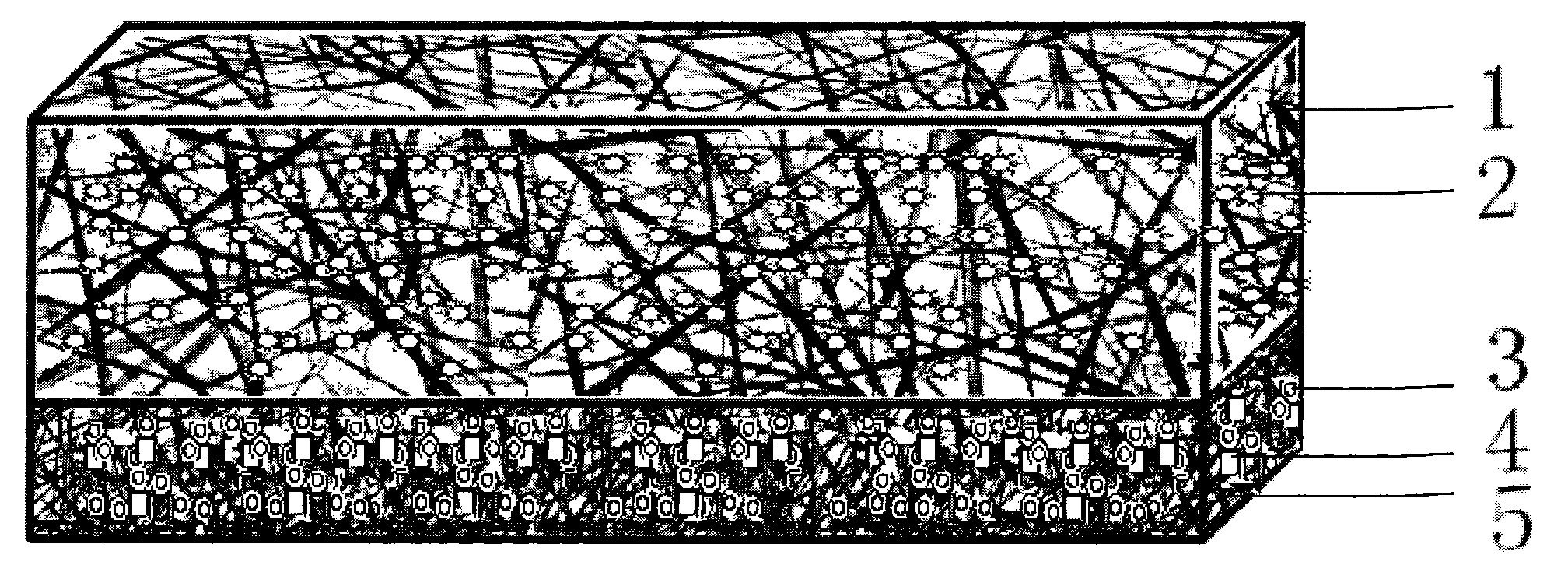

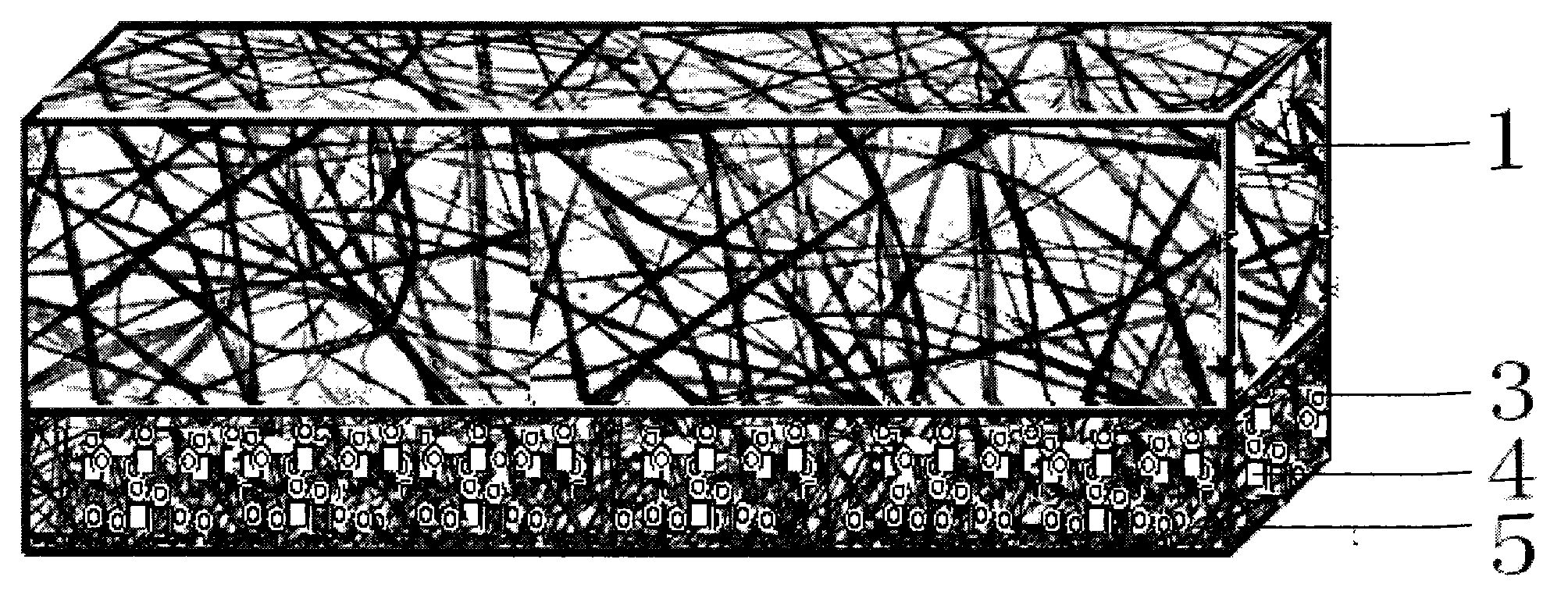

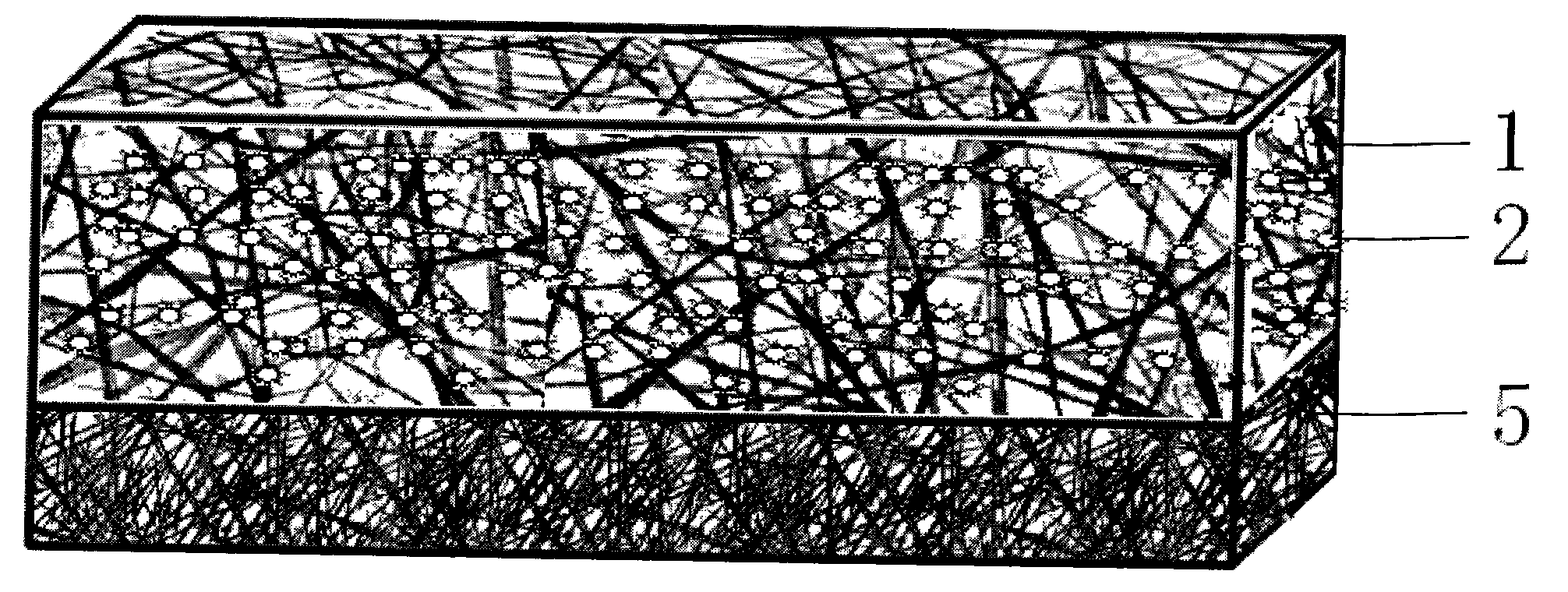

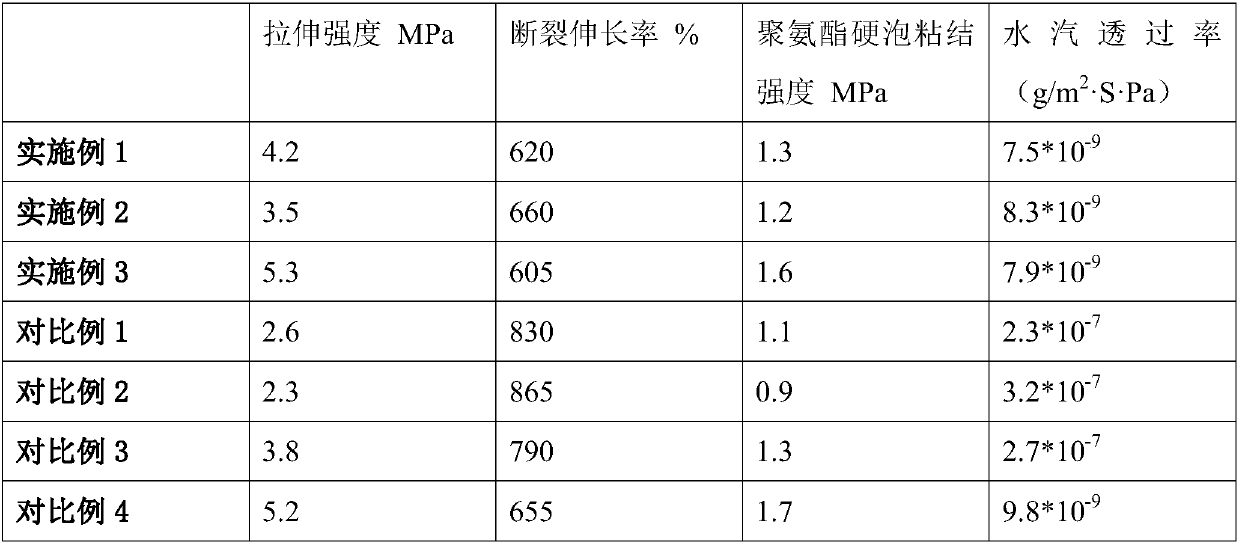

High-vapor-barrier polyurethane coating for refrigeration house and preparation method of high-vapor-barrier polyurethane coating

ActiveCN107903803AEasy to operateShort processPolyurea/polyurethane coatingsVapor barrierAcrylic resin

The invention discloses a high-vapor-barrier polyurethane coating for a refrigeration house and a preparation method of the high-vapor-barrier polyurethane coating. The high-vapor-barrier polyurethanecoating comprises a component A and a component B, the mixing ratio of the weight of the component A to the weight of the component B is 1:2.5, the component A comprises isocyanate and polyether glycol, and the component B comprises a fluoro acrylic resin, polyether glycol, a chain extender, a catalyst, a pigment, a filler, a dispersing agent, a defoamer and an anti-setting agent. The prepared polyurethane coating can be applied to the field of dampproofness and vapor barriering of a polyurethane external thermal insulation system, when the test shows that the thickness of a coating film is more than 1 mm, the moisture-vapor transmission rate is 7.5*10<-9> g / m<2>.S.Pa, the high-vapor-barrier polyurethane coating has an excellent binding force with a polyurethane foam and concrete, and thebonding strength is higher than 1 MPa.

Owner:烟台市顺达聚氨酯有限责任公司

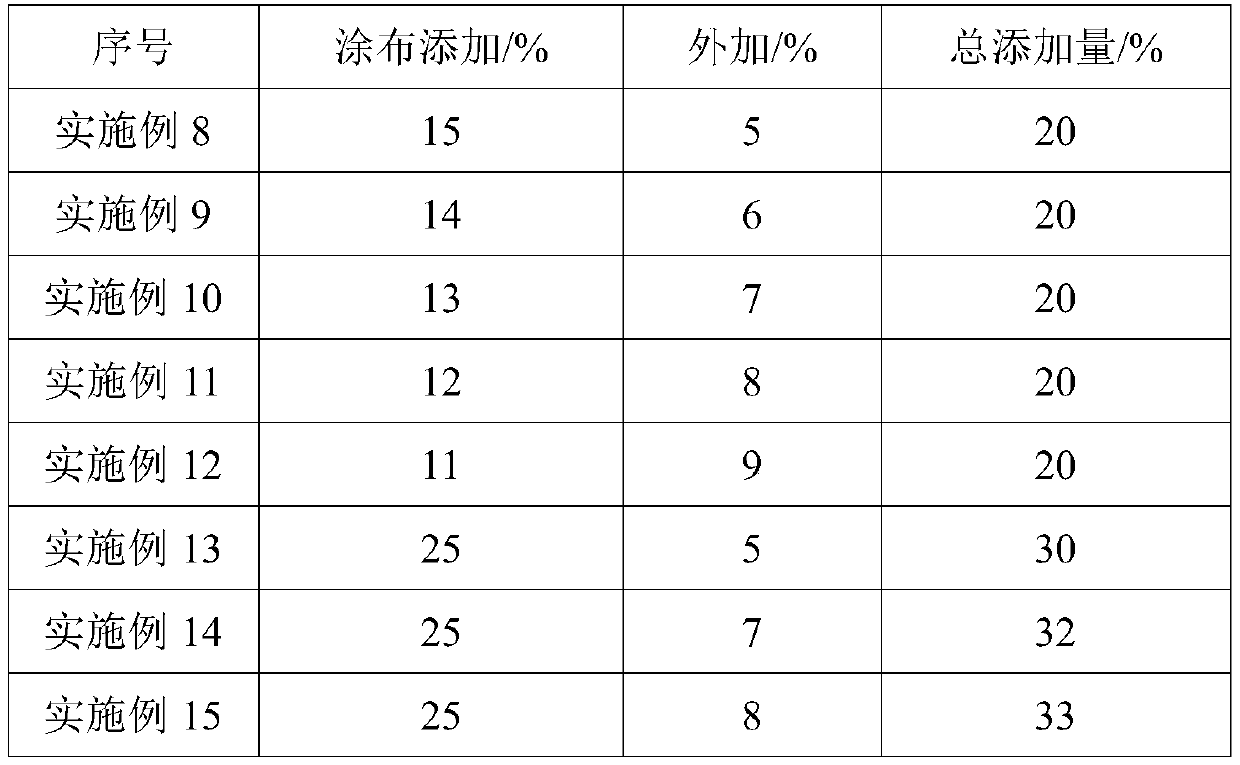

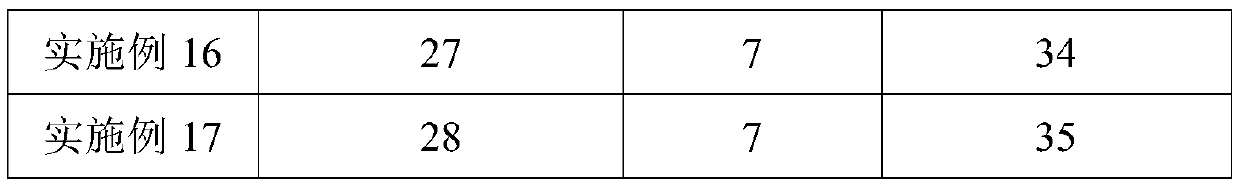

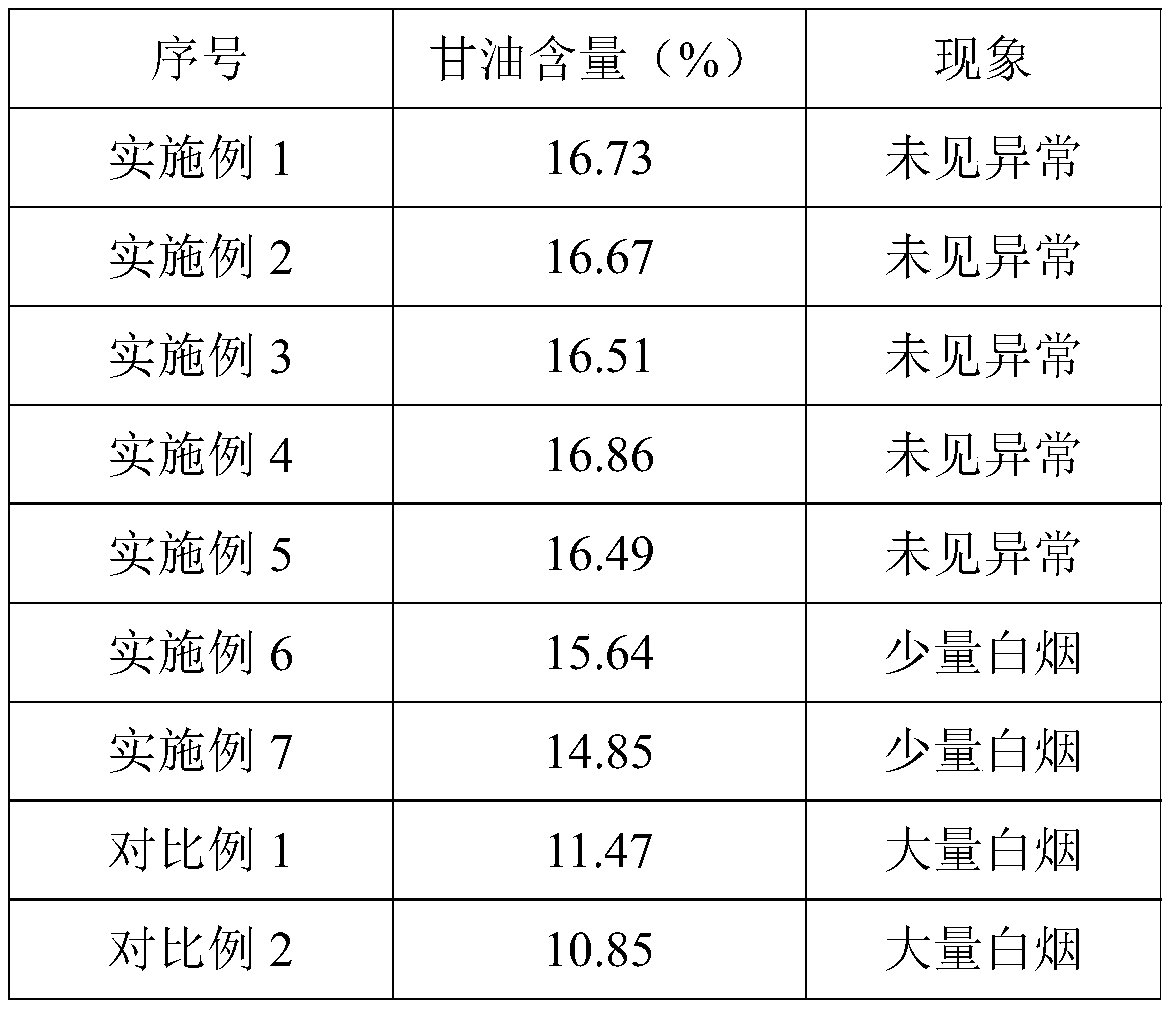

Preparation method of heat-not-burn dry reconstituted tobacco

InactiveCN109875097AImprove physical performanceMeet processing requirementsTobacco preparationGlycerolHeat not burn

The invention discloses a preparation method of heat-not-burn dry reconstituted tobacco. The preparation method comprises the steps of substrate preparation, coating and drying, and further comprisesthe step of drying and calendering treatment. By adjusting the proper calendering pressure and calendering temperature, the physical properties of the heat-not-burn dry reconstituted tobacco are improved, and the processing requirements of the forming process are met; the deformation coefficient of a formed material rod is small, a smoke producing agent is formed by adding coating liquid to be combined with added glycerol, and the drying temperature is adjusted so that it can be guaranteed that the content of glycerol in a product can reach the standard, and processing adaptability indexes such as tensile strength of the heat-not-burn dry reconstituted tobacco can also be met. The smoke producing agent content of the prepared dry reconstituted tobacco can reach 19.53%, the tensile strengthof reconstituted tobacco before calendering is 0.315 KN / m, the tensile elongation of reconstituted tobacco before calendering is 6.05%, the tensile strength of the dry reconstituted tobacco after calendering reaches 0.5337 KN / m, and the tensile elongation of the dry reconstituted tobacco after calendering is 11.13%.

Owner:CHINA TOBACCO GUANGDONG IND +1

Motor rotor web crack welding repair method

ActiveCN103894702AAvoid Welding StressChange stressArc welding apparatusManufacturing stator/rotor bodiesPower flowRepair method

The invention discloses a motor rotor web crack welding repair method and solves the problems that a saw-toothed or crescent electrode is originally used to increase bath width and weld width, thermal stress is large and cracking occurs easily. A linear electrode manipulation method is adopted, a low-current small width welding method is adopted, arc ending is slow, a segment is re-welded to fill an end arc pit, the weld shape is changed, and cracking is avoided accordingly. A welding electrode A507 with higher tensile strength is used, a series of welding processes is taken, and the tensile strength of special equipment and special welds is met. The use of symmetric welding prevents excess welding stress effectively.

Owner:DATANG SHANDONG ELECTRIC POWER OVERHAUL & OPERATION

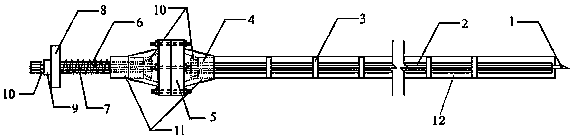

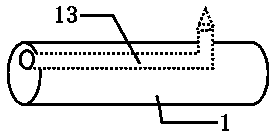

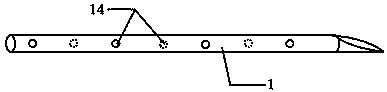

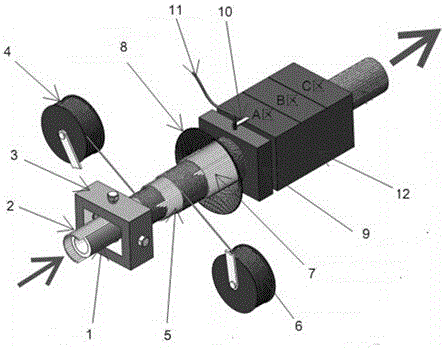

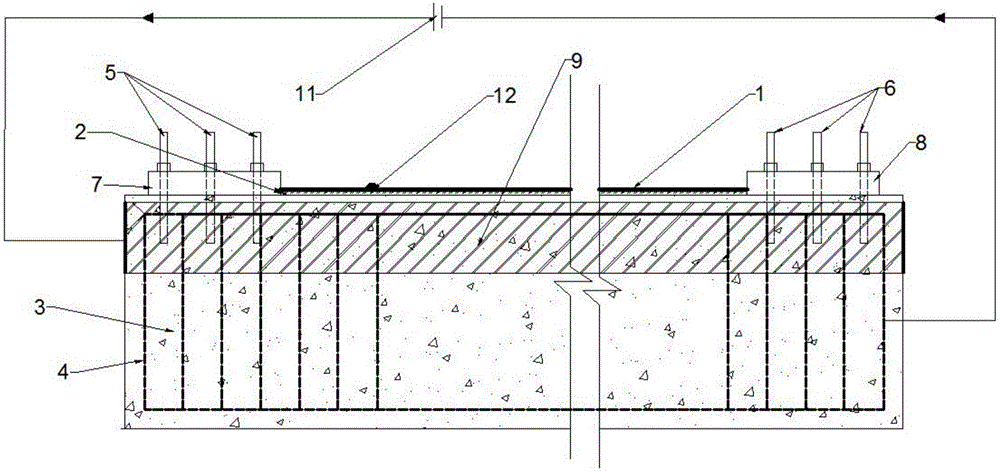

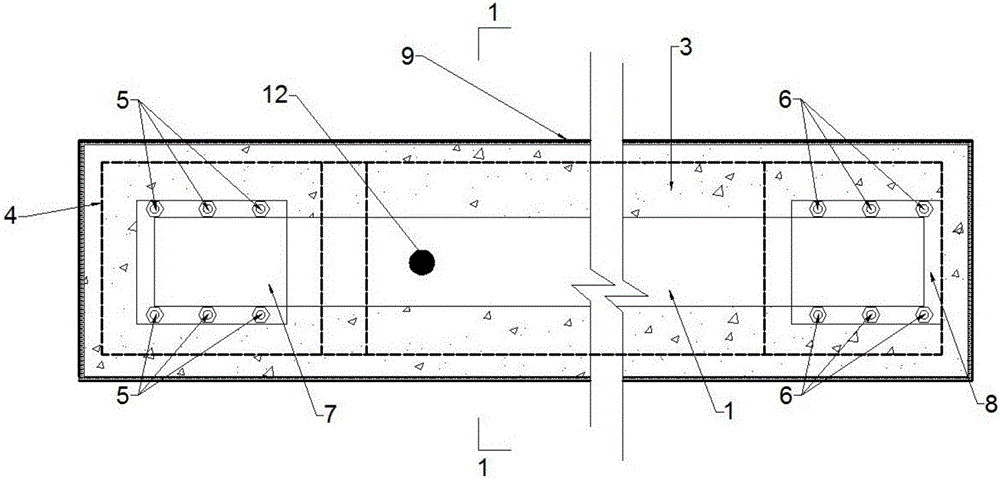

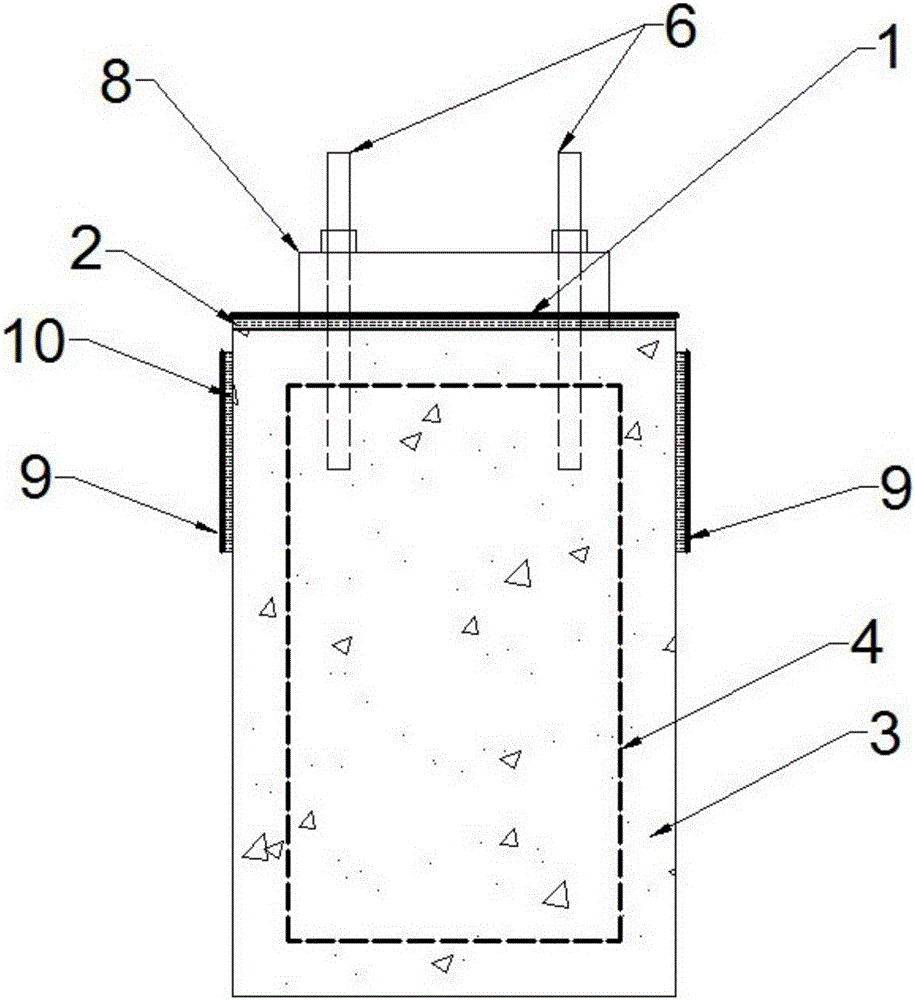

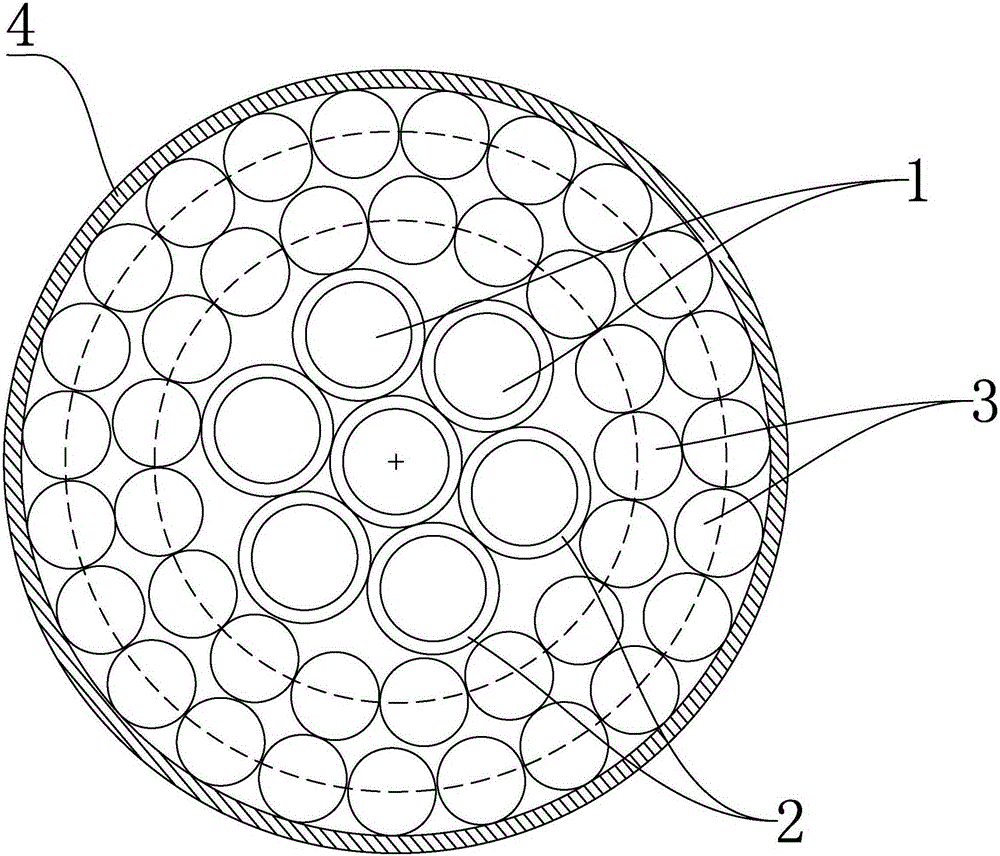

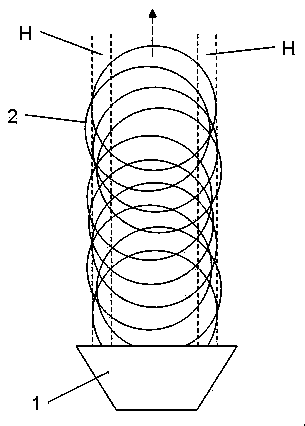

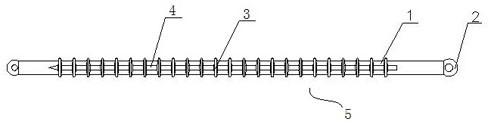

Anchor cable made of continuous basalt fiber composite rib material

The invention relates to an anchor cable made of a continuous basalt fiber composite rib material. The anchor cable comprises a grouting pipe (1), a steel strand (6), a prestress appplying anchor device, a continuous basalt fiber composite rib bundle (2), a flange connection structure and a PVC pipe (12). The anchor cable connects the continuous basalt fiber composite rib bundle with the steel strand together via the flange connection structure and the prestress appplying anchor device. The continuous basalt fiber composite rib bundle is installed in the PVC pipe by a plurality of uniformly distributed positioning centralizers (3). A section of anchoring slurry injection pipe is embedded in the grouting pipe, and anchoring slurry flows into the flange from the pipe to tightly connect the continuous basalt fiber composite rib bundle and the steel strand. The anchor cable made of the continuous basalt fiber composite rib material can replace steel strands, high-strength steel wires and the like to become a main tensile rib material; while tensile strength is met, lower shear strength is provided, and thus, residual anchor cable steel in the soil layer can be easily cut during later construction of surrounding projects.

Owner:EAST CHINA JIAOTONG UNIVERSITY

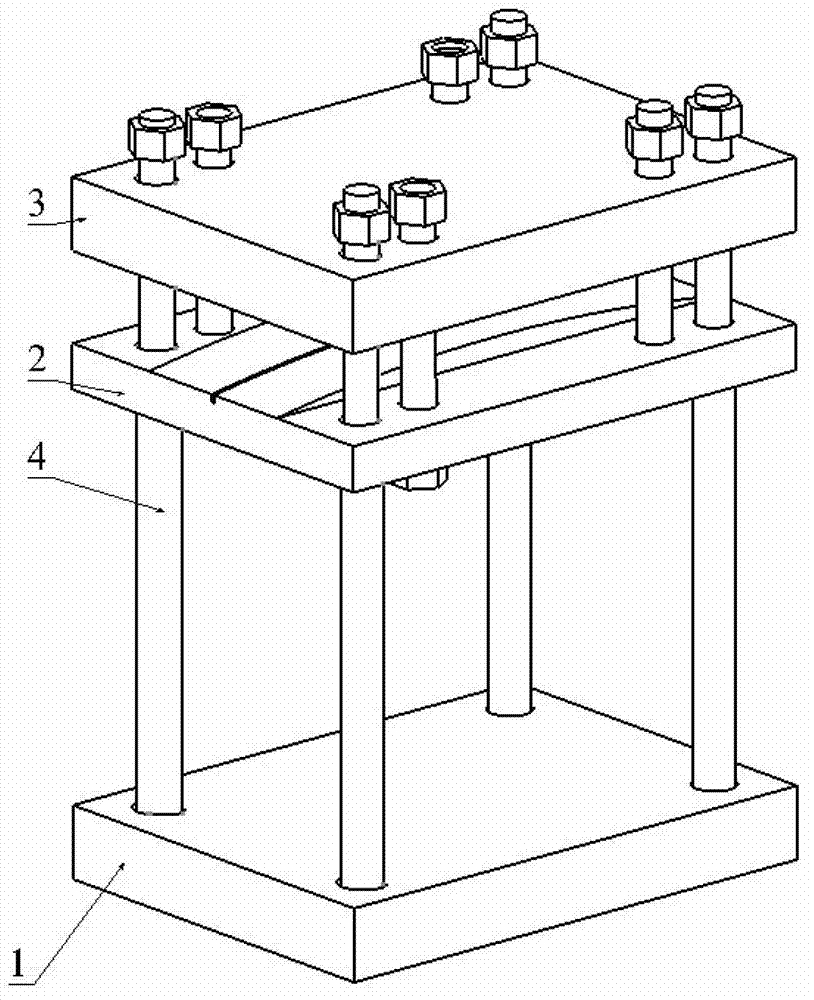

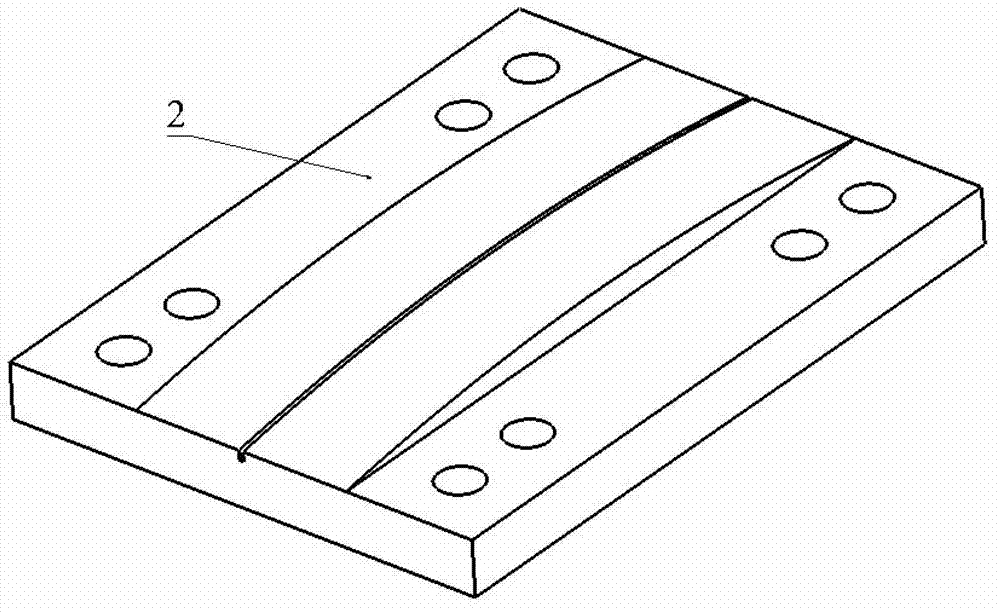

Age forming device

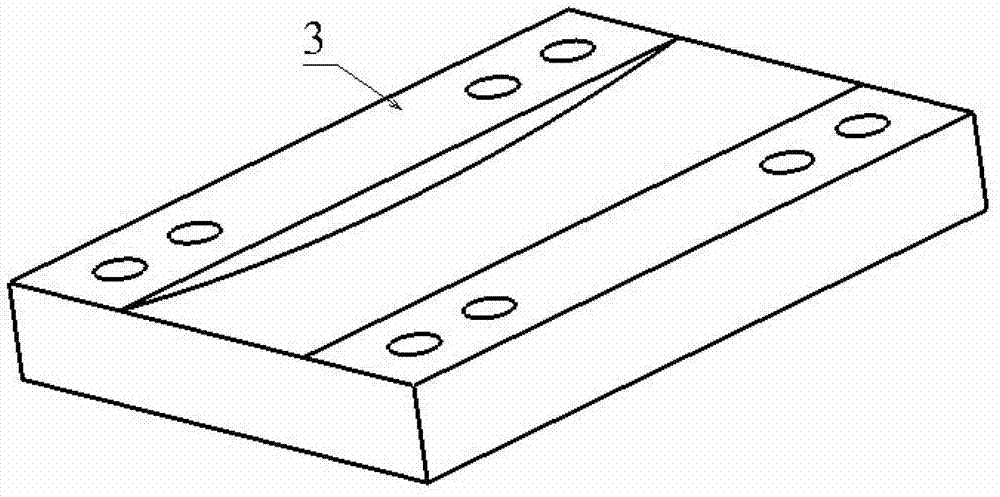

An age forming device comprises a support, a die and a jack. The support comprises a base and four pillars; the die comprises a half male die and a female die; each pillar is respectively fixed on the base; both the male die and the female die are arranged on each pillar in a sleeving manner, and the male die is mounted on a male die mounting surface of each pillar; and the female die is located above the male die. The jack is mounted on the upper surface of the base. The corresponding surfaces of the male die and the female die are both molded surfaces the same as a test piece molded surface; and the molded surface of the male die is matched with the molded surface of the female die. A groove used for placing a T-shaped test piece rib is formed in the center of the length direction of the convex molded surface. The age forming device can be used for bending flat test pieces and T-shaped test pieces of various thickness, provides enough loading force and meets the forming requirement; and since the age forming device has simple structure and small volume, forming requirement of a hot pressing tank can be satisfied and meanwhile the age forming device can be applied to a drying box and a drying heater so as to have better economical efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

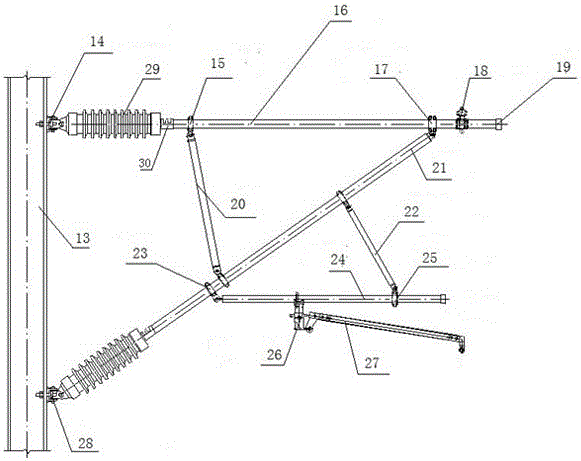

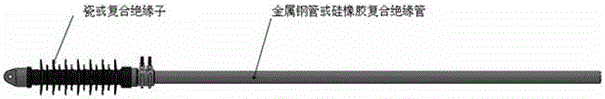

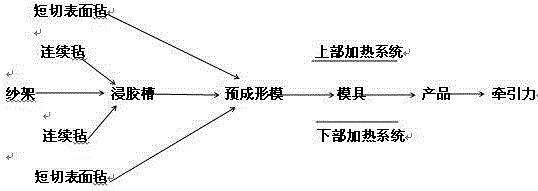

Overall composite insulation cantilever applied to railway overhead contact system as well as manufacturing device and process

ActiveCN106183893AAchieve lightweightIncreased weight reductionTrolley linesSilicon rubberResin adhesive

The invention provides an overall composite insulation cantilever applied to a railway overhead contact system as well as a manufacturing device and process. The composite insulation cantilever comprises a high-strength insulating pipe and cladding insulation silicon rubber, wherein the high-strength insulating pipe is prepared with triple combination processes including continuous fiber pultrusion, continuous fiber winding, continuous fiber weaving for forming mesh tubes and impregnation with resin adhesives, and is coated with the insulation silicon rubber outside. Requirements for mechanical strength such as tensile strength, bending strength, torsional strength, vibration fatigue and the like can be met. The composite insulation cantilever has capacities of corrosion resistance, rust resistance, ultraviolet radiation aging resistance and the like after being coated with the silicon rubber. Besides, the weight of the composite cantilever is only 50% that of a metal cantilever, the lightweight of the overall insulation cantilever is realized, and the economic cost performance is more reasonable due to the increase of the lightweight of the overhead contact system. Particularly, the composite insulation cantilever has outstanding electrical insulation performance, thereby improving the overall insulation level of the overhead contact system. The overall cantilever for the overhead contact system is all insulated, so that the safety and reliability of the overhead contact system are greatly improved.

Owner:艾瑞科电力电子科技(江苏)有限公司

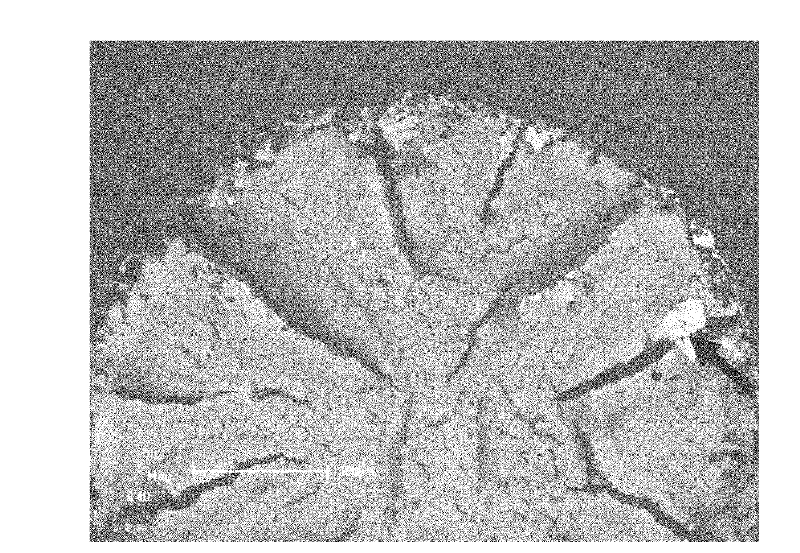

Structure for reinforcing corroded concrete through prestress fiber reinforced composite sheet and reinforcing method

InactiveCN106285036AIncreased durabilityImprove long-term reinforcement effectBuilding repairsBridge erection/assemblyPre stressFiber-reinforced composite

The invention discloses a structure for reinforcing corroded concrete through a prestress fiber reinforced composite sheet and a reinforcing method. The structure comprises a concrete member (3) to be reinforced, the prestress fiber reinforced composite sheet (1), stretching end anchorage device anchor bolts (5), a stretching end anchorage device (7), fixed end anchorage device anchor bolts (6), a fixed end anchorage device (8), non-prestress fiber reinforced composite sheets (9) and an external intermittent constant-current power source (11). The stretching end anchorage device (7) and the fixed end anchorage device (8) clamp the two ends of the prestress fiber reinforced composite sheet (1) correspondingly and fix the prestress fiber reinforced composite sheet (1) to the upper surface of the concrete member (3) to be reinforced. An inner reinforcement cage (4) is arranged in the concrete member (3) to be reinforced. According to the structure and the reinforcing method, the corrosion problem of steel bars and prestress anchorage devices in a concrete structure in the corrosive environment is solved, an auxiliary anode is resistant to corrosion and easy to replace, a reinforcing effect is achieved on the concrete structure, and the repairing cost is remarkably reduced.

Owner:GUANGDONG UNIV OF TECH

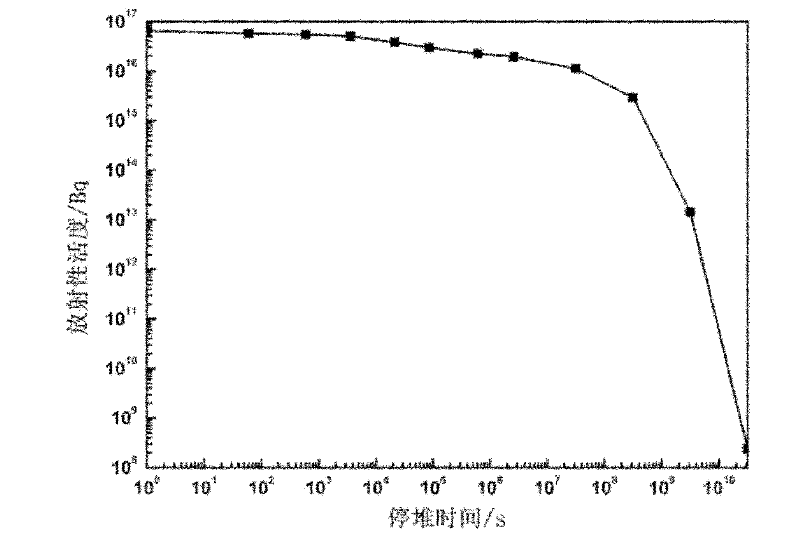

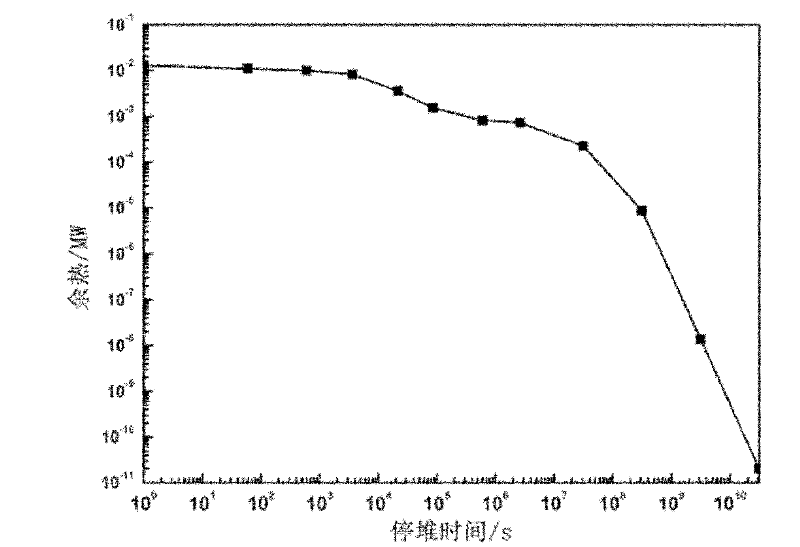

Method for producing nitrogen controlling low activity ferrite martensite steel for fusion reactor

ActiveCN102534393AMeet the tensile strengthTensile strength meets the requirementsLow activityNitrogen

The invention belongs to preparation methods for martensite steel, particularly relates to a preparation method for low activity ferrite / martensite steel for a fusion reactor, which includes the following steps: step 1 ferrum-wolframium (Fe-W) master alloy is prepared, and mass percentage of W in the Fe-W master alloy is smaller than or equal to 20%; step 2 ingredients are added according to preset proportion and comprise chromium, manganese, vanadium, carbon and tantalum, first smelting of alloy is conducted by adopting a vacuum induction smelting method, and the ingredients all adopt high-purity materials; step 3 vacuum self-consuming remelting is conducted; and step 4 hot working is conducted. The method has the advantages that the low activity ferrite / martensite steel prepared through the method meets requirements in aspects of tensile strength, yield strength and elongation coefficient and simultaneously meets a requirement of low activity for the fusion reactor.

Owner:SOUTHWESTERN INST OF PHYSICS

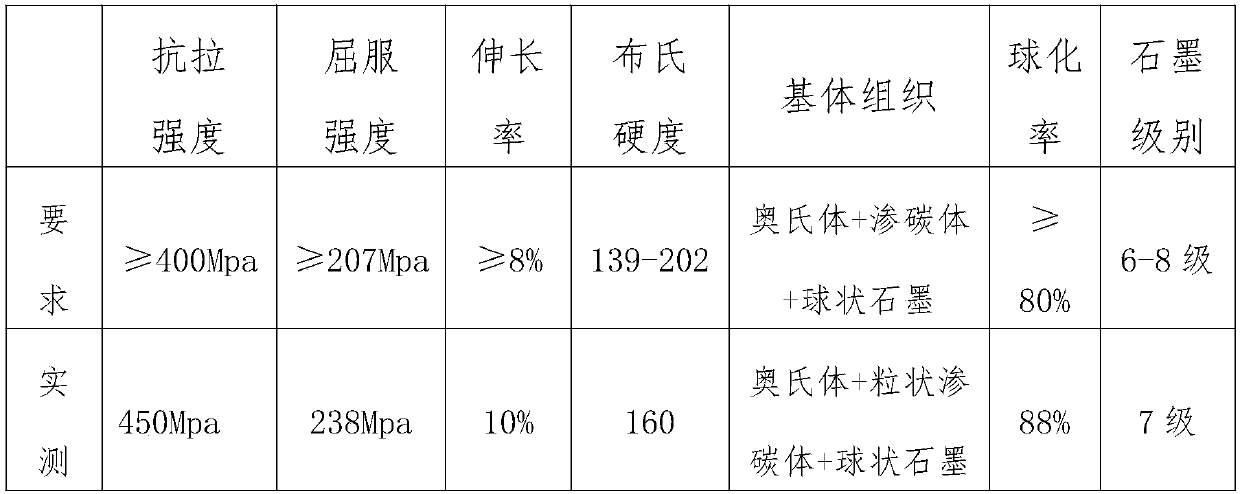

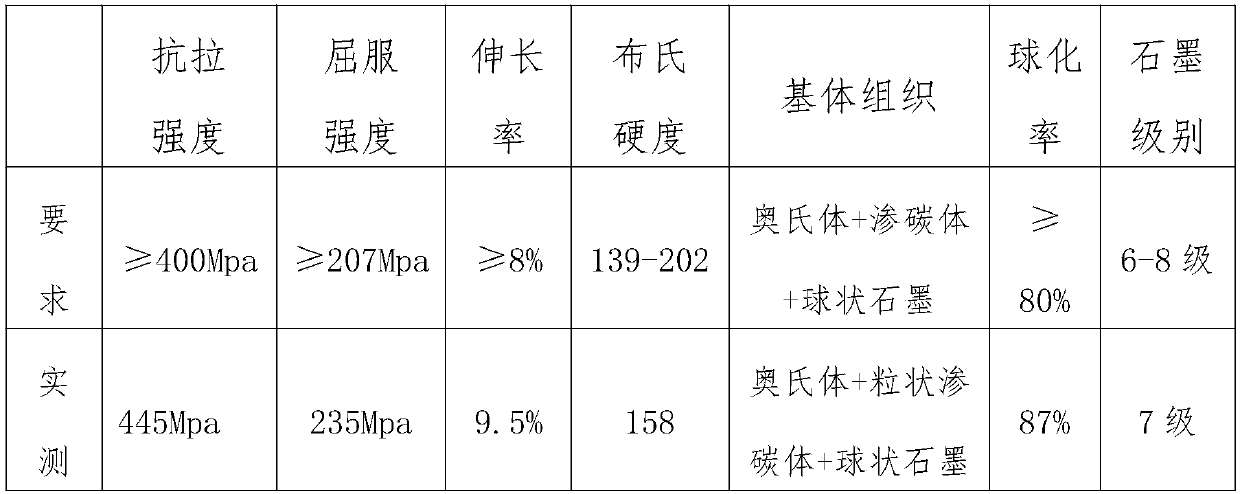

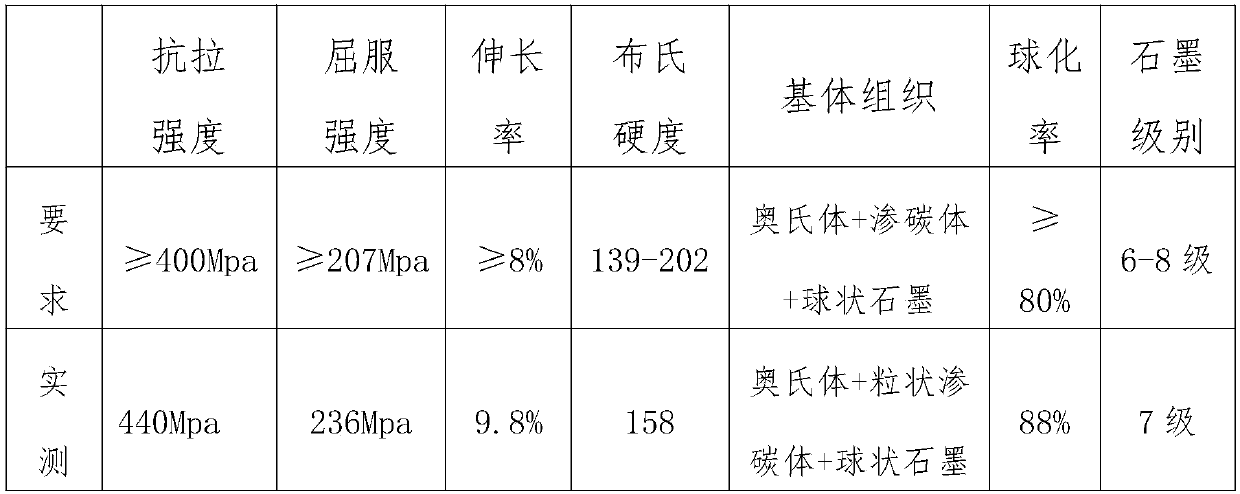

High-nickel austenite nodular cast iron and production technique for same

The invention discloses high-nickel austenite nodular cast iron. The high-nickel austenite nodular cast iron is characterized in that the austenite nodular cast iron comprises the following chemical components in percentage by weight: 2.35-2.7% of carbon, 1.75-2.0% of silicon, 0.7-0.9% of manganese, smaller than or equal to 0.05% of phosphor, 18-19.5% of nickel, 1.75-1.9% of chromium, 0.05-0.065% of magnesium and the balance of iron. The production technique for the high-nickel austenite nodular cast iron comprises the following steps of material preparation, medium-frequency furnace smelting, sampling analysis, molten metal outlet nodulizing, inoculation treatment, solid solution strengthening and ageing treatment. According to the high-nickel austenite nodular cast iron and the production technique, a casting with qualified mechanical performance can be obtained through the reasonable production technique, and the casting is applicable to long-term stable production; a substrate texture is strengthened through thermal treatment modes of solid solution strengthening and ageing treatment, and the tenacity of the substrate texture is enhanced; the grains are refined; segregation is omitted; internal stress is lowered; and therefore the texture and performance are more uniform, and the requirement of corrosion resistance, especially sea water corrosion resistance is met.

Owner:安徽德宝压缩机有限公司

Rare earth microalloyed anti-seismic and hot-rolled H-shaped steel and preparation method of H-shaped steel

The invention discloses a preparation method of a rare earth microalloyed shock-resistant hot-rolled H-shaped steel, which includes: during the smelting process of the converter, controlling the w[S] of the molten iron in the converter to be ≤ 0.009%, increasing the tapping temperature of the converter to about 1600°C, Control the amount of slag in the converter; extend the refining time of the LF furnace during the LF refining process; during the VD vacuum refining process, the argon blowing time of the VD furnace should not be less than 10 minutes; the casting speed range of the continuous casting machine is 0.80m / min~0.9m / min, The superheat degree of the steel type is less than 25°C; in the rolling process, the heating temperature is 1210-1250°C, the starting rolling temperature is ≤1200°C, and the final rolling temperature is 870-890°C to obtain H-shaped steel. The invention also discloses a rare earth micro-alloyed shock-resistant hot-rolled H-shaped steel. The invention adopts the narrow component design, and the obtained H-shaped steel can meet the requirements of the yield strength and tensile strength of the shock-resistant hot-rolled H-shaped steel.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Nitrogen control type low-activity ferritic/martensitic steel for fusion reactor

The invention belongs to martensitic steel and particularly relates to low-activity ferritic / martensitic steel for a fusion reactor. The low-activity ferritic / martensitic steel comprises the following components in percentage by mass: 8.3 to 8.7 percent of chromium, 1.45 to 1.6 percent of tungsten, 0.35 to 0.60 percent of manganese, 0.09 to 0.11 percent of tantalum, 0.24 to 0.28 percent of vanadium, 0.10 to 0.12 percent of carbon, 0.025 to 0.051 percent of nitrogen and the balance of ferrum. The invention has the advantages that the low-activity ferritic / martensitic steel prepared from the components can fully meet the requirement in the aspects of tensile strength, yield strength and elongation, and meets the requirement of the fusion reactor on low activity.

Owner:SOUTHWESTERN INST OF PHYSICS

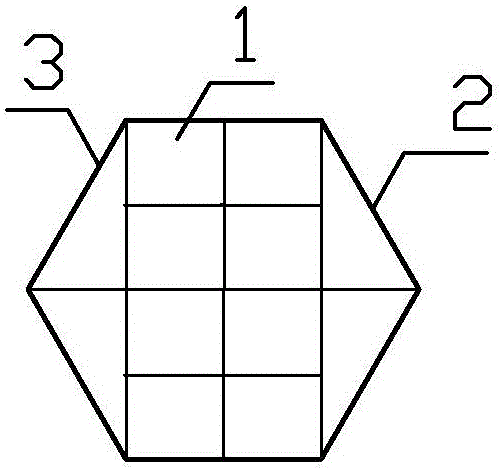

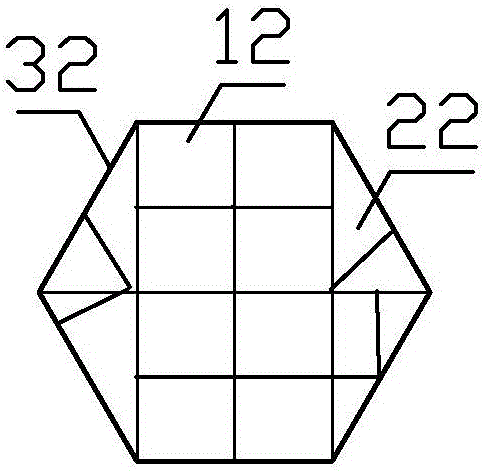

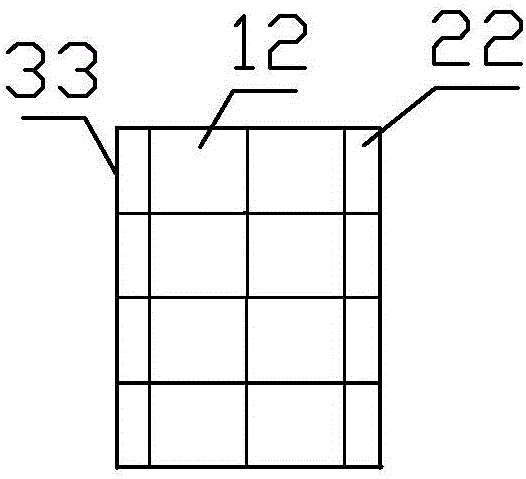

Glass curtain wall single body and integrated honeycombed outwards-convex-type irregular curtain wall structure

ActiveCN105756249AReduce construction difficultyShorten the construction periodWallsHoneycomb likeMechanical engineering

The invention discloses a glass curtain wall single body. The glass curtain wall single body is formed by combining m pieces of standard glass, n pieces of non-standard glass and structural frame lines; the shape of each piece of the standard glass is a rectangle or a square; the structural frame lines are regularly hexagonal, rectangular or trapezoidal; the n pieces of the non-standard glass are positioned in the gaps formed by the peripheries of the m pieces of the standard glass and the structural frame lines; m and n are even numbers between 4 and 12. A honeycombed outwards-convex-type irregular curtain wall is formed by combining p glass curtain wall components; in construction, an integrated honeycombed outwards-convex-type irregular curtain wall structure is formed by connecting every two triangular glass curtain walls with unequal sized planes along equal sides; p is an integer which is greater than 3. The glass curtain wall single body is a plane structural component; the construction process is mature; the glass curtain wall component formed by a plurality of glass curtain wall single bodies is honeycombed and is attractive in appearance; a plurality of adjacent glass curtain wall surface components form the integrated honeycombed outwards-convex-type irregular curtain wall structure; a special-shaped glass curtain wall structure is simplified by using a mature plane glass curtain wall process.

Owner:广西建工第五建筑工程集团有限公司

Non-tempered N80 steel-grade petroleum casing pipe and preparation method thereof

ActiveCN109136786AMake up for the defect of reduced strengthRaise the ratioFurnace typesHeat treatment process controlPetroleumMaterials science

The invention relates to the technical field of metallurgy, and particularly discloses a non-tempered N80 steel-grade petroleum casing pipe and a preparation method thereof. The non-tempered N80 steel-grade petroleum casing pipe comprises the following components in percent by weight: 0.28-0.32% of C, 0.25-0.40% of Si, 1.55-1.70% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.011-0.020% of Nb, 0.05-0.08% of V, 0.007-0.013% of Ti, 0.010-0.040% of Al, 0.013-0.017% of N, smaller than 0.10% of Cr, smaller than or equal to 0.10% of Ni, smaller than or equal to0.10% of Cu, smaller than or equal to 0.020% of As, smaller than or equal to 0.020% of Sn, smaller than or equal to 0.01% of Pb, smaller than or equal to 0.01% of Sb, smaller than or equal to 0.01% ofBi, smaller than or equal to 0.035% of Sn, As, Pb, Sb and Bi and the balance of Fe. Through component adjustment and technology optimization, design requirements on the tensile strength, the yield strength, the elongation and the impact energy of the N80 steel-grade petroleum casing pipe are met; the non-tempered N80 steel-grade petroleum casing pipe is stable in performance; compared with the tempering technology, the preparation method provided by the invention has the advantages as follows: the same quality requirements are met, the production process is shortened, energy is saved, the manufacturing cost is low, and the production efficiency is improved.

Owner:DALIPAL PIPE

Water-soluble quenching medium

The invention provides a water-soluble quenching medium. The water-soluble quenching medium comprises the following components by mass percent: 6-8 percent of sodium hydroxide, 3-4 percent of alum, 1-2 percent of starch, 1-2 percent of potassium chloride, 1-2 percent of a foaming agent, 1-2 percent of a foam booster, and the balance of water. The water-soluble quenching medium is low in cost, good in environment-friendly performance, and convenient to operate. The water-soluble quenching medium is used for quenching hot die steels, and the obtained hot die steels can meet the performance requirements in rigidity, metallographic structure, tensile strength, yield strength, deflection, thermal cracking resistance, wear resistance and the like.

Owner:WUXI YANGGONG MACHINERY MFG

Technique for processing semihard phosphorus deoxidized copper pipes

InactiveCN101078452AGuaranteed performance range requirements for Vickers hardness (HV)Satisfy elongationRigid pipesElectrolysisPhosphor

The invention discloses a processing technology for half-hard phosphorous deoxidized copper pipe, comprising following procedures. Most melting electrolytic copper and iron element with the content of 0.045%-0.05% are added into melting furnace to be melted. Then small residual electrolytic copper is added into the melting furnace to be mixed fully. Phosphor-copper master alloy is added into the melting furnace. Through quick analysis on-the-spot sample it is cast into ingot. Extrusion, rolling pipe, complete hard tension, finishing, complete recrystallization annealing, performance testing are carried out for ingot. Finally pipes are packaged and stored. The merit is that as iron element is added in the melting process, performance range requirement of HV in half-hard phosphorous deoxidized copper pipe can be guaranteed while requirements such as elongation, tensile strength, yield strength and grain size so on of half-hard phosphorous deoxidized copper pipe can be guaranteed. It is provided with stable product performance and high producing feasibility.

Owner:江苏张铜集团有限公司

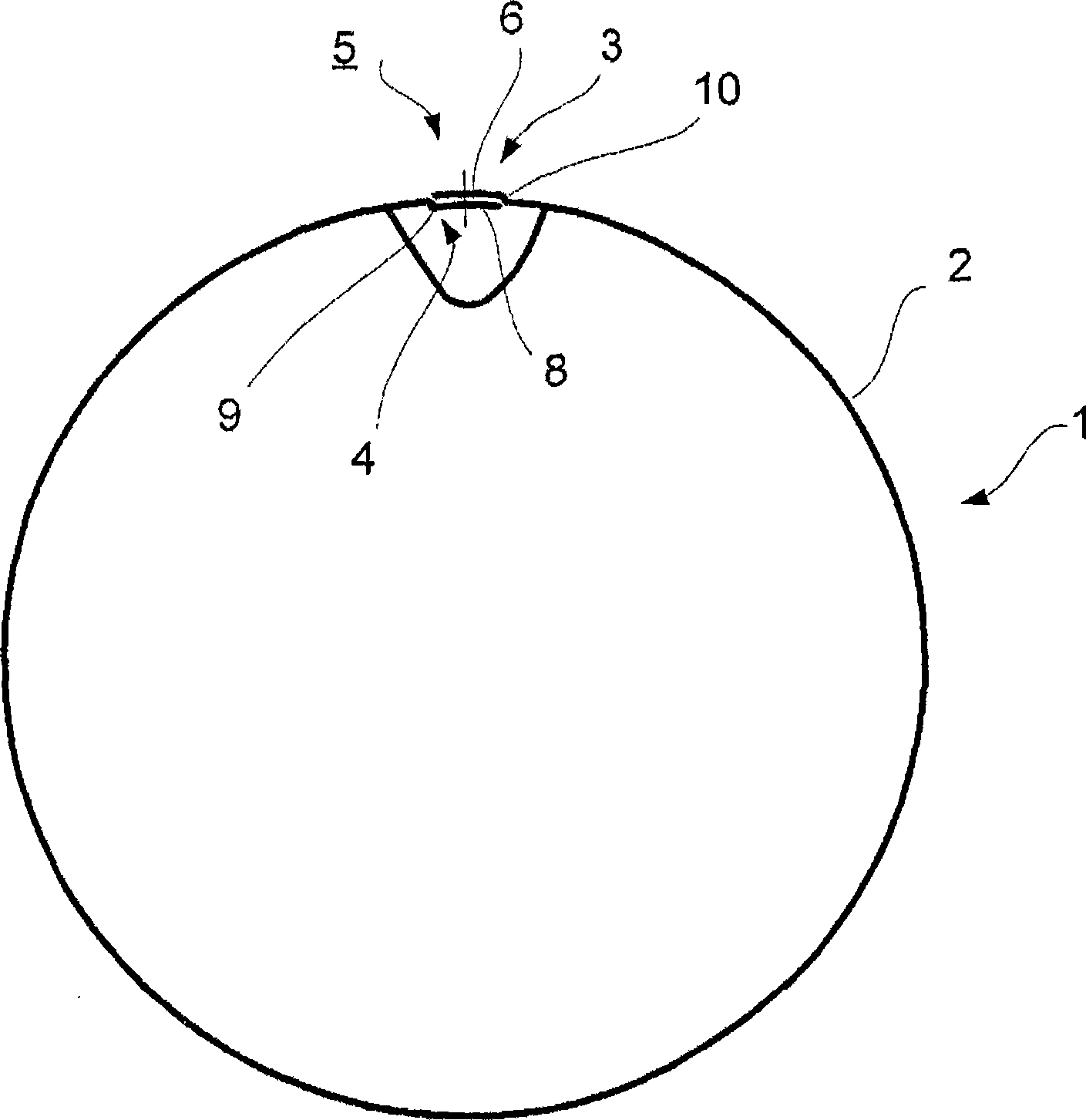

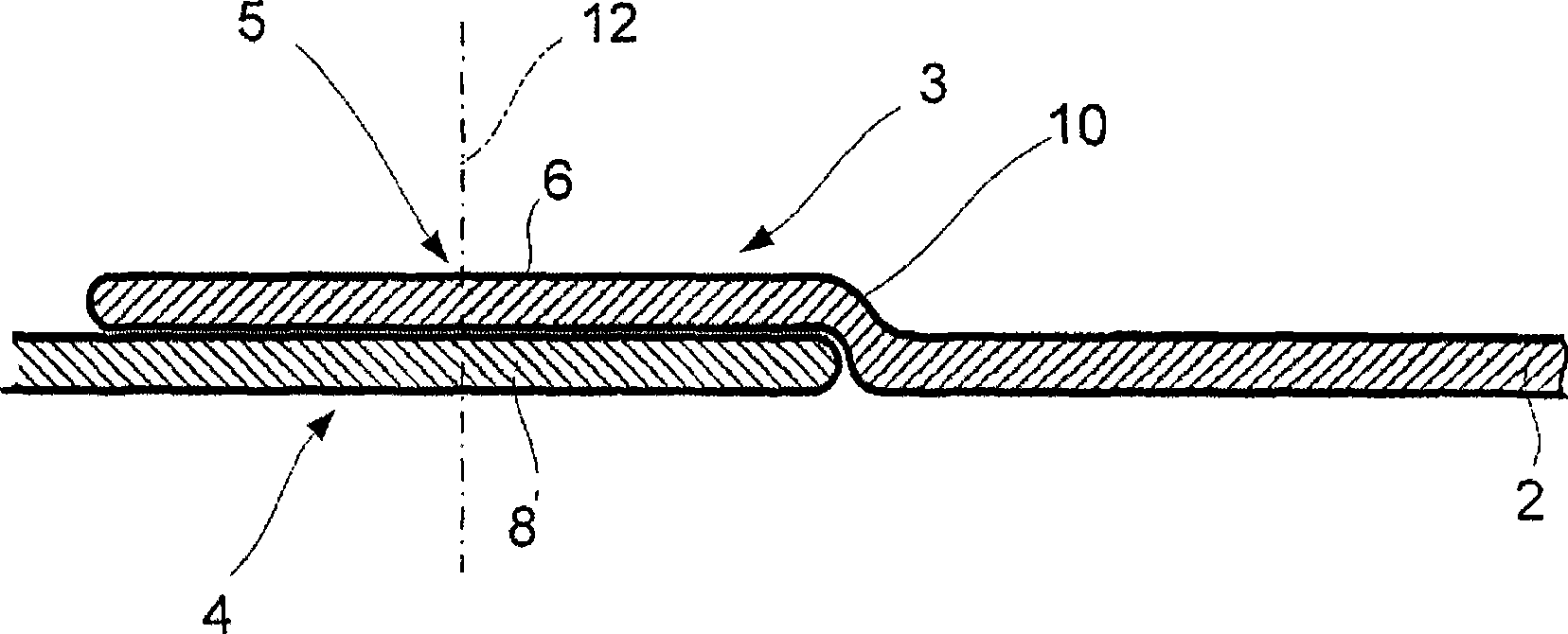

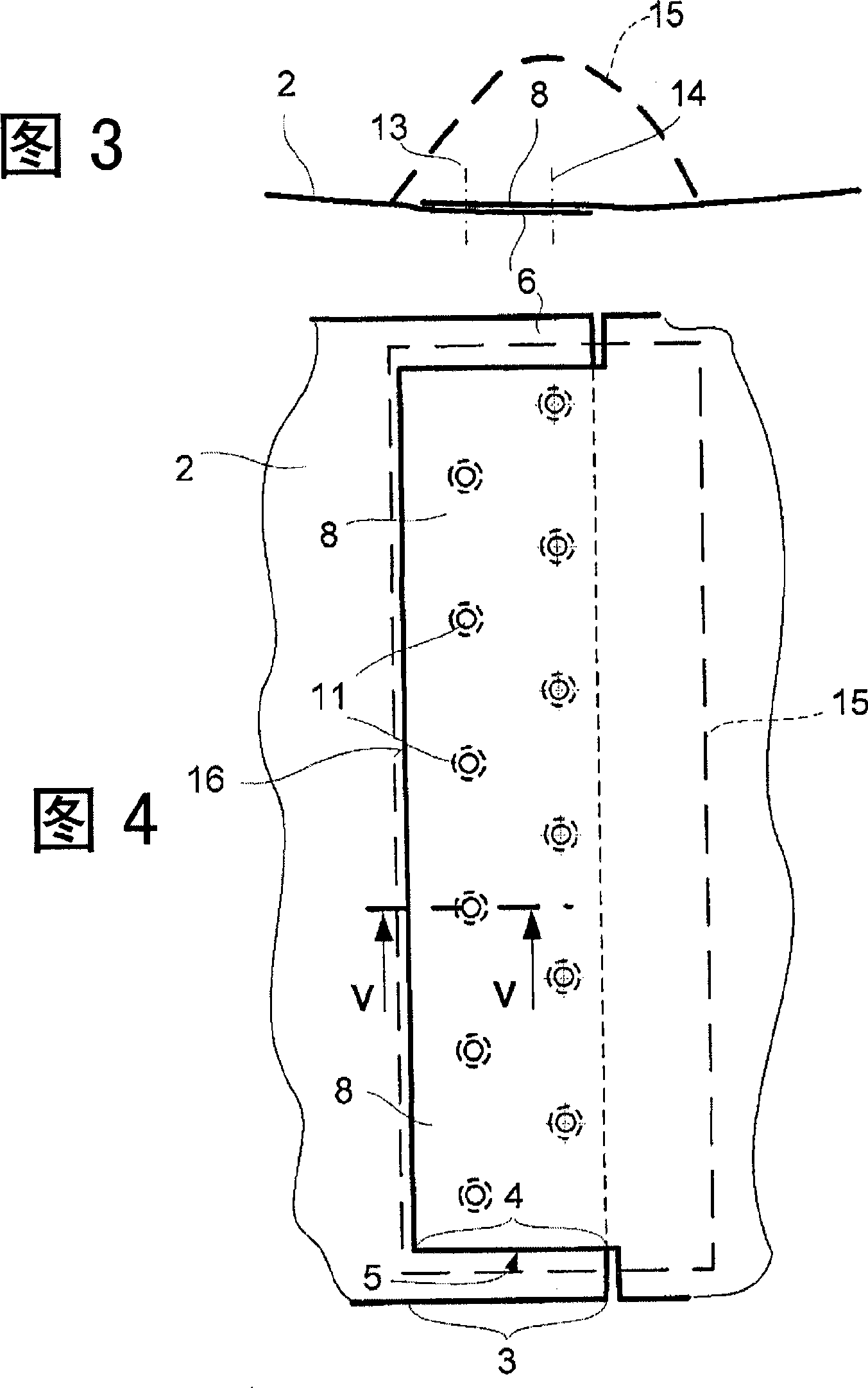

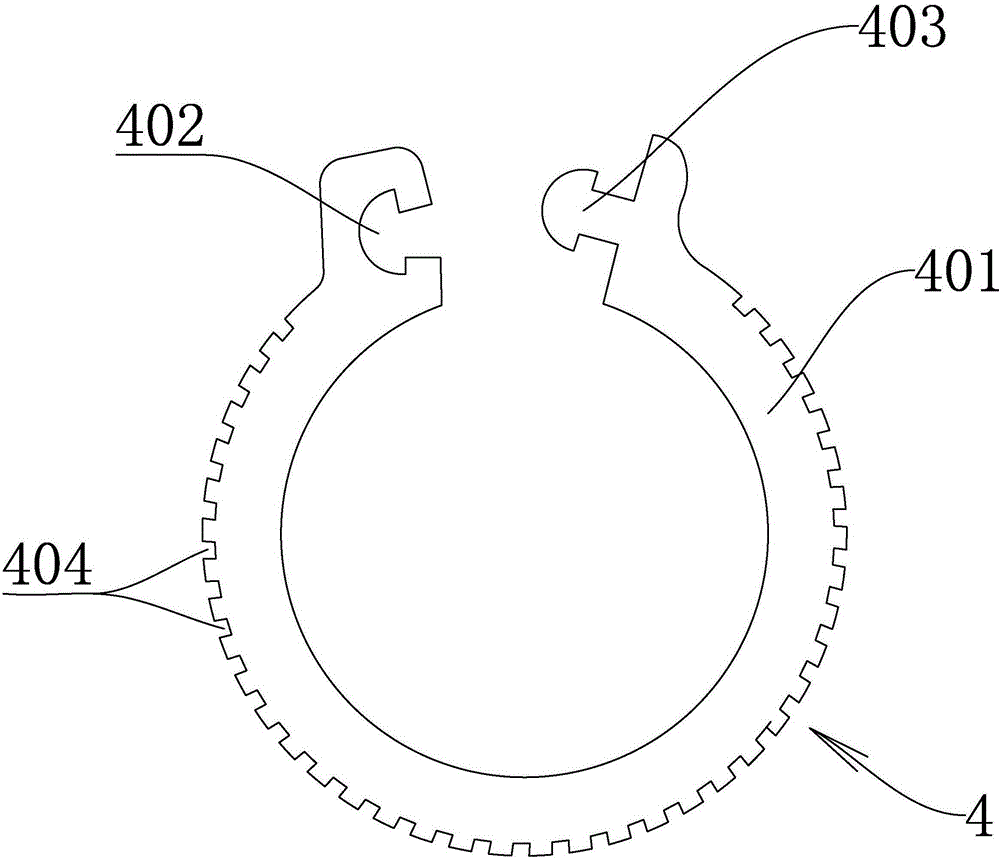

Washing machine laundry drum

ActiveCN101384765AMeet the tensile strengthImprove stabilityOther washing machinesTextiles and paperLaundryMechanical engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Aluminum cable steel reinforced for power grid overhead transmission line

InactiveCN105185457AIncrease ampacityImprove ice resistanceClimate change adaptationInsulated cablesElectrical conductorManganese

The invention relates to an aluminum cable steel reinforced for a power grid overhead transmission line, wherein the aluminum cable steel reinforced is low in cost, large in current-carrying capacity, good in anti-corrosion performance, high in strength, non-magnetic and low in loss. According to the technical scheme of the invention, the aluminum cable steel reinforced for the power grid overhead transmission line comprises a tensile core body and a conductor. The conductor is composed of a plurality of electrical aluminum conductor wires. The aluminum cable steel reinforced is characterized in that the tensile core body is composed of a plurality of non-magnetic stainless steel wires and the steel wires are twisted into strands. The Mn content in the non-magnetic stainless steel of the non-magnetic stainless steel wires is 10-15%, and the Ni content thereof is smaller than 5%. The N content in the non-magnetic stainless steel of the non-magnetic stainless steel wires is 0.3-0.4%. the aluminum cable steel reinforced for the power grid overhead transmission line is applied to the power engineering field.

Owner:张健

Glass fiber reinforced plastic antenna housing and preparation method of glass fiber reinforced plastic antenna housing

InactiveCN106785418AImprove electrical performanceLow dielectric constantRadiating element housingsYarnPolyester

The invention relates to a glass fiber reinforced plastic antenna housing and a preparation method of the glass fiber reinforced plastic antenna housing. The glass fiber reinforced plastic antenna housing is prepared from glass fiber yarns, a glass fiber felt, an outer felt and paste through adopting a pulling-extruding process, wherein the paste is prepared from the following raw materials in parts by weight: 95 to 105 parts of pulled-extruded m-phenylene resin, 3 to 5 parts of glass mciro-bead, 1 to 3 parts of an internal releasing agent, 8 to 12 parts of lightweight active calcium carbonate, 4 to 6 parts of aluminum hydroxide, 1 to 3 parts of an ultraviolet absorbent, 0.4 to 0.6 part of a curing agent AMB, 0.2 to 0.4 part of a curing agent TBPB (Tetrabromophenol Blue) and 3 to 5 parts of polyethylene powder. The glass fiber reinforced plastic antenna housing has the advantages that the outer felt adopts a chopped polyester surface felt and is coordinated with other components, so that the potential of hydrogen and the weather resistance are improved; the service life can reach 200 years or more and is improved by one time or more when being compared with a common antenna housing; meanwhile, the yield of a product can also be improved; meanwhile, all the components have synergistic effect so that the performance of the glass fiber reinforced plastic antenna housing is greatly improved.

Owner:江苏亚信电子科技有限公司

Plastic bipolar plate and preparation method thereof

InactiveCN108134105AMeet the tensile strengthMeet bending strengthFinal product manufactureCollectors/separatorsCompression moldingMixed materials

The invention relates to the field of the preparation of bipolar plates for power supplies, and particularly relates to a plastic bipolar plate and a preparation method thereof. The bipolar plate is prepared from three parts of a conducting material, a resin material and a functional material. The preparation method comprises the following main steps of forcibly mixing the conducting material, theresin material and the functional material, which are in a certain proportion, in a high speed ball mill, and carrying out compression molding on the uniformly mixed materials in a mold at a high temperature, so as to obtain the novel plastic bipolar plate. The plastic bipolar plate can be used for resolving the contradiction between the conductivity and the mechanical performance of a conventional plastic bipolar plate; while the strength and the corrosion resistance of the bipolar plate are improved, the conductivity of the bipolar plate is further ameliorated; further, the bipolar plate prepared by the method has the characteristics of being simple in process and low in raw-material and equipment cost, and the large-scale industrialized production is easily realized.

Owner:SHENZHEN JINGTE INTELLIGENT MFG TECH CO LTD

Production process of high-temperature structural ceramic/metal composite material tube for aluminum alloy die casting machine

ActiveCN113649772AExtended service lifeSimple production processFurnace typesHeat treatment furnacesDie castingCeramic metal

The invention relates to a production process of a high-temperature structural ceramic / metal composite material tube for an aluminum alloy die casting machine. The composite material tube comprises a ceramic lining, a metal jacket and an end cover. The production process of the composite material tube comprises the steps of machining the ceramic lining, machining the metal jacket and the end cover, and assembling and matching the ceramic lining, the metal jacket and the end cover. A ceramic lining machining process comprises the steps of raw material preparation, grinding and pulping, workpiece forming, green body drying, high-temperature firing and inner and outer circle machining. A metal jacket and end cover machining process comprises the steps of metal tube and end cover cutting and blanking, metal tube and end cover inner and outer circle rough machining, heat treatment and metal tube and end cover inner and outer circle finish machining. A ceramic lining, metal jacket and end cover assembling and matching process includes the steps of measurement inspection, combined assembly and thermal adaptation testing. A metal tube and a ceramic tube are compounded, so that the alloy melt corrosion resistance and the wear resistance of the material tube are greatly improved, and the service life is long; the composite material tube is low in heat conductivity coefficient, and energy consumption is reduced; and strength and toughness are good, the manufacturing cost is low, and production period is short.

Owner:江苏三条鱼新材料科技有限公司 +1

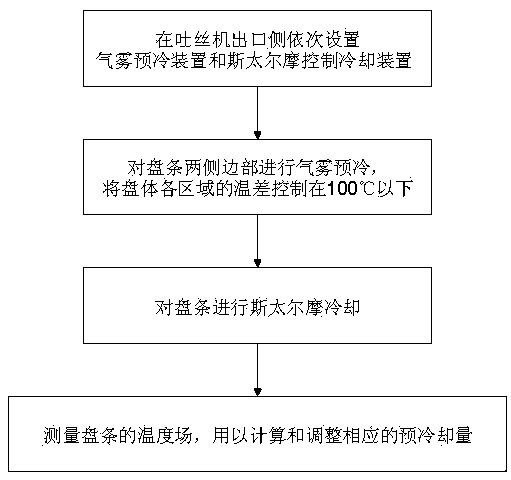

System and method for cooling high-carbon steel wire rod after rolling

ActiveCN102451841BReduce pollutionMeet the tensile strengthTemperature control deviceWork treatment devicesWire rodMetallurgy

The invention discloses a system for cooling a high-carbon steel wire rod after rolling. The device comprises a Stelmor controlled cooling device and a gas fog pre-heating device, wherein the gas fog pre-heating device is arranged on a roller path between a laying head and the Stelmor controlled cooling device. The invention further discloses a method for cooling a high-carbon steel wire rod after rolling. The method comprises the following steps of: controlling the temperature difference among different areas of a rod body to be below 100 DEG C by using the high thermal conductivity of convection vapor during gas fog pre-cooling; and entering the Stelmor controlled cooling device at the temperature of 650-750 DEG C for performing Stelmor cooling. Compared with a wire rod subjected to salt treatment, the finally obtained wire rod in the invention has the advantages that: the mechanical performance and microscopic structure are very close, the tensile strength of cold drawing can be met, and environmental pollution is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

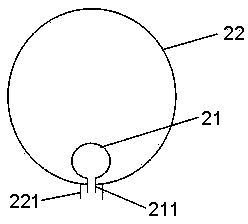

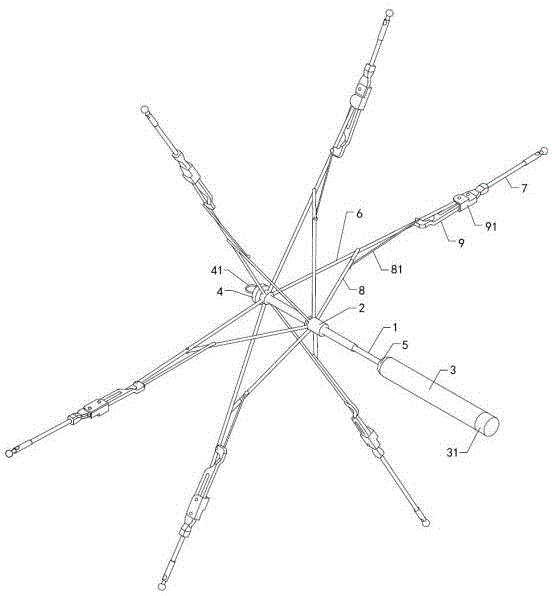

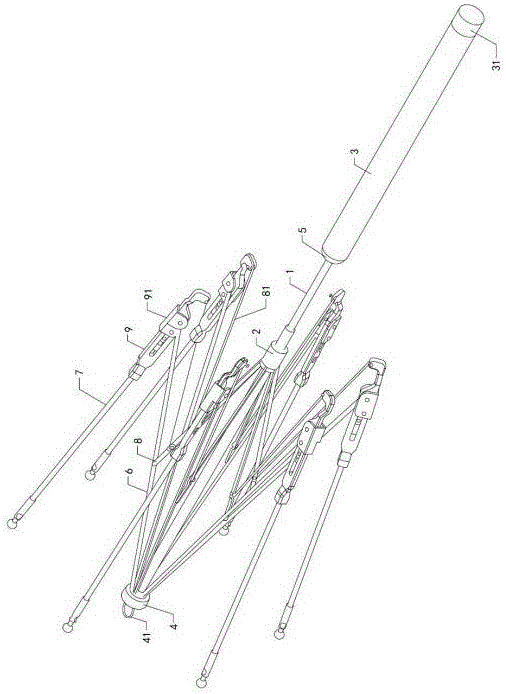

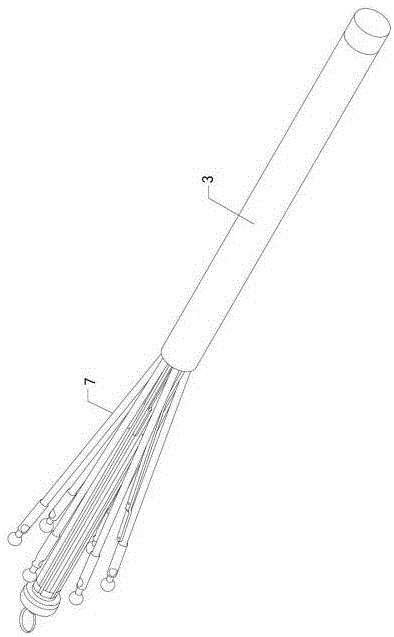

Improved umbrella stand structure

InactiveCN106418947AAvoid getting wetEasy to holdWalking sticksUmbrellasEngineeringBiomedical engineering

The invention provides an improved umbrella stand structure, which comprises an umbrella handle and an umbrella barrel. A fixed nest, a sliding nest and a handle sleeve are arranged at the umbrella handle. The bottom of the umbrella handle is arranged in the inner part of the umbrella barrel through the top of the handle sleeve. The umbrella framework comprises a main bone, a tail bone and a fulcrum, wherein the main bone and the tail bone are fixedly connected with a connector. The two ends of the supporting bone respectively have rotary connection with the main bone and the sliding nest. The supporting bone is connected with a pull handle near the main bone. When the improved umbrella stand structure is utilized, the tail bone can be folded up conveniently through the connector. Furthermore, the sliding nest slides downward along the umbrella handle, and the umbrella handle is integrally inserted into the umbrella barrel. The additional umbrella barrel can contain rainwater and avoid the wet of clothes. Meanwhile, the additional umbrella barrel plays the role of increasing the height and strength of the umbrella handle. The improved umbrella stand structure has the advantages of being simple in structure, convenient in operation, intimate in design and wide in market prospects.

Owner:梁家耀

Method for preparing agricultural mulch film from sound-absorbing cotton leftover scraps used in vehicles

InactiveCN109370030AHighly Hydrophobic SubstancesIncrease filling volumePlant protective coveringsLow-density polyethyleneCerium

The invention belongs to the technical field of preparation of agricultural mulch films, in particular to a method for preparing agricultural mulch film for sound-absorbing cotton leftover scraps usedin vehicles. The preparation method comprises the steps: a step of pulverization of sound-absorbing cotton leftover scraps used in vehicles, a melting and granulating treatment step, a mixed treatment step of low-density polyethylene, polypropylene and liquid paraffin and a step of granulating the all materials through a screw extruder and blowing the materials into a mulch film with the thickness of 0.004mm to 0.1mm through a film blowing machine. Accordign to the degradable agriculture mulch film disclosed by the invention, the sound-absorbing cotton leftover scraps used in vehicles are used as one of the raw materials, and materials such as modified tapioca starch, a photosensitizer cerium stearate powder, a hindered phenolic antioxidant and a thermal degradation enhancer are added, sothat the degradable capability of the mulch film is improved, the degradation time of the mulch film is effectively controlled, the degradation effect is achieved, the production cost is reduced, andwhite pollution is reduced.

Owner:袁志平

Non-quenched and tempered n80 steel grade oil casing and preparation method thereof

ActiveCN109136786BMeet the tensile strengthImprove performanceFurnace typesHeat treatment process controlPetroleumMaterials science

The invention relates to the technical field of metallurgy, and particularly discloses a non-tempered N80 steel-grade petroleum casing pipe and a preparation method thereof. The non-tempered N80 steel-grade petroleum casing pipe comprises the following components in percent by weight: 0.28-0.32% of C, 0.25-0.40% of Si, 1.55-1.70% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.011-0.020% of Nb, 0.05-0.08% of V, 0.007-0.013% of Ti, 0.010-0.040% of Al, 0.013-0.017% of N, smaller than 0.10% of Cr, smaller than or equal to 0.10% of Ni, smaller than or equal to0.10% of Cu, smaller than or equal to 0.020% of As, smaller than or equal to 0.020% of Sn, smaller than or equal to 0.01% of Pb, smaller than or equal to 0.01% of Sb, smaller than or equal to 0.01% ofBi, smaller than or equal to 0.035% of Sn, As, Pb, Sb and Bi and the balance of Fe. Through component adjustment and technology optimization, design requirements on the tensile strength, the yield strength, the elongation and the impact energy of the N80 steel-grade petroleum casing pipe are met; the non-tempered N80 steel-grade petroleum casing pipe is stable in performance; compared with the tempering technology, the preparation method provided by the invention has the advantages as follows: the same quality requirements are met, the production process is shortened, energy is saved, the manufacturing cost is low, and the production efficiency is improved.

Owner:DALIPAL PIPE

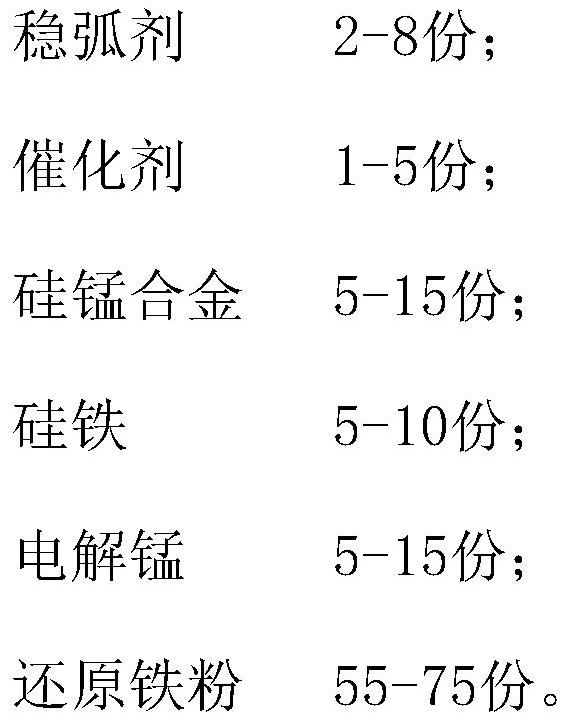

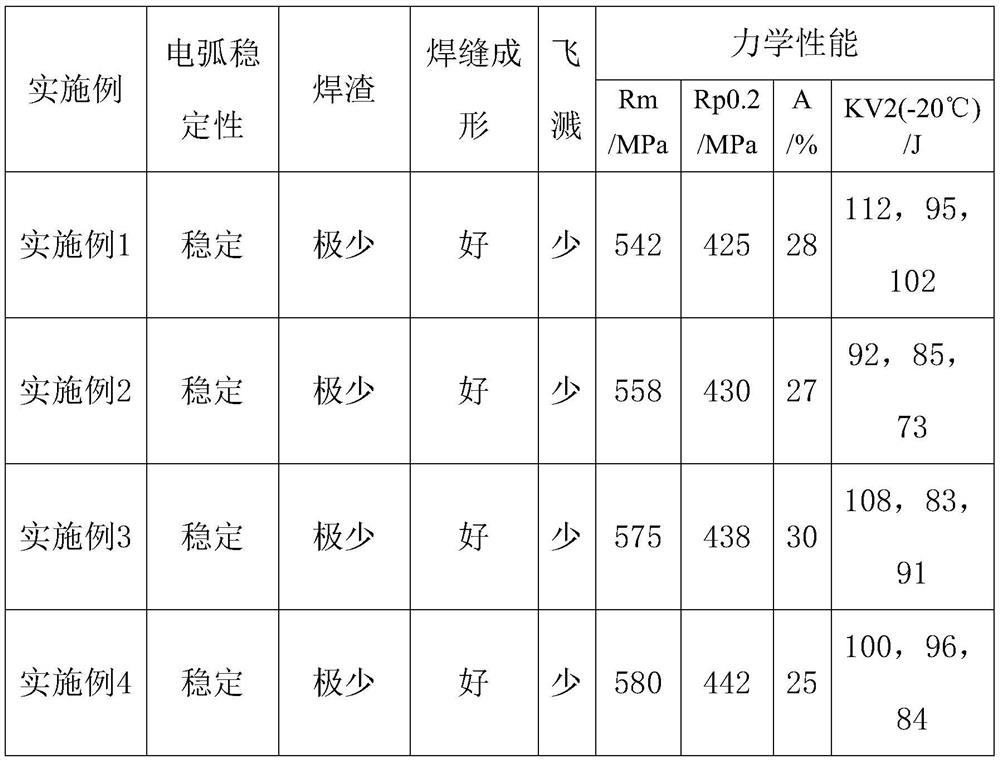

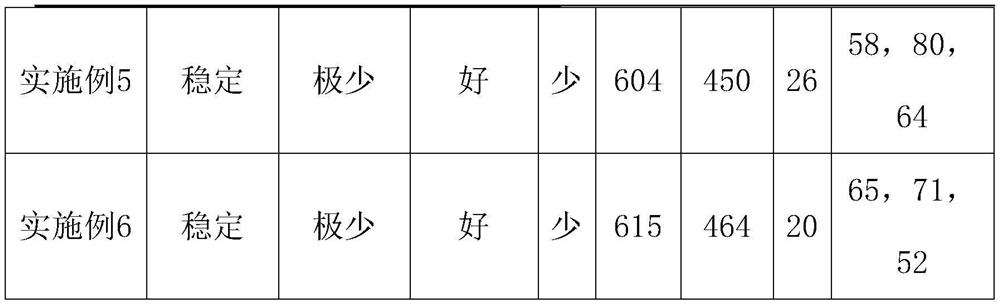

500MPa flux-cored wire and preparation method thereof

InactiveCN111992924AImprove low temperature impact toughnessAvoid heat cracksWelding/cutting media/materialsSoldering mediaSlag (welding)Ptru catalyst

The invention discloses a 500MPa flux-cored wire and a preparation method thereof. The 500MPa flux-cored wire is prepared from a low-carbon steel strip and flux powder. The flux powder is wrapped in the low-carbon steel strip. The flux powder comprises, by mass, 2-8 parts of arc stabilizer, 1-5 parts of catalyst, 5-15 parts of silicon-manganese alloy, 5-10 parts of ferrosilicon, 5-15 parts of electrolytic manganese and 55-75 parts of reduced iron powder. The 500MPa flux-cored wire is low in manufacturing cost. The welded surface has no molten slag. Slag removal is not needed during multilayerand multi-pass welding. The welding efficiency is greatly improved. The 500MPa flux-cored wire is environment-friendly in the welding process, small in welding spatter, small in smoke dust, high in cladding efficiency and capable of being popularized to robot welding and has wide development prospects.

Owner:SHANDONG ENERGY HEAVY EQUIPMENT GROUP HENGTU TECH CO LTD +1

Tripping connecting rod and production process thereof

InactiveCN112713040ALong-term effective operationAvoid breaking accidentsContact driving mechanismsAir-break switch detailsStructural engineeringMechanical engineering

The invention relates to a tripping connecting rod and a production process thereof. The tripping connecting rod comprises a core rod body with hinge structures at two ends and an insulating cladding wrapping the outer side of the core rod body. The insulating cladding is fixedly connected with the core rod body. Compared with the prior art that the tripping connecting rod is integrally processed and formed by one material, the tripping connecting rod is divided into two parts, namely the core rod body and the insulating cladding wrapping the outer side of the core rod body, so that the core rod body can be made of a material with higher tensile strength, and the tripping connecting rod can meet the standard of the tensile strength; in addition, the insulating cladding wrapping outside enables the tripping connecting rod to integrally meet the insulating requirement, so that long-term effective operation of the tripping connecting rod is guaranteed, and breakage accidents are avoided.

Owner:HENAN SENYUAN ELECTRIC CO LTD

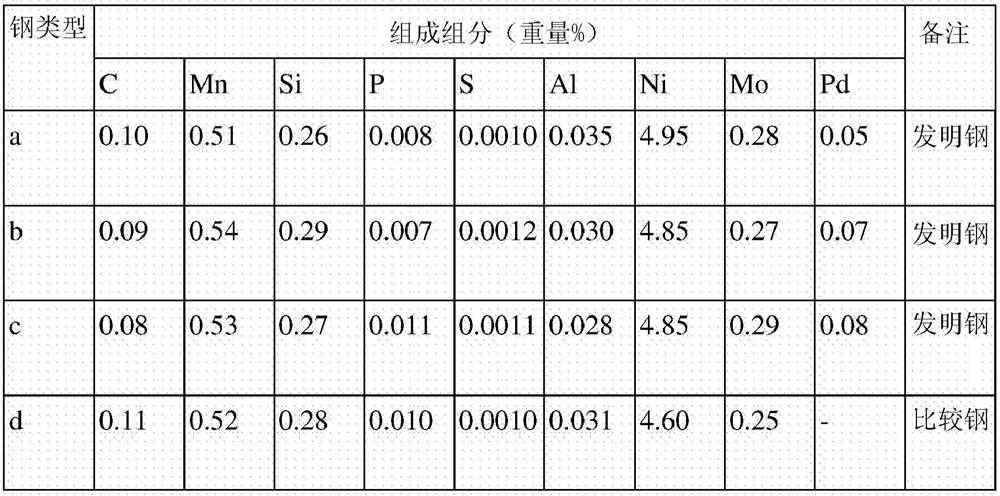

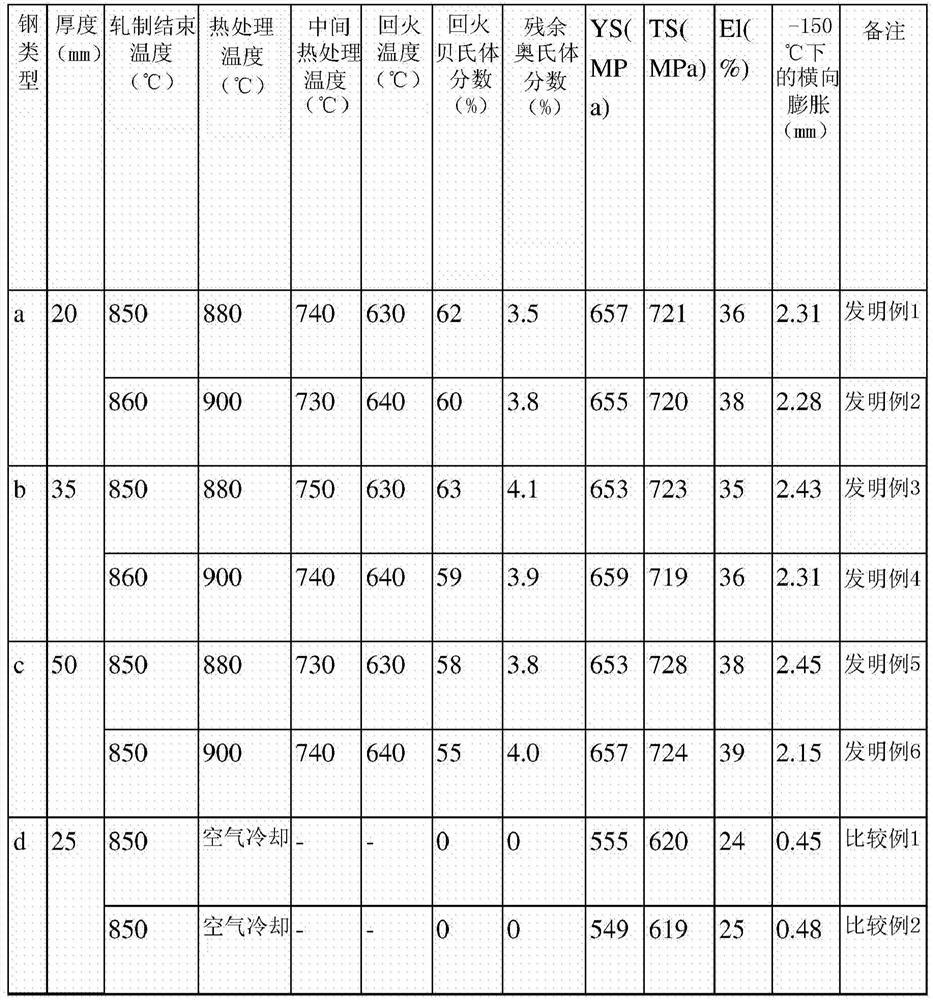

Steel sheet for pressure vessel having excellent low-temperature lateral expansion, and method for manufacturing same

ActiveCN114341382AHigh strengthImprove featuresFurnace typesQuenching agentsMaterials sciencePressure vessel

Owner:POHANG IRON & STEEL CO LTD

A kind of manufacturing method of waterproof and antifreeze kraft paper

ActiveCN110331622BSolve the technical problem of not being waterproof or freezingMeet packaging requirementsFlexible coversWrappersCold chainEconomic benefits

Owner:YUEYANG FOREST & PAPER CO LTD

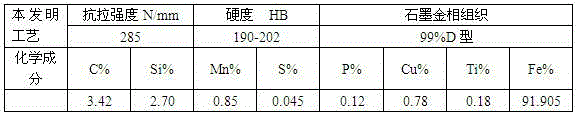

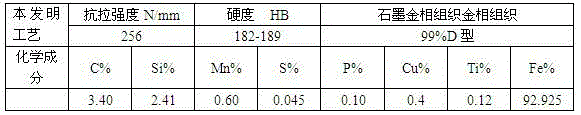

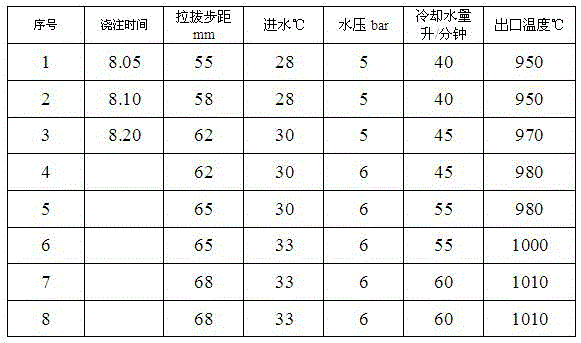

Eutectic graphite gray cast iron continuous casting profile and manufacturing method thereof

The invention discloses a cast iron continuous-cast section material and a manufacturing method thereof, in particular relates to an eutectic graphite grey cast iron continuous-cast section material and the manufacturing method thereof, and belongs to the field of the casting technique. The eutectic graphite grey cast iron continuous-cast section material is prepared from the following raw materials by mass percent: 3.40% to 3.60% of C, 2.4% to 2.9% of Si, 0.6% to 1.0% of Mn, 0.08% to 0.15% of P, less than or equal to 0.07% of S, 0.06% to 0.20% of Ti, 0.3% to 0.80% of Cu and 91.5% to 93% of Fe, wherein the total amount of the raw materials accounts for 100%. The prepared section material is excellent in surface roughness and free of generating shrinkage holes, shrinkage porosity and air holes. The structures, from the center to the edge, of the section material, are uniform and dense. The section material has the characteristics of being high in strength and uniform in hardness. The tensile strength and the uniformity of the section hardness of the material section disclosed by the invention are improved greatly.

Owner:沈阳华铸科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com