500MPa flux-cored wire and preparation method thereof

A technology of flux-cored welding wire and powder, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of increasing labor intensity of workers and affecting welding efficiency, and achieve the effects of improving welding efficiency, reducing smoke and dust, and improving forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

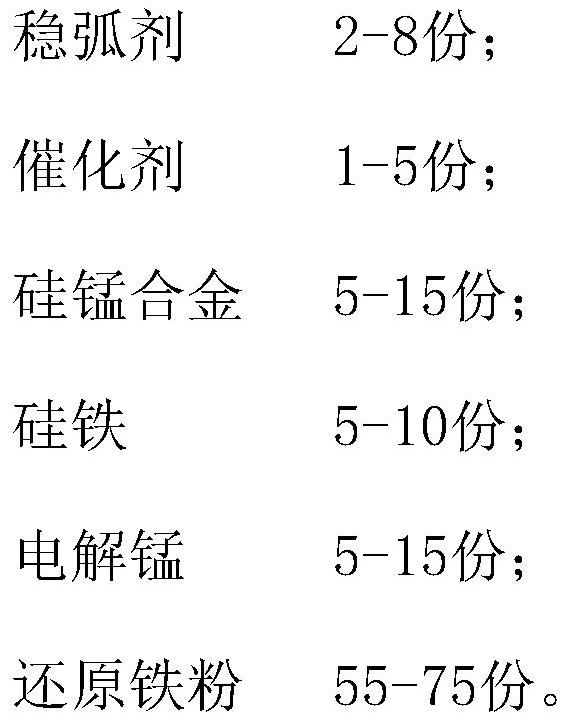

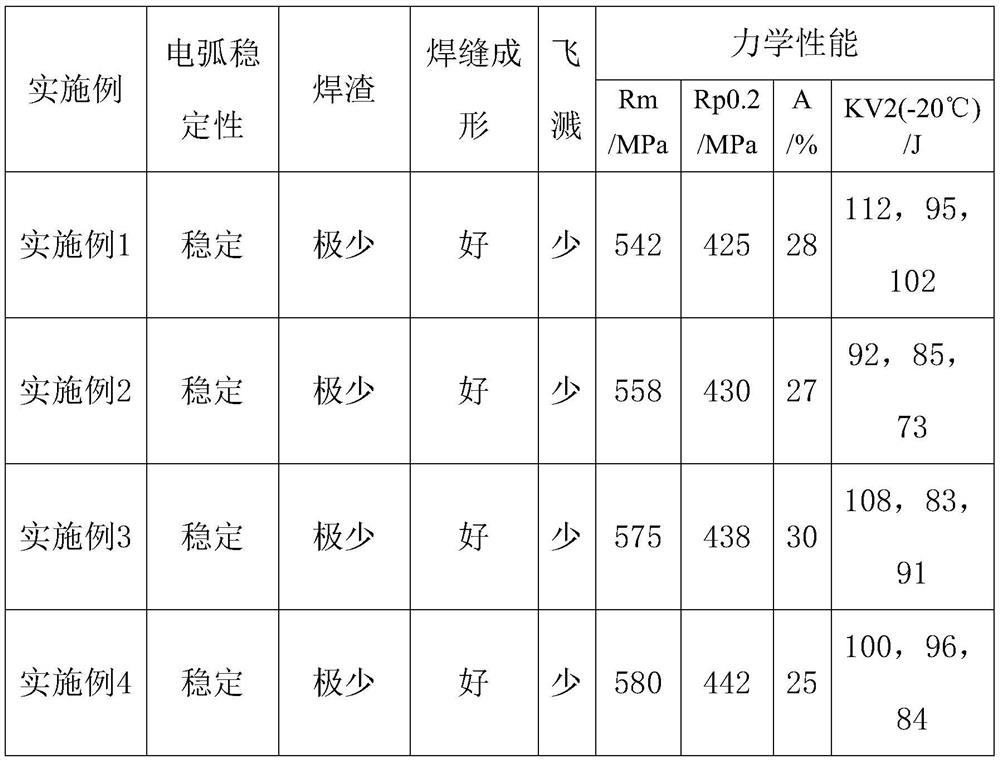

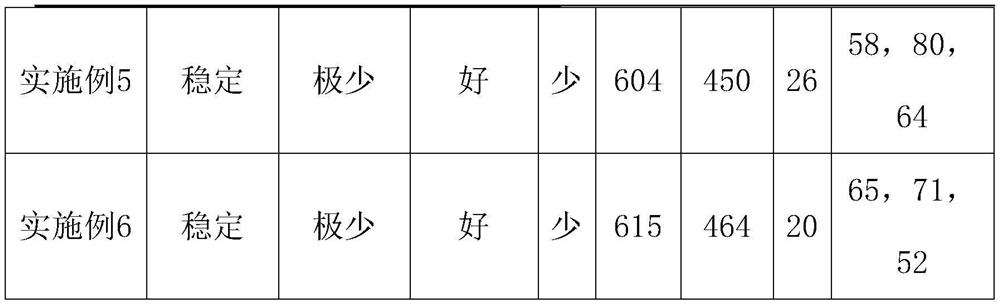

[0028] A 500MPa-grade flux-cored welding wire, consisting of a low-carbon steel strip and powder, the powder is wrapped in the low-carbon steel strip, and the powder is composed of the following components in parts by mass: 2 parts of arc stabilizing agent, 4 parts of catalyst , 10 parts of silicomanganese alloy, 6 parts of ferrosilicon, 12 parts of electrolytic manganese, 66 parts of reduced iron powder, and the powder filling rate is 14%.

Embodiment 2

[0030] A 500MPa-grade flux-cored welding wire, consisting of a low-carbon steel strip and powder, the powder is wrapped in the low-carbon steel strip, and the powder is composed of the following components in parts by mass: 4 parts of arc stabilizing agent, 3 parts of catalyst , 6.5 parts of silicomanganese alloy, 15 parts of ferrosilicon, 15 parts of electrolytic manganese, 56.5 parts of reduced iron powder, and the powder filling rate is 14.5%.

Embodiment 3

[0032] A 500MPa-grade flux-cored welding wire, consisting of a low-carbon steel strip and powder, the powder is wrapped in the low-carbon steel strip, and the powder is composed of the following components in parts by mass: 6 parts of arc stabilizing agent, 2 parts of catalyst , 8 parts of silicomanganese alloy, 12 parts of ferrosilicon, 10 parts of electrolytic manganese, 62 parts of reduced iron powder, and the powder filling rate is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com