Age forming device

A technology of aging forming and mounting surface, which is applied in the field of sheet metal forming, can solve the problems of large volume and poor economy, and achieve the effect of small volume, compact mold structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

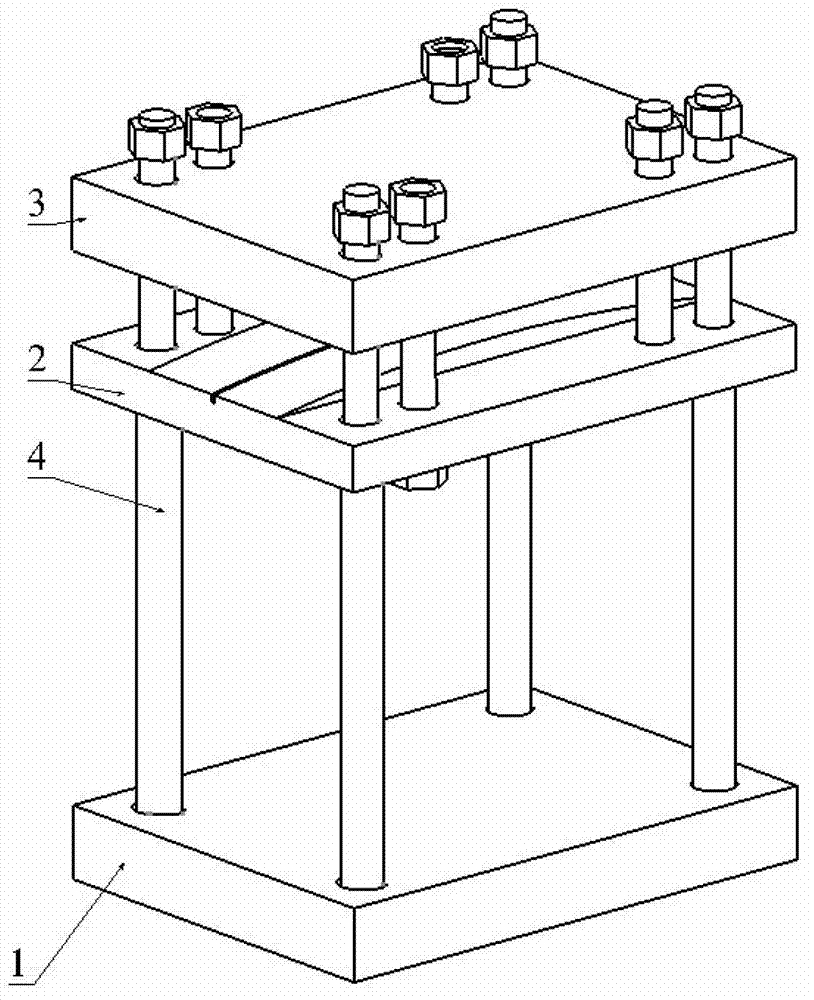

[0021] This embodiment is a bending aging forming device for bending radius test pieces of thick plates and T-shaped test pieces, including a bracket, a mold and a jack.

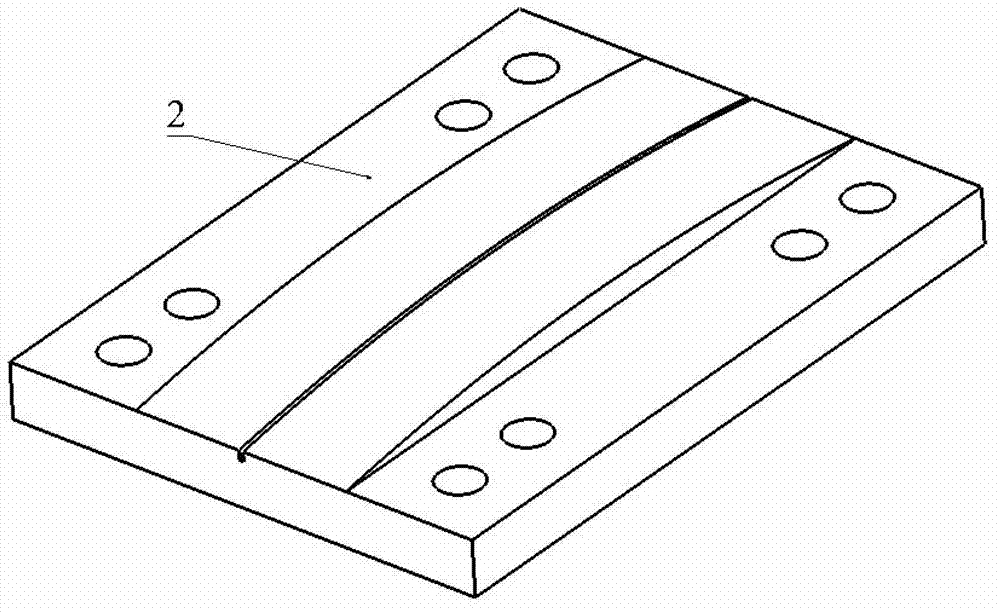

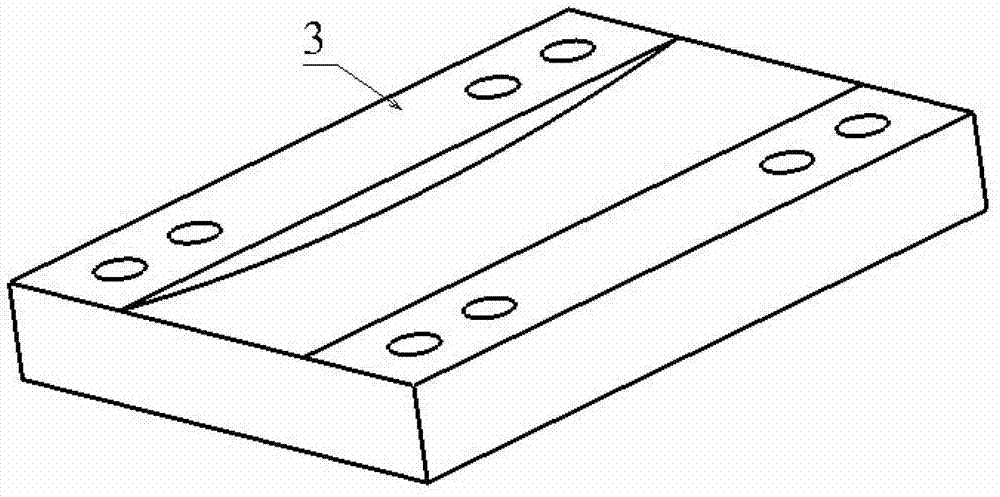

[0022] The support includes a base 1 and a pillar 4 . Wherein, the base 1 is the supporting base of the bending mold, which is a rectangular thick metal plate. Four corners of the base 1 are threadedly fixed with four pillars 4 for bearing the loading force generated by the jack. One end of each pillar 4 is fixed on the base 1 . The outer peripheral surface of the pillar 4 is stepped, wherein the large-diameter section is a supporting section, and the small-diameter section is a mould-moving section. The diameter of the support section of each pillar 4 is larger than the aperture of the through hole on the punch, and the diameter of the mold movement section of each pillar 4 is smaller than the aperture of the through hole on the punch 2 and die 3 in the mold, and is connected by the support section and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com