Full-automatic numerical control bending machine

A bending machine, fully automatic technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of insufficient labor force, low production efficiency, low degree of automation, etc., achieve simple structure, improve production efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

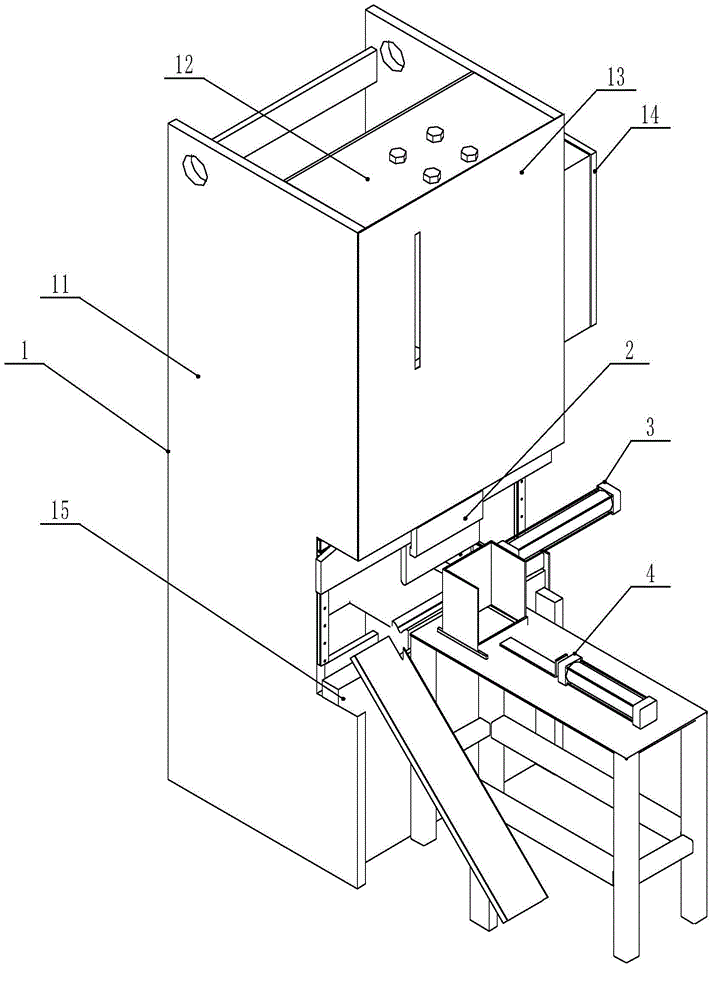

[0027] Such as figure 1 As shown, the fully automatic CNC bending machine includes a frame 1, and the bottom of the frame 1 is provided with a feeding device 4, a bending device 2 and a feeding device 3 that cooperate with each other.

[0028] Such as figure 1 and Figure 5 As shown, the feeding device 4 includes a feeding platform 41, the bottom of the feeding platform 41 is provided with a support frame 45, the feeding platform 41 is provided with a feeding cylinder 44 and a feeding box 42, and the rear of the feeding box 42 is provided with a feeding proximity switch 46. Cylinder 44 is connected with feeding push plate 43; Before work, material is stacked in the feeding box 42, and during feeding, feeding cylinder 44 pistons elongate, drive feeding pushing plate 43 to move forward, and feeding pushing plate 43 pushes the most in feeding box 42. The material at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com