Glass fiber reinforced plastic antenna housing and preparation method of glass fiber reinforced plastic antenna housing

A glass fiber reinforced plastic radome and glass microbead technology, which is applied in the field of radomes, can solve the problems of not being able to meet the indicators required for high-frequency antenna calibration standing wave and isolation, difficult to meet thickness requirements, increasing resistance, etc., so as to improve the surface quality, meet wind load, increase the effect of lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

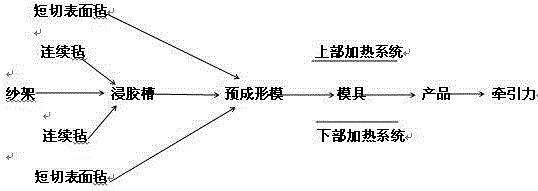

[0043] The preparation method of above-mentioned FRP radome, as figure 1 shown, including the following steps:

[0044] (1) Arrange the glass fiber yarns neatly and orderly on the creel, with 40 balls per layer, 50 layers in total;

[0045] (2) After each ball of glass fiber yarn is tapped from the inner core, pass through the holes arranged in an orderly manner on the creel to the back plate of the dipping tank in advance, and pass the arranged glass fiber yarn through the pulp filled The dipping tank of the material is inserted into the preforming mold to form first, and then the glass fiber yarn is pulled out to the cavity of the pultrusion mold, and the calibration mandrel is fixed;

[0046] (3) Dip the cut glass fiber mat into the slag soaked in the dipping tank, and then introduce the outer mat and the glass fiber mat soaked in slag into the preformed template for forming;

[0047] (4) Preheat the pultrusion mold, mold core and glass fiber yarn for 2.5-3 hours. After t...

Embodiment 1

[0052] The present embodiment FRP radome, this FRP radome is made of the alkali-free pultruded yarn of 4800Tex, the glass fiber mat N8643 of 300 g / square meter produced by Owens Corning in the United States, the chopped polyester surface mat and pulp. The material is made by pultrusion process;

[0053] Among them, the slurry is composed of the following raw materials by weight: 95-105 parts of pultruded isophthalic resin, 3 parts of glass beads, 3 parts of internal mold release agent, 12 parts of light active calcium acid, 6 parts of aluminum hydroxide, 3 parts of ultraviolet absorber, 0.6 part of curing agent AMB, 0.4 part of curing agent TBPB and 5 parts of polyethylene powder; pultruded isophthalic resin, the dielectric constant is lower than 3.5, the viscosity is 400mpa.s, and the acid value is 21.3 mgkoh / g, the solid content is 63.5%; the glass beads are selected as white powder with a specific gravity of 0.5g / cm and a mesh number of 1000 mesh; the internal release agent...

Embodiment 2

[0055] The present embodiment FRP radome, this FRP radome is made of the alkali-free pultruded yarn of 4800Tex, the glass fiber mat N8643 of 300 g / square meter produced by Owens Corning in the United States, the chopped polyester surface mat and pulp. The material is made by pultrusion process;

[0056] Among them, the slurry is composed of the following raw materials in parts by weight: 95-105 parts of pultruded isophthalic resin, 5 parts of glass microspheres, 1 part of internal mold release agent, 8 parts of light active calcium acid, 4 parts of aluminum hydroxide, 1 part of ultraviolet absorber, 0.4 part of curing agent AMB, 0.2 part of curing agent TBPB and 3 parts of polyethylene powder; pultruded isophthalic resin, the dielectric constant is lower than 3.5, the viscosity is 400mpa.s, and the acid value is 21.3 mgkoh / g, the solid content is 63.5%; the glass beads are selected as white powder with a specific gravity of 0.5g / cm and a mesh number of 1000 mesh; the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com