Method for testing shrinkage rate of electronic flat glass

A technology of flat glass and testing methods, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems affecting the quality of electronic products, poor control, etc., and achieve the effects of improving annealing quality, high measurement accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

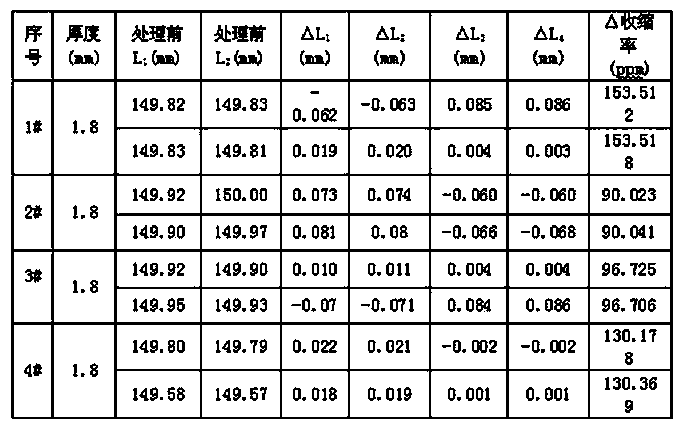

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment:

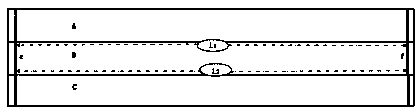

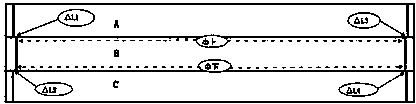

[0019] like figure 1 , figure 2 Shown, a kind of test method of shrinkage of electronic flat glass, described test method comprises the steps:

[0020] 1) Take a sample of electronic flat glass to be tested. In this embodiment, the size of the sample to be tested is 150*90mm; use a marker pen with a thickness of 0.3mm to draw and measure at the two ends of the sample to be tested at a distance of 1mm from the edge. Reference line e and measurement reference line f; then divide the sample to be measured into three pieces A, B, and C along the width direction, of which sample A and sample C are reference pieces, and sample B is a measurement piece; measure the surface of sample B with a vernier caliper Measure the distance between the reference line e and the measurement reference line f, in order to avoid the test error caused by the inclination of the measurement re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com