A kind of annealing process of tft substrate glass and tft substrate glass prepared by the same

An annealing process and substrate technology, applied in the field of TFT substrate glass, can solve the problems of inability to realize TFT substrate glass, small reheat shrinkage rate, etc., and achieve the effects of reducing the maximum stress value, improving the annealing quality, and reducing the reheat shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After taking the OLED display TFT substrate glass with a thickness of 0.4mm and forming it by the overflow method, it is annealed by the annealing process of the present invention. The specific process is as follows:

[0047] During the heat preservation stage, The temperature is 40℃ / s, the length of the holding section of the annealing furnace is 800mm, and the annealing time for the formed substrate glass is 8s;

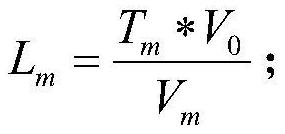

[0048] During the slow cooling stage, the temperature range T m is 400℃, slow cooling cooling rate V m is 49.43℃ / s, the glass plate running speed V in the slow cooling section of the annealing furnace 0 is 100mm / s, and the length of the slow cooling section of the annealing furnace is L m is 809mm;

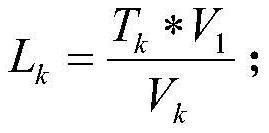

[0049] In the fast cooling stage, the temperature range T k is 300℃, fast cooling cooling rate V k is 197.73℃ / s, the glass plate running speed V in the fast cooling section of the annealing furnace 1 is 100mm / s, and the length of the fast cooling section...

Embodiment 2

[0051] After taking the OLED display TFT substrate glass with a thickness of 0.5mm and forming it by the overflow method, annealing is performed by the annealing process of the present invention. The specific process is as follows:

[0052] During the heat preservation stage, The temperature is 50°C / s, the length of the holding section of the annealing furnace is 1000mm, and the annealing time for the formed substrate glass is 10s;

[0053] In the slow cooling stage, the temperature range T m is 400℃, slow cooling cooling rate V m is 33.08℃ / s, the glass plate running speed V in the slow cooling section of the annealing furnace 0 is 100mm / s, and the length of the slow cooling section of the annealing furnace is L m is 1209mm;

[0054] In the fast cooling stage, the temperature range T k is 300℃, fast cooling cooling rate V k is 132.32℃ / s, the glass plate running speed V in the fast cooling section of the annealing furnace 1 is 100mm / s, and the length of the fast cooling...

Embodiment 3

[0056] After the OLED display TFT substrate glass with a thickness of 0.6 mm is formed by the overflow method, it is annealed by the annealing process of the present invention. The specific process is as follows:

[0057] During the heat preservation stage, The temperature is 60℃ / s, the length of the holding section of the annealing furnace is 1200mm, and the annealing time for the formed substrate glass is 12s;

[0058] During the slow cooling stage, the temperature range T m is 400℃, slow cooling cooling rate V m is 23.83℃ / s, the glass plate running speed V in the slow cooling section of the annealing furnace 0 is 100mm / s, and the length of the slow cooling section of the annealing furnace is L m is 1679mm;

[0059] In the fast cooling stage, the temperature range T k is 300℃, fast cooling cooling rate V k is 95.30℃ / s, the glass plate running speed V in the fast cooling section of the annealing furnace 1 is 100mm / s, and the length of the fast cooling section of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com