High-tenacity high-strength cast steel wear-resistant material and preparation method thereof

A wear-resistant material and high-strength technology, applied in the field of cast steel, can solve the problems of corrosion, uneven wear resistance, and many welding defects, and achieve the effects of avoiding poor weldability, improving annealing quality, and uniform heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

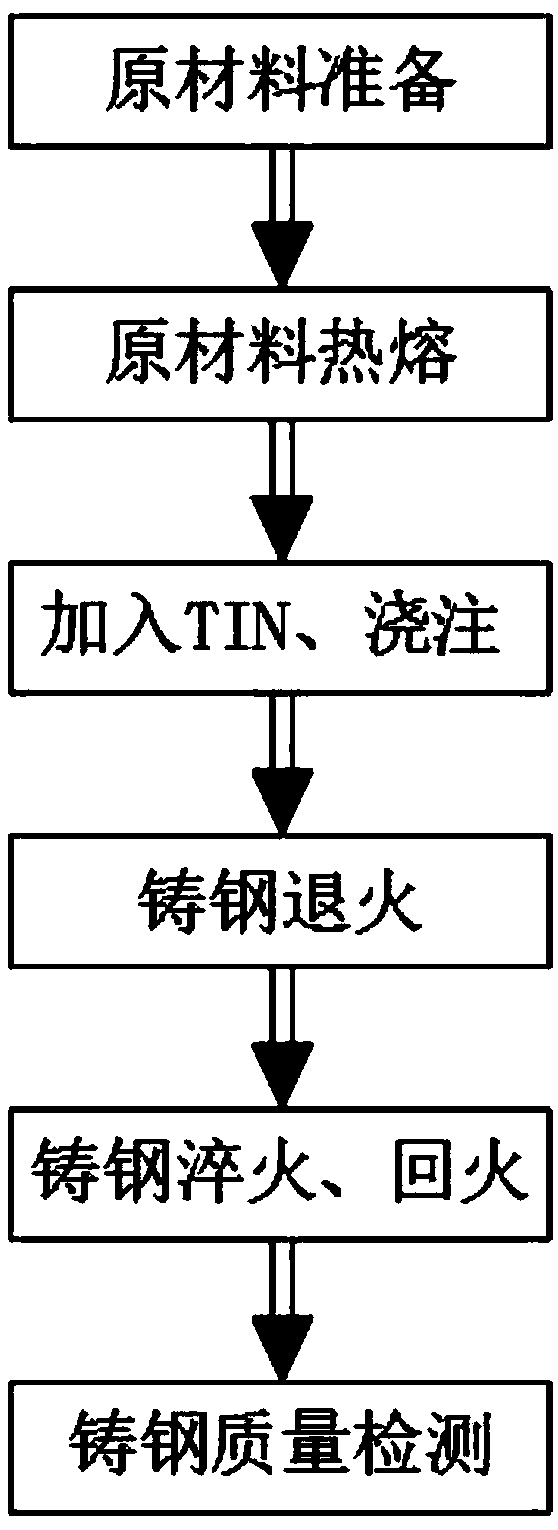

[0042] like figure 1 As shown, a high-toughness and high-strength cast steel wear-resistant material and a preparation method thereof include the process steps of raw material preparation - raw material hot melting - TIN added in proportion - cast steel annealing - cast steel quenching and tempering - cast steel quality inspection, Specific steps are as follows:

[0043] (1) Raw material preparation: prepare the raw materials required for cast steel according to a certain proportion;

[0044] (2) Hot melting of raw materials: control the temperature of the high-temperature furnace, and place the quasi-quilted raw materials in the high-temperature furnace for hot melting;

[0045] (3) TIN is added in proportion: a certain proportion of TIN is added when the raw materials are hot-melted in a high-temperature furnace, and the molten steel is poured after hot-melting;

[0046] (4) The annealing steps of cast steel are as follows:

[0047] ①Place the cast steel on the storage ta...

Embodiment 2

[0055] like Figure 2-5 As shown, the ratio of raw materials in step (1) is: C: 0.2-0.4wt%, Si: 0.5-1.1wt%, Mn: 0.6-1.5wt%, Mo: 0.2-0.8wt%, Ni: 0.4-0.6 wt%, V: 0.04-0.05%, P≤0.025wt%, S≤0.025wt%, Al:≤0.07wt%, W: 0.1-0.2wt%, and the rest are Fe.

[0056] A further improvement scheme of the present invention is: the amount of TIN added in step (2) is 0.02-0.04wt% of the chemical quality of the raw material.

[0057] A further improvement scheme of the present invention is that: the annealing temperature of the cast steel in step (4) is 900±3°C, the temperature of austempering of the cast steel in step (5) is 350±3°C, and the tempering temperature of the cast steel is 550°C ±3°C.

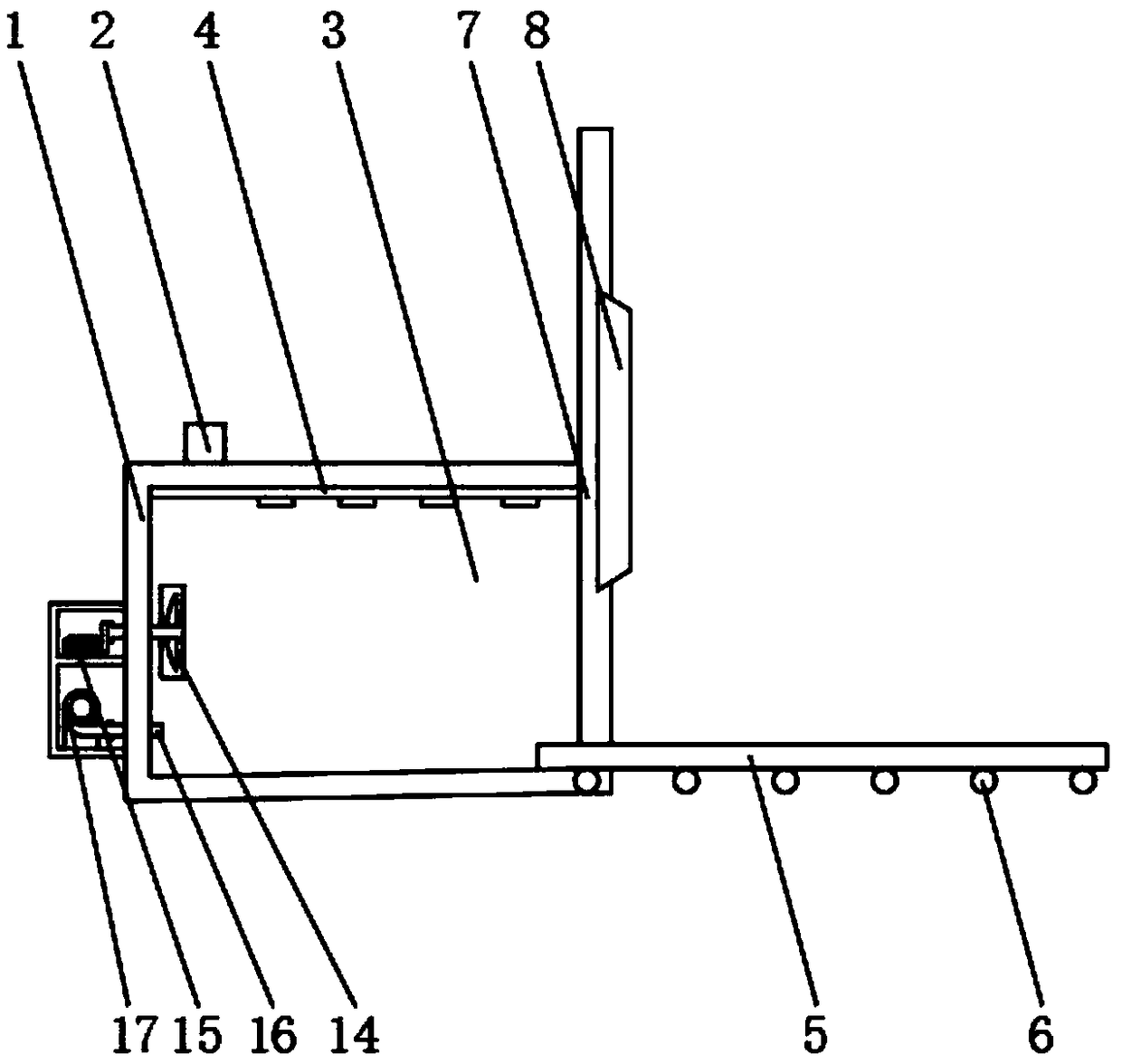

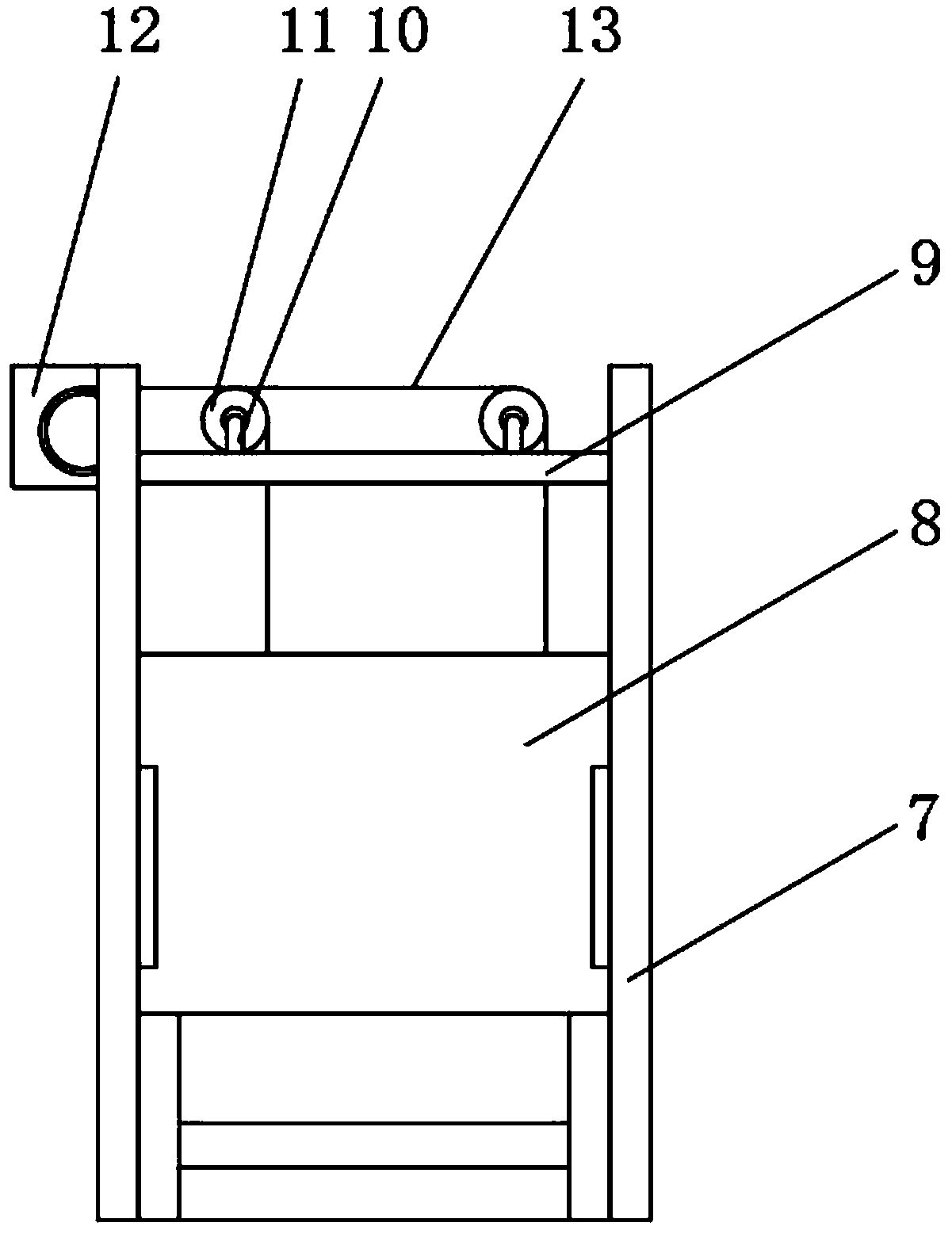

[0058] A further improvement scheme of the present invention is that: the annealing furnace described in step (4) includes a furnace shell 1, an annealing chamber 3 is arranged inside the furnace shell 1, and a slide rail 7 is arranged on an outer surface of one side of the furnace shell 1 , a movab...

Embodiment 3

[0064] like Image 6 As shown, the blast pipe 16 runs through the annealing chamber 3 and the outer surface of one side of the furnace shell 1, the blast pipe 16 and the furnace shell 1 are fixedly connected, and the fan blade 14 is connected to the second motor 15. There is an active connection therebetween, and the input port of the second motor 15 and the blower 17 is electrically connected to the output port of the furnace shell 1 .

[0065] The working principle of the high-toughness and high-strength cast steel wear-resistant material and its preparation method: the user selects the raw materials according to C: 0.2-0.4wt%, Si: 0.5-1.1wt%, Mn: 0.6-1.5wt%, Mo: 0.2 -0.8wt%, Ni: 0.4-0.6wt%, V: 0.04-0.05%, P≤0.025wt%, S≤0.025wt%, Al:≤0.07wt%, W: 0.1-0.2wt%, the rest is Fe For preparation, the raw materials are placed in a high-temperature furnace to be heated and melted, TIN is added to it according to the proportion of the raw materials at 0.02-0.04wt%, the mixed molten st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com