Ammonia storage tank with gas ammonia valve and method for ammonia supply by gas ammonia/liquid ammonia conversion

A technology for ammonia storage tanks and valves, which is applied in the field of ammonia storage tanks with gas ammonia valves and the conversion of gas ammonia and liquid ammonia to supply ammonia, which can solve problems such as unfavorable system pressure, troublesome adjustment, leakage of pipeline joints and valve cores, etc. Achieve the effects of improving annealing quality, reducing labor intensity and stabilizing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

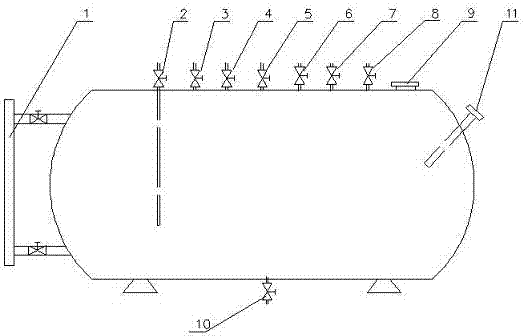

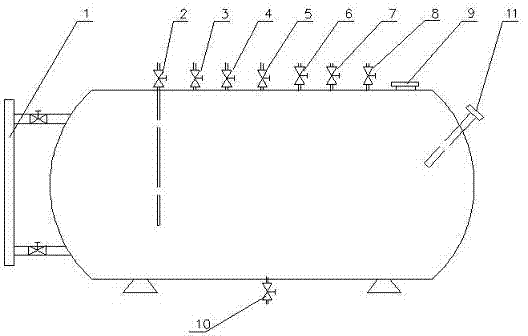

[0010] Example 1: Such as figure 1 Shown: a kind of ammonia storage tank with gas ammonia valve, on the outside of the end of the ammonia storage tank, there is a vertical liquid level gauge 1 which is convenient for observing the liquid level in the ammonia storage tank, and on the outside of the other end of the ammonia storage tank, there is a A thermometer 11 for observing the temperature in the ammonia storage tank; a liquid ammonia output valve 2 and a gas ammonia output valve 4 are respectively installed on the top surface of the ammonia storage tank, and the liquid ammonia output valve 2 and the gas ammonia output valve 4 are respectively connected to the evaporation tank through pipelines , the connecting pipe of the liquid ammonia output valve 2 goes deep into the bottom of the ammonia storage tank, and the gas supply mode is selected according to the external air temperature and the pressure in the ammonia storage tank; a filling pressure balance valve 3 is also in...

Embodiment 2

[0011] Example 2: combine figure 1 : A gas-phase ammonia and liquid-phase ammonia conversion ammonia supply method using an ammonia storage tank with a gas ammonia valve, the gas supply mode of the ammonia storage tank is switched with the rise and fall of the external temperature: the external temperature is greater than 20 ° C, the evaporation of liquid ammonia is large, Using the principle of liquid ammonia evaporation, vaporization, heat absorption, let the liquid ammonia evaporate into ammonia gas in the ammonia storage tank, when the pressure in the ammonia storage tank is 0.6MPa~0.8MPa, close the liquid ammonia output valve 2 of the ammonia storage tank, open the The ammonia gas output valve 4 of the ammonia tank supplies ammonia gas to the evaporation tank (not shown in the figure), so that the temperature in the ammonia storage tank decreases and the pressure decreases accordingly. The outside temperature is not higher than 20°C, the liquid ammonia evaporates less i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com