Non-oriented electrical steel and preparing method and application thereof

A technology of oriented electrical steel and chemistry, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of low yield of non-oriented electrical steel and easy occurrence of broken belts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

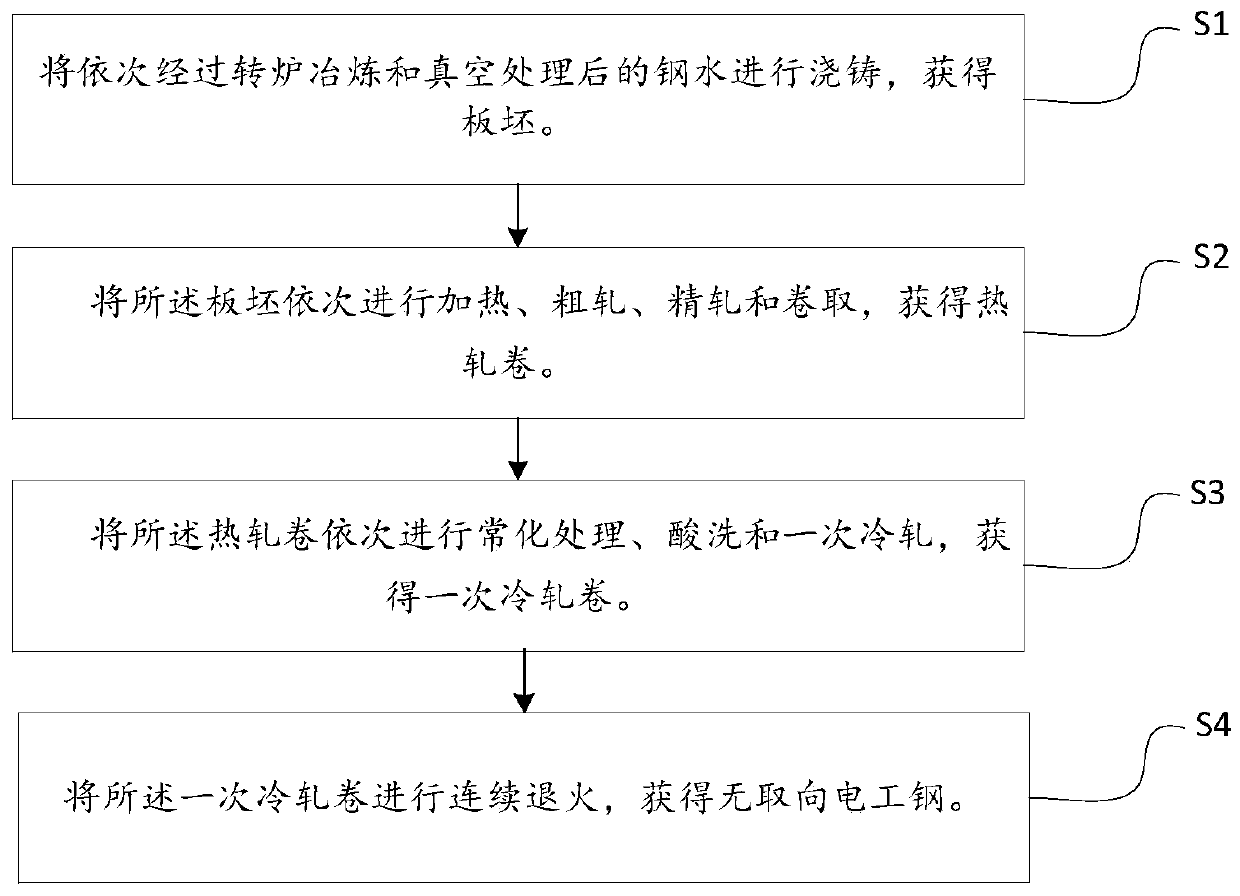

[0068] The embodiment provides a non-oriented electrical steel and a preparation method thereof, the method comprising:

[0069] S1, casting molten steel that has undergone converter smelting and vacuum treatment successively to obtain a steel slab.

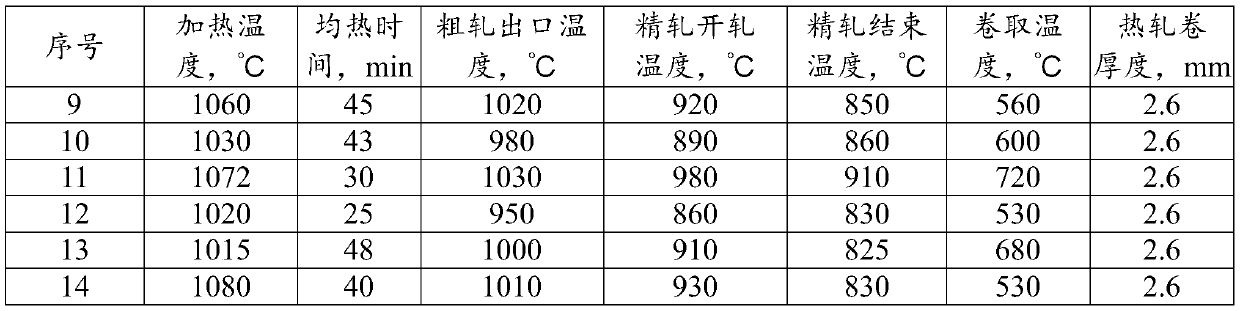

[0070] S2. The slab is heated, rough rolled, finish rolled and coiled in sequence to obtain a hot rolled coil.

[0071] S3, performing normalization treatment, pickling and primary cold rolling on the hot-rolled coils in sequence to obtain primary cold-rolled coils.

[0072] S4, performing continuous annealing on the primary cold-rolled coil to obtain non-oriented electrical steel.

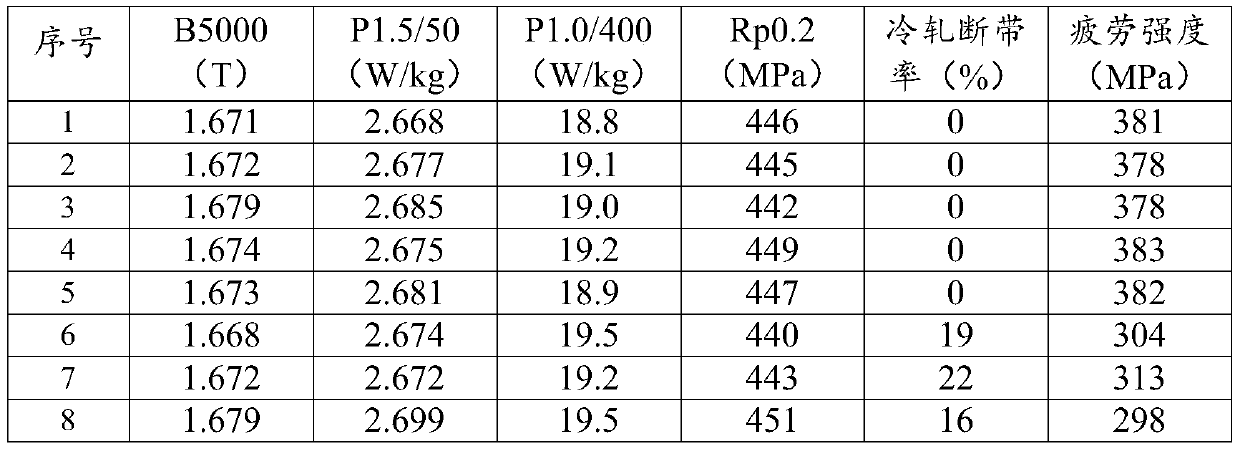

[0073] In this embodiment, the composition is firstly optimized, and the composition control is shown in Table 1.

[0074] Table 1

[0075] serial number C / % Si / % S / % N / % V / % Ti / % Al / % Mn / % Ni / % Cr / % Sn / % Ga / % Hf / % P / % 1 0.0009 2.9 0.0009 0.0012 0.0038 0.0015 0.8 0.51 0.8 0.7 0.08 0.3 0.2 0.0013 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com