Coated semi-processed non-oriented electrical steel sheet and manufacturing method thereof

A kind of oriented electrical steel, semi-process technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low production efficiency and increased cost of bell furnace annealing, to save the leveling process, improve production efficiency, shorten production The effect of cycle time and lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

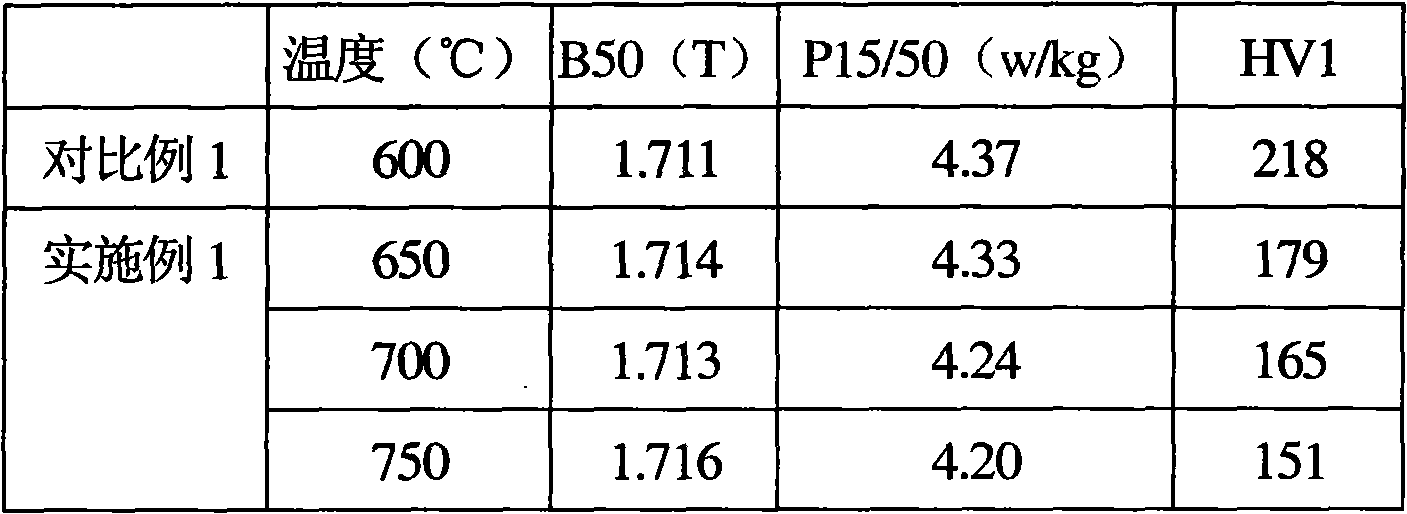

Embodiment 1

[0029] First, according to the mass percentage of chemical composition carbon: 0.0030%, silicon: 1.15%, manganese: 0.35%, sulfur: 0.0035%, aluminum: 0.25%, nitrogen: 0.0040%, phosphorus: 0.035%, smelting steel, continuous casting to make plates The slab is heated at a temperature of 1120°C in a hot rolling furnace.

[0030] Finish rolling was performed at a finish rolling temperature of 900°C, followed by coiling at a temperature of 550°C. The 2.6mm thick hot-rolled steel strip is cold-rolled to 0.5mm thick in the pickling and rolling unit, and then annealed for 2 minutes in the electrical steel continuous annealing coating unit under the condition of 650-750°C and full nitrogen dry atmosphere, and the strip is The steel is finished with a semi-organic coating. When the annealing temperature is between 650~750℃, the iron loss is 4.20~4.33w / kg, the magnetic induction is 1.713~1.716T, and the value changes little at different annealing temperatures; the hardness HV1 is between ...

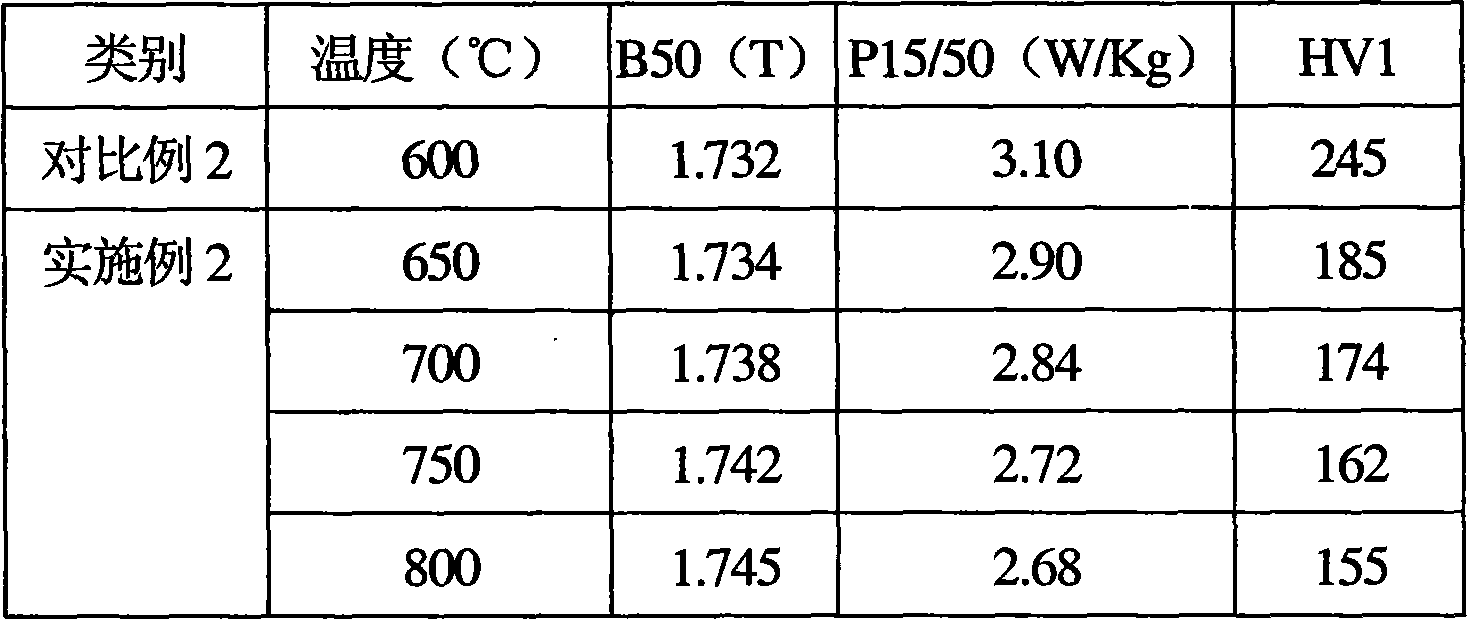

Embodiment 2

[0037] First, according to the chemical composition carbon: 0.0025%, silicon: 1.65%, manganese: 0.50%, sulfur: 0.0045%, aluminum: 0.60%, nitrogen: 0.0020%, phosphorus: 0.016%, smelting steel, continuous casting into slab. The slab is heated at a temperature of 1150° C. in a hot rolling furnace.

[0038] Finish rolling was performed at a finish rolling temperature of 860°C, followed by coiling at a temperature of 600°C. The normalization treatment at 980°C is carried out in the normalization unit, and then the 2.6mm thick hot-rolled steel strip is cold-rolled to 0.5mm thick in the pickling and continuous rolling unit, and then the electric steel continuous annealing coating unit is heated at 650-800℃, Anneal for 3 minutes under the condition of full nitrogen dry atmosphere, and apply semi-organic coating to the steel strip to make the finished product. When the annealing temperature is between 650-800°C, the iron loss is 2.68-2.90w / kg, the magnetic induction is 1.738-1.745T, a...

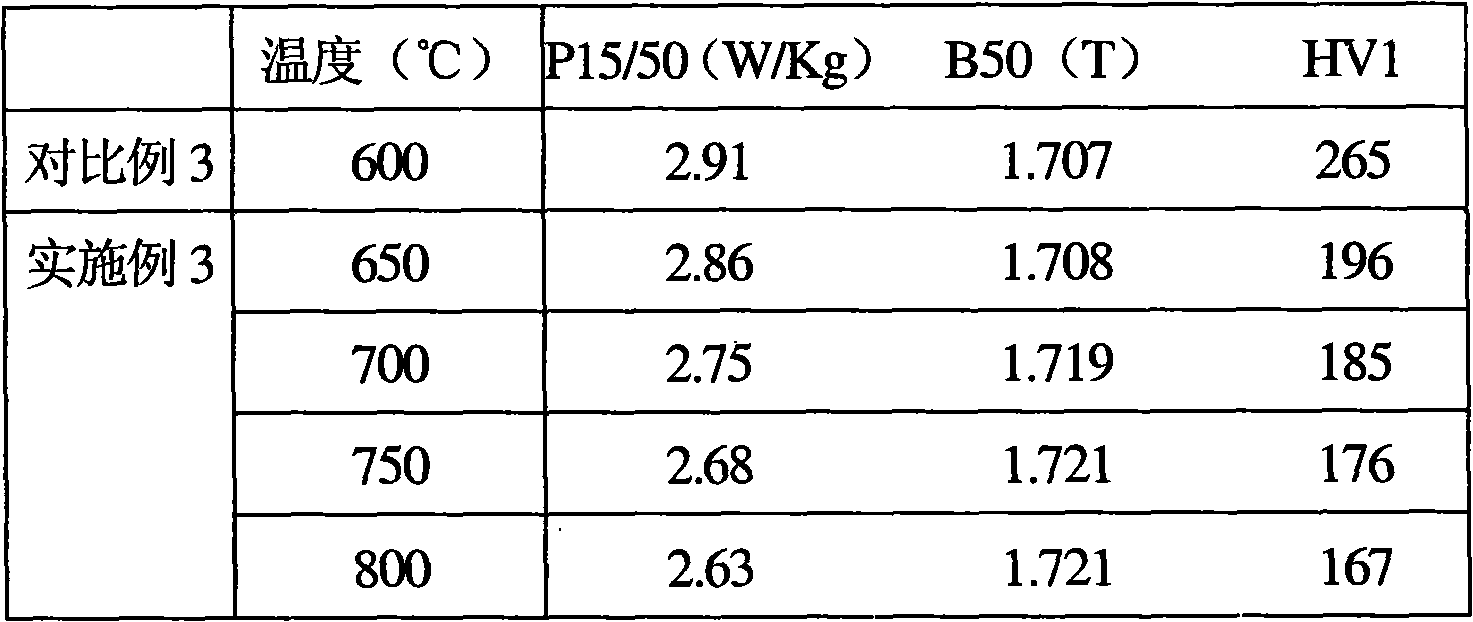

Embodiment 3

[0045] First, according to the chemical composition carbon: 0.0018%, silicon: 2.00%, manganese: 0.35%, sulfur: 0.0025%, aluminum: 0.50%, nitrogen: 0.0014%, phosphorus: 0.050%, steel is smelted and continuously cast into slabs. The slab is heated at a temperature of 1120° C. in a hot rolling furnace.

[0046] Finish rolling was performed at a finish rolling temperature of 860°C, followed by coiling at a temperature of 600°C. The normalization treatment at 950°C is carried out in the normalization unit, and then the 2.6mm thick hot-rolled steel strip is cold-rolled to 0.5mm thick in the pickling and continuous rolling unit, and then the electric steel continuous annealing coating unit is heated at 650-800℃, Anneal for 3 minutes under the condition of full nitrogen dry atmosphere, and apply semi-organic coating to the steel strip to make the finished product. , when the annealing temperature is between 650 and 800°C, the iron loss is 2.63 to 2.86w / kg, the magnetic induction is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com